washer fluid CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 66 of 2438

INSPECTION

Inspect for evidence of fluid running from the up-

per end of the reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage be-

tween the strut rod and strut shaft seal is not un-

usual and does not affect performance of the strut

assembly.

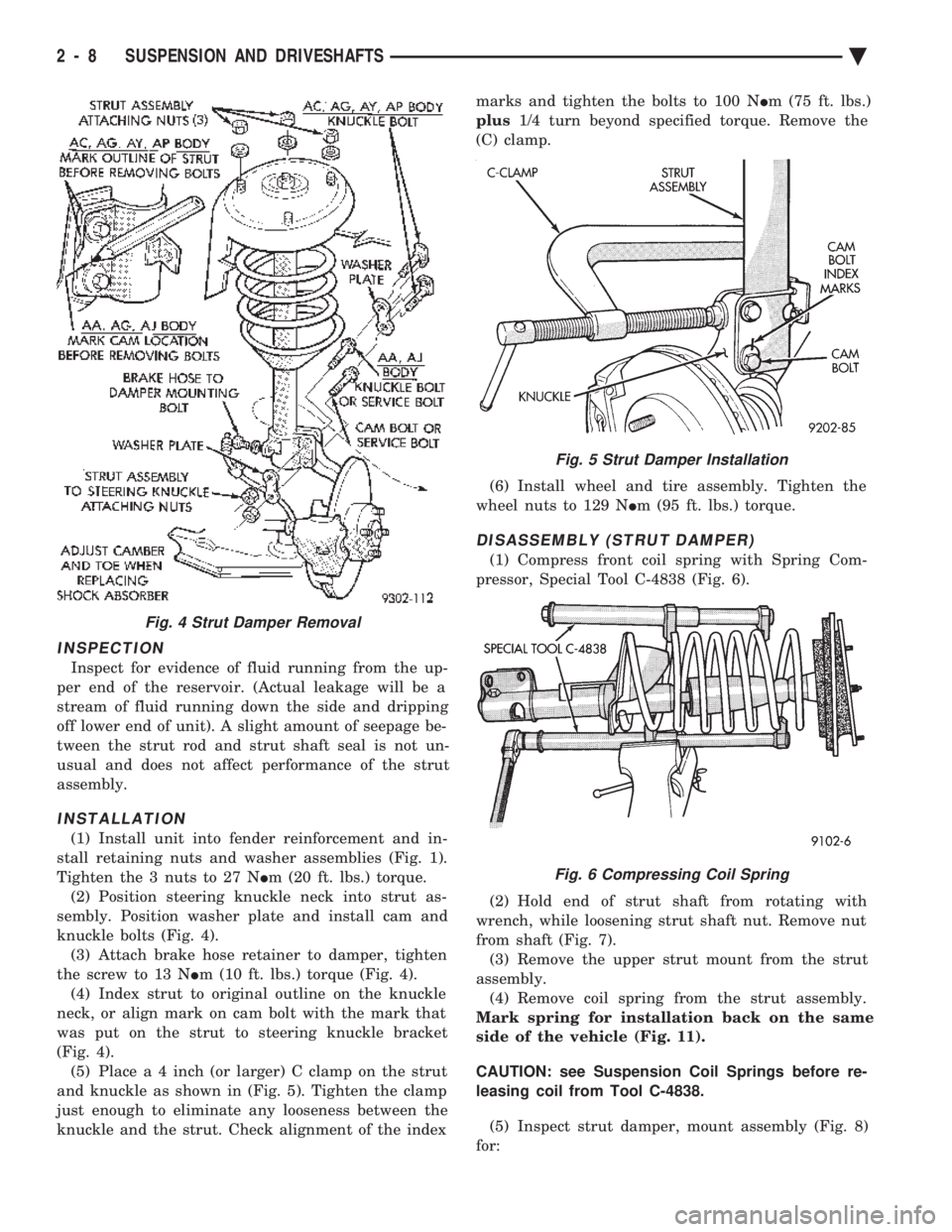

INSTALLATION

(1) Install unit into fender reinforcement and in-

stall retaining nuts and washer assemblies (Fig. 1).

Tighten the 3 nuts to 27 N Im (20 ft. lbs.) torque.

(2) Position steering knuckle neck into strut as-

sembly. Position washer plate and install cam and

knuckle bolts (Fig. 4). (3) Attach brake hose retainer to damper, tighten

the screw to 13 N Im (10 ft. lbs.) torque (Fig. 4).

(4) Index strut to original outline on the knuckle

neck, or align mark on cam bolt with the mark that

was put on the strut to steering knuckle bracket

(Fig. 4). (5) Plac e a 4 inch (or larger) C clamp on the strut

and knuckle as shown in (Fig. 5). Tighten the clamp

just enough to eliminate any looseness between the

knuckle and the strut. Check alignment of the index marks and tighten the bolts to 100 N

Im (75 ft. lbs.)

plus 1/4 turn beyond specified torque. Remove the

(C) clamp.

(6) Install wheel and tire assembly. Tighten the

wheel nuts to 129 N Im (95 ft. lbs.) torque.

DISASSEMBLY (STRUT DAMPER)

(1) Compress front coil spring with Spring Com-

pressor, Special Tool C-4838 (Fig. 6).

(2) Hold end of strut shaft from rotating with

wrench, while loosening strut shaft nut. Remove nut

from shaft (Fig. 7). (3) Remove the upper strut mount from the strut

assembly. (4) Remove coil spring from the strut assembly.

Mark spring for installation back on the same

side of the vehicle (Fig. 11).

CAUTION: see Suspension Coil Springs before re-

leasing coil from Tool C-4838.

(5) Inspect strut damper, mount assembly (Fig. 8)

for:

Fig. 4 Strut Damper Removal

Fig. 5 Strut Damper Installation

Fig. 6 Compressing Coil Spring

2 - 8 SUSPENSION AND DRIVESHAFTS Ä

Page 247 of 2438

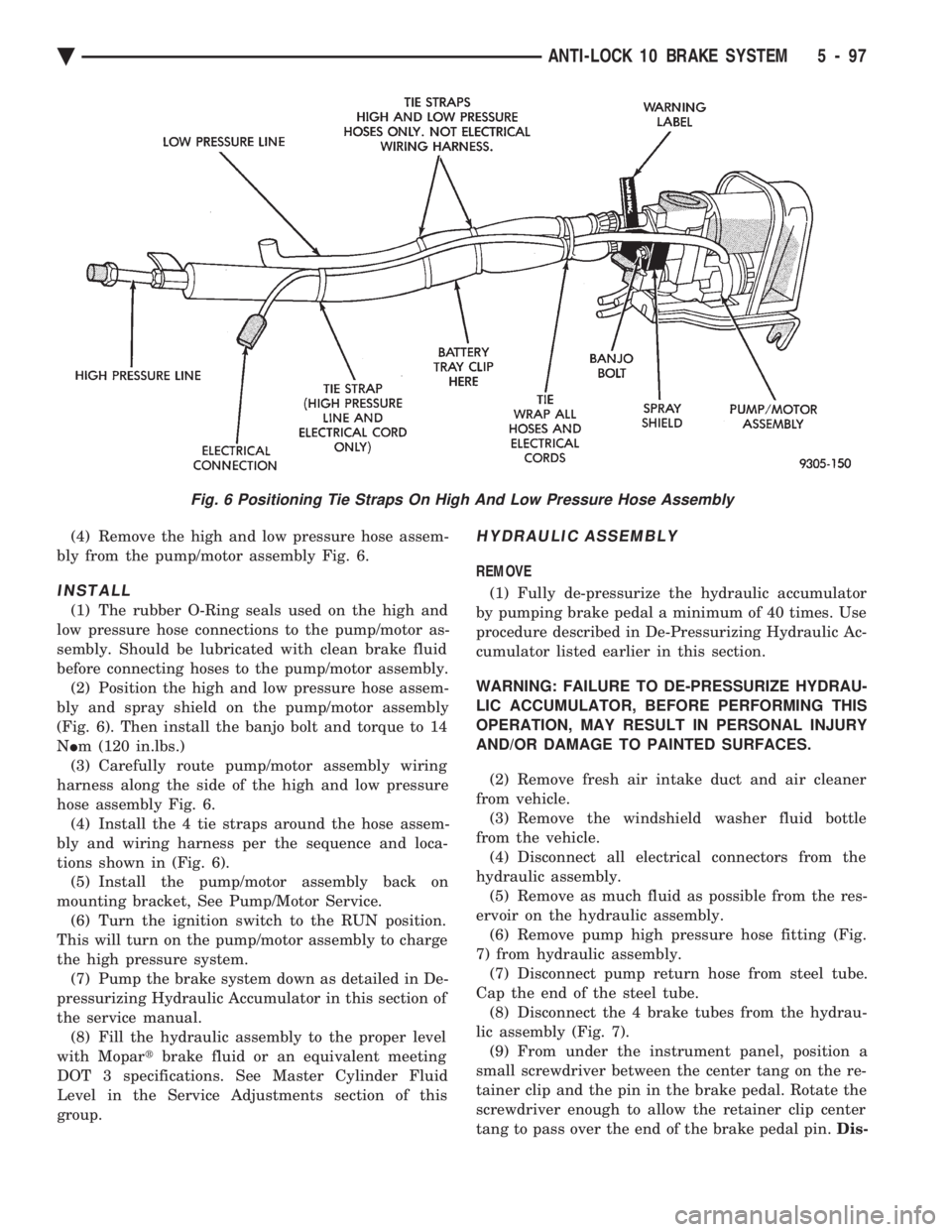

(4) Remove the high and low pressure hose assem-

bly from the pump/motor assembly Fig. 6.

INSTALL

(1) The rubber O-Ring seals used on the high and

low pressure hose connections to the pump/motor as-

sembly. Should be lubricated with clean brake fluid

before connecting hoses to the pump/motor assembly. (2) Position the high and low pressure hose assem-

bly and spray shield on the pump/motor assembly

(Fig. 6). Then install the banjo bolt and torque to 14

N Im (120 in.lbs.)

(3) Carefully route pump/motor assembly wiring

harness along the side of the high and low pressure

hose assembly Fig. 6. (4) Install the 4 tie straps around the hose assem-

bly and wiring harness per the sequence and loca-

tions shown in (Fig. 6). (5) Install the pump/motor assembly back on

mounting bracket, See Pump/Motor Service. (6) Turn the ignition switch to the RUN position.

This will turn on the pump/motor assembly to charge

the high pressure system. (7) Pump the brake system down as detailed in De-

pressurizing Hydraulic Accumulator in this section of

the service manual. (8) Fill the hydraulic assembly to the proper level

with Mopar tbrake fluid or an equivalent meeting

DOT 3 specifications. See Master Cylinder Fluid

Level in the Service Adjustments section of this

group.

HYDRAULIC ASSEMBLY

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove fresh air intake duct and air cleaner

from vehicle. (3) Remove the windshield washer fluid bottle

from the vehicle. (4) Disconnect all electrical connectors from the

hydraulic assembly. (5) Remove as much fluid as possible from the res-

ervoir on the hydraulic assembly. (6) Remove pump high pressure hose fitting (Fig.

7) from hydraulic assembly. (7) Disconnect pump return hose from steel tube.

Cap the end of the steel tube. (8) Disconnect the 4 brake tubes from the hydrau-

lic assembly (Fig. 7). (9) From under the instrument panel, position a

small screwdriver between the center tang on the re-

tainer clip and the pin in the brake pedal. Rotate the

screwdriver enough to allow the retainer clip center

tang to pass over the end of the brake pedal pin. Dis-

Fig. 6 Positioning Tie Straps On High And Low Pressure Hose Assembly

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 97

Page 249 of 2438

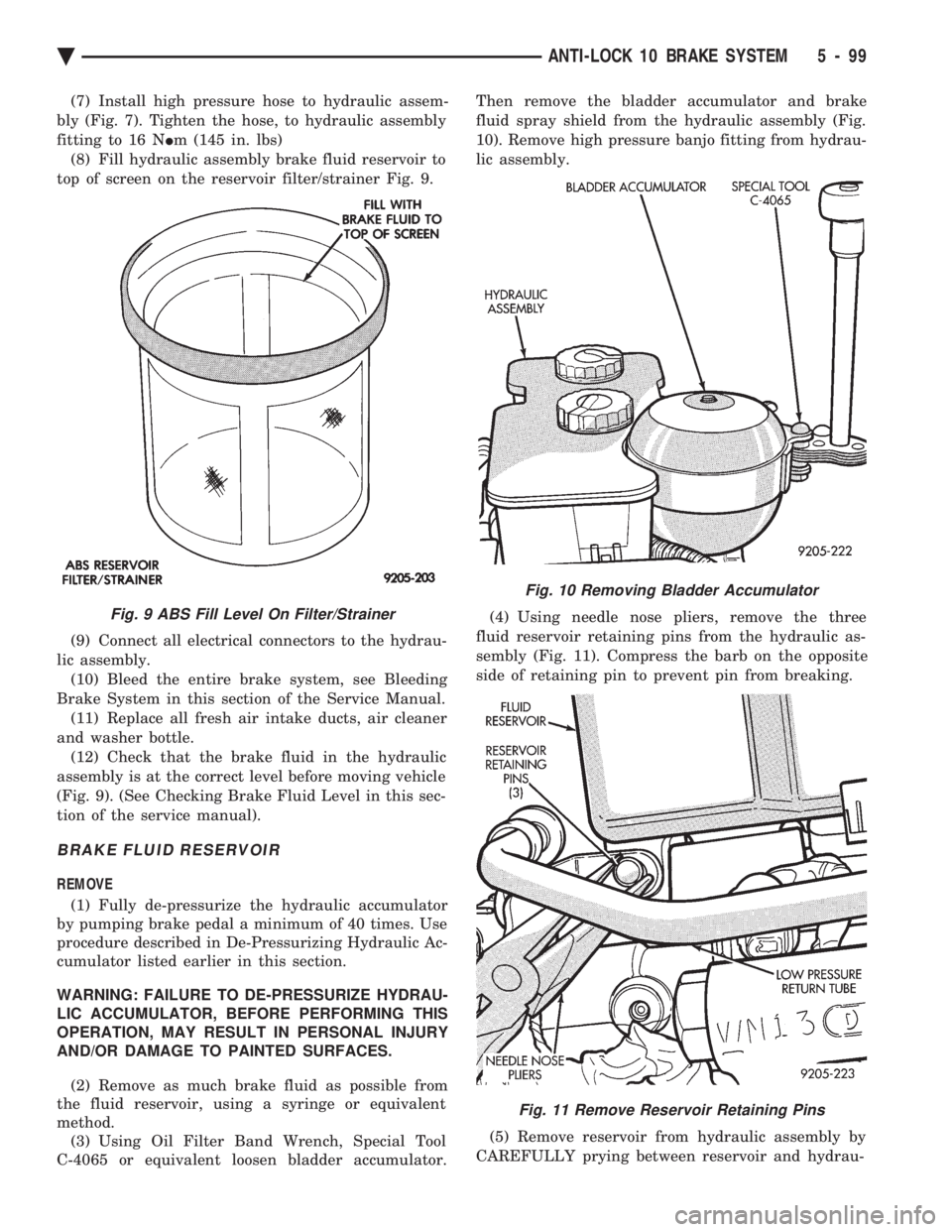

(7) Install high pressure hose to hydraulic assem-

bly (Fig. 7). Tighten the hose, to hydraulic assembly

fitting to 16 N Im (145 in. lbs)

(8) Fill hydraulic assembly brake fluid reservoir to

top of screen on the reservoir filter/strainer Fig. 9.

(9) Connect all electrical connectors to the hydrau-

lic assembly. (10) Bleed the entire brake system, see Bleeding

Brake System in this section of the Service Manual. (11) Replace all fresh air intake ducts, air cleaner

and washer bottle. (12) Check that the brake fluid in the hydraulic

assembly is at the correct level before moving vehicle

(Fig. 9). (See Checking Brake Fluid Level in this sec-

tion of the service manual).

BRAKE FLUID RESERVOIR

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove as much brake fluid as possible from

the fluid reservoir, using a syringe or equivalent

method. (3) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent loosen bladder accumulator. Then remove the bladder accumulator and brake

fluid spray shield from the hydraulic assembly (Fig.

10). Remove high pressure banjo fitting from hydrau-

lic assembly.

(4) Using needle nose pliers, remove the three

fluid reservoir retaining pins from the hydraulic as-

sembly (Fig. 11). Compress the barb on the opposite

side of retaining pin to prevent pin from breaking.

(5) Remove reservoir from hydraulic assembly by

CAREFULLY prying between reservoir and hydrau-

Fig. 9 ABS Fill Level On Filter/Strainer

Fig. 10 Removing Bladder Accumulator

Fig. 11 Remove Reservoir Retaining Pins

Ä ANTI-LOCK 10 BRAKE SYSTEM 5 - 99

Page 424 of 2438

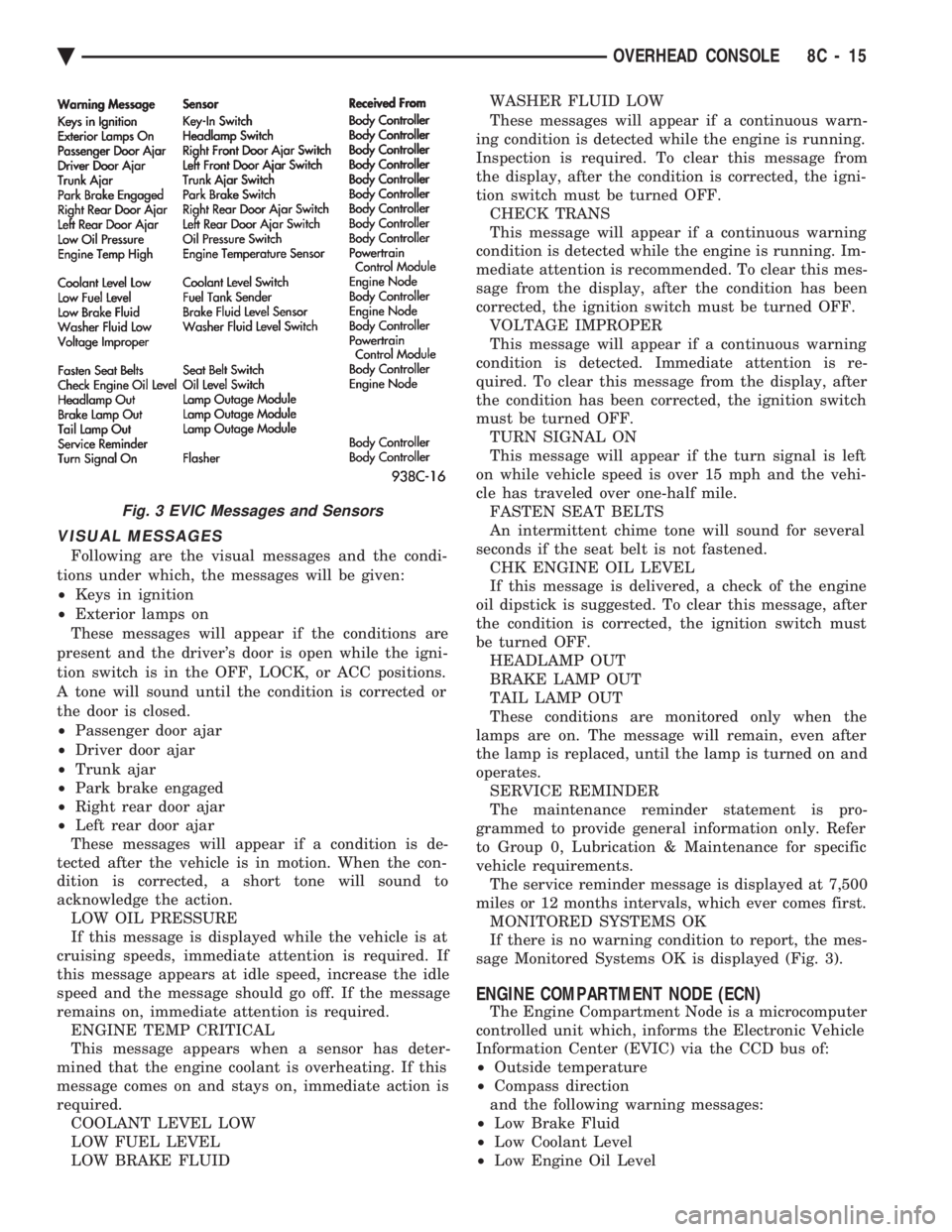

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has determined

that the engine coolant is overheating. If this message

comes on and stays on, immediate action is required.

COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID

WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the lamps

are on. The message will remain, even after the lamp is

replaced, until the lamp is turned on and operates.

SERVICE REMINDER

The maintenance reminder statement is programmed

to provide general information only. Refer to Group 0,

Lubrication & Maintenance for specific vehicle require-

ments.

The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 2).

AUTOMATIC CALIBRATION SET PROCEDURE

The engine compartment node will continuously

and automatically recalibrate the compass under nor-

mal driving conditions. As long as the vehicle is

turning, the engine compartment node will record

new compass data. This new data will be used to

recalibrate the compass at a rate of at least once per

full (360 degree) turn of the vehicle. Automatic cali-

bration does not require operator interface.

MANUAL CALIBRATION SET PROCEDURE

Manual compass calibration has been replaced by

automatic calibration set procedure. The manual cal-

ibration set procedure is available, but no longer

serves any useful purpose.

EVIC SELF CHECK DIAGNOSTICS

Ignition switch ON, the EVIC not displaying any

message, may imply a system failure and not an

EVIC failure. Turn the ignition OFF, close all vehi-

cle doors and wait at least 60 seconds before begin-

ning test. Turn ignition switch to the ON position.

Pressing the TEMP, FUEL and INFO buttons at the

same time shall provide the visual message MOD-

ULE SELF CHECK for two seconds. Following at

two second interval there will be messages:

² E2-0 SELF CHECK

² E3-0 SELF CHECK

² END OF SELF CHECK

Showing the microcomputer is working properly.

When the self check mode and message shows:

² E2-1

² E3-2

This would show a fault exists in the EVIC's micro-

computer and the EVIC should be replaced (Fig. 3).

8C - 8 OVERHEAD CONSOLE Ä

Page 431 of 2438

VISUAL MESSAGES

Following are the visual messages and the condi-

tions under which, the messages will be given:

² Keys in ignition

² Exterior lamps on

These messages will appear if the conditions are

present and the driver's door is open while the igni-

tion switch is in the OFF, LOCK, or ACC positions.

A tone will sound until the condition is corrected or

the door is closed.

² Passenger door ajar

² Driver door ajar

² Trunk ajar

² Park brake engaged

² Right rear door ajar

² Left rear door ajar

These messages will appear if a condition is de-

tected after the vehicle is in motion. When the con-

dition is corrected, a short tone will sound to

acknowledge the action. LOW OIL PRESSURE

If this message is displayed while the vehicle is at

cruising speeds, immediate attention is required. If

this message appears at idle speed, increase the idle

speed and the message should go off. If the message

remains on, immediate attention is required. ENGINE TEMP CRITICAL

This message appears when a sensor has deter-

mined that the engine coolant is overheating. If this

message comes on and stays on, immediate action is

required. COOLANT LEVEL LOW

LOW FUEL LEVEL

LOW BRAKE FLUID WASHER FLUID LOW

These messages will appear if a continuous warn-

ing condition is detected while the engine is running.

Inspection is required. To clear this message from

the display, after the condition is corrected, the igni-

tion switch must be turned OFF. CHECK TRANS

This message will appear if a continuous warning

condition is detected while the engine is running. Im-

mediate attention is recommended. To clear this mes-

sage from the display, after the condition has been

corrected, the ignition switch must be turned OFF. VOLTAGE IMPROPER

This message will appear if a continuous warning

condition is detected. Immediate attention is re-

quired. To clear this message from the display, after

the condition has been corrected, the ignition switch

must be turned OFF. TURN SIGNAL ON

This message will appear if the turn signal is left

on while vehicle speed is over 15 mph and the vehi-

cle has traveled over one-half mile. FASTEN SEAT BELTS

An intermittent chime tone will sound for several

seconds if the seat belt is not fastened. CHK ENGINE OIL LEVEL

If this message is delivered, a check of the engine

oil dipstick is suggested. To clear this message, after

the condition is corrected, the ignition switch must

be turned OFF. HEADLAMP OUT

BRAKE LAMP OUT

TAIL LAMP OUT

These conditions are monitored only when the

lamps are on. The message will remain, even after

the lamp is replaced, until the lamp is turned on and

operates. SERVICE REMINDER

The maintenance reminder statement is pro-

grammed to provide general information only. Refer

to Group 0, Lubrication & Maintenance for specific

vehicle requirements. The service reminder message is displayed at 7,500

miles or 12 months intervals, which ever comes first. MONITORED SYSTEMS OK

If there is no warning condition to report, the mes-

sage Monitored Systems OK is displayed (Fig. 3).

ENGINE COMPARTMENT NODE (ECN)

The Engine Compartment Node is a microcomputer

controlled unit which, informs the Electronic Vehicle

Information Center (EVIC) via the CCD bus of:

² Outside temperature

² Compass direction

and the following warning messages:

² Low Brake Fluid

² Low Coolant Level

² Low Engine Oil Level

Fig. 3 EVIC Messages and Sensors

Ä OVERHEAD CONSOLE 8C - 15

Page 494 of 2438

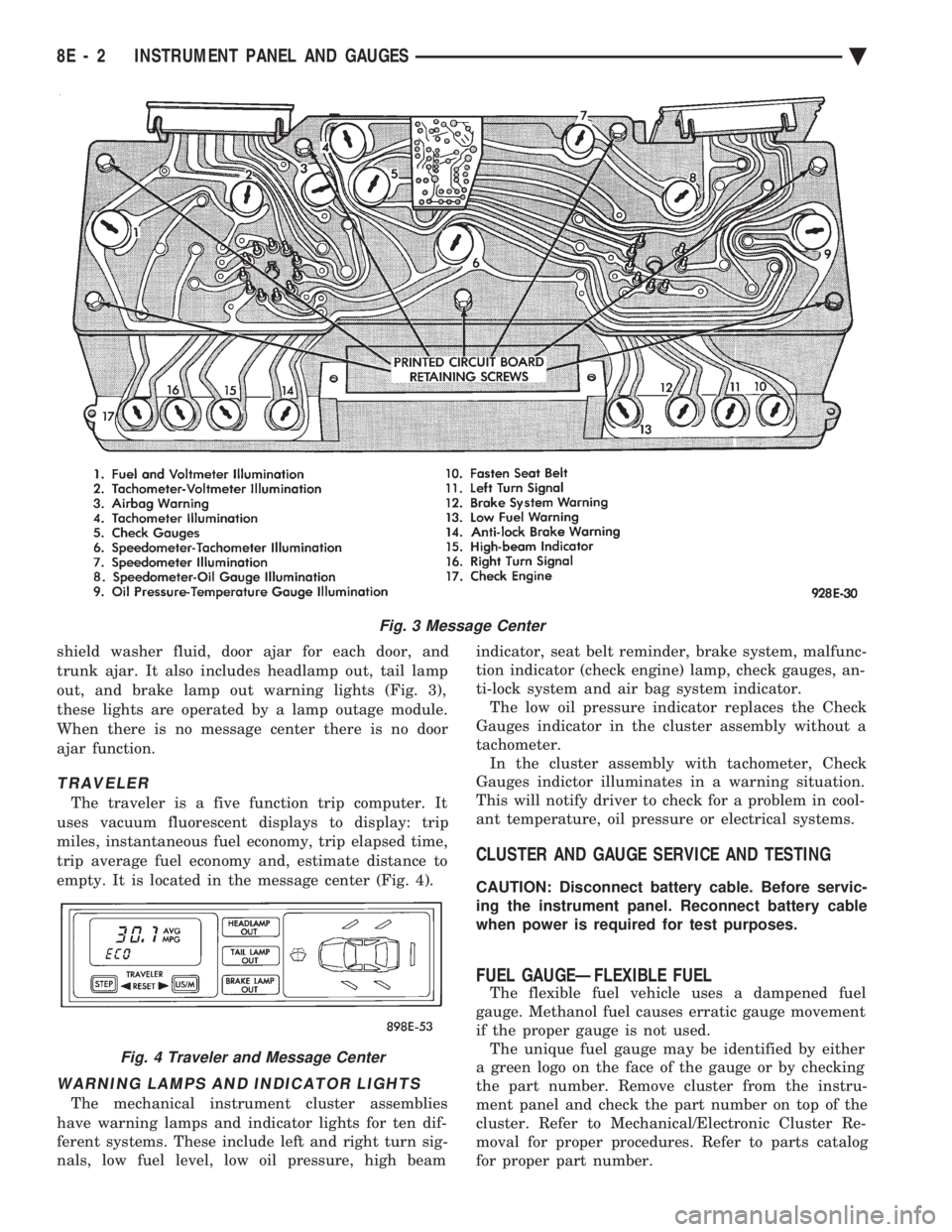

shield washer fluid, door ajar for each door, and

trunk ajar. It also includes headlamp out, tail lamp

out, and brake lamp out warning lights (Fig. 3),

these lights are operated by a lamp outage module.

When there is no message center there is no door

ajar function.

TRAVELER

The traveler is a five function trip computer. It

uses vacuum fluorescent displays to display: trip

miles, instantaneous fuel economy, trip elapsed time,

trip average fuel economy and, estimate distance to

empty. It is located in the message center (Fig. 4).

WARNING LAMPS AND INDICATOR LIGHTS

The mechanical instrument cluster assemblies

have warning lamps and indicator lights for ten dif-

ferent systems. These include left and right turn sig-

nals, low fuel level, low oil pressure, high beam indicator, seat belt reminder, brake system, malfunc-

tion indicator (check engine) lamp, check gauges, an-

ti-lock system and air bag system indicator. The low oil pressure indicator replaces the Check

Gauges indicator in the cluster assembly without a

tachometer. In the cluster assembly with tachometer, Check

Gauges indictor illuminates in a warning situation.

This will notify driver to check for a problem in cool-

ant temperature, oil pressure or electrical systems.

CLUSTER AND GAUGE SERVICE AND TESTING

CAUTION: Disconnect battery cable. Before servic-

ing the instrument panel. Reconnect battery cable

when power is required for test purposes.

FUEL GAUGEÐFLEXIBLE FUEL

The flexible fuel vehicle uses a dampened fuel

gauge. Methanol fuel causes erratic gauge movement

if the proper gauge is not used. The unique fuel gauge may be identified by either

a green logo on the face of the gauge or by checking

the part number. Remove cluster from the instru-

ment panel and check the part number on top of the

cluster. Refer to Mechanical/Electronic Cluster Re-

moval for proper procedures. Refer to parts catalog

for proper part number.

Fig. 3 Message Center

Fig. 4 Traveler and Message Center

8E - 2 INSTRUMENT PANEL AND GAUGES Ä

Page 515 of 2438

AC AND AY BODIES INDEX

page page

Electronic Cluster ........................ 34

Gauges ................................ 28

General Information ....................... 23

Interior Lamp Replacement ................. 41 Mechanical Cluster and Gauge Service

........ 24

Mechanical/Electronic Cluster Removal ........ 25

Switch and Panel Component Service ......... 37

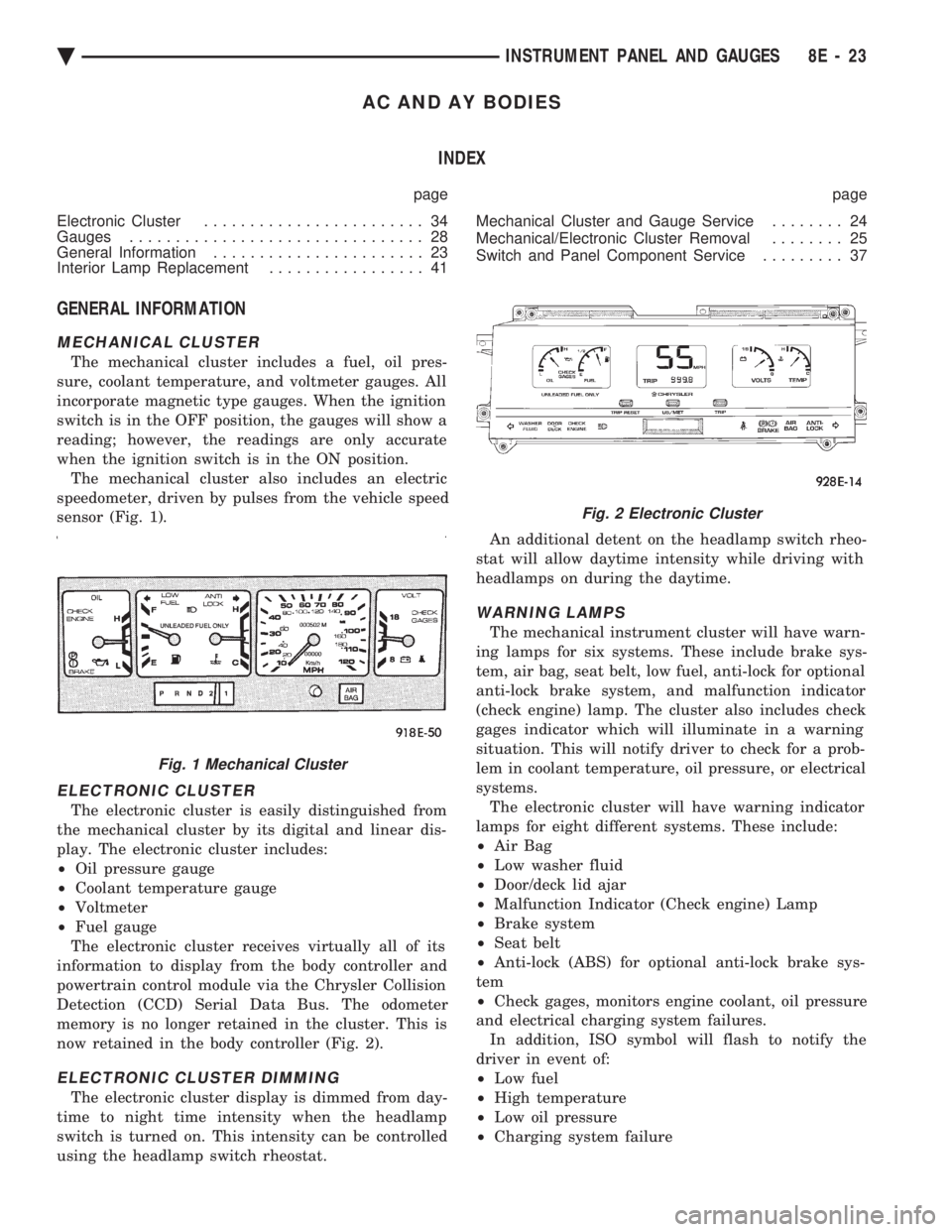

GENERAL INFORMATION

MECHANICAL CLUSTER

The mechanical cluster includes a fuel, oil pres-

sure, coolant temperature, and voltmeter gauges. All

incorporate magnetic type gauges. When the ignition

switch is in the OFF position, the gauges will show a

reading; however, the readings are only accurate

when the ignition switch is in the ON position. The mechanical cluster also includes an electric

speedometer, driven by pulses from the vehicle speed

sensor (Fig. 1).

ELECTRONIC CLUSTER

The electronic cluster is easily distinguished from

the mechanical cluster by its digital and linear dis-

play. The electronic cluster includes:

² Oil pressure gauge

² Coolant temperature gauge

² Voltmeter

² Fuel gauge

The electronic cluster receives virtually all of its

information to display from the body controller and

powertrain control module via the Chrysler Collision

Detection (CCD) Serial Data Bus. The odometer

memory is no longer retained in the cluster. This is

now retained in the body controller (Fig. 2).

ELECTRONIC CLUSTER DIMMING

The electronic cluster display is dimmed from day-

time to night time intensity when the headlamp

switch is turned on. This intensity can be controlled

using the headlamp switch rheostat. An additional detent on the headlamp switch rheo-

stat will allow daytime intensity while driving with

headlamps on during the daytime.

WARNING LAMPS

The mechanical instrument cluster will have warn-

ing lamps for six systems. These include brake sys-

tem, air bag, seat belt, low fuel, anti-lock for optional

anti-lock brake system, and malfunction indicator

(check engine) lamp. The cluster also includes check

gages indicator which will illuminate in a warning

situation. This will notify driver to check for a prob-

lem in coolant temperature, oil pressure, or electrical

systems. The electronic cluster will have warning indicator

lamps for eight different systems. These include:

² Air Bag

² Low washer fluid

² Door/deck lid ajar

² Malfunction Indicator (Check engine) Lamp

² Brake system

² Seat belt

² Anti-lock (ABS) for optional anti-lock brake sys-

tem

² Check gages, monitors engine coolant, oil pressure

and electrical charging system failures. In addition, ISO symbol will flash to notify the

driver in event of:

² Low fuel

² High temperature

² Low oil pressure

² Charging system failure

Fig. 1 Mechanical Cluster

Fig. 2 Electronic Cluster

Ä INSTRUMENT PANEL AND GAUGES 8E - 23

Page 526 of 2438

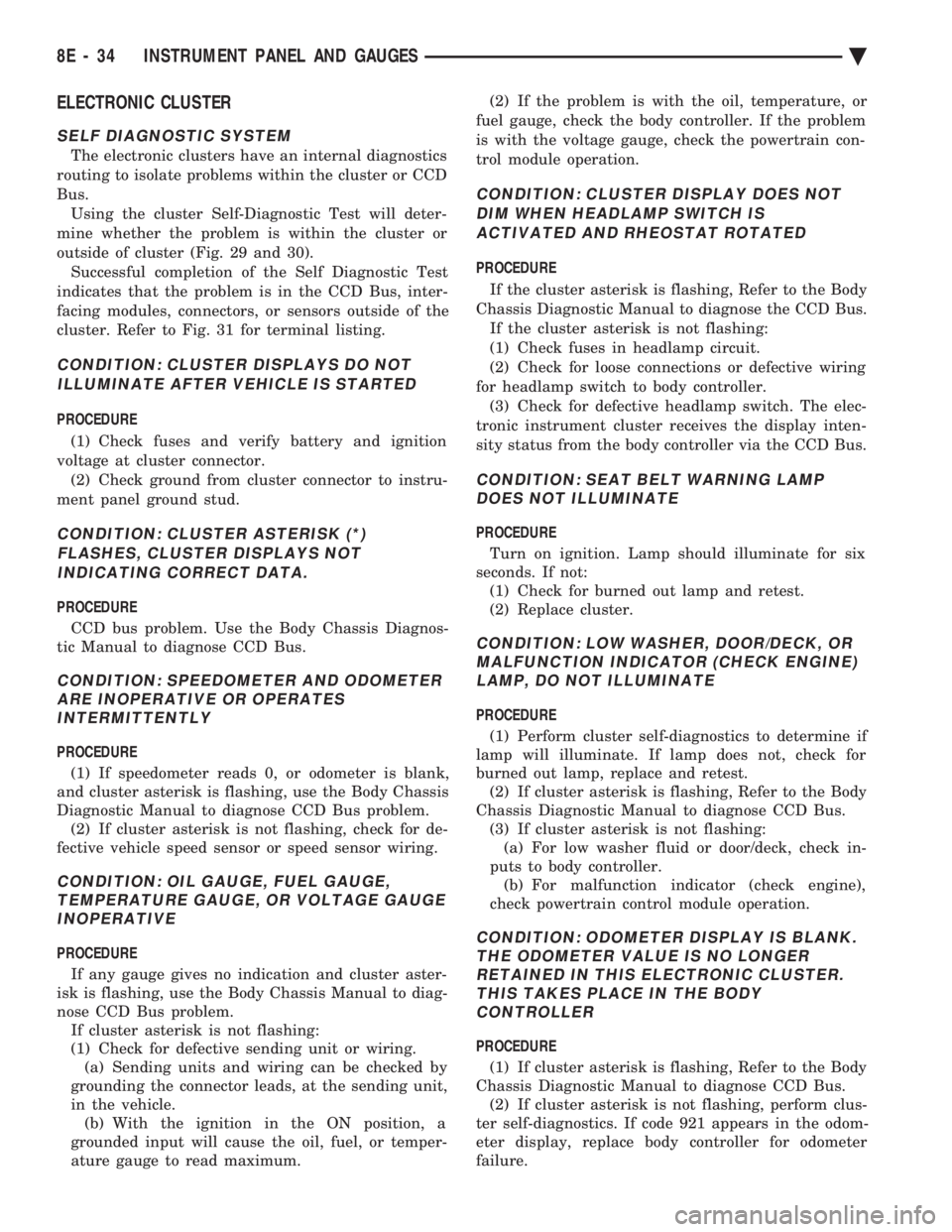

ELECTRONIC CLUSTER

SELF DIAGNOSTIC SYSTEM

The electronic clusters have an internal diagnostics

routing to isolate problems within the cluster or CCD

Bus. Using the cluster Self-Diagnostic Test will deter-

mine whether the problem is within the cluster or

outside of cluster (Fig. 29 and 30). Successful completion of the Self Diagnostic Test

indicates that the problem is in the CCD Bus, inter-

facing modules, connectors, or sensors outside of the

cluster. Refer to Fig. 31 for terminal listing.

CONDITION: CLUSTER DISPLAYS DO NOT ILLUMINATE AFTER VEHICLE IS STARTED

PROCEDURE

(1) Check fuses and verify battery and ignition

voltage at cluster connector. (2) Check ground from cluster connector to instru-

ment panel ground stud.

CONDITION: CLUSTER ASTERISK (*) FLASHES, CLUSTER DISPLAYS NOTINDICATING CORRECT DATA.

PROCEDURE

CCD bus problem. Use the Body Chassis Diagnos-

tic Manual to diagnose CCD Bus.

CONDITION: SPEEDOMETER AND ODOMETER ARE INOPERATIVE OR OPERATESINTERMITTENTLY

PROCEDURE

(1) If speedometer reads 0, or odometer is blank,

and cluster asterisk is flashing, use the Body Chassis

Diagnostic Manual to diagnose CCD Bus problem. (2) If cluster asterisk is not flashing, check for de-

fective vehicle speed sensor or speed sensor wiring.

CONDITION: OIL GAUGE, FUEL GAUGE, TEMPERATURE GAUGE, OR VOLTAGE GAUGEINOPERATIVE

PROCEDURE

If any gauge gives no indication and cluster aster-

isk is flashing, use the Body Chassis Manual to diag-

nose CCD Bus problem. If cluster asterisk is not flashing:

(1) Check for defective sending unit or wiring. (a) Sending units and wiring can be checked by

grounding the connector leads, at the sending unit,

in the vehicle. (b) With the ignition in the ON position, a

grounded input will cause the oil, fuel, or temper-

ature gauge to read maximum. (2) If the problem is with the oil, temperature, or

fuel gauge, check the body controller. If the problem

is with the voltage gauge, check the powertrain con-

trol module operation.

CONDITION: CLUSTER DISPLAY DOES NOT DIM WHEN HEADLAMP SWITCH ISACTIVATED AND RHEOSTAT ROTATED

PROCEDURE

If the cluster asterisk is flashing, Refer to the Body

Chassis Diagnostic Manual to diagnose the CCD Bus. If the cluster asterisk is not flashing:

(1) Check fuses in headlamp circuit.

(2) Check for loose connections or defective wiring

for headlamp switch to body controller. (3) Check for defective headlamp switch. The elec-

tronic instrument cluster receives the display inten-

sity status from the body controller via the CCD Bus.

CONDITION: SEAT BELT WARNING LAMP DOES NOT ILLUMINATE

PROCEDURE

Turn on ignition. Lamp should illuminate for six

seconds. If not: (1) Check for burned out lamp and retest.

(2) Replace cluster.

CONDITION: LOW WASHER, DOOR/DECK, OR MALFUNCTION INDICATOR (CHECK ENGINE)LAMP, DO NOT ILLUMINATE

PROCEDURE

(1) Perform cluster self-diagnostics to determine if

lamp will illuminate. If lamp does not, check for

burned out lamp, replace and retest. (2) If cluster asterisk is flashing, Refer to the Body

Chassis Diagnostic Manual to diagnose CCD Bus. (3) If cluster asterisk is not flashing:(a) For low washer fluid or door/deck, check in-

puts to body controller. (b) For malfunction indicator (check engine),

check powertrain control module operation.

CONDITION: ODOMETER DISPLAY IS BLANK. THE ODOMETER VALUE IS NO LONGERRETAINED IN THIS ELECTRONIC CLUSTER.THIS TAKES PLACE IN THE BODYCONTROLLER

PROCEDURE

(1) If cluster asterisk is flashing, Refer to the Body

Chassis Diagnostic Manual to diagnose CCD Bus. (2) If cluster asterisk is not flashing, perform clus-

ter self-diagnostics. If code 921 appears in the odom-

eter display, replace body controller for odometer

failure.

8E - 34 INSTRUMENT PANEL AND GAUGES Ä

Page 534 of 2438

AG AND AJ BODIES INDEX

page page

Cigar Lighter Removal ..................... 55

Cluster and Gauge Service and Testing ....... 43

Electronic Cluster ........................ 50

Electronic Vehicle Information Center (EVIC) .... 42

Engine Compartment Node ................. 55

Gauges ................................ 44 General Information

....................... 42

Instrument Panel Roll Down Procedure ........ 56

Interior Lamp Removal .................... 57

Mechanical/Electronic Cluster Removal ........ 43

Switch and Panel Component Service ......... 51

Switch Pod Assembly Removal .............. 43

GENERAL INFORMATION

CONVENTIONAL INSTRUMENT CLUSTER

The conventional instrument cluster incorporates

magnetic type gauges (Fig. 1).

The readings are only accurate when the ignition

switch is in the ON position.

TACHOMETER DRIVE MODULE

The tachometer drive module is an electronic mod-

ule used to drive a magnetic tachometer in a conven-

tional instrument cluster.

MESSAGE CENTER

The message center provides the driver with infor-

mation in addition to the standard vehicle instru-

mentation. A bezel will light up with door ajar,

washer fluid, deck ajar and alarm set information.

For vehicles without message center a plain bezel is

used.

ELECTRONIC VEHICLE INFORMATION CENTER

(EVIC)

The Electronic Vehicle Information Center is a

computer controlled warning system which, monitors

various sensors used on the vehicle. The system sup-

plements the warning indicators in the instrument

cluster. Visual warning messages are displayed by a

digital display (Fig. 2). Refer to Group 8C, Overhead

Console.

ELECTRONIC INSTRUMENT CLUSTER

The electronic instrument cluster uses vacuum flu-

orescent displays to display:

² Oil pressure

² System voltage

² Engine temperature

² Fuel level

² Speedometer and tachometer readings as well as

all warning indicators. The electronic cluster is eas-

ily distinguished from the conventional cluster by its

digital and linear display (Fig. 3.

ELECTRONIC CLUSTER DIMMING

The electronic cluster display is dimmed from day-

time to nighttime intensity when the head]lamp

switch is turned on. This intensity can be controlled

using the headlamp switch sliding rheostat. An additional detent on the headlamp switch rheo-

stat will allow daytime intensity while driving with

headlamps ON in daytime.

Fig. 1 Conventional Instrument Cluster

Fig. 2 EVIC

Fig. 3 Electronic Instrument Cluster

8E - 42 INSTRUMENT PANEL AND GAUGES Ä

Page 637 of 2438

WINDSHIELD WASHERS INDEX

page page

General Information ....................... 17

Washer Nozzle .......................... 19 Washer Reservoir Pump

................... 18

Washer Reservoirs ....................... 17

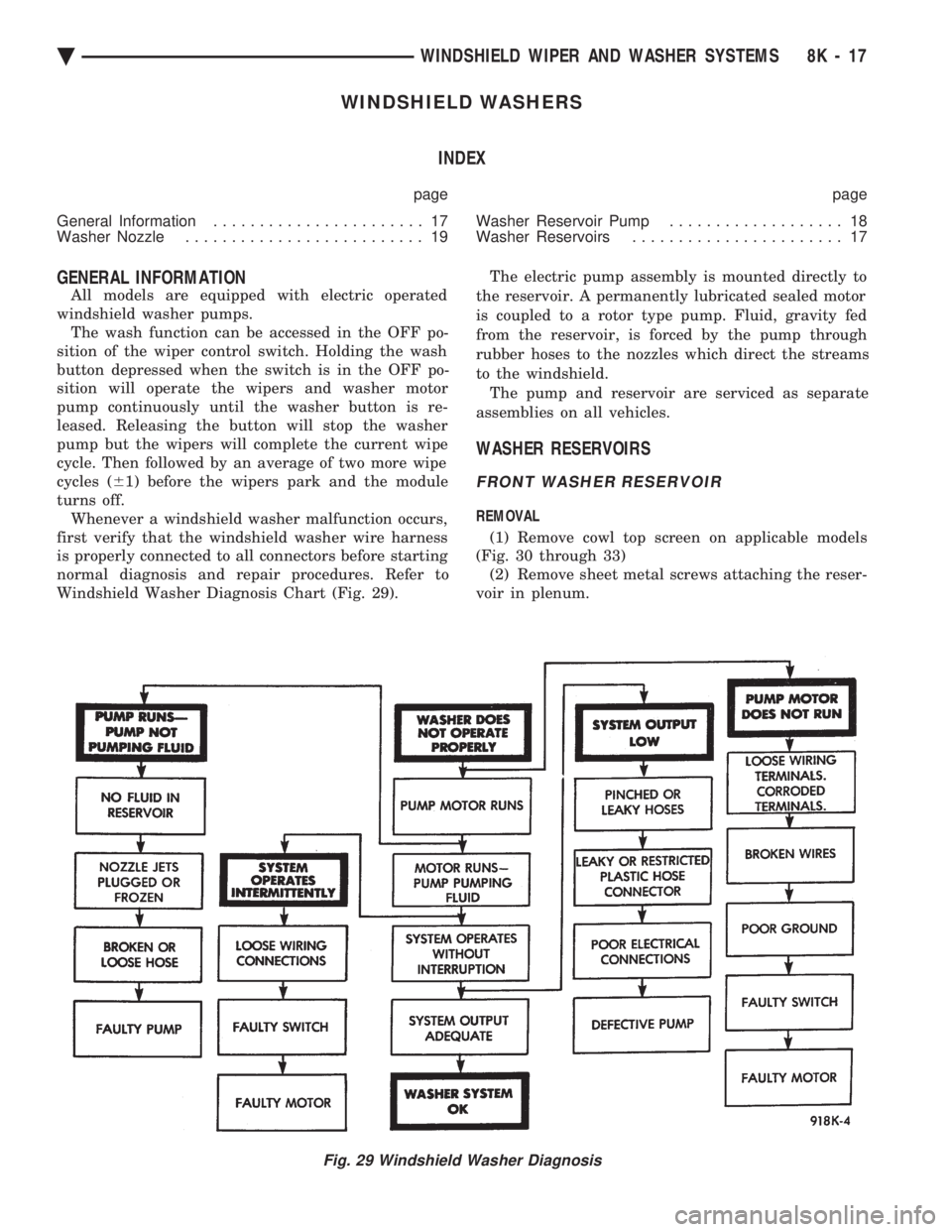

GENERAL INFORMATION

All models are equipped with electric operated

windshield washer pumps. The wash function can be accessed in the OFF po-

sition of the wiper control switch. Holding the wash

button depressed when the switch is in the OFF po-

sition will operate the wipers and washer motor

pump continuously until the washer button is re-

leased. Releasing the button will stop the washer

pump but the wipers will complete the current wipe

cycle. Then followed by an average of two more wipe

cycles ( 61) before the wipers park and the module

turns off. Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harness

is properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer Diagnosis Chart (Fig. 29). The electric pump assembly is mounted directly to

the reservoir. A permanently lubricated sealed motor

is coupled to a rotor type pump. Fluid, gravity fed

from the reservoir, is forced by the pump through

rubber hoses to the nozzles which direct the streams

to the windshield. The pump and reservoir are serviced as separate

assemblies on all vehicles.

WASHER RESERVOIRS

FRONT WASHER RESERVOIR

REMOVAL

(1) Remove cowl top screen on applicable models

(Fig. 30 through 33) (2) Remove sheet metal screws attaching the reser-

voir in plenum.

Fig. 29 Windshield Washer Diagnosis

Ä WINDSHIELD WIPER AND WASHER SYSTEMS 8K - 17