maintenance schedule CHEVROLET DYNASTY 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: DYNASTY, Model: CHEVROLET DYNASTY 1993Pages: 2438, PDF Size: 74.98 MB

Page 37 of 2438

LUBRICATION AND MAINTENANCE

CONTENTS

page page

CHASSIS AND BODY .................... 19

DRIVETRAIN ........................... 16 ENGINE

................................ 8

GENERAL INFORMATION .................. 1

GENERAL INFORMATION INDEX

page page

Classification of Lubricants .................. 1

Fluid Capacities .......................... 4

Fuel Usage .............................. 1

Hoisting Recommendations .................. 5

Introduction .............................. 1 Jump Starting Procedure

.................... 4

Parts and Lubricant Recommendations ......... 1

Parts Requiring No Lubrication ............... 4

Severe Service ........................... 1

Towing Recommendations ................... 7

INTRODUCTION

Chrysler Corporation has compiled recommended

lubrication and maintenance schedules and proce-

dures to help reduce premature wear or failure over

a broad range of operating conditions. When select-

ing the proper maintenance schedule, the climate

and operating conditions must be considered. A vehi-

cle subjected to severe usage requires service more

frequently than a vehicle used for general transpor-

tation.

PARTS AND LUBRICANT RECOMMENDATIONS

When service is required, Chrysler Corporation rec-

ommends that only Mopar tbrand parts, lubricants

and chemicals be used. Mopar tprovides the best en-

gineered products for servicing Chrysler Corporation

vehicles.

SEVERE SERVICE

If a vehicle is operated under any of the following

conditions, it is considered severe service.

² Extremely dusty areas.

² 50% or more of vehicle operation in 32ÉC (90ÉF) or

higher temperatures.

² Prolonged idling ( such as, vehicle operation in

stop and go traffic).

² Frequent short running periods. Not allowing en-

gine to warm to operating temperatures.

² Police or taxi usage.

FUEL USAGE

All Chrysler Corporation engines require the use of

unleaded fuel to reduce exhaust emissions. Use fuel

with a minimum octane rating of 87,(R + M)/2. See

Engine section of this group for Fuel Recommenda-

tions.

CLASSIFICATION OF LUBRICANTS

Only lubricants that are endorsed by the following

organizations standards should be used to service a

Chrysler Corporation vehicle.

² Society of Automotive Engineers (SAE)

² American Petroleum Institute (API)

² National Lubricating Grease Institute (NLGI)

ENGINE OIL

SAE GRADE RATING INDICATES ENGINE OIL VISCOSITY

² SAE 30 = single grade engine oil.

² SAE 5W-30 = multiple grade engine oil.

API QUALITY CLASSIFICATION.

² SG service engine oil is a high quality crankcase

lubricant designed for use in all naturally aspirated

engines.

² SG/CD service engine oil is a high quality crank-

case lubricant designed for use in most naturally as-

pirated and turbocharged gasoline or diesel engines.

GEAR LUBRICANTS

SAE ratings also apply to multiple grade gear lu-

bricants. In addition, API classification defines the

lubricants usage.

Ä LUBRICATION AND MAINTENANCE 0 - 1

Page 38 of 2438

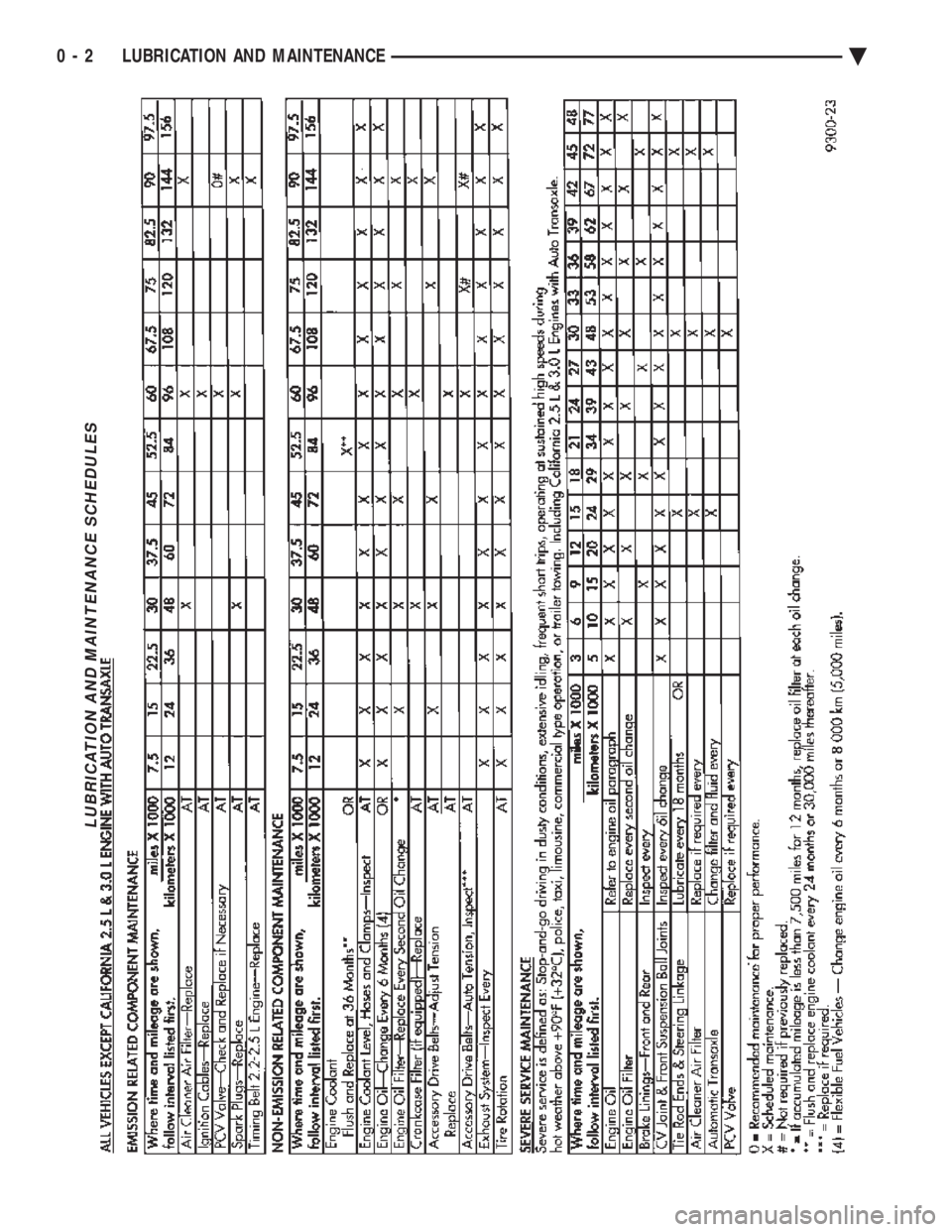

LUBRICATION AND MAINTENANCE SCHEDULES

0 - 2 LUBRICATION AND MAINTENANCEÄ

Page 45 of 2438

² SG service engine oil is a high quality crankcase

lubricant designed for use in all naturally aspirated

engines. If SG service engine oil is used in turbo-

charged engine, change engine oil at every 4 800

km (3,000 miles) or three months.

² SG/CD service engine oil is a high quality crank-

case lubricant designed for use in most naturally as-

pirated and turbocharged gasoline or diesel engines.

FLEXIBLE FUEL VEHICLES

Vehicles operated using Flexible Fuel (M85) re-

quire engine oil that meet or exceed Chrysler Stan-

dard MS-9214. Mopar Flexible Fuel engine oil or

equivalent should be used when adding or changing

crankcase lubricant. The API symbol (Fig. 1) on the

container indicates the viscosity grade, quality and

fuel economy ratings of the lubricant it contains. Use

ENERGY CONSERVING II motor oil with API SER-

VICE SG or SG/CD classification.

ENGINE OIL ADDITIVES

Chrysler Corporation recommends that Mopar En-

gine Oil Supplement or equivalent be used when fric-

tion and corrosion reducing materials added to the

crankcase lubricant is desired.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

Inspect engine oil level approximately every 800

kilometers (500 miles). Position vehicle on level sur- face. With engine OFF, allow enough time for oil to

settle to bottom of crankcase, remove engine oil level

indicator (dipstick) and wipe clean. Install dipstick

and verify it is seated in the tube. Remove dipstick,

with handle above tip, take oil level reading (Fig. 2).

Add oil only if level is below MIN or ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Lubrication and Maintenance Schedules.

Position the vehicle on a level surface. Hoist and

support vehicle on safety stands. Refer to Hoisting

and Jacking Recommendations in this group. Place a

suitable 3.8 liter (4 qt.) drain pan under crankcase

drain. Remove drain plug from crankcase. Inspect

drain plug threads for stretching or other damage.

Replace drain plug and gasket if damaged. Install

drain plug in crankcase. Lower vehicle and fill

crankcase with specified type and amount of engine

oil described in this section. Start engine and inspect

for leaks. Stop engine and inspect oil level.

ENGINE OIL FILTER

SELECTING OIL FILTER

Chrysler Corporation recommends a Mopar or

equivalent oil filter be used when replacement is re-

quired. A replacement filter must be designed to

withstand 1756 kPa (256 psi) of internal pressure.

OIL FILTER REPLACEMENT

Position a drain pan under the oil filter. Using a

suitable oil filter wrench (Fig. 3) loosen filter. When

filter separates from adapter nipple, tip gasket end

upward to minimize oil spill. Remove filter from ve-

hicle. With a wiping cloth, clean the gasket sealing

surface (Fig. 4) of oil and grime. Wipe off oil residue

from below oil filter adapter.

TO INSTALL NEW OIL FILTER: Lightly lubricate oil filter gasket with engine oil or

chassis grease. Thread filter onto adapter nipple.

When gasket makes contact with sealing surface,

tighten filter one full turn. If necessary use a filter

wrench, do not over tighten. Add oil, verify crank-

case oil level and start engine. Inspect for oil leaks.

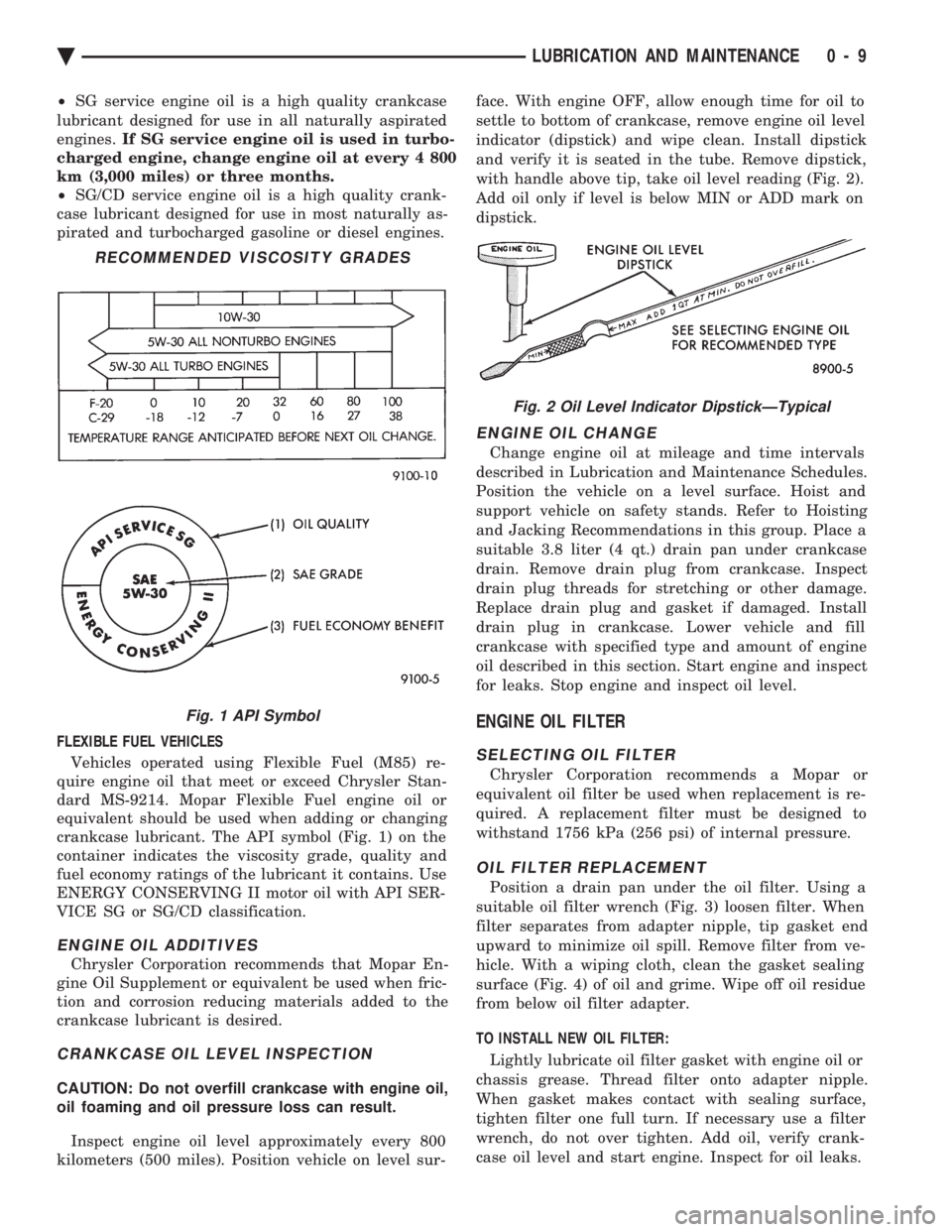

RECOMMENDED VISCOSITY GRADES

Fig. 1 API Symbol

Fig. 2 Oil Level Indicator DipstickÐTypical

Ä LUBRICATION AND MAINTENANCE 0 - 9

Page 47 of 2438

tifreeze to achieve adequate protection. A mix table

on the coolant container indicates the amount of an-

tifreeze required to winterize the cooling system

based on the capacity, see Capacity Chart in General

Information section of this group.

SELECTING ANTIFREEZE

Chrysler Corporation recommends Mopar Anti-

freeze/Summer Coolant, or equivalent be used to win-

terize and protect cooling system.

RADIATOR CAP

The radiator cap must be secure to provide proper

pressure release and coolant recovery. Inspect and

test radiator cap when cooling system service is per-

formed or when problem is suspected.

COOLING SYSTEM SERVICE

The cooling system should be drained, flushed and

filled with the proper coolant mixture at the inter-

vals described in the Lubrication and Maintenance

Schedules. Refer to General Information section of

this group. For proper service instructions see Group

7, Cooling System.

ENGINE AIR CLEANER

The engine air cleaner should be serviced at the in-

tervals described in the Lubrication and Mainte-

nance Schedules. Refer to General Information

section of this group. Additional information can be

found in Group 14, Fuel System and Group 25, Emis-

sion System. Inspect all air cleaner hoses or tubes for

damage or leaks when other engine compartment

service is performed. Replace faulty components.

AIR CLEANER SERVICE

CAUTION: The air cleaner cover must be installed

properly for the emissions system and engine con-

troller to function correctly. Do not immerse paper air filter element or temper-

ature sensor in cleaning solvents, damage can re-

sult.

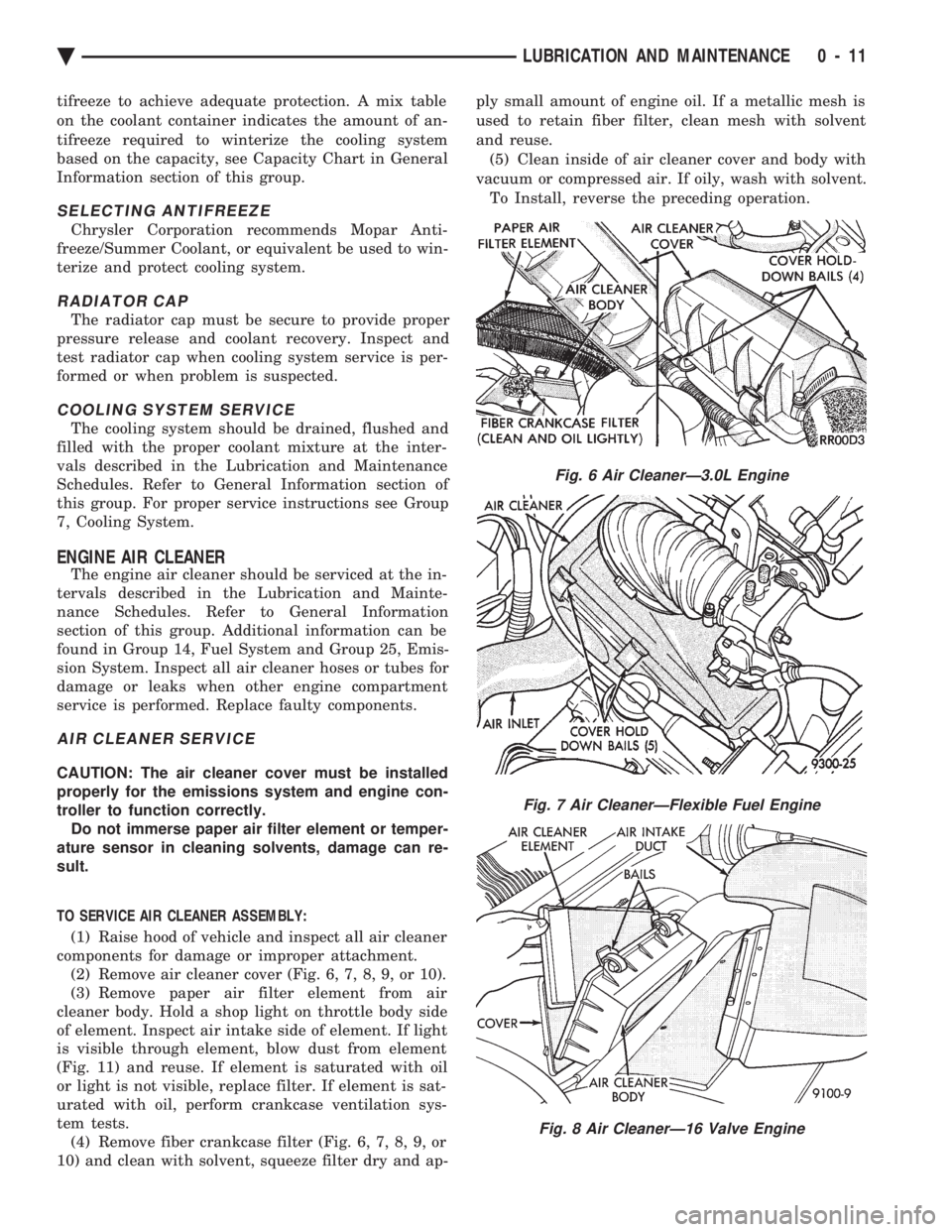

TO SERVICE AIR CLEANER ASSEMBLY: (1) Raise hood of vehicle and inspect all air cleaner

components for damage or improper attachment. (2) Remove air cleaner cover (Fig. 6, 7, 8, 9, or 10).

(3) Remove paper air filter element from air

cleaner body. Hold a shop light on throttle body side

of element. Inspect air intake side of element. If light

is visible through element, blow dust from element

(Fig. 11) and reuse. If element is saturated with oil

or light is not visible, replace filter. If element is sat-

urated with oil, perform crankcase ventilation sys-

tem tests. (4) Remove fiber crankcase filter (Fig. 6, 7, 8, 9, or

10) and clean with solvent, squeeze filter dry and ap- ply small amount of engine oil. If a metallic mesh is

used to retain fiber filter, clean mesh with solvent

and reuse.

(5) Clean inside of air cleaner cover and body with

vacuum or compressed air. If oily, wash with solvent. To Install, reverse the preceding operation.

Fig. 6 Air CleanerÐ3.0L Engine

Fig. 7 Air CleanerÐFlexible Fuel Engine

Fig. 8 Air CleanerÐ16 Valve Engine

Ä LUBRICATION AND MAINTENANCE 0 - 11

Page 50 of 2438

PCV SYSTEM TEST

Refer to group 25, Emission Control System for

proper procedures to test PCV system.

FUEL RECOMMENDATIONS

Chrysler Corporation recommends that only fuel pur-

chased from a reputable retailer be used. Use high qual-

ity, unleaded gasoline to provide satisfactory

driveability and highest fuel economy. Gasoline contain-

ing detergent and corrosion control additives are desire-

able. If the engine develops spark knock (audible ping),

poor performance, hard starting or stalling, purchase

fuel from another source. Engine performance can vary

when using different brands of gasoline with the same

octane rating. Occasional light engine spark knock un-

der heavy acceleration, at low speed or when vehicle is

heavily loaded is not harmful. Extended periods of

spark knock under moderate acceleration or at cruising

speed can damage the engine. The cause of excessive

spark knock condition must be diagnosed and corrected.

For diagnostic procedures refer to Group 14, Fuel Sys-

tem and Powertrain Diagnostic Procedures manual.

SELECTING GASOLINE

CAUTION:Do not use fuel containing METHANOL

(methyl or wood alcohol), damage to fuel system

will result. Do not use leaded gasoline, damage to catalytic

converter will result and vehicle will not conform to

emission control standards.

ETHANOL, MTBE OR ETBE BLENDS

All Chrysler Corporation vehicles are designed to

use unleaded gasoline ONLY. Gasohol blends, con-

taining 10% Ethanol (ethyl or grain alcohol) 90% un-

leaded gasoline can be used provided it has adequate

octane rating. Fuel blends containing up to 15% MTBE (Methyl

Tertiary Butyl Ether) and 85% unleaded gasoline can

be used. Fuel blends containing up to 17% ETBE

(Ethyl Tertiary Butyl Ether) and 83% unleaded gas-

oline can also be used. Fuel blended with ethanol, MTBE or ETBE are

also referred to as reformulated or clean air gasoline.

These fuels contribute less emissions to the atmo-

sphere. Chrysler Corporation recommends that

blended fuels be used when available

METHANOL BLENDS Using gasoline blended with methanol can result

in starting and driveability problems. Deterioration

of fuel system components will result. Methanol in-

duced problems are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty. NON-TURBOCHARGED ENGINES

Use regular unleaded gasoline having a minimum

octane rating of 87 (R+M)/2. Higher octane premium

unleaded gasoline can be used if desired.

2.2L 16 VALVE TURBOCHARGED ENGINE

Use premium unleaded gasoline having a mini-

mum octane rating of 91 (R+M)/2. Gasoline with oc-

tane rating less than 91 (R+M)/2 can be used if

recommended gasoline is not available. Low octane

gasoline will reduce engine performance.

FLEXIBLE FUEL VEHICLES

CAUTION: Do not use 100% methanol, damage to

fuel system can result. Use unleaded regular gasoline having a minimum

octane rating of 87 (R=M)/2 and M85 fuel that is

85% methanol and 15% unleaded gasoline, or a mix-

ture of these two.

FUEL FILTER

The fuel filter requires service only when a fuel

contamination problem is suspected. For proper diag-

nostic and service procedures refer to Group 14, Fuel

System,

IGNITION CABLES, DISTRIBUTOR CAP, AND

ROTOR

Inspect and test ignition cables, distributor cap and

rotor when the spark plugs are replaced. Oil and

grime should be cleaned from the ignition cables and

distributor cap to avoid possible spark plug fouling.

Mopar, Foamy Engine Degreaser, or equivalent is

recommended for cleaning the engine compartment.

For proper service and diagnostic procedures refer to

Group 8D, Ignition System.

SPARK PLUGS

Ignition spark plugs should be replaced at the

mileage interval described in the Lubrication and

Maintenance Schedules. Refer to the General Infor-

mation section of this group. For proper service pro-

cedures refer to Group 8D, Ignition Systems.

DRIVE BELTS

Inspect and adjust drive belts at the interval de-

scribed in the Lubrication and Maintenance Sched-

ules. Refer to General Information section of this

group. For proper inspection and adjustment proce-

dures, see Group 7, Cooling System.

EMISSION CONTROL SYSTEM

Inspect all emission control components and hoses

when other under hood service is performed. Refer to

emission system Vacuum Hose Label located on the

0 - 14 LUBRICATION AND MAINTENANCE Ä

Page 53 of 2438

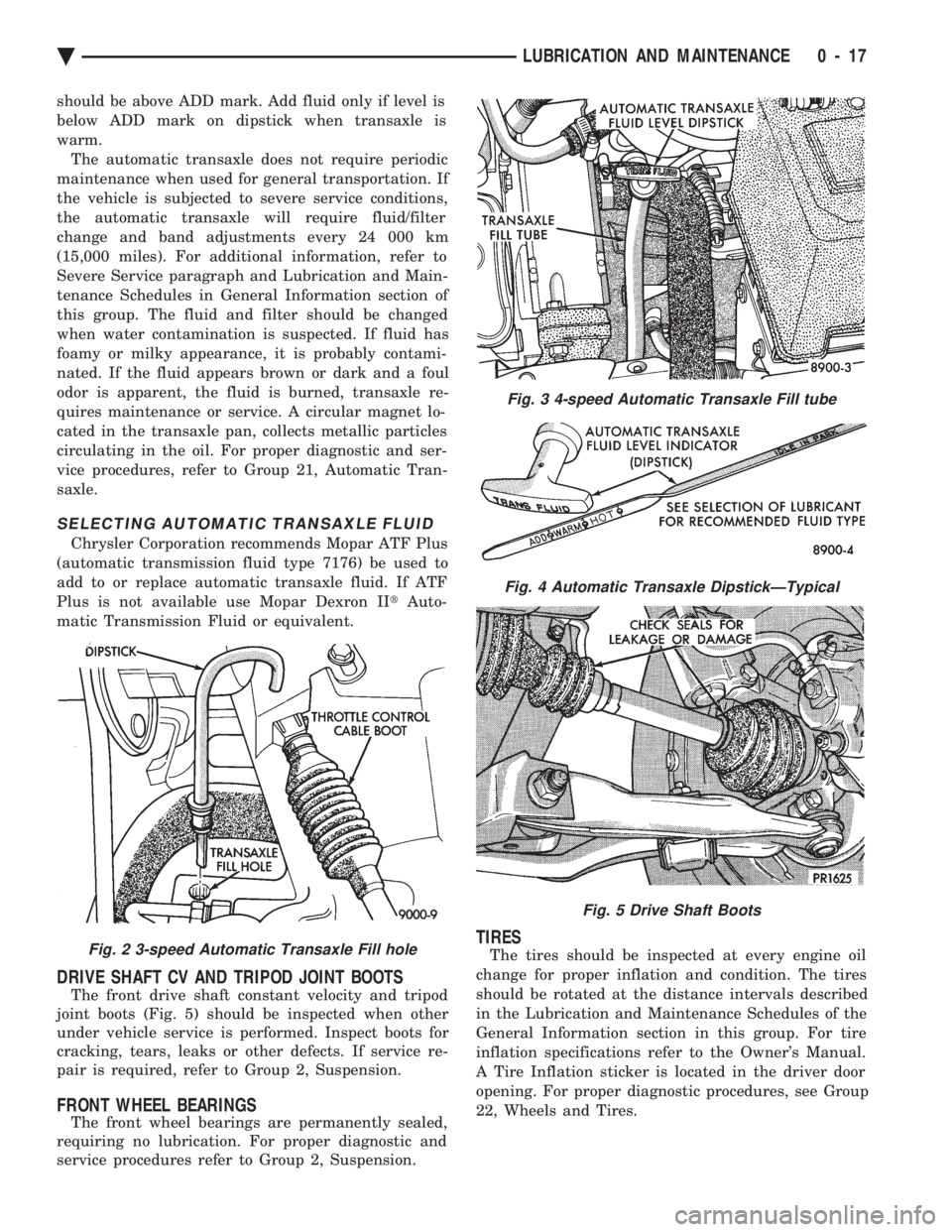

should be above ADD mark. Add fluid only if level is

below ADD mark on dipstick when transaxle is

warm.The automatic transaxle does not require periodic

maintenance when used for general transportation. If

the vehicle is subjected to severe service conditions,

the automatic transaxle will require fluid/filter

change and band adjustments every 24 000 km

(15,000 miles). For additional information, refer to

Severe Service paragraph and Lubrication and Main-

tenance Schedules in General Information section of

this group. The fluid and filter should be changed

when water contamination is suspected. If fluid has

foamy or milky appearance, it is probably contami-

nated. If the fluid appears brown or dark and a foul

odor is apparent, the fluid is burned, transaxle re-

quires maintenance or service. A circular magnet lo-

cated in the transaxle pan, collects metallic particles

circulating in the oil. For proper diagnostic and ser-

vice procedures, refer to Group 21, Automatic Tran-

saxle.

SELECTING AUTOMATIC TRANSAXLE FLUID

Chrysler Corporation recommends Mopar ATF Plus

(automatic transmission fluid type 7176) be used to

add to or replace automatic transaxle fluid. If ATF

Plus is not available use Mopar Dexron II tAuto-

matic Transmission Fluid or equivalent.

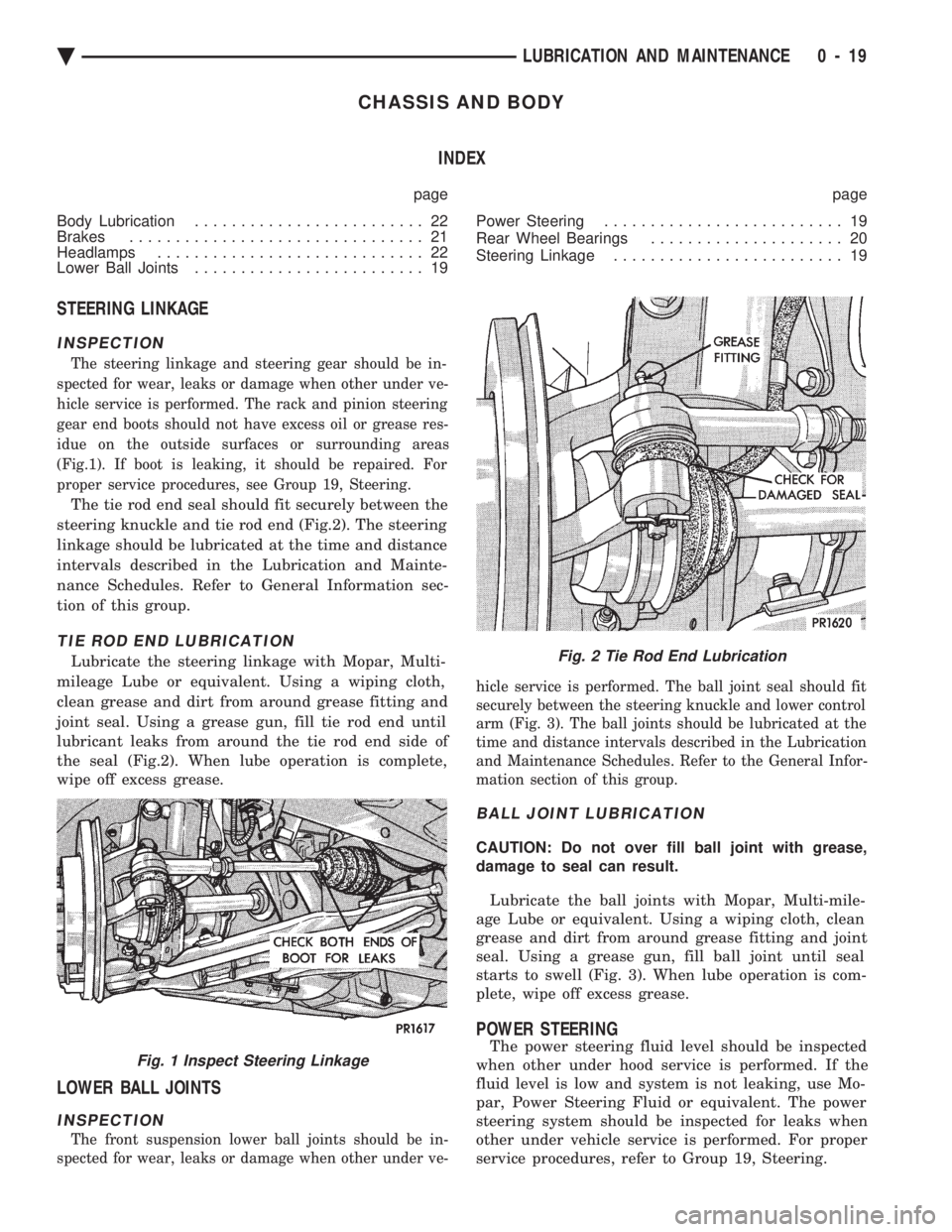

DRIVE SHAFT CV AND TRIPOD JOINT BOOTS

The front drive shaft constant velocity and tripod

joint boots (Fig. 5) should be inspected when other

under vehicle service is performed. Inspect boots for

cracking, tears, leaks or other defects. If service re-

pair is required, refer to Group 2, Suspension.

FRONT WHEEL BEARINGS

The front wheel bearings are permanently sealed,

requiring no lubrication. For proper diagnostic and

service procedures refer to Group 2, Suspension.

TIRES

The tires should be inspected at every engine oil

change for proper inflation and condition. The tires

should be rotated at the distance intervals described

in the Lubrication and Maintenance Schedules of the

General Information section in this group. For tire

inflation specifications refer to the Owner's Manual.

A Tire Inflation sticker is located in the driver door

opening. For proper diagnostic procedures, see Group

22, Wheels and Tires.Fig. 2 3-speed Automatic Transaxle Fill hole

Fig. 3 4-speed Automatic Transaxle Fill tube

Fig. 4 Automatic Transaxle DipstickÐTypical

Fig. 5 Drive Shaft Boots

Ä LUBRICATION AND MAINTENANCE 0 - 17

Page 55 of 2438

CHASSIS AND BODY INDEX

page page

Body Lubrication ......................... 22

Brakes ................................ 21

Headlamps ............................. 22

Lower Ball Joints ......................... 19 Power Steering

.......................... 19

Rear Wheel Bearings ..................... 20

Steering Linkage ......................... 19

STEERING LINKAGE

INSPECTION

The steering linkage and steering gear should be in-

spected for wear, leaks or damage when other under ve-

hicle service is performed. The rack and pinion steering

gear end boots should not have excess oil or grease res-

idue on the outside surfaces or surrounding areas

(Fig.1). If boot is leaking, it should be repaired. For

proper service procedures, see Group 19, Steering.

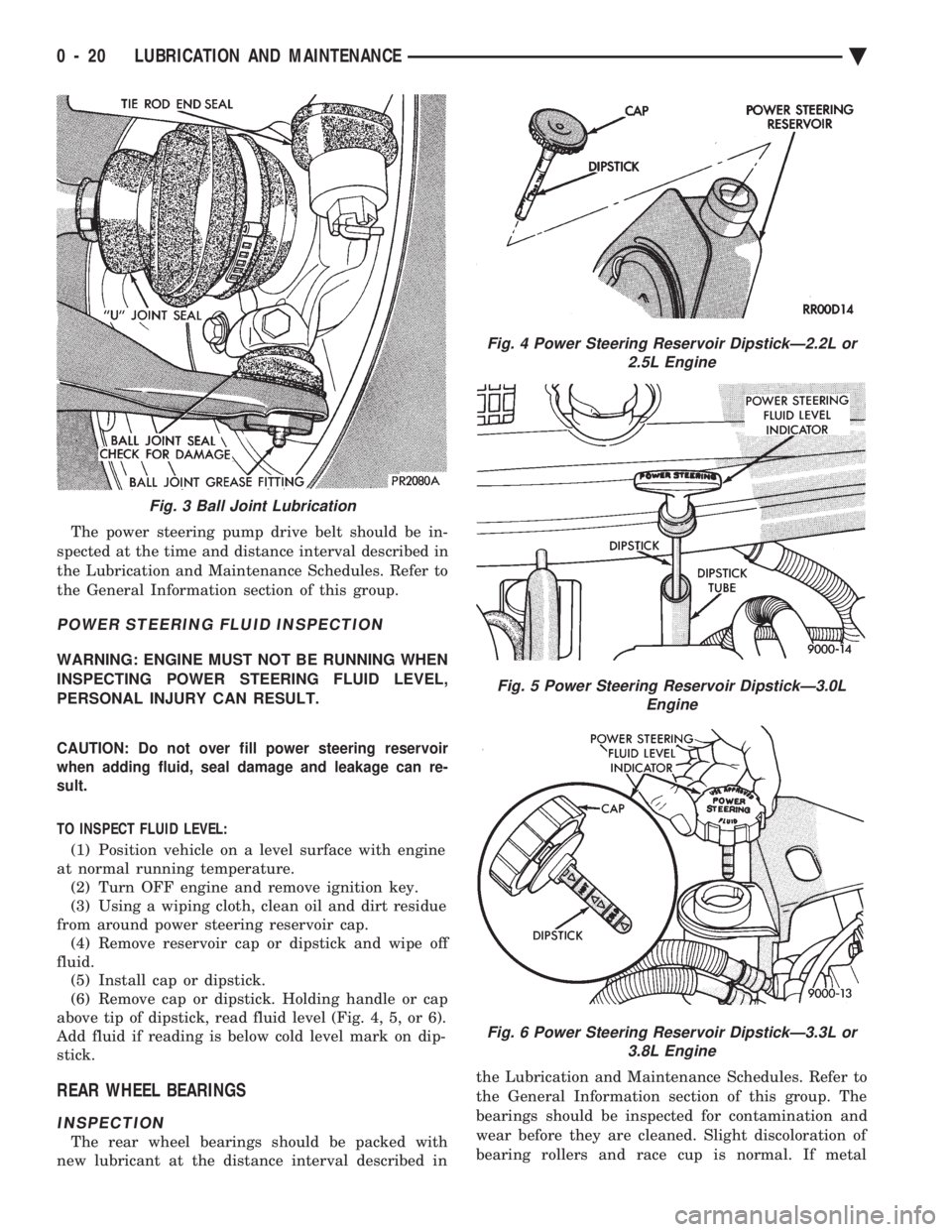

The tie rod end seal should fit securely between the

steering knuckle and tie rod end (Fig.2). The steering

linkage should be lubricated at the time and distance

intervals described in the Lubrication and Mainte-

nance Schedules. Refer to General Information sec-

tion of this group.

TIE ROD END LUBRICATION

Lubricate the steering linkage with Mopar, Multi-

mileage Lube or equivalent. Using a wiping cloth,

clean grease and dirt from around grease fitting and

joint seal. Using a grease gun, fill tie rod end until

lubricant leaks from around the tie rod end side of

the seal (Fig.2). When lube operation is complete,

wipe off excess grease.

LOWER BALL JOINTS

INSPECTION

The front suspension lower ball joints should be in-

spected for wear, leaks or damage when other under ve- hicle service is performed. The ball joint seal should fit

securely between the steering knuckle and lower control

arm (Fig. 3). The ball joints should be lubricated at the

time and distance intervals described in the Lubrication

and Maintenance Schedules. Refer to the General Infor-

mation section of this group.

BALL JOINT LUBRICATION

CAUTION: Do not over fill ball joint with grease,

damage to seal can result.

Lubricate the ball joints with Mopar, Multi-mile-

age Lube or equivalent. Using a wiping cloth, clean

grease and dirt from around grease fitting and joint

seal. Using a grease gun, fill ball joint until seal

starts to swell (Fig. 3). When lube operation is com-

plete, wipe off excess grease.

POWER STEERING

The power steering fluid level should be inspected

when other under hood service is performed. If the

fluid level is low and system is not leaking, use Mo-

par, Power Steering Fluid or equivalent. The power

steering system should be inspected for leaks when

other under vehicle service is performed. For proper

service procedures, refer to Group 19, Steering.Fig. 1 Inspect Steering Linkage

Fig. 2 Tie Rod End Lubrication

Ä LUBRICATION AND MAINTENANCE 0 - 19

Page 56 of 2438

The power steering pump drive belt should be in-

spected at the time and distance interval described in

the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group.

POWER STEERING FLUID INSPECTION

WARNING: ENGINE MUST NOT BE RUNNING WHEN

INSPECTING POWER STEERING FLUID LEVEL,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not over fill power steering reservoir

when adding fluid, seal damage and leakage can re-

sult.

TO INSPECT FLUID LEVEL:

(1) Position vehicle on a level surface with engine

at normal running temperature. (2) Turn OFF engine and remove ignition key.

(3) Using a wiping cloth, clean oil and dirt residue

from around power steering reservoir cap. (4) Remove reservoir cap or dipstick and wipe off

fluid. (5) Install cap or dipstick.

(6) Remove cap or dipstick. Holding handle or cap

above tip of dipstick, read fluid level (Fig. 4, 5, or 6).

Add fluid if reading is below cold level mark on dip-

stick.

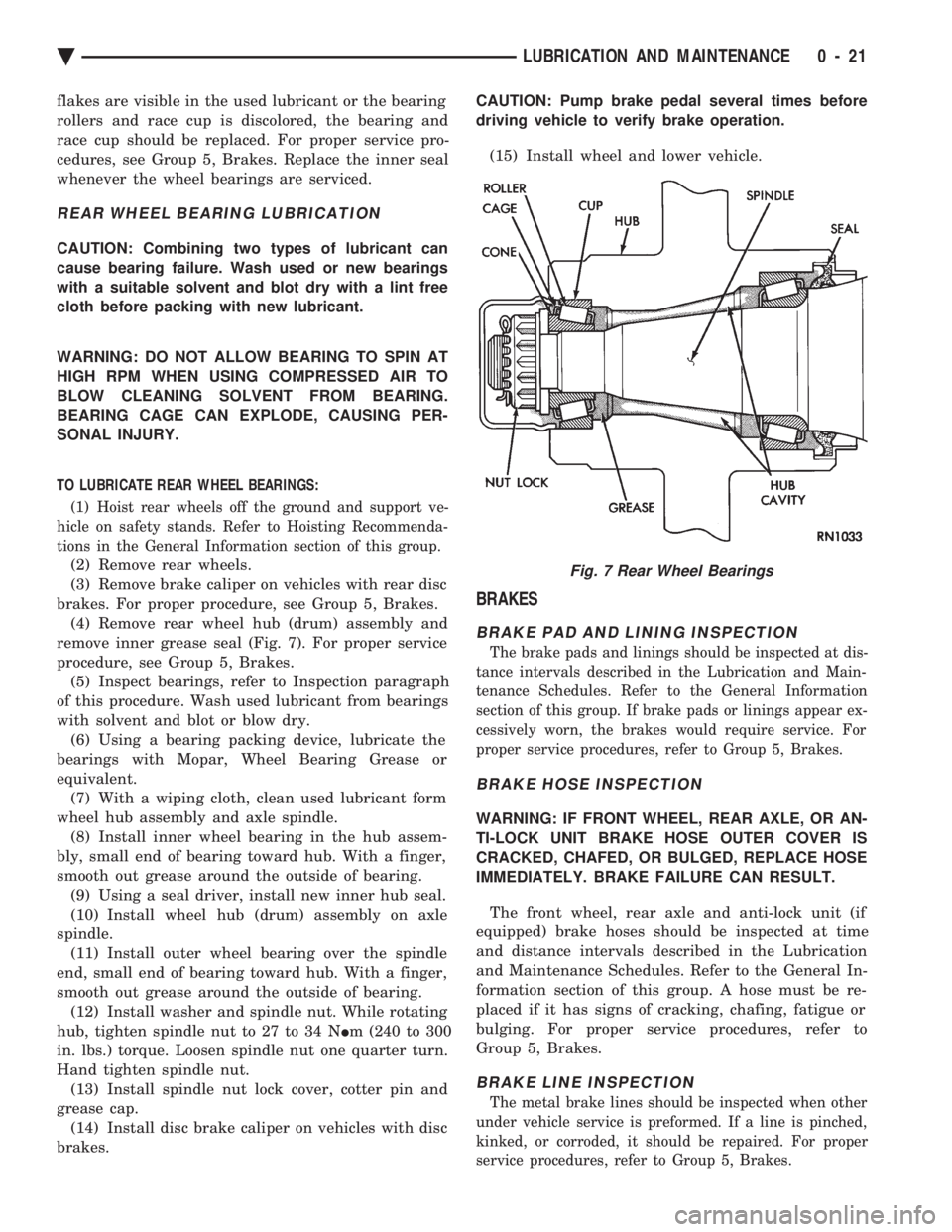

REAR WHEEL BEARINGS

INSPECTION

The rear wheel bearings should be packed with

new lubricant at the distance interval described in the Lubrication and Maintenance Schedules. Refer to

the General Information section of this group. The

bearings should be inspected for contamination and

wear before they are cleaned. Slight discoloration of

bearing rollers and race cup is normal. If metal

Fig. 3 Ball Joint Lubrication

Fig. 4 Power Steering Reservoir DipstickÐ2.2L or 2.5L Engine

Fig. 5 Power Steering Reservoir DipstickÐ3.0L Engine

Fig. 6 Power Steering Reservoir DipstickÐ3.3L or3.8L Engine

0 - 20 LUBRICATION AND MAINTENANCE Ä

Page 57 of 2438

flakes are visible in the used lubricant or the bearing

rollers and race cup is discolored, the bearing and

race cup should be replaced. For proper service pro-

cedures, see Group 5, Brakes. Replace the inner seal

whenever the wheel bearings are serviced.

REAR WHEEL BEARING LUBRICATION

CAUTION: Combining two types of lubricant can

cause bearing failure. Wash used or new bearings

with a suitable solvent and blot dry with a lint free

cloth before packing with new lubricant.

WARNING: DO NOT ALLOW BEARING TO SPIN AT

HIGH RPM WHEN USING COMPRESSED AIR TO

BLOW CLEANING SOLVENT FROM BEARING.

BEARING CAGE CAN EXPLODE, CAUSING PER-

SONAL INJURY.

TO LUBRICATE REAR WHEEL BEARINGS:

(1) Hoist rear wheels off the ground and support ve-

hicle on safety stands. Refer to Hoisting Recommenda-

tions in the General Information section of this group.

(2) Remove rear wheels.

(3) Remove brake caliper on vehicles with rear disc

brakes. For proper procedure, see Group 5, Brakes. (4) Remove rear wheel hub (drum) assembly and

remove inner grease seal (Fig. 7). For proper service

procedure, see Group 5, Brakes. (5) Inspect bearings, refer to Inspection paragraph

of this procedure. Wash used lubricant from bearings

with solvent and blot or blow dry. (6) Using a bearing packing device, lubricate the

bearings with Mopar, Wheel Bearing Grease or

equivalent. (7) With a wiping cloth, clean used lubricant form

wheel hub assembly and axle spindle. (8) Install inner wheel bearing in the hub assem-

bly, small end of bearing toward hub. With a finger,

smooth out grease around the outside of bearing. (9) Using a seal driver, install new inner hub seal.

(10) Install wheel hub (drum) assembly on axle

spindle. (11) Install outer wheel bearing over the spindle

end, small end of bearing toward hub. With a finger,

smooth out grease around the outside of bearing. (12) Install washer and spindle nut. While rotating

hub, tighten spindle nut to 27 to 34 N Im (240 to 300

in. lbs.) torque. Loosen spindle nut one quarter turn.

Hand tighten spindle nut. (13) Install spindle nut lock cover, cotter pin and

grease cap. (14) Install disc brake caliper on vehicles with disc

brakes. CAUTION: Pump brake pedal several times before

driving vehicle to verify brake operation.

(15) Install wheel and lower vehicle.

BRAKES

BRAKE PAD AND LINING INSPECTION

The brake pads and linings should be inspected at dis-

tance intervals described in the Lubrication and Main-

tenance Schedules. Refer to the General Information

section of this group. If brake pads or linings appear ex-

cessively worn, the brakes would require service. For

proper service procedures, refer to Group 5, Brakes.

BRAKE HOSE INSPECTION

WARNING: IF FRONT WHEEL, REAR AXLE, OR AN-

TI-LOCK UNIT BRAKE HOSE OUTER COVER IS

CRACKED, CHAFED, OR BULGED, REPLACE HOSE

IMMEDIATELY. BRAKE FAILURE CAN RESULT.

The front wheel, rear axle and anti-lock unit (if

equipped) brake hoses should be inspected at time

and distance intervals described in the Lubrication

and Maintenance Schedules. Refer to the General In-

formation section of this group. A hose must be re-

placed if it has signs of cracking, chafing, fatigue or

bulging. For proper service procedures, refer to

Group 5, Brakes.

BRAKE LINE INSPECTION

The metal brake lines should be inspected when other

under vehicle service is preformed. If a line is pinched,

kinked, or corroded, it should be repaired. For proper

service procedures, refer to Group 5, Brakes.

Fig. 7 Rear Wheel Bearings

Ä LUBRICATION AND MAINTENANCE 0 - 21

Page 357 of 2438

-37ÉC (-35ÉF) to -59ÉC (-50ÉF). If it looses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed solution.

SERVICE

Coolant should be changed at 52,500 miles or three

years, whichever occurs first, then every two years or

30,000 miles.

ROUTINE LEVEL CHECK

Do not remove radiator cap for routine coolant

level inspections. The coolant reserve system provides a quick visual

method for determining the coolant level without re-

moving the radiator cap. Simply observe, with the

engine idling and warmed up to normal operating

temperature, that the level of the coolant in the reserve

tank (Figs. 5 and 6) is between the minimum and

maximum marks.

ADDING ADDITIONAL COOLANT

The radiator cap should not be removed. When

additional coolant is needed to maintain this level, it

should be added to the coolant reserve tank. Use only

50/50 concentration of ethylene glycol type antifreeze

and water.

SERVICE COOLANT LEVEL

The cooling system is closed and designed to main-

tain coolant level to the top of the radiator. When servicing requires a coolant level check in the

radiator, the engine must be offand notunder pres-

sure. Drain several ounces of coolant from the radiator

drain cock while observing the Coolant Recovery Sys-

tem (CRS) Tank. Coolant level in the CRS tank should

drop slightly. Then remove the radiator cap. The radia-

tor should be full to the top. If not, and the coolant level

in the CRS tank is at the MIN mark there is a air leak

in the CRS system. Check hose or hose connections to

the CRS tank, radiator filler neck or the pressure cap

seal to the radiator filler neck for leaks.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will equal-

ize in both tanks with engine off. With engine at

running operating temperature the high pressure inlet

tank runs full and the low pressure outlet tank drops.

If this level drops below the top of the transmission oil

cooler, air will be sucked into the water pump:

² Transmission oil will become hotter.

² High reading shown on the temperature gauge.

² Air in the coolant will also cause loss of flow through

the heater.

² Exhaust gas leaks into the coolant can also cause the

same problems.

DEAERATION

Air can only be removed from the system by gather-

ing under the pressure cap. On the next heat up it will

be pushed past the pressure cap into the CRS tank by

thermal expansion of the coolant. It then escapes to the

atmosphere in the CRS tank and is replaced with solid

coolant on cool down.

COOLING SYSTEM DRAIN, CLEAN, FLUSH AND

REFILL

Drain, flush, and fill the cooling system at the

mileage or time intervals specified in the Maintenance

Schedule in this Group. If the solution is dirty or rusty

or contains a considerable amount of sediment, clean

and flush with a reliable cooling system cleaner. Care

should be taken in disposing of the used engine coolant

from your vehicle. Check governmental regulations for

disposal of used engine coolant.

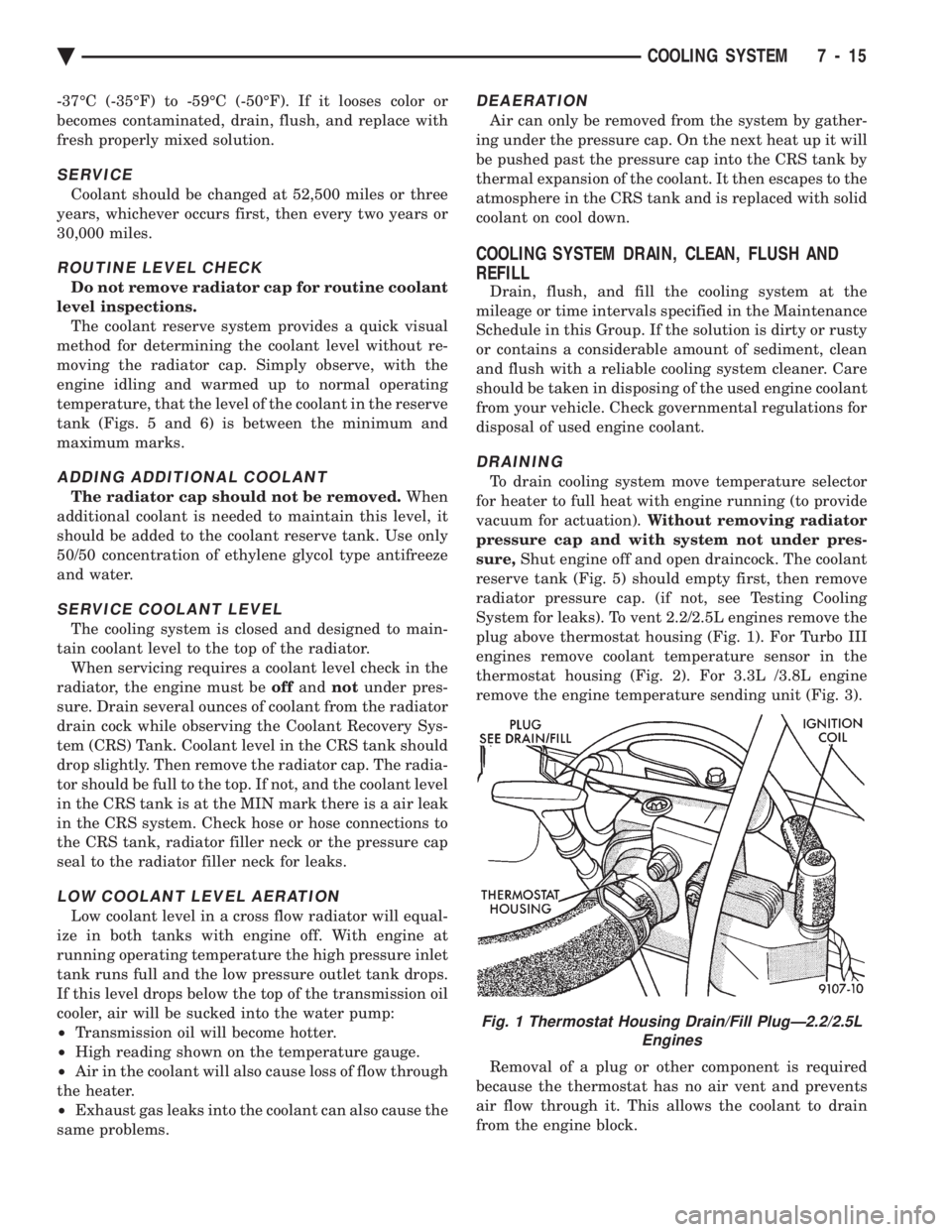

DRAINING

To drain cooling system move temperature selector

for heater to full heat with engine running (to provide

vacuum for actuation). Without removing radiator

pressure cap and with system not under pres-

sure, Shut engine off and open draincock. The coolant

reserve tank (Fig. 5) should empty first, then remove

radiator pressure cap. (if not, see Testing Cooling

System for leaks). To vent 2.2/2.5L engines remove the

plug above thermostat housing (Fig. 1). For Turbo III

engines remove coolant temperature sensor in the

thermostat housing (Fig. 2). For 3.3L /3.8L engine

remove the engine temperature sending unit (Fig. 3).

Removal of a plug or other component is required

because the thermostat has no air vent and prevents

air flow through it. This allows the coolant to drain

from the engine block.

Fig. 1 Thermostat Housing Drain/Fill PlugÐ2.2/2.5L Engines

Ä COOLING SYSTEM 7 - 15