brakes CHEVROLET EXPRESS 1997 1.G Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1997, Model line: EXPRESS, Model: CHEVROLET EXPRESS 1997 1.GPages: 386, PDF Size: 20.32 MB

Page 190 of 386

Downloaded from www.Manualslib.com manuals search engine Parking on Hills

You really should not park your vehicle, with a trailer

attached, on a hill. If something goes wrong, your rig

could start

to move. People can be injured, and both

your vehicle and the trailer can be damaged.

But if

you ever have to park your rig on a hill, here’s

how

to do it:

1.

2.

3.

4.

5.

Apply your regular brakes, but don’t shift into

PARK

(P) yet. Then turn your wheels into the curb

if facing downhill or into traffic if facing uphill.

Have someone place chocks under the trailer wheels.

When the wheel chocks are in place, release the

regular brakes until

the chocks absorb the load.

Re-apply the regular brakes. Then apply your

parking brake and then shift to PARK

(P).

Release the reguIar brakes.

When You Are Ready to Leave After

Parking on a Hill

I. Apply your regular brakes and hold the pedal down

while

you:

Start your engine;

0 Shift into a gear; and

0 Release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the chocks.

Maintenance When Trailer Towing

Your vehicle will need service more often when you’re

pulling a trailer. See

the Maintenance Schedule for more

on this. Things that are especially important in trailer

operation are automatic transmission fluid (don’t

overfill), engine oil, axle lubricant, belt, cooling system

and brake adjustment. Each

of these is covered in this

manual, and the Index will help you find them quickly.

If you’re trailering, it’s a good idea to review these

sections before you start your trip.

Check periodically

to see that all hitch nuts and bolts

are tight.

Page 191 of 386

Downloaded from www.Manualslib.com manuals search engine Trailer Wiring Harness

The light-duty trailer wiring harness is a six-wire

harness assembly. The optional heavy-duty trailer

wiring package is an eight-wire harness assembly. The

harness is stored under the vehicle, along the driver’s

side rear corner of the frame rail.

The heavy-duty trailer

wiring harness has a 30-amp feed wire. Both harnesses

come without connectors and should be wired by a

qualified electrical technician. The technician can use

the following color code chart when connecting the

wiring harness to your trailer.

0

0

0

0

0

0

0

0

Dark Blue: Use for electric trailer brakes (eight-wire

harness only)

Orange: Trailer accessory (eight-wire harness only)

Light Green: Back-up lamps

Brown: Parking lamps

Yellow: Left stoplamp and turn signal

Dark Green: Right stoplamp and turn signal

White (heavy gage): Ground wire

White (light gage): Center high-mounted stoplamp

Securely attach the harness to the trailer, then tape or

strap it

to your vehicle’s frame rail. Be sure you leave it

loose enough

so the wiring doesn’t bend or break, but

not

so loose that it drags on the ground. Store the

harness in its original place. Wrap

the harness together

and

tie it neatly so it won’t be damaged.

Page 234 of 386

Downloaded from www.Manualslib.com manuals search engine Section 6 Service and Appearance Care

Here you will find information about the care of your vehicle. This section begins with service and fuel information,

and then it shows how to check important fluid and lubricant levels. There

is also technical information about your

vehicle, and

a part devoted to its appearance care.

6-2

6-3

6-5

6-5

6-7

6-1 1

6-12 6-17

6-18

6-22

6-22

6-25

6-26 6-26

6-27

6-28 6-32 Service

Fuel (Gasoline Engine)

Fuels in Foreign Countries

Filling Your Tank

Checking Things Under the Hood

Noise Control System

Engine Oil (Gasoline Engine)

Air Cleaner (Gasoline Engines)

Automatic Transmission Fluid

Rear Axle

Engine Coolant Radiator Pressure Cap

Thermostat Power Steering Fluid

Windshield Washer Fluid

Brakes

Battery 6-32

6-32

6-40

6-4

1

6-49

6-50

6-54

6-55

6-55

6-55

6-56

6-57

6-5 8

6-59

6-63

6-66

6-67 Bulb Replacement

Halogen Bulbs

Windshield Wiper Blade Replacement

Tires Appearance Care

Cleaning the Inside

of Your Vehicle

Cleaning the Outside of Your Vehicle

Cleaning Aluminum Wheels

(If Equipped)

Cleaning Tires Sheet Metal Damage

Finish Damage

Appearance Care Materials Chart

Vehicle Identification Number (VIN)

Electrical System

Capacities and Specifications

Air Conditioning Refrigerants

Lamp and Bulb Data

Page 261 of 386

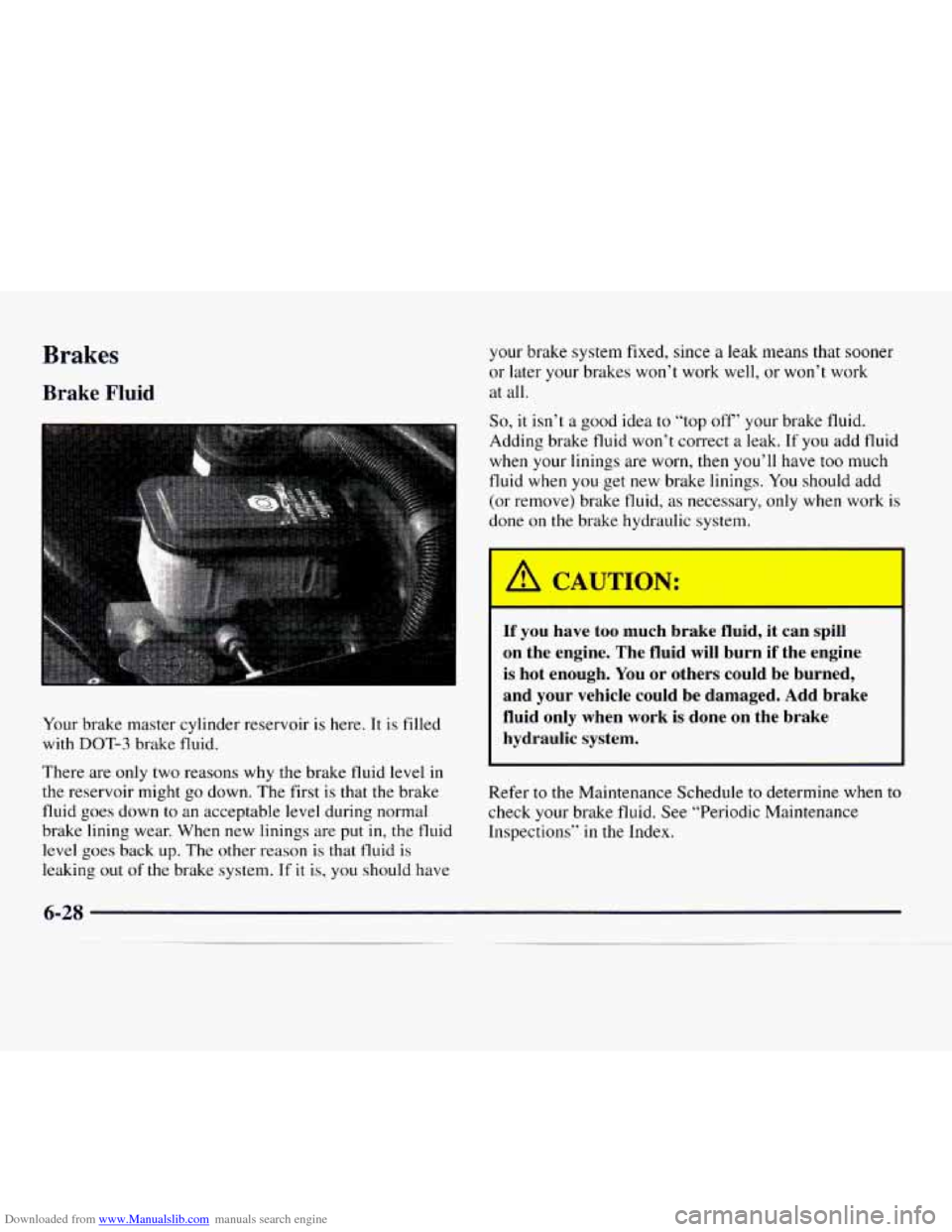

Downloaded from www.Manualslib.com manuals search engine Brakes

Brake Fluid

Your brake master cylinder reservoir is here. It is filled

with

DOT-3 brake fluid.

There are only two reasons why the brake fluid level in

the reservoir might go down. The first is that the brake

fluid goes down to an acceptable level during normal

brake lining wear. When new linings are put in, the fluid

level goes back up. The other reason is that fluid is

leaking out

of the brake system. If it is, you should have your brake system

fixed, since a leak means that sooner

or later your brakes won’t work well, or won’t work

at all.

So, it isn’t a good idea to “top off’ your brake fluid.

Adding brake fluid won’t correct

a leak. If you add fluid

when your linings are worn, then you’ll have too much

fluid when you get new brake linings.

You should add

(or remove) brake fluid,

as necessary, only when work is

done on

the brake hydraulic system.

If you have too much brake fluid, it can spill

on the engine. The fluid will burn

if the engine

is hot enough. You or others could be burned,

and your vehicle could be damaged. Add brake

fluid only when work is done on the brake

hydraulic system.

Refer to the Maintenance Schedule to determine when to

check your brake fluid. See “Periodic Maintenance

Inspections”

in the Index.

6-28

Page 262 of 386

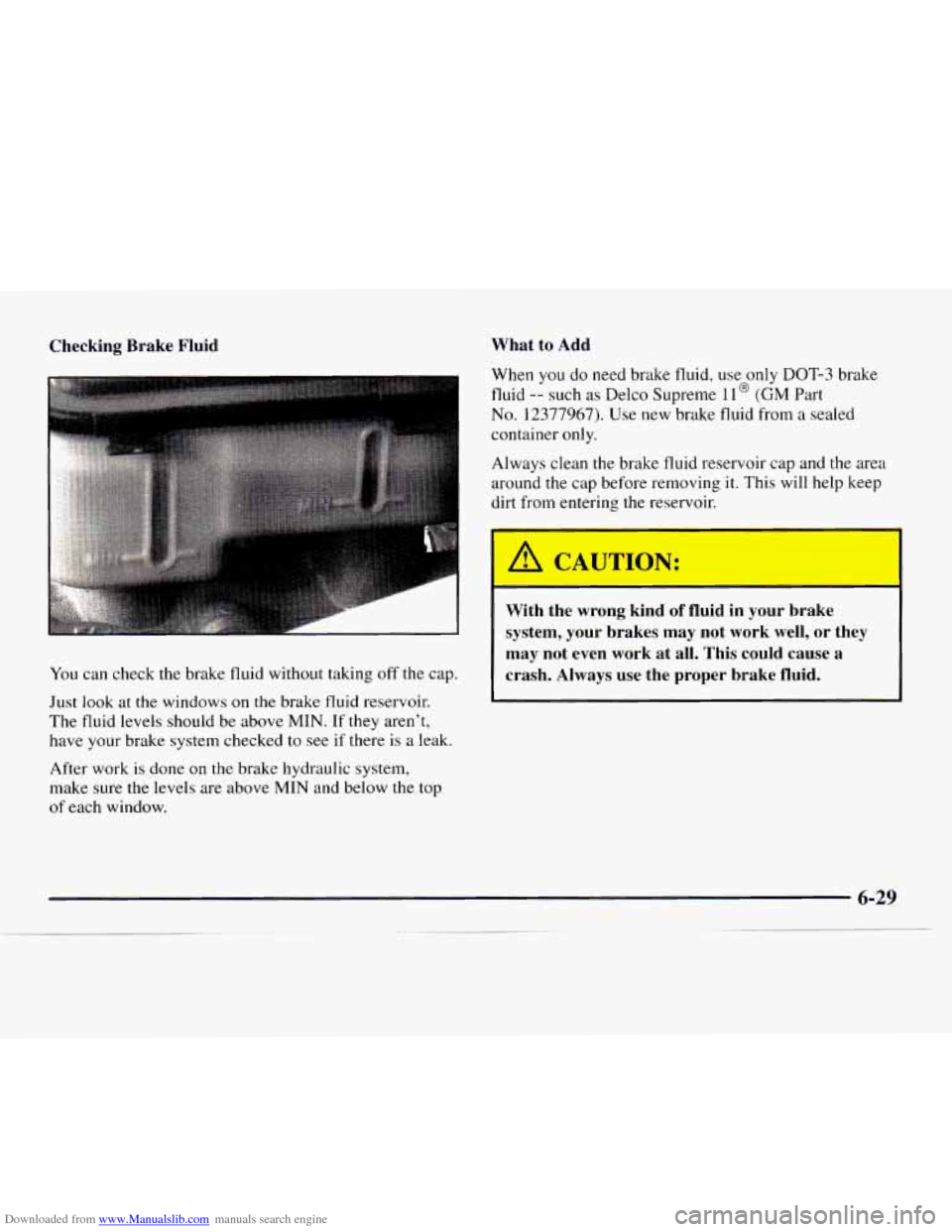

Downloaded from www.Manualslib.com manuals search engine Checking Brake Fluid What

to Add

You can check the brake fluid without taking off the cap.

Just

look at the windows on the brake fluid reservoir.

The fluid levels should be above

MIN. If they aren't,

have your brake system checked to see if there

is a leak.

After work is done

on the brake hydraulic system,

make sure the levels are above

MIN and below the top

of each window. When

you do

need brake fluid, use only DOT-3 brake

fluid

-- such as Delco Supreme 11 @ (GM Part

No. 12377967). Use new brake fluid from a sealed

container only.

Always clean the brake fluid reservoir cap and the area

around the cap before removing

it. This will help keep

dirt from entering the reservoir.

, A CAUTION:

H

With the wrong kind of fluid in your brake

system, your brakes may

not work well, or they

may not even work at all. This could cause a

crash. Always use the proper brake fluid.

Page 263 of 386

Downloaded from www.Manualslib.com manuals search engine NOTICE:

a

a

Using the wrong fluid can badly damage

brake system parts. For example, just

a few

drops

of mineral-based oil, such as engine

oil, in your brake system can damage brake

system parts

so badly that they’ll have to be

replaced. Don’t let someone put in the

wrong kind

of fluid.

If you spill brake fluid on your vehicle’s

painted surfaces, the paint finish can be

damaged.

Be careful not to spill brake fluid

on your vehicle.

If you do, wash it off

immediately. See “Appearance Care” in

the Index.

Brake Wear

Your vehicle has front disc brakes and rear drum brakes.

Disc brake pads have built-in wear indicators that

make a high-pitched warning sound when

the brake

pads are worn and new pads are needed. The sound may

come

and go or be heard all the time your vehicle is

moving (except when

you are pushing on the brake

pedal firmly).

A CAUTION:

The brake wear warning sound means that soon

your brakes won’t work well. That could lead to

an accident. When you hear the brake wear

warning sound, have your vehicle serviced.

NOTICE:

Continuing to drive with worn-out brake pads

could result in costly brake repair.

6-30

Page 264 of 386

Downloaded from www.Manualslib.com manuals search engine Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does

not mean something is wrong with

your brakes.

Properly torqued wheel

nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly torque wheel nuts in the

proper sequence to

GM specifications.

Your rear drum brakes don’t have wear indicators, but

if you ever hear a rear brake rubbing noise, have the

rear brake linings inspected. Also, the rear brake drums

should be removed and inspected each time the tires

are removed for rotation or changing. When you have

the front brake pads replaced, have the rear brakes

inspected,

too.

Brake linings should always be replaced as complete

axle sets.

See “Brake System Inspection” in Section

7 of this

manual under Part

C “Periodic Maintenance

Inspections”.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in pedal

travel. This could be

a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

If your brake pedal goes down farther than normal, your

rear drum brakes may need adjustment. Adjust them by

backing up and firmly applying the brakes a few times.

Replacing Brake System Parts

The braking system on a modern vehicle is complex.

Its many parts have to be

of top quality and work well

together if the vehicle is to have really good braking.

Your vehicle was designed and tested with top-quality

GM brake parts. When you replace parts of your braking

system

-- for example, when your brake linings wear

down and you have

to have new ones put in -- be sure

you get new approved

GM replacement parts. If you

don’t, your brakes may no longer work properly. For

example,

if someone puts in brake linings that are wrong

for your vehicle, the balance between your front and

rear brakes can change

-- for the worse. The braking

performance you’ve come to expect can change in many

other ways

if someone puts in the wrong replacement

brake parts.

Page 311 of 386

Downloaded from www.Manualslib.com manuals search engine I Short TripKity Maintenance Schedule =- Gasoline Engines I

The services shown in this schedule up to 100,000 miles

(1 66 000 km) should be performed after 100,000 miles

(166

000 km) at the same intervals. The services shown

at 150,000 miles

(240 000 km) should be performed at

the same interval after 150,000 miles (240 000 km).

See “Owner Checks and Services” and “Periodic

Maintenance Inspections” following.

Footnotes

3- The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will

not nullify

the emission warranty or limit recall liability prior

to the

completion of the vehicle’s useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the maintenance

be recorded.

# Lubricate the front suspension, kingpin bushings,

steering linkage and rear driveline center splines.

+ A good time to check your brakes is during tire

rotation. See “Brake System Inspection’’ under “Periodic

Maintenance Inspection’’ in Part

C of this schedule.

** Drive axle service (see “Recommended Fluids and

Lubricants’’

in the Index for proper lubricant to use):

0

0

0

Locking Differential -- Drain fluid and refill at first

engine

oil change. At subsequent oil changes, check

fluid level and add fluid as needed.

If driving in

dusty areas or towing a trailer, drain fluid and refill

every 15,000 miles (25

000 km).

Standard Differential

-- Check fluid level and add

fluid as needed at every oil change. If driving in

dusty areas or towing a trailer, drain fluid and refill

every

15,000 miles (25 000 km).

More frequent lubrication may be required for

heavy-duty use.

Page 335 of 386

Downloaded from www.Manualslib.com manuals search engine Long Trip/Highway Maintenance Schedule -- Gasoline Engines I

The services shown in this schedule up to 100,000 miles

(166 000 km) should be performed after 100,000 miles

(166 000 km) at the same intervals. The services shown

at 150,000 miles

(240 000 km) should be performed at

the same interval after

150,000 miles (240 000 km).

See “Owner Checks and Services” and “Periodic

Maintenance Inspections” following.

Footnotes

ri‘ The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not

nullify

the emission warranty or limit recall liability prior to the

completion of the vehicle’s useful

life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the maintenance

be recorded.

## Lubricate the front suspension, kingpin bushings,

steering linkage and rear driveline center splines.

+ A good time to check your brakes is during tire

rotation. See “Brake System Inspection” under “Periodic

Maintenance Inspections”

in Part C of this schedule.

** Drive axle service (see “Recommended Fluids and

Lubricants”

in the Index for proper lubricant to use):

Locking Differential -- Drain fluid and refill at first

engine oil change. At subsequent

oil changes, check

fluid level and add fluid

as needed.

Standard Differential -- Check fluid level and add

fluid

as needed at every engine oil change.

7-32

Page 351 of 386

Downloaded from www.Manualslib.com manuals search engine Parking Brake and Automatic Transmission

PARK (P) Mechanism Check

I A CAUTION:

When you are doing this check, your vehicle

could begin to move. You or others could be

injured and property could be damaged. Make

sure there is room in front

of your vehicle in case

it begins to roll. Be ready to apply the regular

brake at once should the vehicle begin to move.

Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot

on the regular brake, set the

parking brake.

To check the parking brake’s holding ability:

With the engine running and transmission in

NEUTRAL (N), slowly remove foot pressure from

the regular brake pedal.

Do this until the vehicle is

held by the parking brake only.

To check the PARK (P) mechanism’s holding ability:

With the engine runnine. shift

to PARK (P). Then

release all brakes.

7-48