tow CHEVROLET EXPRESS CARGO VAN 2006 1.G Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2006, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2006 1.GPages: 406, PDF Size: 2.51 MB

Page 277 of 406

Then, without shutting off the engine, follow these steps:

The transmission dipstick

is located near the center

of the engine compartment

and will be labeled with

the graphic shown.

SeeEngine Compartment Overview on page 5-12for

more information on location.

1. Flip the handle up and then pull out the dipstick

and wipe it with a clean rag or paper towel.

2. Push it back in all the way, wait three seconds and

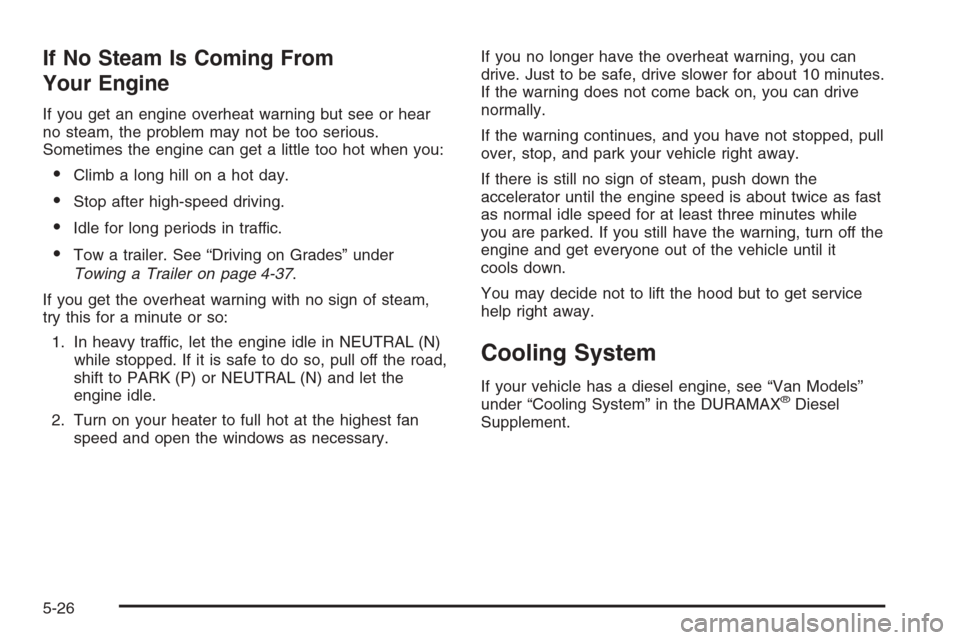

then pull it back out again.3. Check both sides of the dipstick, and read the lower

level. The fluid level must be in the COLD area for

a cold check or in the HOT or cross-hatched

area for a hot check. Be sure to keep the dipstick

pointed down to get an accurate reading.

4. If the fluid level is in the acceptable range, push the

dipstick back in all the way; then flip the handle

down to lock the dipstick in place.

5-21

Page 282 of 406

If No Steam Is Coming From

Your Engine

If you get an engine overheat warning but see or hear

no steam, the problem may not be too serious.

Sometimes the engine can get a little too hot when you:

•Climb a long hill on a hot day.

•Stop after high-speed driving.

•Idle for long periods in traffic.

•Tow a trailer. See “Driving on Grades” under

Towing a Trailer on page 4-37.

If you get the overheat warning with no sign of steam,

try this for a minute or so:

1. In heavy traffic, let the engine idle in NEUTRAL (N)

while stopped. If it is safe to do so, pull off the road,

shift to PARK (P) or NEUTRAL (N) and let the

engine idle.

2. Turn on your heater to full hot at the highest fan

speed and open the windows as necessary.If you no longer have the overheat warning, you can

drive. Just to be safe, drive slower for about 10 minutes.

If the warning does not come back on, you can drive

normally.

If the warning continues, and you have not stopped, pull

over, stop, and park your vehicle right away.

If there is still no sign of steam, push down the

accelerator until the engine speed is about twice as fast

as normal idle speed for at least three minutes while

you are parked. If you still have the warning, turn off the

engine and get everyone out of the vehicle until it

cools down.

You may decide not to lift the hood but to get service

help right away.

Cooling System

If your vehicle has a diesel engine, see “Van Models”

under “Cooling System” in the DURAMAX®Diesel

Supplement.

5-26

Page 288 of 406

Engine Fan Noise

Your vehicle has a clutched engine cooling fan. When

the clutch is engaged, the fan spins faster to provide

more air to cool the engine. In most everyday driving

conditions, the fan is spinning slower and the clutch is

not fully engaged. This improves fuel economy and

reduces fan noise. Under heavy vehicle loading, trailer

towing, and/or high outside temperatures, the fan

speed increases as the clutch more fully engages,

so you may hear an increase in fan noise. This is normal

and should not be mistaken as the transmission

slipping or making extra shifts. It is merely the cooling

system functioning properly. The fan will slow down

when additional cooling is not required and the clutch

partially disengages.

You may also hear this fan noise when you start the

engine. It will go away as the fan clutch partially

disengages.

Power Steering Fluid

The power steering fluid

reservoir is located in the

engine compartment

on the driver’s side of the

vehicle. SeeEngine

Compartment Overview on

page 5-12for reservoir

location.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering fluid

unless you suspect there is a leak in the system or

you hear an unusual noise. A fluid loss in this system

could indicate a problem. Have the system inspected

and repaired.

5-32

Page 319 of 406

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the Tire and

Loading Information label. SeeLoading Your Vehicle on

page 4-30. Make certain that all wheel nuts are

properly tightened. See “Wheel Nut Torque” under

Capacities and Speci�cations on page 5-99.

{CAUTION:

Rust or dirt on a wheel, or on the parts to

which it is fastened, can make wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

places where the wheel attaches to the vehicle.

In an emergency, you can use a cloth or a

paper towel to do this; but be sure to use a

scraper or wire brush later, if needed, to get

all the rust or dirt off. SeeChanging a Flat Tire

on page 5-71.

When It Is Time for New Tires

One way to tell when it is

time for new tires is to

check the treadwear

indicators, which will

appear when your tires

have only 1/16 inch

(1.6 mm) or less of tread

remaining. Some

commercial truck tires

may not have treadwear

indicators.

You need a new tire if any of the following statements

are true:

•You can see the indicators at three or more places

around the tire.

•You can see cord or fabric showing through the

tire’s rubber.

•The tread or sidewall is cracked, cut or snagged

deep enough to show cord or fabric.

•The tire has a bump, bulge, or split.

•The tire has a puncture, cut, or other damage that

cannot be repaired well because of the size or

location of the damage.

5-63

Page 326 of 406

If a Tire Goes Flat

It is unusual for a tire to blowout while you are driving,

especially if you maintain your vehicle’s tires properly.

If air goes out of a tire, it is much more likely to leak out

slowly. But if you should ever have a blowout, here

are a few tips about what to expect and what to do:

If a front tire fails, the flat tire will create a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blowout, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blowout remove your foot from

the accelerator pedal. Get the vehicle under control

by steering the way you want the vehicle to go. It may

be very bumpy and noisy, but you can still steer. Gently

brake to a stop, well off the road if possible.{CAUTION:

Lifting a vehicle and getting under it to do

maintenance or repairs is dangerous without

the appropriate safety equipment and training.

The jack provided with your vehicle is

designed only for changing a �at tire. If it is

used for anything else, you or others could be

badly injured or killed if the vehicle slips off

the jack. Use the jack provided with your

vehicle only for changing a �at tire.

If a tire goes flat, the next part shows how to use the

jacking equipment to change a flat tire safely.

5-70

Page 330 of 406

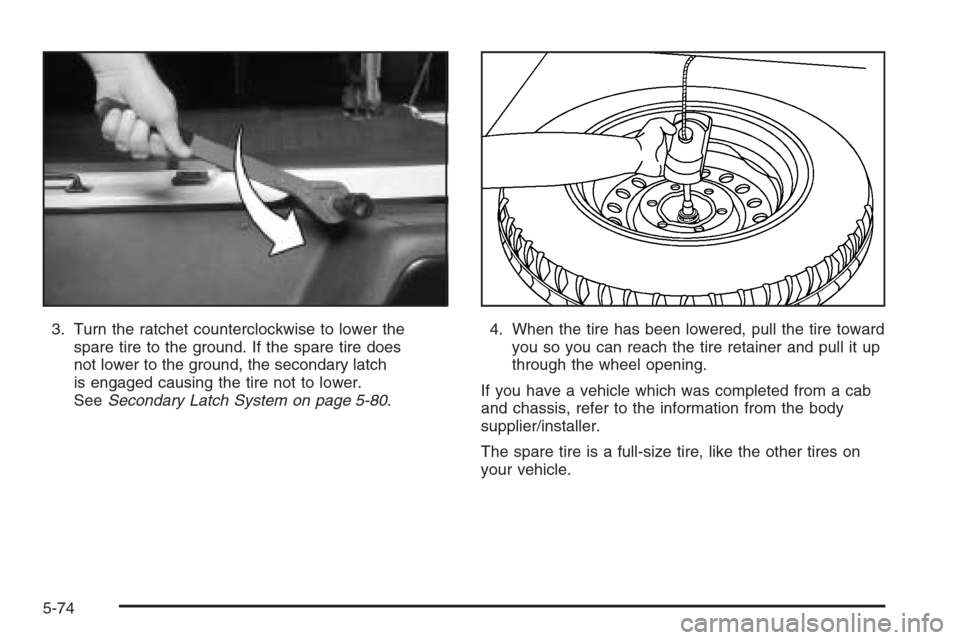

3. Turn the ratchet counterclockwise to lower the

spare tire to the ground. If the spare tire does

not lower to the ground, the secondary latch

is engaged causing the tire not to lower.

SeeSecondary Latch System on page 5-80.4. When the tire has been lowered, pull the tire toward

you so you can reach the tire retainer and pull it up

through the wheel opening.

If you have a vehicle which was completed from a cab

and chassis, refer to the information from the body

supplier/installer.

The spare tire is a full-size tire, like the other tires on

your vehicle.

5-74

Page 334 of 406

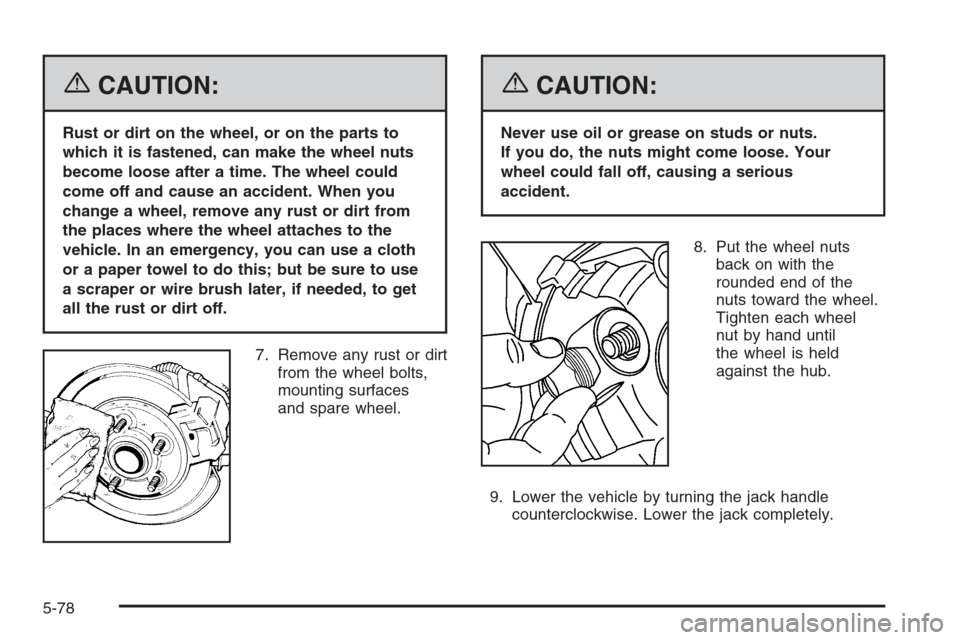

{CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

the places where the wheel attaches to the

vehicle. In an emergency, you can use a cloth

or a paper towel to do this; but be sure to use

a scraper or wire brush later, if needed, to get

all the rust or dirt off.

7. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{CAUTION:

Never use oil or grease on studs or nuts.

If you do, the nuts might come loose. Your

wheel could fall off, causing a serious

accident.

8. Put the wheel nuts

back on with the

rounded end of the

nuts toward the wheel.

Tighten each wheel

nut by hand until

the wheel is held

against the hub.

9. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

5-78

Page 336 of 406

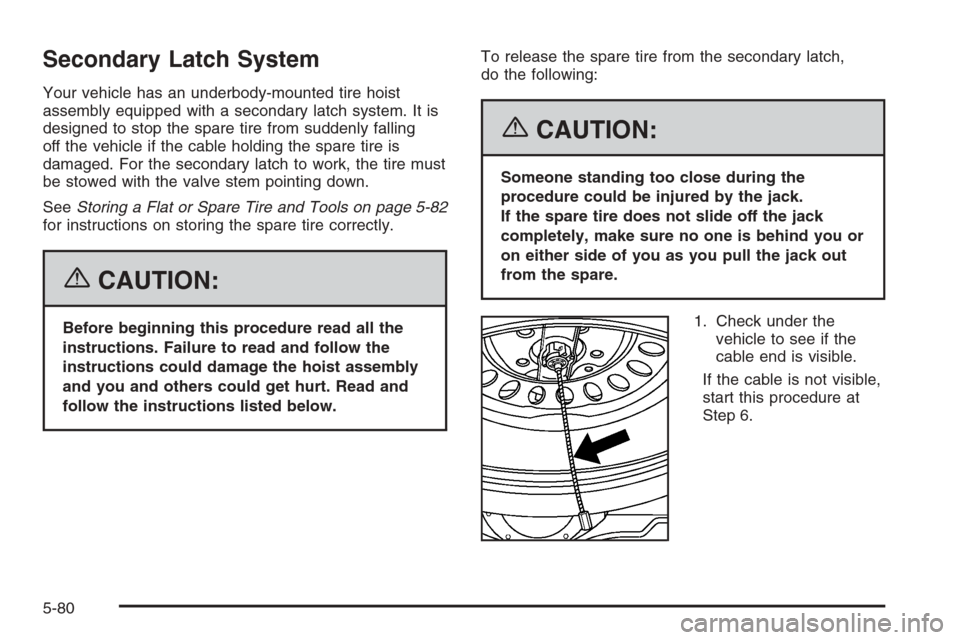

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system. It is

designed to stop the spare tire from suddenly falling

off the vehicle if the cable holding the spare tire is

damaged. For the secondary latch to work, the tire must

be stowed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools on page 5-82

for instructions on storing the spare tire correctly.

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed below.To release the spare tire from the secondary latch,

do the following:

{CAUTION:

Someone standing too close during the

procedure could be injured by the jack.

If the spare tire does not slide off the jack

completely, make sure no one is behind you or

on either side of you as you pull the jack out

from the spare.

1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not visible,

start this procedure at

Step 6.

5-80

Page 339 of 406

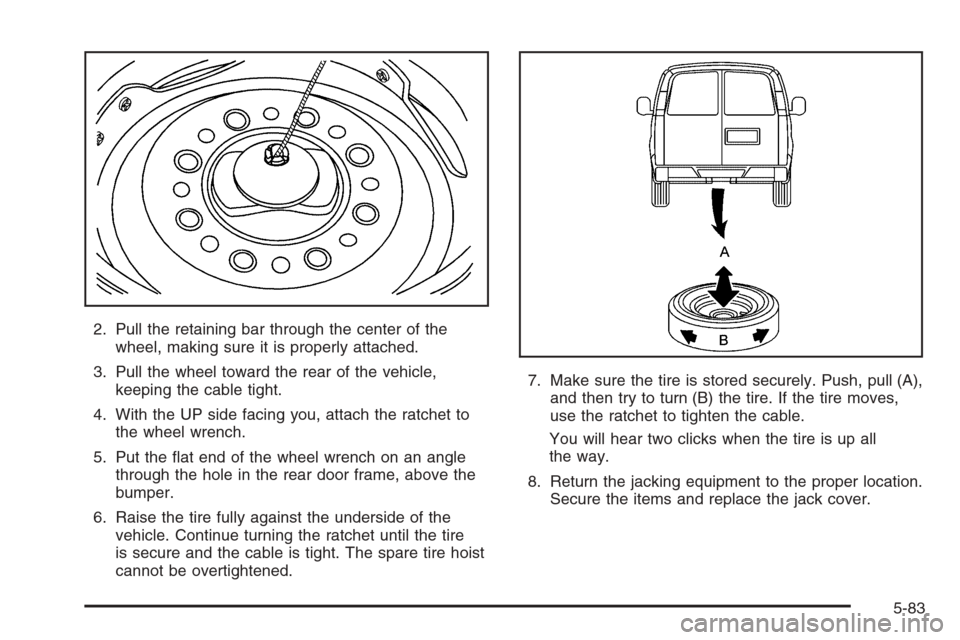

2. Pull the retaining bar through the center of the

wheel, making sure it is properly attached.

3. Pull the wheel toward the rear of the vehicle,

keeping the cable tight.

4. With the UP side facing you, attach the ratchet to

the wheel wrench.

5. Put the flat end of the wheel wrench on an angle

through the hole in the rear door frame, above the

bumper.

6. Raise the tire fully against the underside of the

vehicle. Continue turning the ratchet until the tire

is secure and the cable is tight. The spare tire hoist

cannot be overtightened.7. Make sure the tire is stored securely. Push, pull (A),

and then try to turn (B) the tire. If the tire moves,

use the ratchet to tighten the cable.

You will hear two clicks when the tire is up all

the way.

8. Return the jacking equipment to the proper location.

Secure the items and replace the jack cover.

5-83

Page 342 of 406

Fabric/Carpet

Use a vacuum cleaner with a soft brush attachment

frequently to remove dust and loose dirt. A canister

vacuum with a beater bar in the nozzle may only

be used on floor carpet and carpeted floor mats.

For soils, always try to remove them first with plain

water or club soda. Before cleaning, gently remove as

much of the soil as possible using one of the following

techniques:

•For liquids: gently blot the remaining soil with a

paper towel. Allow the soil to absorb into the

paper towel until no more can be removed.

•For solid dry soils: remove as much as possible

and then vacuum.To clean, use the following instructions:

1. Saturate a lint-free, clean white cloth with water or

club soda.

2. Wring the cloth to remove excess moisture.

3. Start on the outside edge of the soil and gently rub

toward the center. Continue cleaning, using a clean

area of the cloth each time it becomes soiled.

4. Continue to gently rub the soiled area until the

cleaning cloth remains clean.

5. If the soil is not completely removed, use a mild

soap solution and repeat the cleaning process

that was used with plain water.

If any of the soil remains, a commercial fabric cleaner or

spot lifter may be necessary. When a commercial

upholstery cleaner or spot lifter is to be used, test a

small hidden area for colorfastness first. If the locally

cleaned area gives any impression that a ring formation

may result, clean the entire surface.

After the cleaning process has been completed, a paper

towel can be used to blot excess moisture from the

fabric or carpet.

5-86