lock CHEVROLET EXPRESS CARGO VAN 2009 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2009, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2009 1.GPages: 408, PDF Size: 2.36 MB

Page 327 of 408

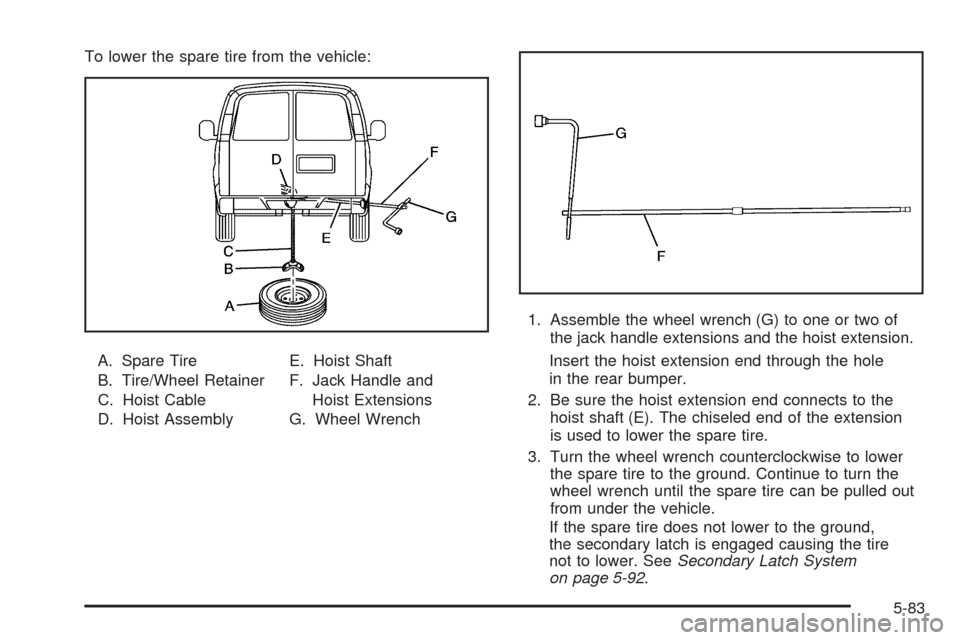

To lower the spare tire from the vehicle:

A. Spare Tire

B. Tire/Wheel Retainer

C. Hoist Cable

D. Hoist AssemblyE. Hoist Shaft

F. Jack Handle and

Hoist Extensions

G. Wheel Wrench1. Assemble the wheel wrench (G) to one or two of

the jack handle extensions and the hoist extension.

Insert the hoist extension end through the hole

in the rear bumper.

2. Be sure the hoist extension end connects to the

hoist shaft (E). The chiseled end of the extension

is used to lower the spare tire.

3. Turn the wheel wrench counterclockwise to lower

the spare tire to the ground. Continue to turn the

wheel wrench until the spare tire can be pulled out

from under the vehicle.

If the spare tire does not lower to the ground,

the secondary latch is engaged causing the tire

not to lower. SeeSecondary Latch System

on page 5-92.

5-83

Page 328 of 408

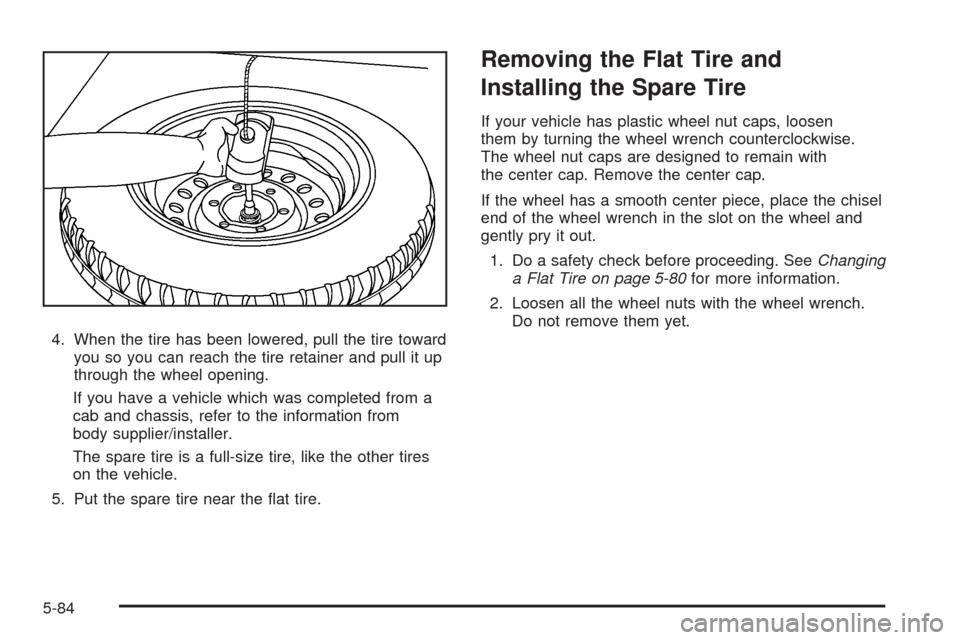

4. When the tire has been lowered, pull the tire toward

you so you can reach the tire retainer and pull it up

through the wheel opening.

If you have a vehicle which was completed from a

cab and chassis, refer to the information from

body supplier/installer.

The spare tire is a full-size tire, like the other tires

on the vehicle.

5. Put the spare tire near the flat tire.

Removing the Flat Tire and

Installing the Spare Tire

If your vehicle has plastic wheel nut caps, loosen

them by turning the wheel wrench counterclockwise.

The wheel nut caps are designed to remain with

the center cap. Remove the center cap.

If the wheel has a smooth center piece, place the chisel

end of the wheel wrench in the slot on the wheel and

gently pry it out.

1. Do a safety check before proceeding. SeeChanging

a Flat Tire on page 5-80for more information.

2. Loosen all the wheel nuts with the wheel wrench.

Do not remove them yet.

5-84

Page 331 of 408

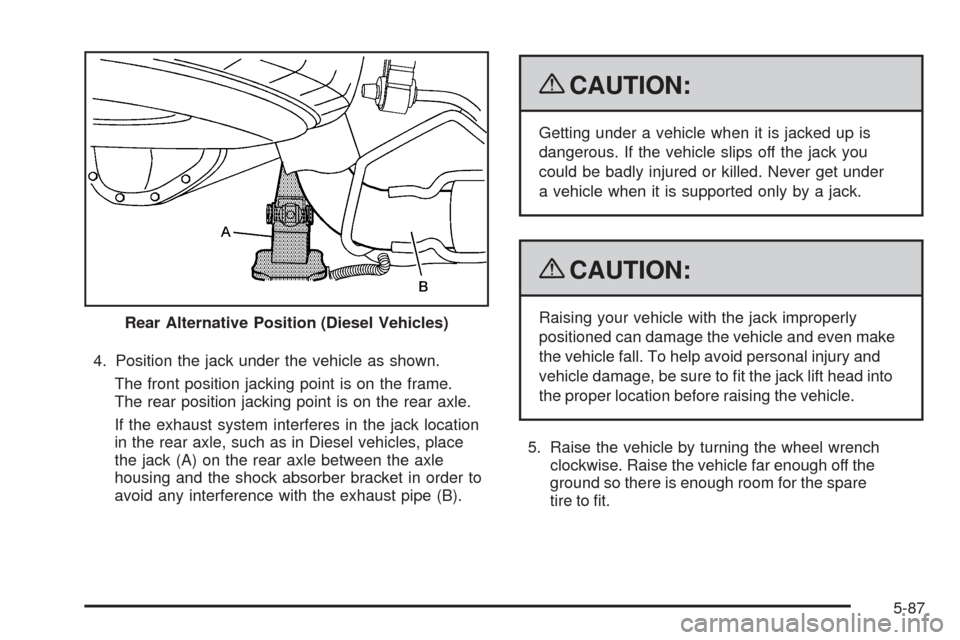

4. Position the jack under the vehicle as shown.

The front position jacking point is on the frame.

The rear position jacking point is on the rear axle.

If the exhaust system interferes in the jack location

in the rear axle, such as in Diesel vehicles, place

the jack (A) on the rear axle between the axle

housing and the shock absorber bracket in order to

avoid any interference with the exhaust pipe (B).

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get under

a vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even make

the vehicle fall. To help avoid personal injury and

vehicle damage, be sure to fit the jack lift head into

the proper location before raising the vehicle.

5. Raise the vehicle by turning the wheel wrench

clockwise. Raise the vehicle far enough off the

ground so there is enough room for the spare

tire to fit. Rear Alternative Position (Diesel Vehicles)

5-87

Page 334 of 408

10. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{CAUTION:

Wheel nuts that are not tight can work loose. If all

the nuts on a wheel come off, the wheel can come

off the vehicle, causing a crash. All wheel nuts

must be properly tightened. Follow the rules in this

section to be sure they are.

{CAUTION:

If wheel studs are damaged, they can break. If all

the studs on a wheel broke, the wheel could come

off and cause a crash. If any stud is damaged

because of a loose-running wheel, it could be that

all of the studs are damaged. To be sure, replace

all studs on the wheel. If the stud holes in a wheel

have become larger, the wheel could collapse in

operation. Replace any wheel if its stud holes have

become larger or distorted in any way. Inspect hubs

and hub-piloted wheels for damage. Because of

loose running wheels, piloting pad damage may

occur and require replacement of the entire hub,

for proper centering of the wheels. When replacing

studs, hubs, wheel nuts or wheels, be sure to use

GM original equipment parts.

5-90

Page 335 of 408

{CAUTION:

Incorrect or improperly tightened wheel nuts can

cause the wheel to come loose and even come off.

This could lead to a crash. If you have to replace

them, be sure to get new original equipment wheel

nuts. Stop somewhere as soon as you can and

have the nuts tightened with a torque wrench to the

proper torque specification. SeeCapacities and

Specifications on page 5-111for wheel nut torque

specification.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 5-111for the wheel

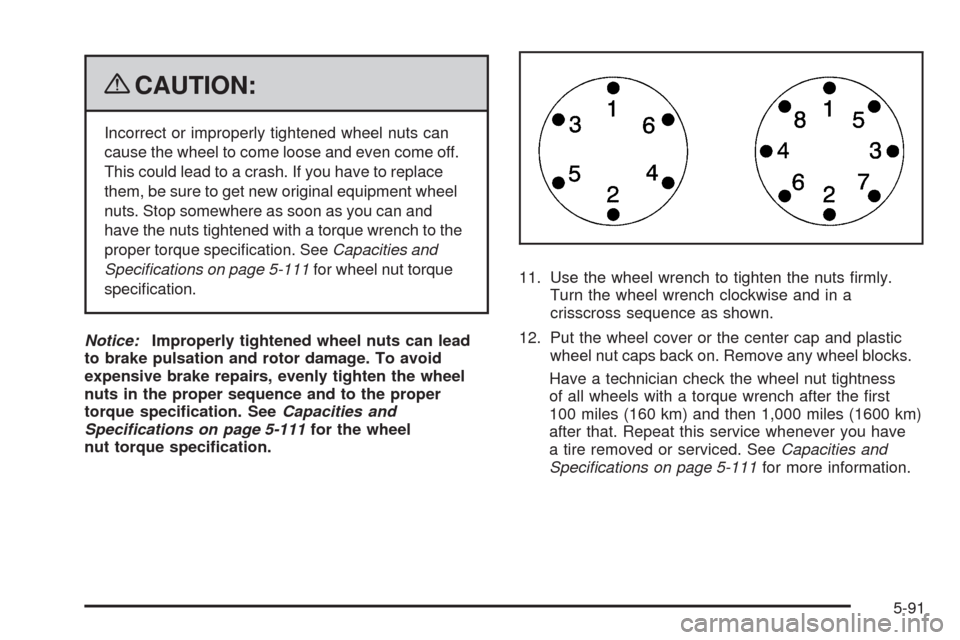

nut torque speci�cation.11. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

12. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Have a technician check the wheel nut tightness

of all wheels with a torque wrench after the first

100 miles (160 km) and then 1,000 miles (1600 km)

after that. Repeat this service whenever you have

a tire removed or serviced. SeeCapacities and

Specifications on page 5-111for more information.

5-91

Page 336 of 408

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system.

It is designed to stop the spare tire from suddenly falling

off the vehicle if the cable holding the spare tire is

damaged. For the secondary latch to work, the tire

must be stowed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools on page 5-95

for instructions on storing the spare tire correctly.

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed next.To release the spare tire from the secondary latch:

{CAUTION:

Someone standing too close during the procedure

could be injured by the jack. If the spare tire does

not slide off the jack completely, make sure no

one is behind you or on either side of you as you

pull the jack out from the under spare.

1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not

visible, start this

procedure at Step 6.

2. Turn the hoist extension counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

5-92

Page 337 of 408

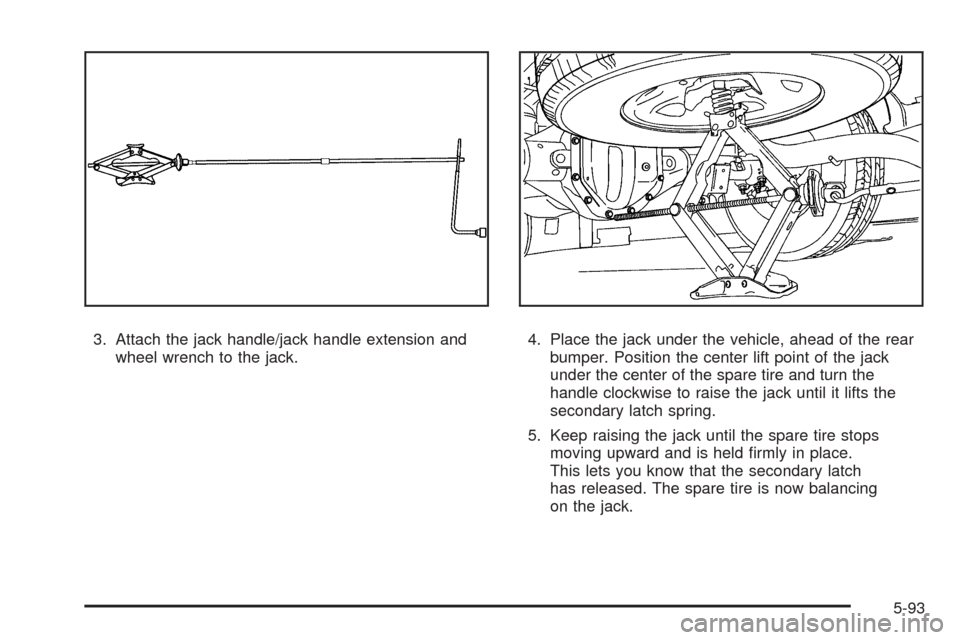

3. Attach the jack handle/jack handle extension and

wheel wrench to the jack.4. Place the jack under the vehicle, ahead of the rear

bumper. Position the center lift point of the jack

under the center of the spare tire and turn the

handle clockwise to raise the jack until it lifts the

secondary latch spring.

5. Keep raising the jack until the spare tire stops

moving upward and is held firmly in place.

This lets you know that the secondary latch

has released. The spare tire is now balancing

on the jack.

5-93

Page 338 of 408

6. Lower the jack by turning the wheel wrench

counterclockwise. Keep lowering the jack until

the spare tire slides off the jack or is hanging

by the cable.

7. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while firmly pulling the jack out

from under the spare tire with the other hand.

If the spare tire is hanging from the cable, assembly

the wheel wrench onto the hoist extension and

insert the chisel end of the hoist extension into

the hoist shaft hole above the bumper. Turn

the wheel wrench counterclockwise to lower

the spare the rest of the way.8. Tilt the retainer at the end of the cable and pull it

through the wheel opening. Pull the tire out from

under the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

9. If the cable is hanging under the vehicle, turn the

wheel wrench in the hoist shaft hole in the bumper

clockwise to raise the cable back up.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare or flat tire using

the hoist assembly until it has been repaired or replaced.

To continue changing the flat tire, return to Step 4 of

Removing the Flat Tire and Installing the Spare Tire on

page 5-84.

5-94

Page 349 of 408

Electrical System

Add-On Electrical Equipment

Notice:Do not add anything electrical to the

vehicle unless you check with your dealer/retailer

�rst. Some electrical equipment can damage

the vehicle and the damage would not be covered

by the vehicle’s warranty. Some add-on electrical

equipment can keep other components from

working as they should.

Add-on equipment can drain the vehicle battery, even if

the vehicle is not operating.

The vehicle has an airbag system. Before attempting to

add anything electrical to the vehicle, seeServicing

Your Airbag-Equipped Vehicle on page 1-76.

Headlamp Wiring

The headlamp wiring is protected by fuses in the engine

compartment fuse block. An electrical overload will

cause the lamps to flicker on and off, or in some cases

to remain off. If this happens, have your headlamp

wiring checked right away.

Windshield Wiper Fuses

The windshield wiper motor is protected by a circuit

breaker and a fuse. If the motor overheats due to heavy

snow, etc., the wiper will stop until the motor cools.

Although the circuit is protected from electrical overload,

overload due to heavy snow, etc., may cause wiper

linkage damage. Always clear ice and heavy snow from

the windshield before using the windshield wipers. If the

overload is caused by some electrical problem and not

snow, etc., be sure to get it fixed.

Fuses and Circuit Breakers

The wiring circuits in the vehicle are protected from

short circuits by a combination of fuses and circuit

breakers. This greatly reduces the chance of fires

caused by electrical problems.

Look at the silver-colored band inside the fuse. If the

band is broken or melted, replace the fuse. Be sure you

replace a bad fuse with a new one of the identical

size and rating.

Floor Console Fuse Block

The floor console fuse block is located under the

driver seat.

5-105

Page 351 of 408

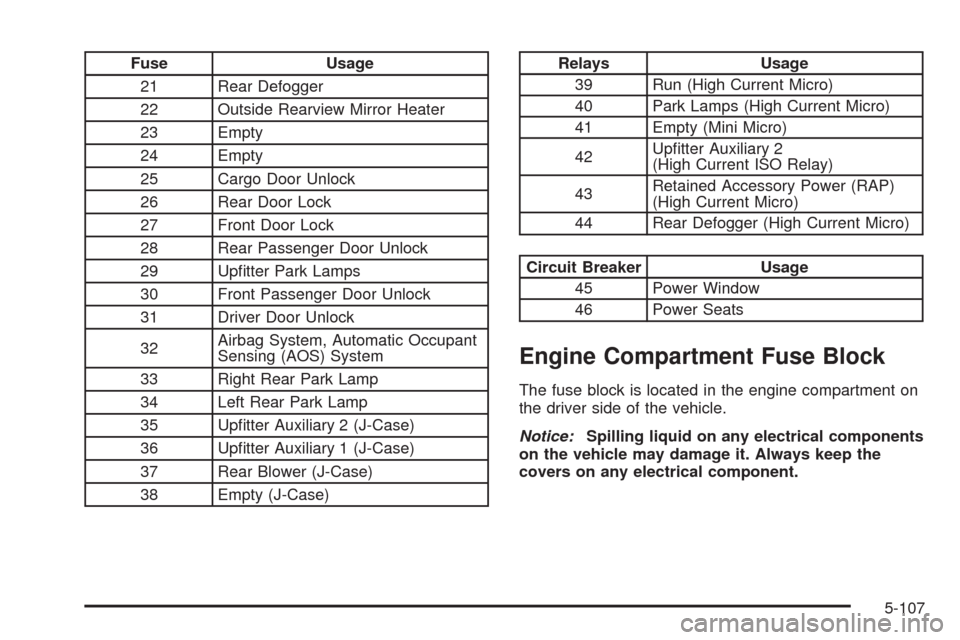

Fuse Usage

21 Rear Defogger

22 Outside Rearview Mirror Heater

23 Empty

24 Empty

25 Cargo Door Unlock

26 Rear Door Lock

27 Front Door Lock

28 Rear Passenger Door Unlock

29 Upfitter Park Lamps

30 Front Passenger Door Unlock

31 Driver Door Unlock

32Airbag System, Automatic Occupant

Sensing (AOS) System

33 Right Rear Park Lamp

34 Left Rear Park Lamp

35 Upfitter Auxiliary 2 (J-Case)

36 Upfitter Auxiliary 1 (J-Case)

37 Rear Blower (J-Case)

38 Empty (J-Case)Relays Usage

39 Run (High Current Micro)

40 Park Lamps (High Current Micro)

41 Empty (Mini Micro)

42Upfitter Auxiliary 2

(High Current ISO Relay)

43Retained Accessory Power (RAP)

(High Current Micro)

44 Rear Defogger (High Current Micro)

Circuit Breaker Usage

45 Power Window

46 Power Seats

Engine Compartment Fuse Block

The fuse block is located in the engine compartment on

the driver side of the vehicle.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

5-107