service CHEVROLET EXPRESS CARGO VAN 2009 1.G Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2009, Model line: EXPRESS CARGO VAN, Model: CHEVROLET EXPRESS CARGO VAN 2009 1.GPages: 408, PDF Size: 2.36 MB

Page 309 of 408

Federal Communications

Commission (FCC) and

Industry and Science Canada

The Tire Pressure Monitor System (TPMS) operates

on a radio frequency and complies with Part 15 of

the FCC Rules. Operation is subject to the following

two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation.

The TPMS operates on a radio frequency and complies

with RSS-210 of Industry and Science Canada.

Operation is subject to the following two conditions:

1. This device may not cause interference.

2. This device must accept any interference received,

including interference that may cause undesired

operation of the device.

Changes or modifications to this system by other than

an authorized service facility could void authorization to

use this equipment.

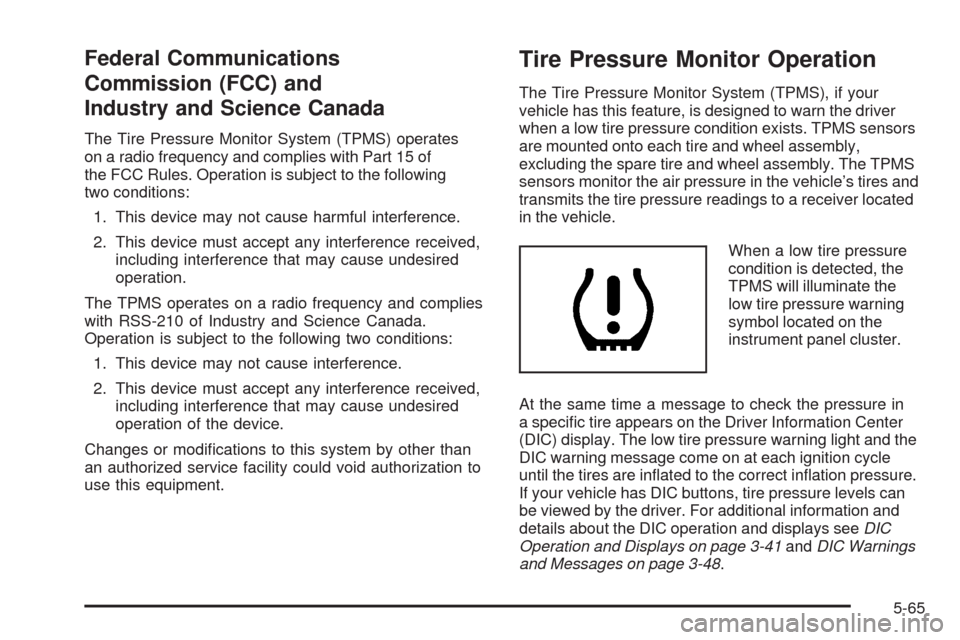

Tire Pressure Monitor Operation

The Tire Pressure Monitor System (TPMS), if your

vehicle has this feature, is designed to warn the driver

when a low tire pressure condition exists. TPMS sensors

are mounted onto each tire and wheel assembly,

excluding the spare tire and wheel assembly. The TPMS

sensors monitor the air pressure in the vehicle’s tires and

transmits the tire pressure readings to a receiver located

in the vehicle.

When a low tire pressure

condition is detected, the

TPMS will illuminate the

low tire pressure warning

symbol located on the

instrument panel cluster.

At the same time a message to check the pressure in

a specific tire appears on the Driver Information Center

(DIC) display. The low tire pressure warning light and the

DIC warning message come on at each ignition cycle

until the tires are inflated to the correct inflation pressure.

If your vehicle has DIC buttons, tire pressure levels can

be viewed by the driver. For additional information and

details about the DIC operation and displays seeDIC

Operation and Displays on page 3-41andDIC Warnings

and Messages on page 3-48.

5-65

Page 311 of 408

•One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

•Replacement tires or wheels do not match your

vehicle’s original equipment tires or wheels. Tires

and wheels other than those recommended for your

vehicle could prevent the TPMS from functioning

properly. SeeBuying New Tires on page 5-72.

•Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or

signal a low tire condition. See your dealer/retailer for

service if the TPMS malfunction light and DIC message

comes on and stays on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you rotate your vehicle’s tires or replace one

or more of the TPMS sensors, the identification codes

will need to be matched to the new tire/wheel position.

The sensors are matched to the tire/wheel positions in

the following order: driver side front tire, passenger side

front tire, passenger side rear tire, and driver side rear tire

using a TPMS diagnostic tool. See your dealer/retailer for

service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the tire’s

air pressure. If increasing the tire’s air pressure, do not

exceed the maximum inflation pressure indicated on the

tire’s sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gage, or a key.

You have two minutes to match the first tire/wheel

position, and five minutes overall to match all four

tire/wheel positions. If it takes longer than two minutes,

to match the first tire and wheel, or more than

five minutes to match all four tire and wheel positions

the matching process stops and you need to start over.

5-67

Page 318 of 408

Uniform Tire Quality Grading

Quality grades can be found where applicable

on the tire sidewall between tread shoulder

and maximum section width. For example:

Treadwear 200 Traction AA

Temperature A

The following information relates to the system

developed by the United States National Highway

Traffic Safety Administration (NHTSA), which

grades tires by treadwear, traction, and

temperature performance. This applies only to

vehicles sold in the United States. The grades are

molded on the sidewalls of most passenger car

tires. The Uniform Tire Quality Grading (UTQG)

system does not apply to deep tread, winter-type

snow tires, space-saver, or temporary use

spare tires, tires with nominal rim diameters

of 10 to 12 inches (25 to 30 cm), or to some

limited-production tires.While the tires available on General Motors

passenger cars and light trucks may vary with

respect to these grades, they must also conform

to federal safety requirements and additional

General Motors Tire Performance Criteria (TPC)

standards.

Treadwear

The treadwear grade is a comparative rating

based on the wear rate of the tire when tested

under controlled conditions on a specified

government test course. For example, a tire

graded 150 would wear one and a half (1.5) times

as well on the government course as a tire

graded 100. The relative performance of tires

depends upon the actual conditions of their use,

however, and may depart significantly from the

norm due to variations in driving habits, service

practices, and differences in road characteristics

and climate.

5-74

Page 335 of 408

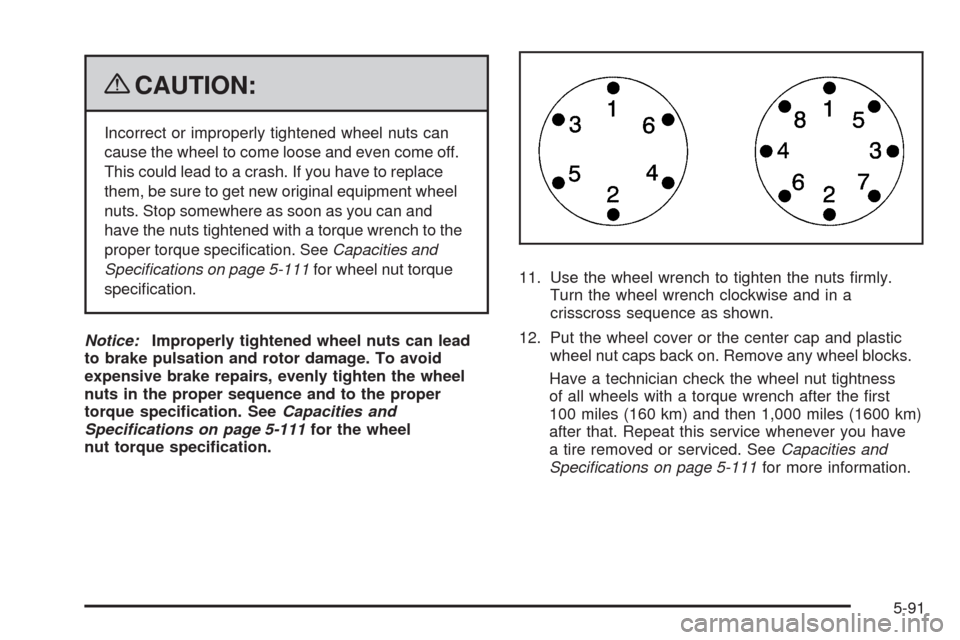

{CAUTION:

Incorrect or improperly tightened wheel nuts can

cause the wheel to come loose and even come off.

This could lead to a crash. If you have to replace

them, be sure to get new original equipment wheel

nuts. Stop somewhere as soon as you can and

have the nuts tightened with a torque wrench to the

proper torque specification. SeeCapacities and

Specifications on page 5-111for wheel nut torque

specification.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 5-111for the wheel

nut torque speci�cation.11. Use the wheel wrench to tighten the nuts firmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

12. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Have a technician check the wheel nut tightness

of all wheels with a torque wrench after the first

100 miles (160 km) and then 1,000 miles (1600 km)

after that. Repeat this service whenever you have

a tire removed or serviced. SeeCapacities and

Specifications on page 5-111for more information.

5-91

Page 348 of 408

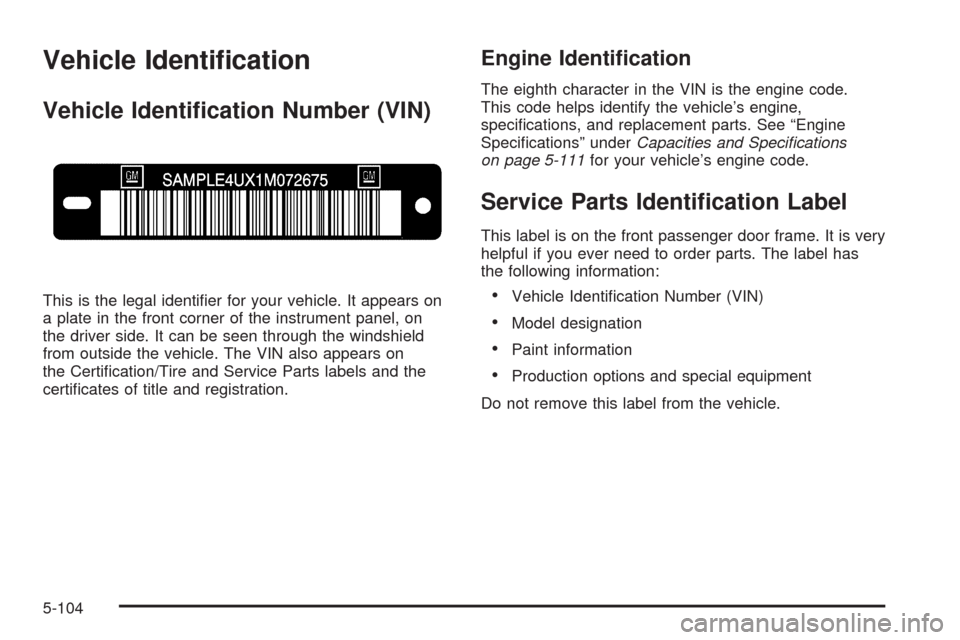

Vehicle Identi�cation

Vehicle Identi�cation Number (VIN)

This is the legal identifier for your vehicle. It appears on

a plate in the front corner of the instrument panel, on

the driver side. It can be seen through the windshield

from outside the vehicle. The VIN also appears on

the Certification/Tire and Service Parts labels and the

certificates of title and registration.

Engine Identi�cation

The eighth character in the VIN is the engine code.

This code helps identify the vehicle’s engine,

specifications, and replacement parts. See “Engine

Specifications” underCapacities and Specifications

on page 5-111for your vehicle’s engine code.

Service Parts Identi�cation Label

This label is on the front passenger door frame. It is very

helpful if you ever need to order parts. The label has

the following information:

•Vehicle Identification Number (VIN)

•Model designation

•Paint information

•Production options and special equipment

Do not remove this label from the vehicle.

5-104

Page 357 of 408

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Maintenance Requirements..............................6-2

Your Vehicle and the Environment....................6-2

Using the Maintenance Schedule......................6-3

Scheduled Maintenance...................................6-4

Additional Required Services............................6-6

Maintenance Footnotes (Gasoline Engine)..........6-8

Owner Checks and Services..........................6-10At the First 100, 1,000 and 6,000 Miles

(160, 1 600 and 10 000 km).......................6-10

At Each Fuel Fill..........................................6-10

At Least Once a Month.................................6-11

At Least Once a Year...................................6-11

Recommended Fluids and Lubricants...............6-13

Maintenance Replacement Parts.....................6-15

Engine Drive Belt Routing..............................6-16

Maintenance Record.....................................6-17

Section 6 Maintenance Schedule

6-1

Page 359 of 408

Using the Maintenance Schedule

We want to help keep this vehicle in good working

condition. But we do not know exactly how you will

drive it. You might drive very short distances only a

few times a week. Or you might drive long distances

all the time in very hot, dusty weather. You might

use the vehicle in making deliveries. Or you might

drive it to work, to do errands, or in many other ways.

Because of all the different ways people use their

vehicles, maintenance needs vary. You might need more

frequent checks and replacements. So please read

the following and note how you drive. If you have any

questions on how to keep the vehicle in good condition,

see your dealer/retailer.

This schedule is for vehicles that:

•carry passengers and cargo within recommended

limits on the Tire and Loading Information label.

SeeLoading the Vehicle on page 4-19.

•are driven on reasonable road surfaces within legal

driving limits.

•use the recommended fuel. SeeGasoline Octane

on page 5-6.The services inScheduled Maintenance on page 6-4

should be performed when indicated. SeeAdditional

Required Services on page 6-6andMaintenance

Footnotes (Gasoline Engine) on page 6-8for further

information.

{CAUTION:

Performing maintenance work on a vehicle can be

dangerous. In trying to do some jobs, you can be

seriously injured. Do your own maintenance work

only if you have the required know-how and the

proper tools and equipment for the job. If you have

any doubt, see your dealer/retailer to have a

qualified technician do the work. SeeDoing Your

Own Service Work on page 5-4.

Some maintenance services can be complex. So, unless

you are technically qualified and have the necessary

equipment, have your dealer/retailer do these jobs.

When you go to your dealer/retailer for service, trained

and supported service technicians will perform the

work using genuine parts.

6-3

Page 360 of 408

To purchase service information, seeService

Publications Ordering Information on page 7-16.

Owner Checks and Services on page 6-10tells what

should be checked, when to check it, and what can easily

be done to help keep the vehicle in good condition.

The proper replacement parts, fluids, and lubricants to

use are listed inRecommended Fluids and Lubricants

on page 6-13andMaintenance Replacement Parts

on page 6-15. When the vehicle is serviced, make sure

these are used. All parts should be replaced and all

necessary repairs done before you or anyone else

drives the vehicle. We recommend the use of genuine

parts from your dealer/retailer.

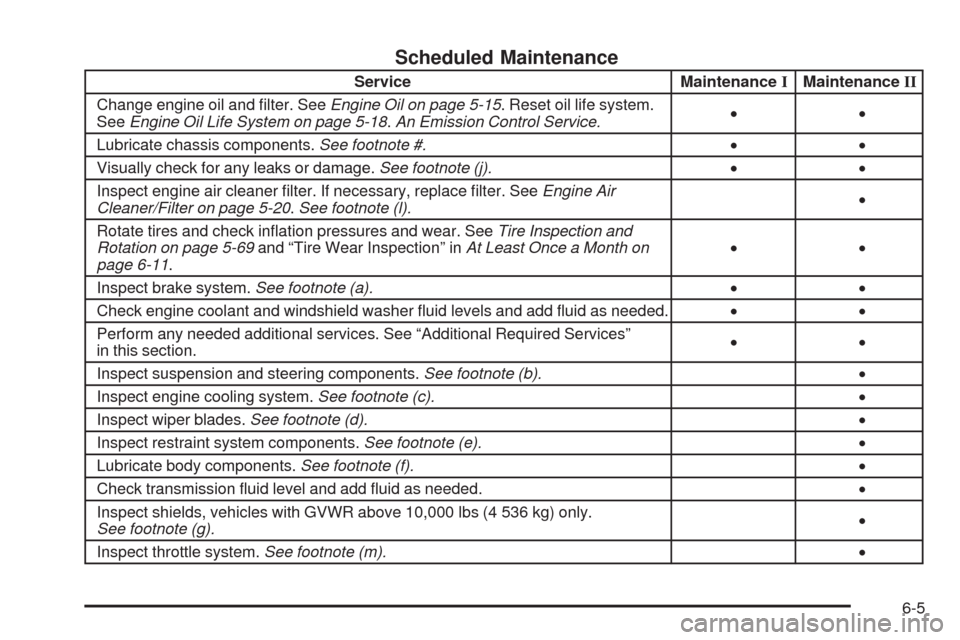

Scheduled Maintenance

This maintenance section applies to vehicles with a

gasoline engine. For diesel engine vehicles, see

the maintenance schedule section in the DURAMAX

®

Diesel manual.

When the CHANGE ENGINE OIL SOON message

displays, service is required for the vehicle. Have the

vehicle serviced as soon as possible within the next

600 miles (1 000 km). It is possible that, if driving under

the best conditions, the engine oil life system may

not indicate that vehicle service is necessary for over

a year. However, the engine oil and filter must be

changed at least once a year and at this time the systemmust be reset. Your dealer/retailer has trained service

technicians who will perform this work using genuine

parts and reset the system.

If the engine oil life system is ever reset accidentally,

service the vehicle within 3,000 miles (5 000 km)

since the last service. Remember to reset the oil life

system whenever the oil is changed. SeeEngine Oil Life

System on page 5-18for information on the Engine

Oil Life System and resetting the system.

When the CHANGE ENGINE OIL SOON message

appears, certain services, checks, and inspections are

required. Required services are described in the

following for “MaintenanceI” and “MaintenanceII.”

Generally, it is recommended that the first service be

MaintenanceI, the second service be MaintenanceII,

and then alternate MaintenanceIand MaintenanceII

thereafter. However, in some cases, MaintenanceIImay

be required more often.

MaintenanceI— Use MaintenanceIif the CHANGE

ENGINE OIL SOON message displays within 10 months

since the vehicle was purchased or MaintenanceII

was performed.

MaintenanceII— Use MaintenanceIIif the previous

service performed was MaintenanceI. Always use

MaintenanceIIwhenever the message displays

10 months or more since the last service or if the

message has not come on at all for one year.

6-4

Page 361 of 408

Scheduled Maintenance

Service MaintenanceIMaintenanceII

Change engine oil and filter. SeeEngine Oil on page 5-15. Reset oil life system.

SeeEngine Oil Life System on page 5-18.An Emission Control Service.••

Lubricate chassis components.See footnote #.••

Visually check for any leaks or damage.See footnote (j).••

Inspect engine air cleaner filter. If necessary, replace filter. SeeEngine Air

Cleaner/Filter on page 5-20.See footnote (l).•

Rotate tires and check inflation pressures and wear. SeeTire Inspection and

Rotation on page 5-69and “Tire Wear Inspection” inAt Least Once a Month on

page 6-11.••

Inspect brake system.See footnote (a).••

Check engine coolant and windshield washer fluid levels and add fluid as needed.••

Perform any needed additional services. See “Additional Required Services”

in this section.••

Inspect suspension and steering components.See footnote (b).•

Inspect engine cooling system.See footnote (c).•

Inspect wiper blades.See footnote (d).•

Inspect restraint system components.See footnote (e).•

Lubricate body components.See footnote (f).•

Check transmission fluid level and add fluid as needed.•

Inspect shields, vehicles with GVWR above 10,000 lbs (4 536 kg) only.

See footnote (g).•

Inspect throttle system.See footnote (m).•

6-5

Page 362 of 408

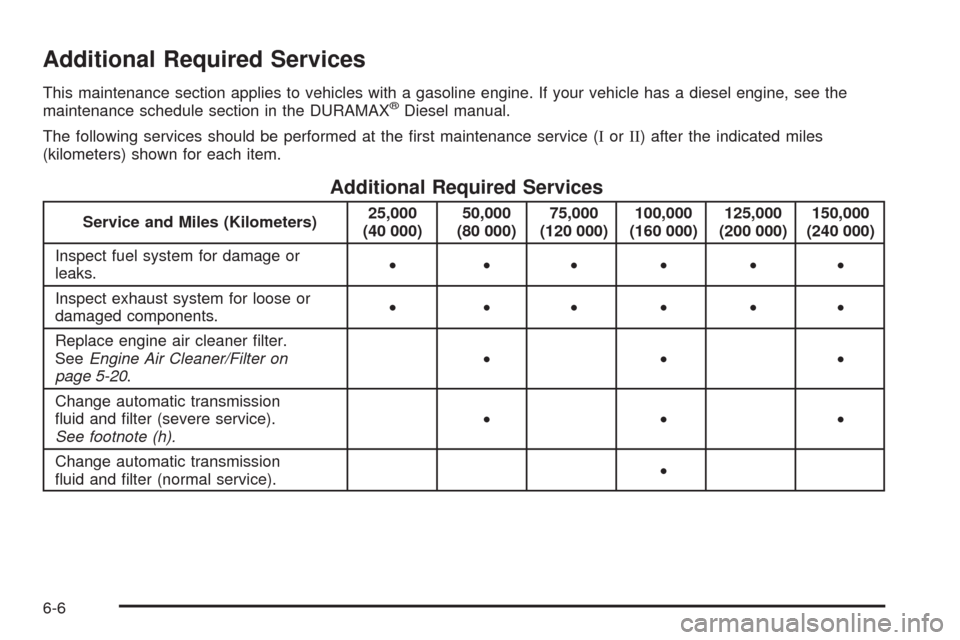

Additional Required Services

This maintenance section applies to vehicles with a gasoline engine. If your vehicle has a diesel engine, see the

maintenance schedule section in the DURAMAX®Diesel manual.

The following services should be performed at the first maintenance service (IorII) after the indicated miles

(kilometers) shown for each item.

Additional Required Services

Service and Miles (Kilometers)25,000

(40 000)50,000

(80 000)75,000

(120 000)100,000

(160 000)125,000

(200 000)150,000

(240 000)

Inspect fuel system for damage or

leaks.• •••••

Inspect exhaust system for loose or

damaged components.• •••••

Replace engine air cleaner filter.

SeeEngine Air Cleaner/Filter on

page 5-20.•••

Change automatic transmission

fluid and filter (severe service).

See footnote (h).•••

Change automatic transmission

fluid and filter (normal service).•

6-6