CHEVROLET EXPRESS PASSANGER 2005 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2005, Model line: EXPRESS PASSANGER, Model: CHEVROLET EXPRESS PASSANGER 2005 1.GPages: 388, PDF Size: 2.42 MB

Page 321 of 388

{CAUTION:

Rust or dirt on the wheel, or on the parts to

which it is fastened, can make the wheel nuts

become loose after a time. The wheel could

come off and cause an accident. When you

change a wheel, remove any rust or dirt from

the places where the wheel attaches to the

vehicle. In an emergency, you can use a cloth

or a paper towel to do this; but be sure to use

a scraper or wire brush later, if you need to, to

get all the rust or dirt off.

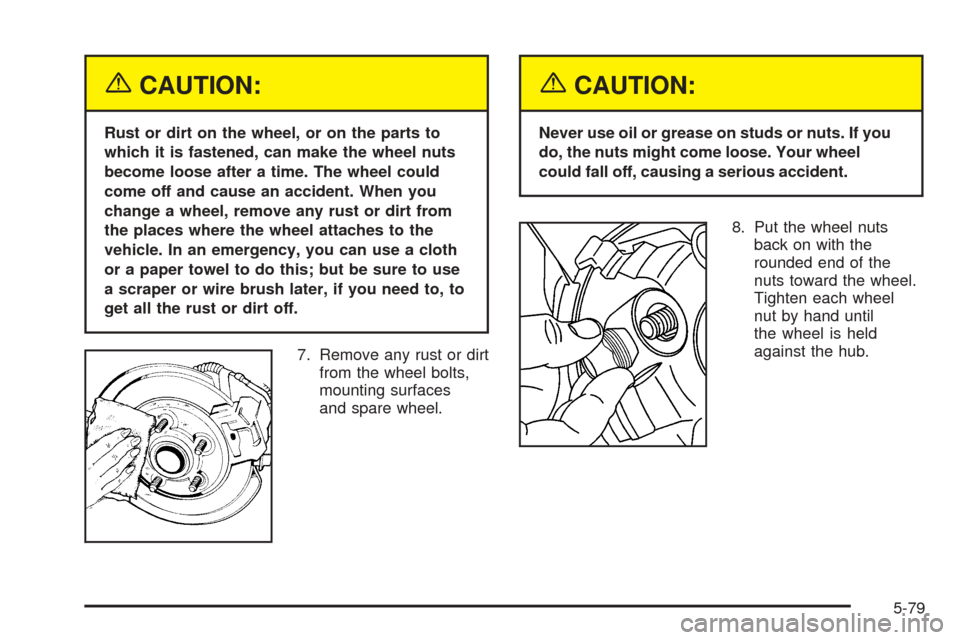

7. Remove any rust or dirt

from the wheel bolts,

mounting surfaces

and spare wheel.

{CAUTION:

Never use oil or grease on studs or nuts. If you

do, the nuts might come loose. Your wheel

could fall off, causing a serious accident.

8. Put the wheel nuts

back on with the

rounded end of the

nuts toward the wheel.

Tighten each wheel

nut by hand until

the wheel is held

against the hub.

5-79

Page 322 of 388

9. Lower the vehicle by turning the jack handle

counterclockwise. Lower the jack completely.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci�cation. SeeCapacities

and Specifications on page 5-100for wheel nut

torque speci�cation.

Notice:Improperly tightened wheel nuts can lead

to brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper

torque speci�cation. SeeCapacities and

Specifications on page 5-100for the wheel nut

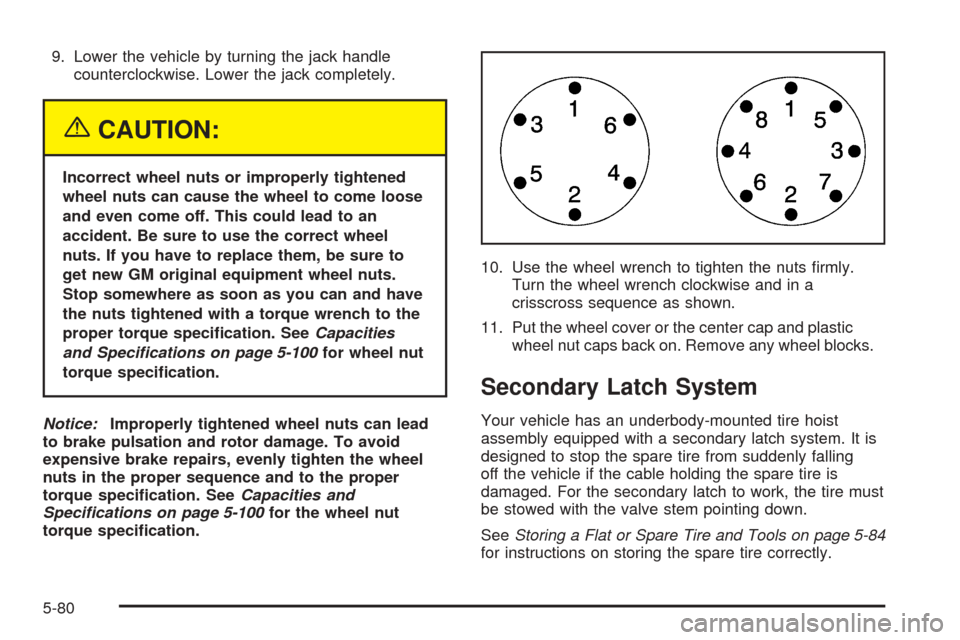

torque speci�cation.10. Use the wheel wrench to tighten the nuts �rmly.

Turn the wheel wrench clockwise and in a

crisscross sequence as shown.

11. Put the wheel cover or the center cap and plastic

wheel nut caps back on. Remove any wheel blocks.

Secondary Latch System

Your vehicle has an underbody-mounted tire hoist

assembly equipped with a secondary latch system. It is

designed to stop the spare tire from suddenly falling

off the vehicle if the cable holding the spare tire is

damaged. For the secondary latch to work, the tire must

be stowed with the valve stem pointing down.

SeeStoring a Flat or Spare Tire and Tools on page 5-84

for instructions on storing the spare tire correctly.

5-80

Page 323 of 388

{CAUTION:

Before beginning this procedure read all the

instructions. Failure to read and follow the

instructions could damage the hoist assembly

and you and others could get hurt. Read and

follow the instructions listed below.

To release the spare tire from the secondary latch, do

the following:

{CAUTION:

Someone standing too close during the

procedure could be injured by the jack. If the

spare tire does not slide off the jack

completely, make sure no one is behind you or

on either side of you as you pull the jack out

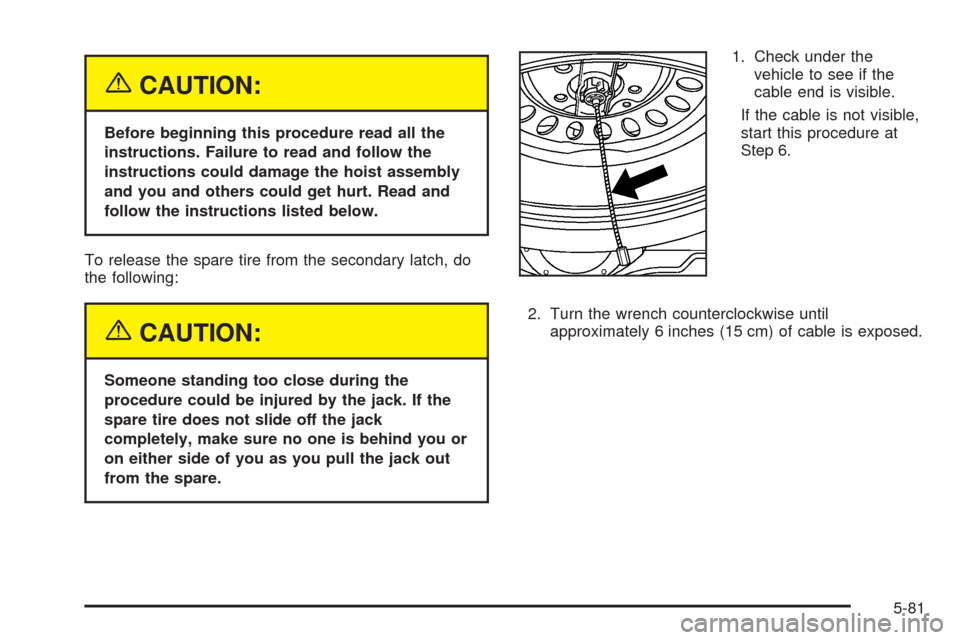

from the spare.1. Check under the

vehicle to see if the

cable end is visible.

If the cable is not visible,

start this procedure at

Step 6.

2. Turn the wrench counterclockwise until

approximately 6 inches (15 cm) of cable is exposed.

5-81

Page 324 of 388

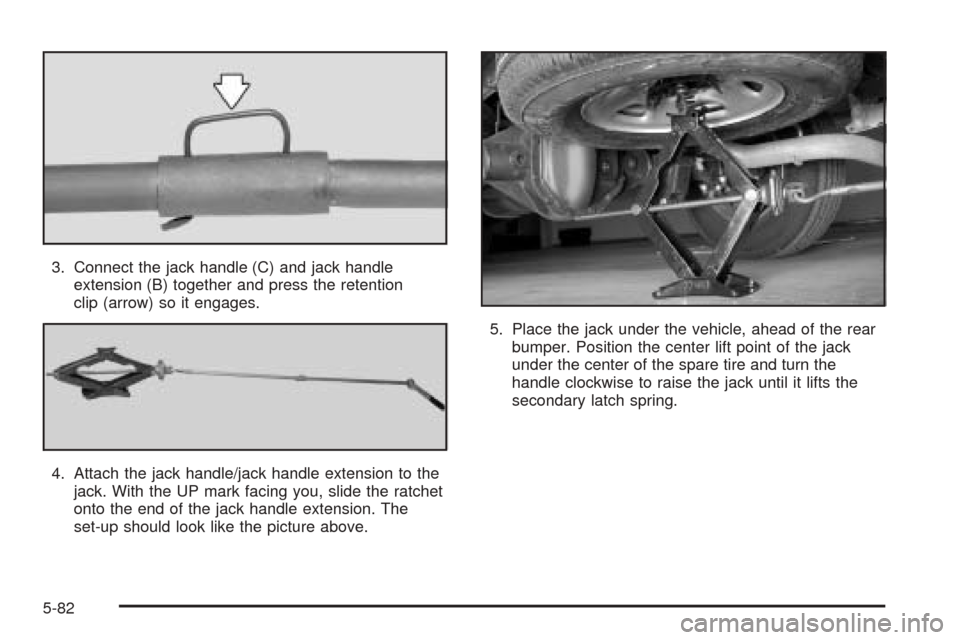

3. Connect the jack handle (C) and jack handle

extension (B) together and press the retention

clip (arrow) so it engages.

4. Attach the jack handle/jack handle extension to the

jack. With the UP mark facing you, slide the ratchet

onto the end of the jack handle extension. The

set-up should look like the picture above.5. Place the jack under the vehicle, ahead of the rear

bumper. Position the center lift point of the jack

under the center of the spare tire and turn the

handle clockwise to raise the jack until it lifts the

secondary latch spring.

5-82

Page 325 of 388

6. Keep raising the jack until the spare tire stops

moving upward and is held �rmly in place. this lets

you know that the secondary latch has released.

The spare tire is now balancing on the jack.

7. Lower the jack by turning the ratchet

counterclockwise. Keep lowering the jack until the

spare tire slides off the jack or is hanging by

the cable.

8. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to push

against the spare while �rmly pulling the jack out

from under the spare tire with the other hand.

If the spare tire is hanging from the cable, slide the

ratchet onto the wheel wrench and insert the

wheel wrench into the hoist shaft hole above the

bumper. Turn the wheel wrench counterclockwise to

lower the spare the rest of the way. Be sure the

DOWN mark on the ratchet is facing you.9. Tilt the retainer at the end of the cable and pull it

through the wheel opening. Pull the tire out from

under the vehicle.

Notice:If you drive away before the spare tire or

secondary latch system cable has been reinstalled,

you could damage your vehicle. Always reinstall

this cable before driving your vehicle.

10. If the cable is hanging under the vehicle, turn the

wheel wrench in the hoist shaft hole in the bumper

clockwise to raise the cable back up.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare or �at tire using

the hoist assembly until it has been repaired or replaced.

To continue changing the �at tire, return to Step 4 of

Removing the Flat Tire and Installing the Spare Tire on

page 5-75.

5-83

Page 326 of 388

Storing a Flat or Spare Tire and

Tools

{CAUTION:

Storing a jack, a tire, or other equipment in the

passenger compartment of the vehicle could

cause injury. In a sudden stop or collision,

loose equipment could strike someone. Store

all these in the proper place.

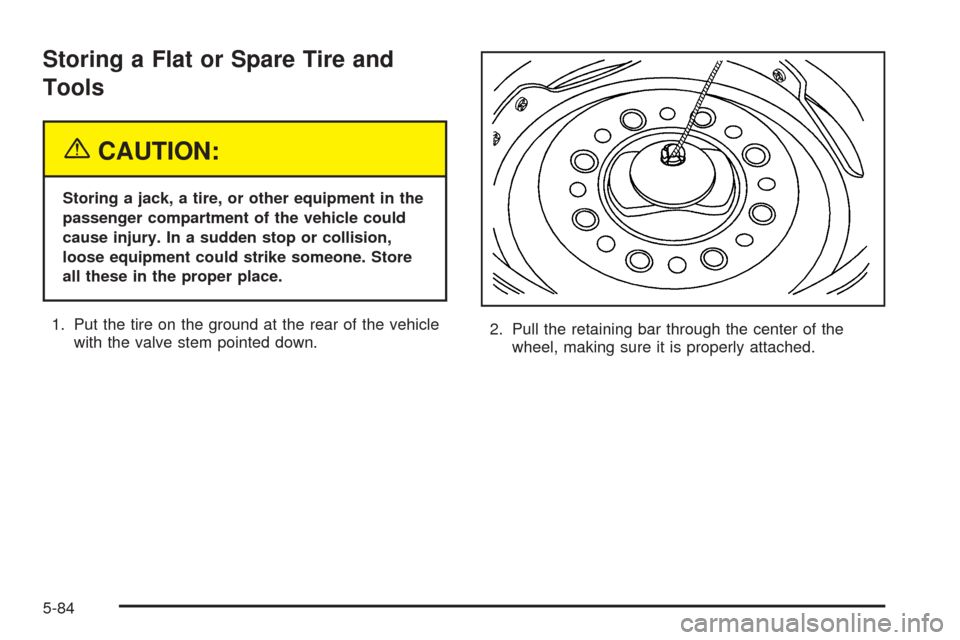

1. Put the tire on the ground at the rear of the vehicle

with the valve stem pointed down.2. Pull the retaining bar through the center of the

wheel, making sure it is properly attached.

5-84

Page 327 of 388

3. Pull the wheel toward the rear of the vehicle,

keeping the cable tight.

4. With the UP side facing you, attach the ratchet to

the wheel wrench.5. Put the �at end of the wheel wrench on an angle

through the hole in the rear door frame, above the

bumper.

6. Raise the tire fully against the underside of the

vehicle. Continue turning the ratchet until the tire

is secure and the cable is tight. The spare tire hoist

cannot be overtightened.

7. Make sure the tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If the tire

moves, use the ratchet to tighten the cable.

You will hear two clicks when the tire is up all the way.

Return the jacking equipment to the proper location.

Secure the items and replace the jack cover.

5-85

Page 328 of 388

Spare Tire

Your vehicle, when new, had a fully in�ated spare tire.

A spare tire may lose air over time, so check its

in�ation pressure regularly. SeeIn�ation - Tire Pressure

on page 5-60andLoading Your Vehicle on page 4-31

for information regarding proper tire in�ation and loading

your vehicle. For instructions on how to remove,

install or store a spare tire, seeRemoving the Flat Tire

and Installing the Spare Tire on page 5-75and

Storing a Flat or Spare Tire and Tools on page 5-84.

After installing the spare tire on your vehicle, you should

stop as soon as possible and make sure the spare is

correctly in�ated. Have the damaged or �at road

tire repaired or replaced as soon as you can and

installed back onto your vehicle. This way, a spare tire

will be available in case you need it again.

Your vehicle may have a different size spare tire than

the road tires — those originally installed on your

vehicle. This spare tire was developed for use on your

vehicle, so it’s all right to drive on it.

If your vehicle has a spare tire that does not match your

vehicle’s original road tires and wheels in size and

type, do not include the spare in the tire rotation.

Appearance Care

Cleaning products can be hazardous. Some are toxic.

Other cleaning products can burst into �ames if a match

is struck near them or if they get on a hot part of the

vehicle. Some are dangerous if their fumes are inhaled

in an enclosed space. When anything from a container

is used to clean the vehicle, be sure to follow the

manufacturer’s warnings and instructions. Always open

the doors or windows of the vehicle when cleaning

the inside.

Never use these to clean the vehicle:

Benzene

Naphtha

Carbon Tetrachloride

Acetone

Paint Thinner

Turpentine

Lacquer Thinner

Nail Polish Remover

They can all be hazardous — some more than

others — and they can all damage the vehicle, too.

5-86

Page 329 of 388

Do not use any of these products unless this manual

says you can. In many uses, these will damage

the vehicle:

Alcohol

Laundry Soap

Bleach

Reducing Agents

Cleaning the Inside of Your Vehicle

Your vehicle’s interior will continue to look its best if

it is cleaned often. Although not always visible, dust and

dirt can accumulate on your upholstery. Dirt can

damage carpet, fabric, leather, and plastic surfaces.

Regular vacuuming is recommended to remove particles

from your upholstery. It is important to keep your

upholstery from becoming and remaining heavily soiled.

Soils should be removed as quickly as possible. Your

vehicle’s interior may experience extremes of heat

that could cause stains to set rapidly.

Lighter colored interiors may require more frequent

cleaning. Use care because newspapers and garments

that transfer color to your home furnishings may also

transfer color to your vehicle’s interior.When cleaning your vehicle’s interior, only use cleaners

speci�cally designed for the surfaces being cleaned.

Permanent damage may result from using cleaners on

surfaces for which they were not intended. Use glass

cleaner only on glass. Remove any accidental over-spray

from other surfaces immediately. To prevent over-spray,

apply cleaner directly to the cleaning cloth.

Notice:If you use abrasive cleaners when cleaning

glass surfaces on your vehicle, you could scratch

the glass and/or cause damage to the rear window

defogger. When cleaning the glass on your

vehicle, use only a soft cloth and glass cleaner.

Many cleaners contain solvents that may become

concentrated in your vehicle’s breathing space. Before

using cleaners, read and adhere to all safety

instructions on the label. While cleaning your vehicle’s

interior, maintain adequate ventilation by opening

your vehicle’s doors and windows.

Dust may be removed from small buttons and knobs

using a small brush with soft bristles.

Your GM dealer has a product for cleaning your

vehicle’s glass. Should it become necessary, you can

also obtain a product from your GM dealer to remove

odors from your vehicle’s upholstery.

5-87

Page 330 of 388

Do not clean your vehicle using the following cleaners

or techniques:

Never use a knife or any other sharp object to

remove a soil from any interior surface.

Never use a stiff brush. It can cause damage to

your vehicle’s interior surfaces.

Never apply heavy pressure or rub aggressively

with a cleaning cloth. Use of heavy pressure

can damage your interior and does not improve the

effectiveness of soil removal.

Use only mild, neutral-pH soaps. Avoid laundry

detergents or dishwashing soaps with degreasers.

Using too much soap will leave a residue that

leaves streaks and attracts dirt. For liquid cleaners,

about 20 drops per gallon (3.78 L) of water is a

good guide.

Do not heavily saturate your upholstery while

cleaning.

Damage to your vehicle’s interior may result from

the use of many organic solvents such as naptha,

alcohol, etc.

Fabric/Carpet

Use a vacuum cleaner with a soft brush attachment

frequently to remove dust and loose dirt. A canister

vacuum with a beater bar in the nozzle may only be used

on �oor carpet and carpeted �oor mats. For soils, always

try to remove them �rst with plain water or club soda.

Before cleaning, gently remove as much of the soil as

possible using one of the following techniques:

For liquids: gently blot the remaining soil with a paper

towel. Allow the soil to absorb into the paper towel

until no more can be removed.

For solid dry soils: remove as much as possible and

then vacuum.

To clean, use the following instructions:

1. Saturate a lint-free, clean white cloth with water or

club soda.

2. Wring the cloth to remove excess moisture.

3. Start on the outside edge of the soil and gently rub

toward the center. Continue cleaning, using a clean

area of the cloth each time it becomes soiled.

4. Continue to gently rub the soiled area until the

cleaning cloth remains clean.

5. If the soil is not completely removed, use a mild

soap solution and repeat the cleaning process

that was used with plain water.

5-88