engine CHEVROLET EXPRESS PASSANGER 2007 1.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2007, Model line: EXPRESS PASSANGER, Model: CHEVROLET EXPRESS PASSANGER 2007 1.GPages: 458, PDF Size: 2.62 MB

Page 333 of 458

{CAUTION:

Fans or other moving engine parts can

injure you badly. Keep your hands away

from moving parts once the engine is

running.

5. Check that the jumper cables do not have

loose or missing insulation. If they do, you

could get a shock. The vehicles could

be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+)

will go to positive (+) or to a remote

positive (+) terminal if the vehicle has one.

Negative (−) will go to a heavy, unpainted

metal engine part or to a remote negative (−)

terminal if the vehicle has one.

Do not connect positive (+) to negative (−)

or you will get a short that would damage

the battery and maybe other parts too.

And do not connect the negative (−) cable

to the negative (−) terminal on the dead

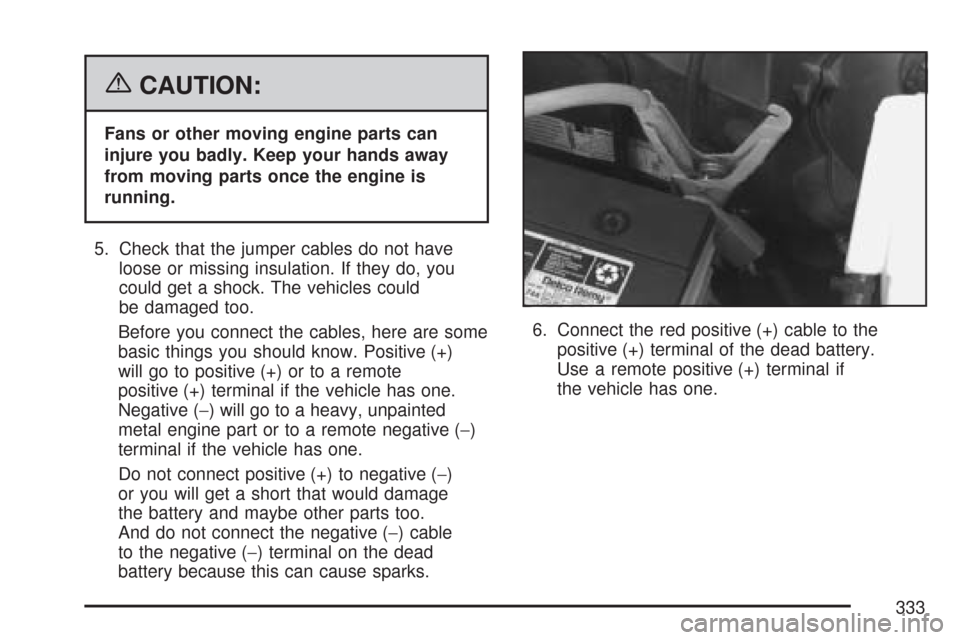

battery because this can cause sparks.6. Connect the red positive (+) cable to the

positive (+) terminal of the dead battery.

Use a remote positive (+) terminal if

the vehicle has one.

333

Page 334 of 458

7. Do not let the other end touch metal.

Connect it to the positive (+) terminal of the

good battery. Use a remote positive (+)

terminal if the vehicle has one.

8. Now connect the black negative (−) cable to

the negative (−) terminal of the good battery.

Use a remote negative (−) terminal if the

vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−)

cable does not go to the dead battery. It goes to

a heavy, unpainted metal engine part or to a

remote negative (−) terminal on the vehicle

with the dead battery.9. Connect the other end of the negative (−)

cable to the negative (−) terminal location

on the vehicle with the dead battery.

Your vehicle has a remote negative (−)

terminal for this purpose. It is marked GND.

10. Now start the vehicle with the good battery

and run the engine for a while.

11. Try to start the vehicle that had the dead

battery. If it will not start after a few tries,

it probably needs service.

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting

may occur and damage the vehicle. The repairs

would not be covered by your warranty. Always

connect and remove the jumper cables in the

correct order, making sure that the cables do

not touch each other or other metal.

334

Page 335 of 458

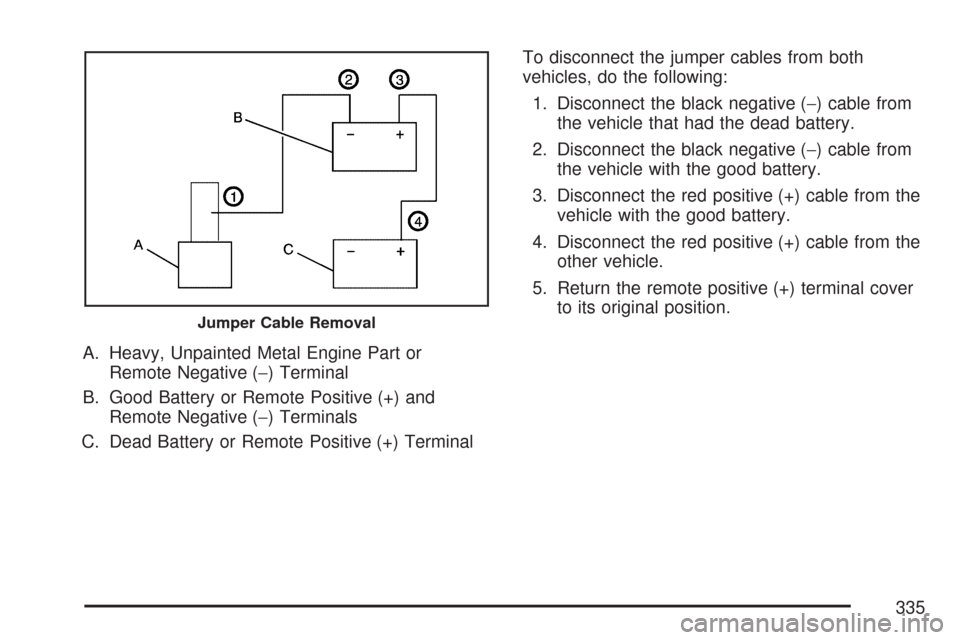

A. Heavy, Unpainted Metal Engine Part or

Remote Negative (−) Terminal

B. Good Battery or Remote Positive (+) and

Remote Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both

vehicles, do the following:

1. Disconnect the black negative (−) cable from

the vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from

the vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the

other vehicle.

5. Return the remote positive (+) terminal cover

to its original position.

Jumper Cable Removal

335

Page 336 of 458

All-Wheel Drive

Lubricant checks in this section also apply to

these vehicles. However, there are two additional

systems that need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance (Gasoline Engine) on page 405.

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.If the level is below the bottom of the filler plug

hole, you’ll need to add some lubricant. Add

enough lubricant to raise the level to the bottom of

the filler plug hole. Use care not to overtighten

the plug.

What to Use

Refer to the Maintenance Schedule to determine

what kind of lubricant to use. SeeRecommended

Fluids and Lubricants on page 415.

336

Page 337 of 458

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant. SeeScheduled

Maintenance (Gasoline Engine) on page 405.

How to Check Lubricant

To get an accurate reading, the vehicle should be

on a level surface.If you have the 1500 Series, the proper level

is from 5/8 inch (15 mm) to 1 5/8 inch (40 mm)

below the bottom of the filler plug hole. The

proper level for the 2500 and 3500 Series is

from 0 to 1/4 (6 mm) below the bottom of the

filler plug hole. Add only enough fluid to reach

the proper level.

What to Use

Refer to the Maintenance Schedule to determine

what kind of lubricant to use. SeeRecommended

Fluids and Lubricants on page 415.

337

Page 338 of 458

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant and when

to change it. SeeScheduled Maintenance

(Gasoline Engine) on page 405.

How to Check Lubricant

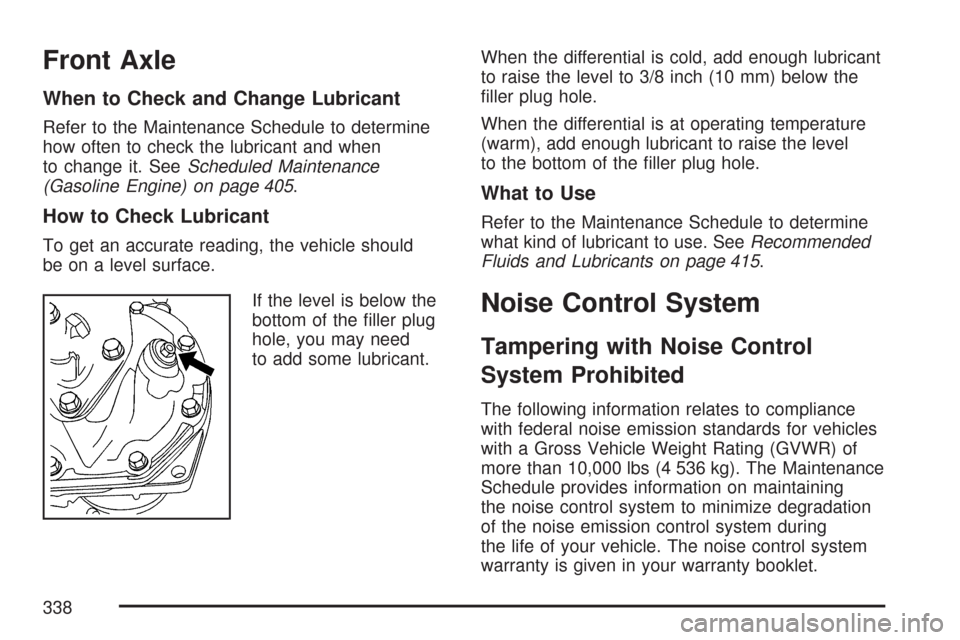

To get an accurate reading, the vehicle should

be on a level surface.

If the level is below the

bottom of the filler plug

hole, you may need

to add some lubricant.When the differential is cold, add enough lubricant

to raise the level to 3/8 inch (10 mm) below the

filler plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level

to the bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine

what kind of lubricant to use. SeeRecommended

Fluids and Lubricants on page 415.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance

with federal noise emission standards for vehicles

with a Gross Vehicle Weight Rating (GVWR) of

more than 10,000 lbs (4 536 kg). The Maintenance

Schedule provides information on maintaining

the noise control system to minimize degradation

of the noise emission control system during

the life of your vehicle. The noise control system

warranty is given in your warranty booklet.

338

Page 339 of 458

These standards apply only to vehicles sold in

the United States.

Federal law prohibits the following acts or the

causing thereof:

1. The removal or rendering inoperative by

any person, other than for purposes of

maintenance, repair or replacement, of any

device or element of design incorporated into

any new vehicle for the purpose of noise

control, prior to its sale or delivery to

the ultimate purchaser or while it is in use; or

2. The use of the vehicle after such device or

element of design has been removed or

rendered inoperative by any person.

Among those acts presumed to constitute

tampering are the acts listed below.

Insulation:

•

Removal of the noise shields or any

underhood insulation.

Engine:

•

Removal or rendering engine speed governor,

if the vehicle has one, inoperative so as to

allow engine speed to exceed manufacturer

specifications.

Fan and Drive:

•

Removal of fan clutch, if the vehicle has one,

or rendering clutch inoperative.

•Removal of the fan shroud, if the vehicle

has one.

Air Intake:

•

Removal of the air cleaner silencer.

•Modification of the air cleaner.

Exhaust:

•

Removal of the muffler and/or resonator.

•Removal of the exhaust pipes and exhaust

pipe clamps.

Fuel Operated Heater (FOH) — Diesel

Engine:

•

Removal of the muffler.

339

Page 344 of 458

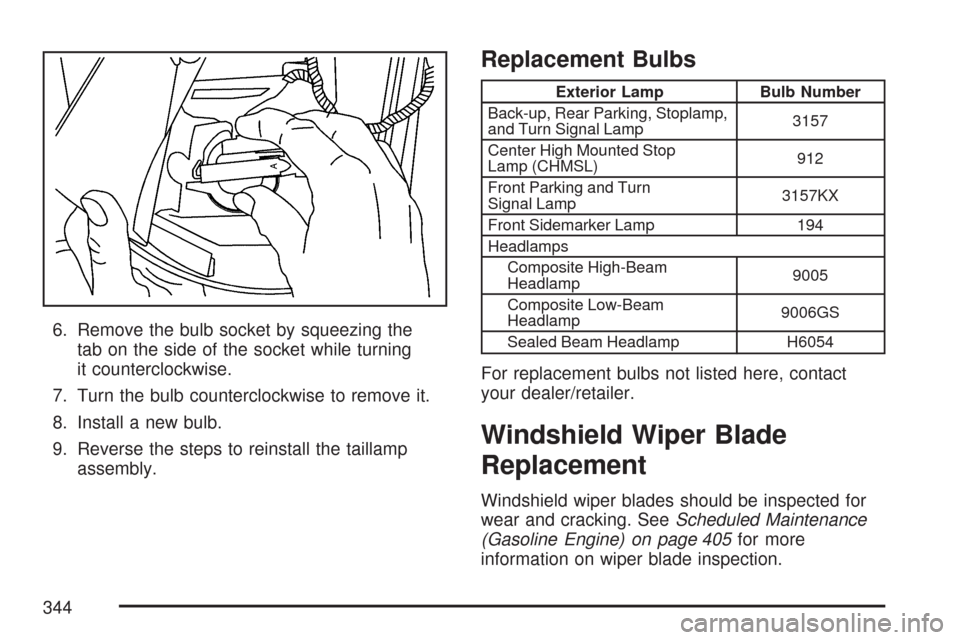

6. Remove the bulb socket by squeezing the

tab on the side of the socket while turning

it counterclockwise.

7. Turn the bulb counterclockwise to remove it.

8. Install a new bulb.

9. Reverse the steps to reinstall the taillamp

assembly.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up, Rear Parking, Stoplamp,

and Turn Signal Lamp3157

Center High Mounted Stop

Lamp (CHMSL)912

Front Parking and Turn

Signal Lamp3157KX

Front Sidemarker Lamp 194

Headlamps

Composite High-Beam

Headlamp9005

Composite Low-Beam

Headlamp9006GS

Sealed Beam Headlamp H6054

For replacement bulbs not listed here, contact

your dealer/retailer.

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for

wear and cracking. SeeScheduled Maintenance

(Gasoline Engine) on page 405for more

information on wiper blade inspection.

344

Page 350 of 458

Tire Size

The following examples show the different parts of

a tire size.

(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter P

as the first character in the tire size means a

passenger vehicle tire engineered to standards set

by the U.S. Tire and Rim Association.(A) Light Truck (LT-Metric) Tire:The

United States version of a metric tire sizing system.

The letters LT as the first two characters in the

tire size means a light truck tire engineered to

standards set by the U.S. Tire and Rim Association.

(B) Tire Width:The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

(C) Aspect Ratio:A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is 75, as

shown in item C of the light truck (LT-Metric) tire

illustration, it would mean that the tire’s sidewall is

75 percent as high as it is wide.

(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The

letter R means radial ply construction; the letter D

means diagonal or bias ply construction; and the

letter B means belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel

in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a

tire. The load index can range from 1 to 279.

Speed ratings range from A to Z.

Passenger (P-Metric) Tire

Light Truck (LT-Metric) Tire

350

Page 355 of 458

Radial tires may look properly inflated even when

they’re underinflated. Check the tire’s inflation

pressure when the tires are cold. Cold means your

vehicle has been sitting for at least three hours

or driven no more than 1 mile (1.6 km).

Remove the valve cap from the tire valve stem.

Press the tire gage firmly onto the valve to

get a pressure measurement. If the cold tire

inflation pressure matches the recommended

pressure on the tire and loading information label,

no further adjustment is necessary. If the

pressure is low, add air until you reach the

recommended amount.

If you overfill the tire, release air by pushing on

the metal stem in the center of the tire valve.

Recheck the tire pressure with the tire gage.

Be sure to put the valve caps back on the valve

stems. They help prevent leaks by keeping out

dirt and moisture.

Dual Tire Operation

When the vehicle is new, or whenever a wheel,

wheel bolt or wheel nut is replaced, check

the wheel nut torque after 100, 1,000 and

6,000 miles (160, 1 600 and 10 000 km) of driving.For proper wheel nut tightening information, see

“Removing the Flat Tire and Installing the Spare

Tire” later in this section, underChanging a Flat

Tire on page 366. Also see “Wheel Nut Torque”

underCapacities and Speci�cations on page 398.

The outer tire on a dual wheel setup generally

wears faster than the inner tire. Your tires will wear

more evenly and last longer if you rotate the

tires periodically. SeeTire Inspection and Rotation

on page 356. Also seeScheduled Maintenance

(Gasoline Engine) on page 405.

{CAUTION:

If you operate your vehicle with a tire

that is badly underin�ated, the tire can

overheat. An overheated tire can lose

air suddenly or catch �re. You or

others could be injured. Be sure all tires

(including the spare) are properly in�ated.

SeeTires on page 346andIn�ation - Tire

Pressure on page 354for more information on

proper tire inflation.

355