CHEVROLET HHR 2009 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2009, Model line: HHR, Model: CHEVROLET HHR 2009 1.GPages: 450, PDF Size: 2.49 MB

Page 321 of 450

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by the vehicle warranty. Always

connect and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal (GND)

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalTo disconnect the jumper cables from both vehicles:

1. Disconnect the black negative (−) cable from

the vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the positive (+) terminal cover to its original

position.

Jumper Cable Removal

5-43

Page 322 of 450

Headlamp Aiming

The vehicle has a visual optical headlamp aiming

system. The aim has been preset at the factory and

should need no further adjustment.

However, if the vehicle is damaged in a crash, the

headlamp aim may be affected and adjustment may be

necessary.

If oncoming vehicles �ash their high beams at you, this

may also mean the vertical aim needs to be adjusted.

It is recommended that the vehicle is taken to your

dealer/retailer for service if the headlamps need to

be re-aimed. It is possible however, to re-aim the

headlamps as described.

The vehicle should:

Be placed so the headlamps are 25 ft. (7.6 m) from

a light colored wall.

Have all four tires on a level surface which is level

all the way to the wall.

Be placed so it is perpendicular to the wall or other

�at surface.

Not have any snow, ice, or mud on it.

Be fully assembled and all other work stopped while

headlamp aiming is being performed.

Normally loaded with a full tank of fuel and one

person or 160 lbs (75 kg) sitting on the driver seat.

Have all tires properly in�ated.

Have the spare tire is in its original location in the

vehicle.

Headlamp aiming is done with the vehicle’s low-beam

headlamps. The high-beam headlamps will be correctly

aimed if the low-beam headlamps are aimed properly.

5-44

Page 323 of 450

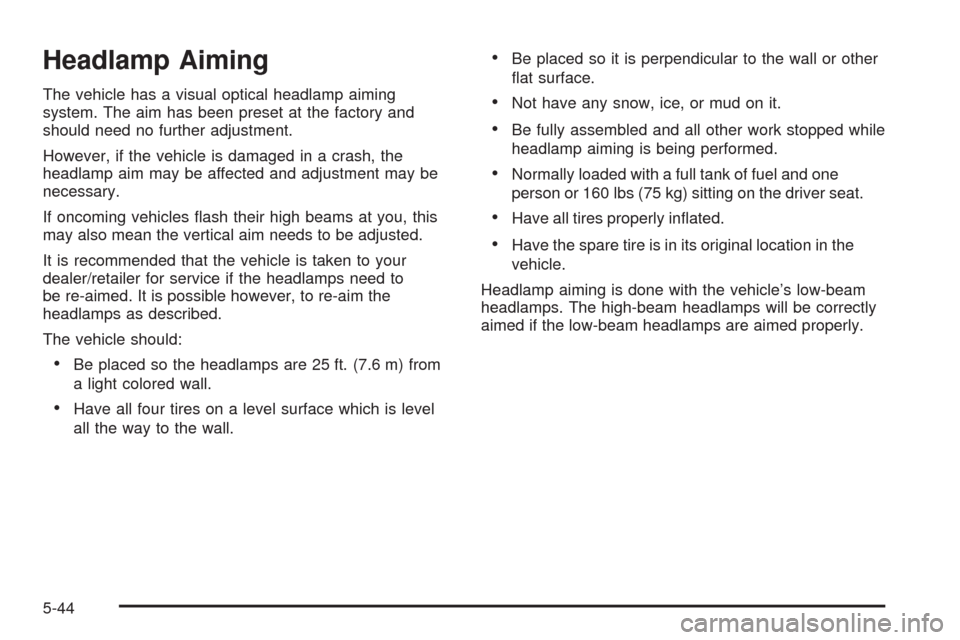

To adjust the vertical aim:

1. Open the hood. SeeHood Release on page 5-13

for more information.

2. Find the aim dot on the lens of the low-beam

headlamp.

3. Measure the distance from the ground to the aim

dot on the low-beam headlamp. Record the

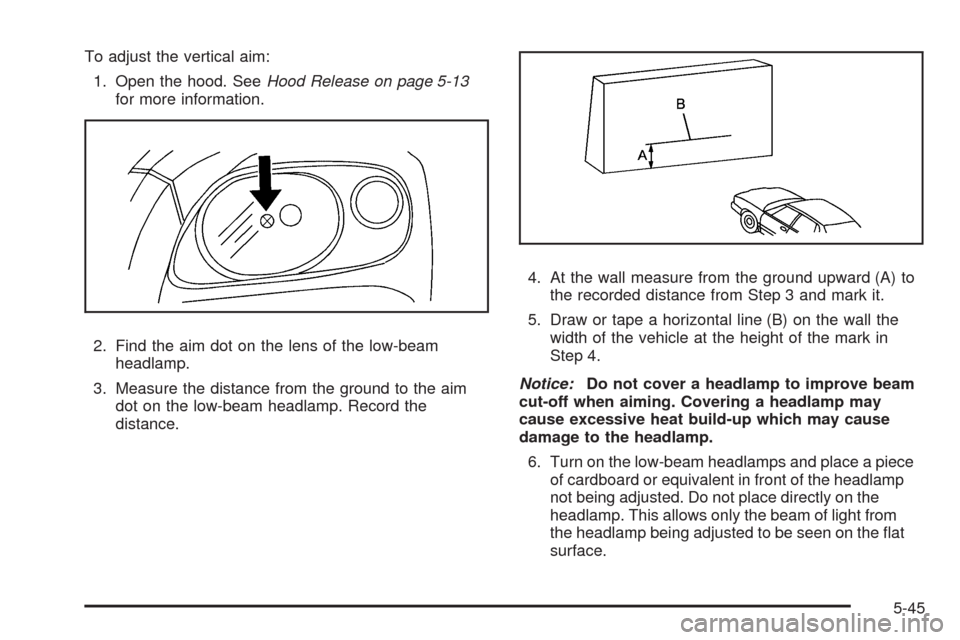

distance.4. At the wall measure from the ground upward (A) to

the recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall the

width of the vehicle at the height of the mark in

Step 4.

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a piece

of cardboard or equivalent in front of the headlamp

not being adjusted. Do not place directly on the

headlamp. This allows only the beam of light from

the headlamp being adjusted to be seen on the �at

surface.

5-45

Page 324 of 450

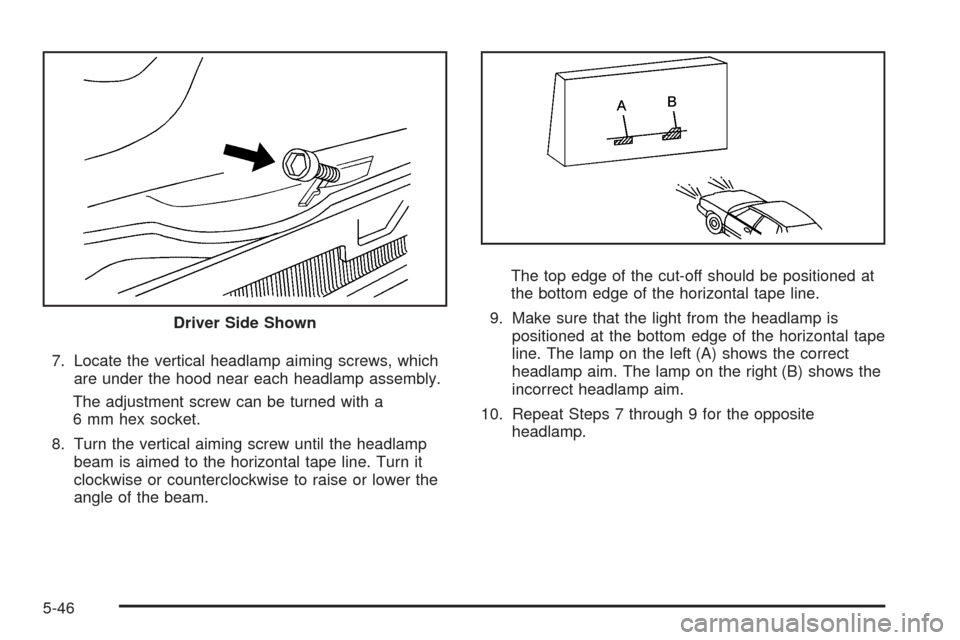

7. Locate the vertical headlamp aiming screws, which

are under the hood near each headlamp assembly.

The adjustment screw can be turned with a

6 mm hex socket.

8. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.The top edge of the cut-off should be positioned at

the bottom edge of the horizontal tape line.

9. Make sure that the light from the headlamp is

positioned at the bottom edge of the horizontal tape

line. The lamp on the left (A) shows the correct

headlamp aim. The lamp on the right (B) shows the

incorrect headlamp aim.

10. Repeat Steps 7 through 9 for the opposite

headlamp. Driver Side Shown

5-46

Page 325 of 450

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 5-51.

For any bulb changing procedure not listed in this

section, contact your dealer/retailer.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and follow

the instructions on the bulb package.

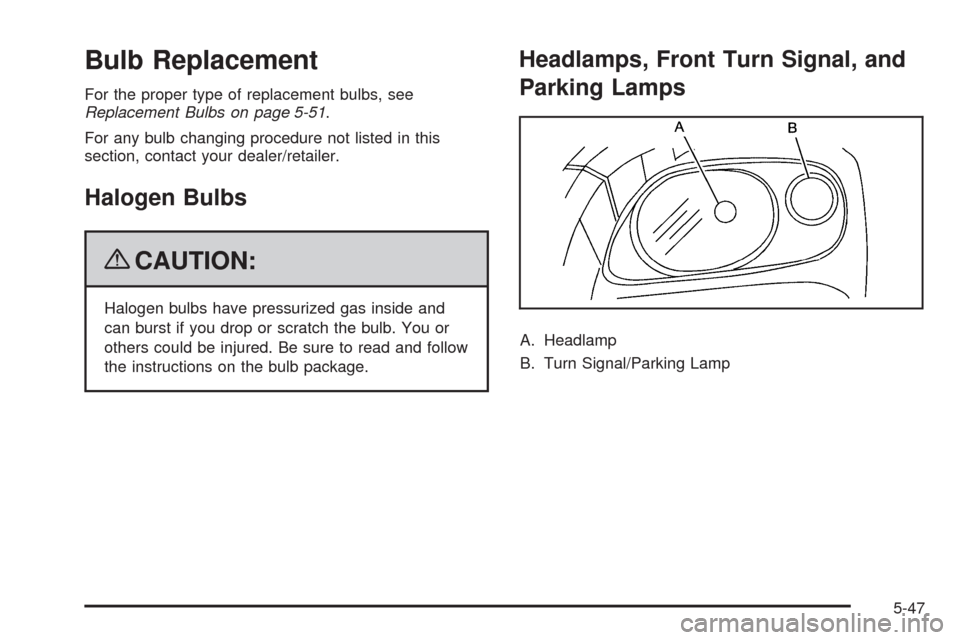

Headlamps, Front Turn Signal, and

Parking Lamps

A. Headlamp

B. Turn Signal/Parking Lamp

5-47

Page 326 of 450

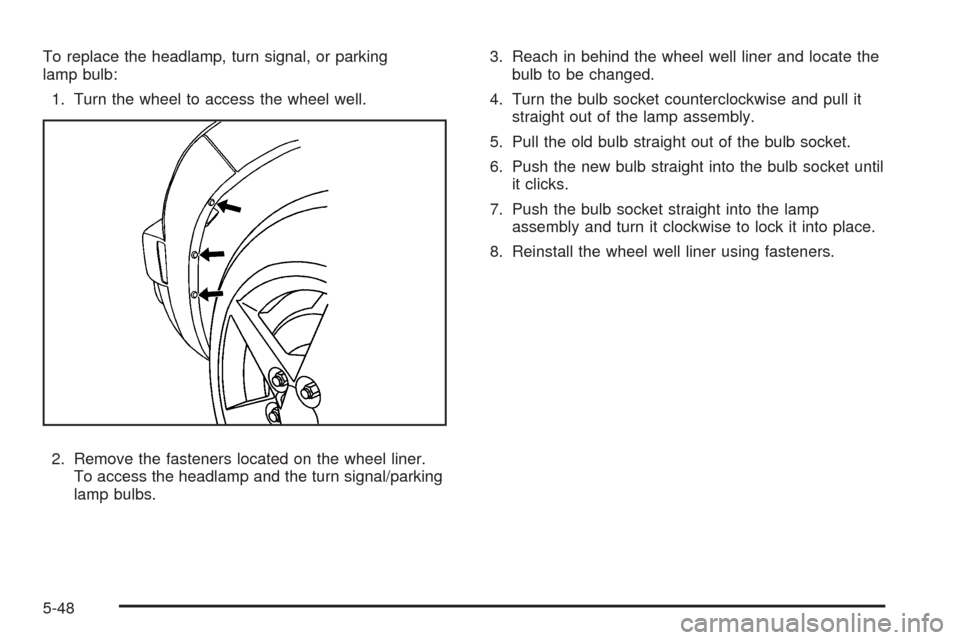

To replace the headlamp, turn signal, or parking

lamp bulb:

1. Turn the wheel to access the wheel well.

2. Remove the fasteners located on the wheel liner.

To access the headlamp and the turn signal/parking

lamp bulbs.3. Reach in behind the wheel well liner and locate the

bulb to be changed.

4. Turn the bulb socket counterclockwise and pull it

straight out of the lamp assembly.

5. Pull the old bulb straight out of the bulb socket.

6. Push the new bulb straight into the bulb socket until

it clicks.

7. Push the bulb socket straight into the lamp

assembly and turn it clockwise to lock it into place.

8. Reinstall the wheel well liner using fasteners.

5-48

Page 327 of 450

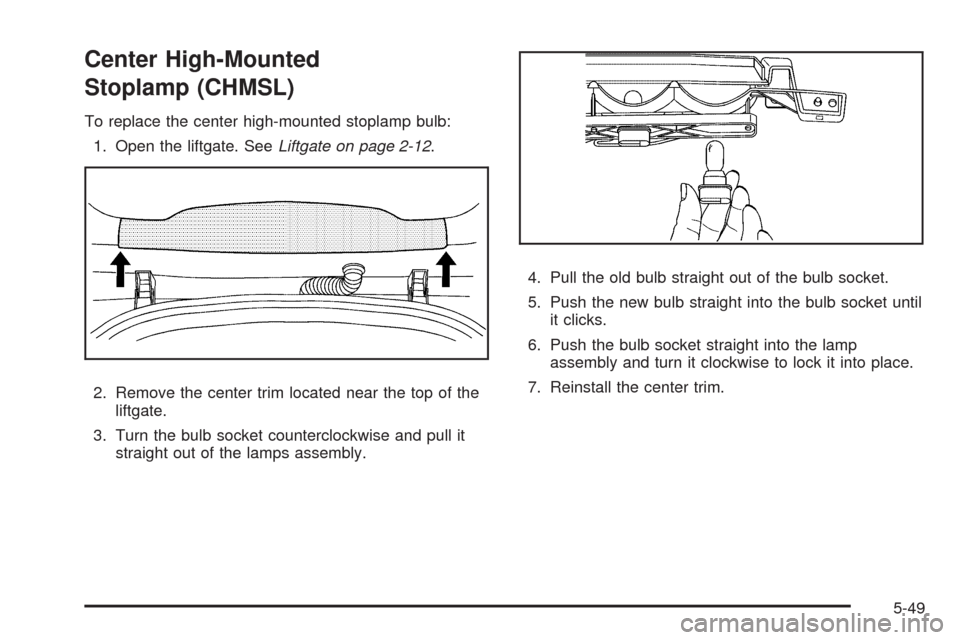

Center High-Mounted

Stoplamp (CHMSL)

To replace the center high-mounted stoplamp bulb:

1. Open the liftgate. SeeLiftgate on page 2-12.

2. Remove the center trim located near the top of the

liftgate.

3. Turn the bulb socket counterclockwise and pull it

straight out of the lamps assembly.4. Pull the old bulb straight out of the bulb socket.

5. Push the new bulb straight into the bulb socket until

it clicks.

6. Push the bulb socket straight into the lamp

assembly and turn it clockwise to lock it into place.

7. Reinstall the center trim.

5-49

Page 328 of 450

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

A. Stoplamp/Taillamp/Turn Signal Lamp

B. Back-up LampTo replace one of these bulbs:

1. Open the liftgate. SeeLiftgate on page 2-12.

2. Remove the cover in the rear cargo area of the

vehicle to access the bulbs.

3. Turn the bulb socket counterclockwise and pull it

straight out of the lamp assembly.

4. Pull the bulb straight out of the socket.

5. Install a new bulb. When installing the bulb socket

into the assembly, line up the tabs with the slots in

the bulb assembly.

5-50

Page 329 of 450

6. Push the bulb socket straight into the lamp

assembly and turn it clockwise to lock it into place.

7. Reinstall the cover.

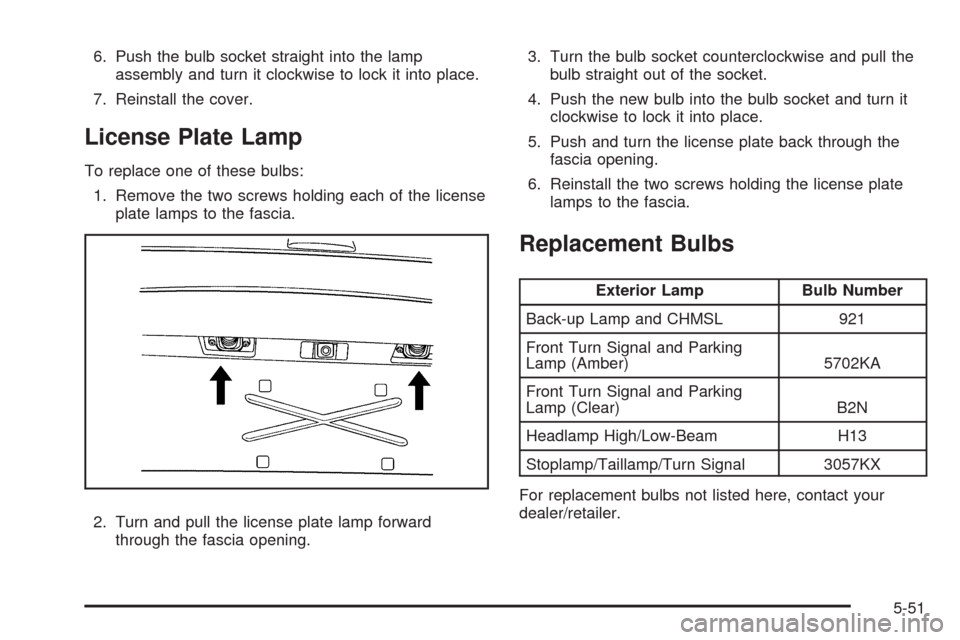

License Plate Lamp

To replace one of these bulbs:

1. Remove the two screws holding each of the license

plate lamps to the fascia.

2. Turn and pull the license plate lamp forward

through the fascia opening.3. Turn the bulb socket counterclockwise and pull the

bulb straight out of the socket.

4. Push the new bulb into the bulb socket and turn it

clockwise to lock it into place.

5. Push and turn the license plate back through the

fascia opening.

6. Reinstall the two screws holding the license plate

lamps to the fascia.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp and CHMSL 921

Front Turn Signal and Parking

Lamp (Amber) 5702KA

Front Turn Signal and Parking

Lamp (Clear) B2N

Headlamp High/Low-Beam H13

Stoplamp/Taillamp/Turn Signal 3057KX

For replacement bulbs not listed here, contact your

dealer/retailer.

5-51

Page 330 of 450

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

or cracking. SeeScheduled Maintenance on page 6-4

for more information on wiper blade inspection.

Replacement blades come in different types and are

removed in different ways. For the proper type and

length, seeMaintenance Replacement Parts on

page 6-16. Here’s how to remove the wiper blade:

1. Pull the windshield wiper arm away from the

windshield.2. While holding the wiper arm, lift the clip up from the

blade connecting point, and pull the blade assembly

down toward the windshield to remove it from the

wiper arm.

3. Install the new wiper blade on the wiper arm and

press down on the clip to snap it into place.

5-52