ignition CHEVROLET HHR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: HHR, Model: CHEVROLET HHR 2010 1.GPages: 480, PDF Size: 5.25 MB

Page 369 of 480

TPMS Malfunction Light and Message

The TPMS will not function properly if one or more of

the TPMS sensors are missing or inoperable. When the

system detects a malfunction, the low tire warning light

flashes for about one minute and then stays on for the

remainder of the ignition cycle. A DIC warning message

is also displayed. The low tire warning light and DIC

warning message come on at each ignition cycle until

the problem is corrected. Some of the conditions that

can cause the malfunction light and DIC message to

come on are:

.One of the road tires has been replaced with the

spare tire. The spare tire does not have a TPMS

sensor. The TPMS malfunction light and DIC

message should go off once you re‐install the

road tire containing the TPMS sensor.

.The TPMS sensor matching process was started

but not completed or not completed successfully

after rotating the vehicle's tires. The DIC message

and TPMS malfunction light should go off once the

TPMS sensor matching process is performed

successfully. See“TPMS Sensor Matching

Process” later in this section.

.One or more TPMS sensors are missing or

damaged. The DIC message and the TPMS

malfunction light should go off when the TPMS

sensors are installed and the sensor matching

process is performed successfully. See your

dealer/retailer for service.

.Replacement tires or wheels do not match your

vehicle's original equipment tires or wheels. Tires

and wheels other than those recommended for

your vehicle could prevent the TPMS from

functioning properly. See Buying New Tires

on

page 6‑72.

.Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMS

could cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signal

a low tire condition. See your dealer/retailer for service

if the TPMS malfunction light and DIC message comes

on and stays on.

6-67

Page 370 of 480

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.

Any time you replace one or more of the TPMS sensors

or rotate the vehicle's tires, the identification codes

need to be matched to the new tire/wheel location. The

sensors are matched, to the tire/wheel locations, in the

following order: driver side front tire, passenger side

front tire, passenger side rear tire, and driver side rear

tire using a TPMS diagnostic tool. See your dealer/

retailer for service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the tire's

air pressure. When increasing the tire's pressure, do not

exceed the maximum inflation pressure indicated on the

tire's sidewall. To decrease the tire's air-pressure use

the pointed end of the valve cap, a pencil-style air

pressure gauge, or a key.

You have two minutes to match each tire and wheel

position. If it takes longer than two minutes to match

any tire and wheel position, the matching process stops

and you need to start over.

The TPMS matching process is outlined below:1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the engine off. 3. Press and hold the Remote Keyless Entry (RKE)

transmitter's LOCK and UNLOCK buttons, at the

same time, for about five seconds to start the

TPMS learn mode. The horn sounds twice

indicating the TPMS receiver is ready and in

learn mode.

4. Start with the driver side front tire. The driver side front turn signal also comes on to indicate that

corner's sensor is ready to be learned.

5. Remove the valve cap from the tire's valve stem. Activate the TPMS sensor by increasing or

decreasing the tire's air pressure for about

eight seconds. The horn chirp, can take up to

30 seconds to sound. It chirps one time and then

all the turn signals flash one time to confirm the

sensor identification code has been matched to the

tire/wheel position.

6. The passenger side front turn signal comes on to indicate that corner sensor is ready to be learned.

Proceed to the passenger side front tire and repeat

the procedure in Step 5.

7. The passenger side rear turn signal comes on to indicate that corner sensor is ready to be learned.

Proceed to the passenger side rear tire and repeat

the procedure in Step 5.

6-68

Page 371 of 480

8. The driver side rear turn signal comes on toindicate that corner sensor is ready to be learned.

Proceed to the driver side rear tire, and repeat the

procedure in Step 5.

9. After hearing the single horn chirp for the driver side rear tire, two additional horn chirps sound to

indicate the tire learning process is done. Turn the

ignition switch to LOCK/OFF.

If no tires are learned after entering the TPMS

learn mode, or if communication with the receiver

stops, or if the time limit has expired, turn the

ignition switch to LOCK/OFF and start over

beginning with Step 2.

10. Set all four tires to the recommended air pressure level as indicated on the Tire and Loading

Information label.

11. Put the valve caps back on the valve stems.Tire Inspection and Rotation

We recommend that you regularly inspect your

vehicle's tires, including the spare tire, for signs of

wear or damage. See When It Is Time for New

Tires

on page 6‑71for more information.

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km). See Scheduled Maintenance

on page 7‑3.

The purpose of a regular tire rotation is to achieve

a uniform wear for all tires on the vehicle. This will

ensure that your vehicle continues to perform

most like it did when the tires were new.

Any time you notice unusual wear, rotate the tires

as soon as possible and check wheel alignment.

Also check for damaged tires or wheels.

SeeWhen It Is Time for New Tires

on page 6‑71

and Wheel Replacementon page 6‑76.

6-69

Page 423 of 480

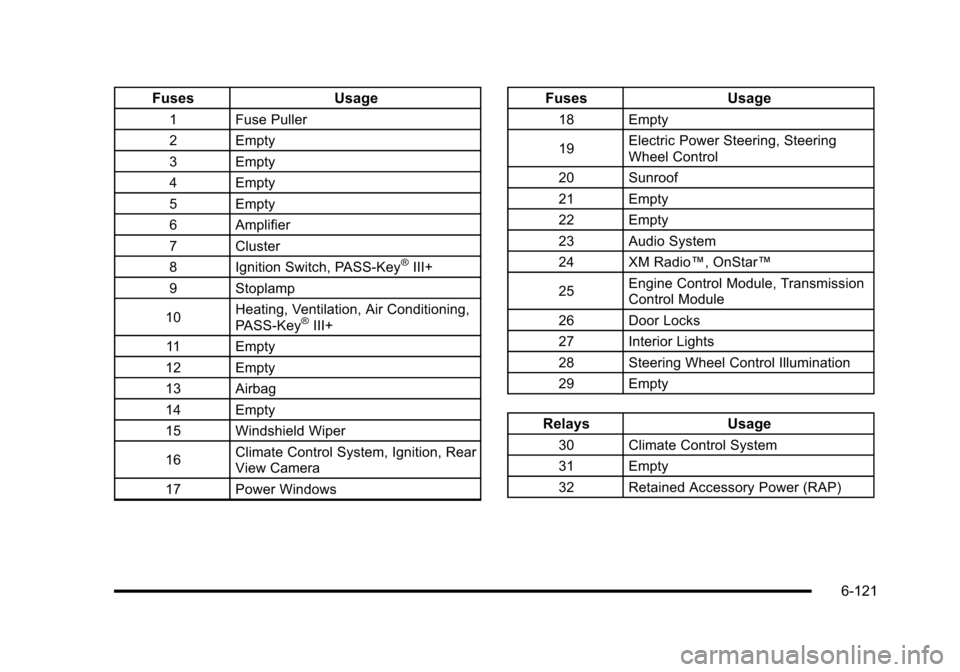

FusesUsage

1 Fuse Puller

2 Empty

3 Empty

4 Empty

5 Empty

6 Amplifier

7 Cluster

8 Ignition Switch, PASS-Key

®III+

9 Stoplamp

10 Heating, Ventilation, Air Conditioning,

PASS-Key

®III+

11 Empty

12 Empty

13 Airbag

14 Empty

15 Windshield Wiper

16 Climate Control System, Ignition, Rear

View Camera

17 Power Windows

Fuses Usage

18 Empty

19Electric Power Steering, Steering

Wheel Control

20 Sunroof

21 Empty

22 Empty

23 Audio System

24 XM Radio™, OnStar™

25 Engine Control Module, Transmission

Control Module

26 Door Locks

27 Interior Lights

28 Steering Wheel Control Illumination

29 Empty

Relays Usage

30 Climate Control System

31 Empty

32 Retained Accessory Power (RAP)

6-121

Page 425 of 480

FusesUsage

36 Power Windows

37 Power Seat (Option)

40 Cooling Fan

41 Engine Control Module

42 Cam Phaser (Turbo Only)

43 Engine Control Module, Transmission

44 Antilock Brake System (Option)

45 Injectors, Ignition Module

46 Backup Lamps

47 Heated Seat

49 Windshield Washer Pump

53 Fog Lamps (Option)

56Sensing and Diagnostic

Module (SDM)

Fuses

Usage

57 Antilock Brake System (Option)

58 Windshield Wiper Diode

59 Windshield Wiper

60 Horn

61 Antilock Brake System (Option)

62 Instrument Panel, Ignition

63 Driver Side High-Beam

64 Canister Vent

65 Driver Side Low-Beam

66 Passenger Side Low-Beam

67 Passenger Side High-Beam

69 Parking Lamps

6-123

Page 433 of 480

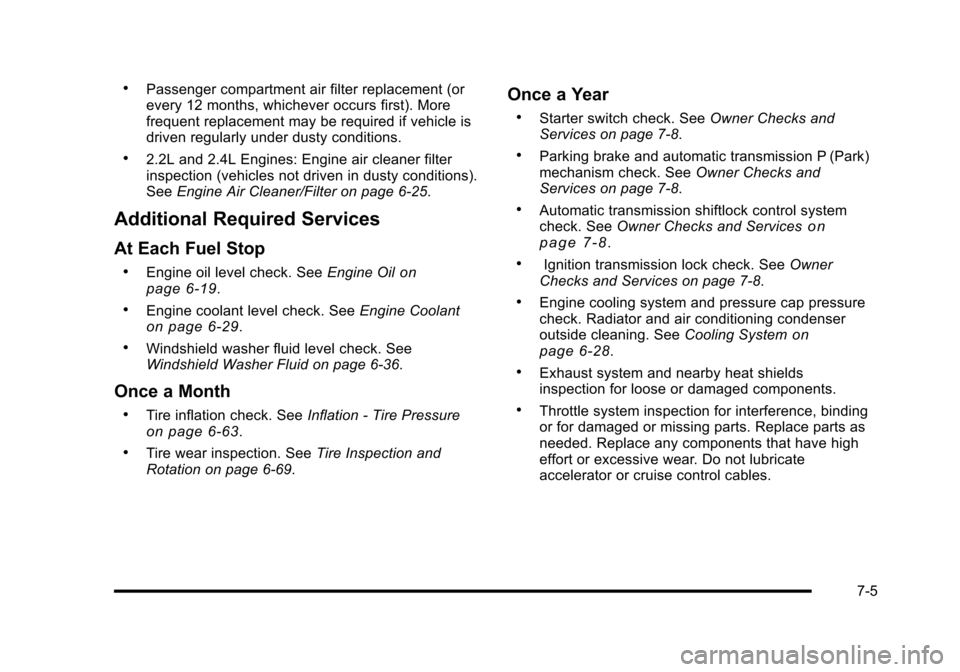

.Passenger compartment air filter replacement (or

every 12 months, whichever occurs first). More

frequent replacement may be required if vehicle is

driven regularly under dusty conditions.

.2.2L and 2.4L Engines: Engine air cleaner filter

inspection (vehicles not driven in dusty conditions).

SeeEngine Air Cleaner/Filter on page 6‑25.

Additional Required Services

At Each Fuel Stop

.Engine oil level check. See Engine Oilon

page 6‑19.

.Engine coolant level check. See Engine Coolanton page 6‑29.

.Windshield washer fluid level check. See

Windshield Washer Fluid on page 6‑36.

Once a Month

.Tire inflation check. SeeInflation - Tire Pressureon page 6‑63.

.Tire wear inspection. See Tire Inspection and

Rotation on page 6‑69.

Once a Year

.Starter switch check. See Owner Checks and

Services on page 7‑8.

.Parking brake and automatic transmission P (Park)

mechanism check. See Owner Checks and

Services on page 7‑8.

.Automatic transmission shiftlock control system

check. See Owner Checks and Serviceson

page 7‑8.

.Ignition transmission lock check. See Owner

Checks and Services on page 7‑8.

.Engine cooling system and pressure cap pressure

check. Radiator and air conditioning condenser

outside cleaning. See Cooling System

on

page 6‑28.

.Exhaust system and nearby heat shields

inspection for loose or damaged components.

.Throttle system inspection for interference, binding

or for damaged or missing parts. Replace parts as

needed. Replace any components that have high

effort or excessive wear. Do not lubricate

accelerator or cruise control cables.

7-5

Page 436 of 480

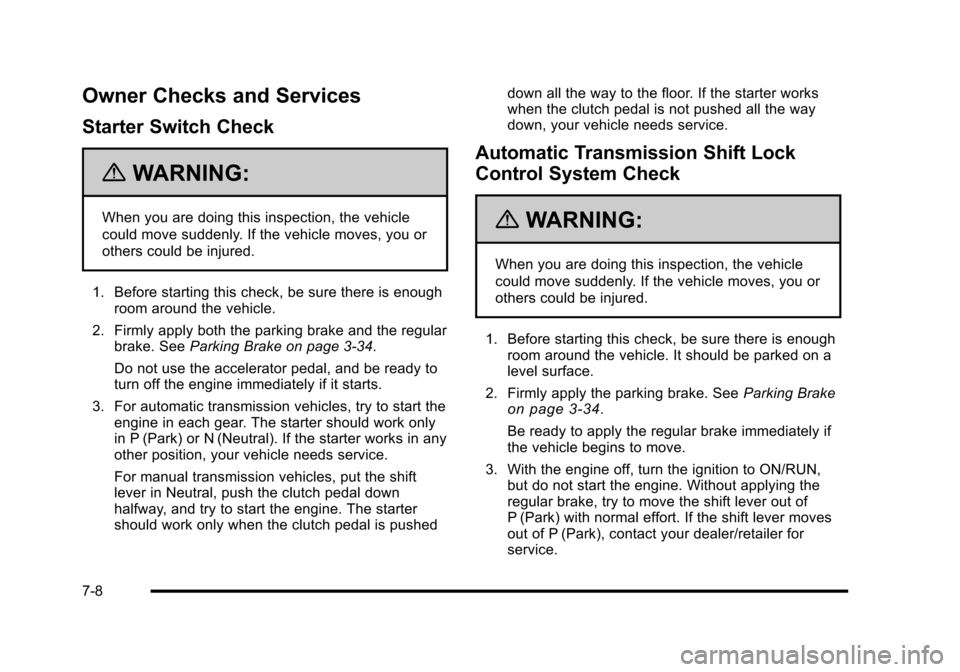

Owner Checks and Services

Starter Switch Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough room around the vehicle.

2. Firmly apply both the parking brake and the regular brake. See Parking Brake on page 3‑34.

Do not use the accelerator pedal, and be ready to

turn off the engine immediately if it starts.

3. For automatic transmission vehicles, try to start the engine in each gear. The starter should work only

in P (Park) or N (Neutral). If the starter works in any

other position, your vehicle needs service.

For manual transmission vehicles, put the shift

lever in Neutral, push the clutch pedal down

halfway, and try to start the engine. The starter

should work only when the clutch pedal is pushed down all the way to the floor. If the starter works

when the clutch pedal is not pushed all the way

down, your vehicle needs service.

Automatic Transmission Shift Lock

Control System Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enough room around the vehicle. It should be parked on a

level surface.

2. Firmly apply the parking brake. See Parking Brake

on page 3‑34.

Be ready to apply the regular brake immediately if

the vehicle begins to move.

3. With the engine off, turn the ignition to ON/RUN, but do not start the engine. Without applying the

regular brake, try to move the shift lever out of

P (Park) with normal effort. If the shift lever moves

out of P (Park), contact your dealer/retailer for

service.

7-8

Page 437 of 480

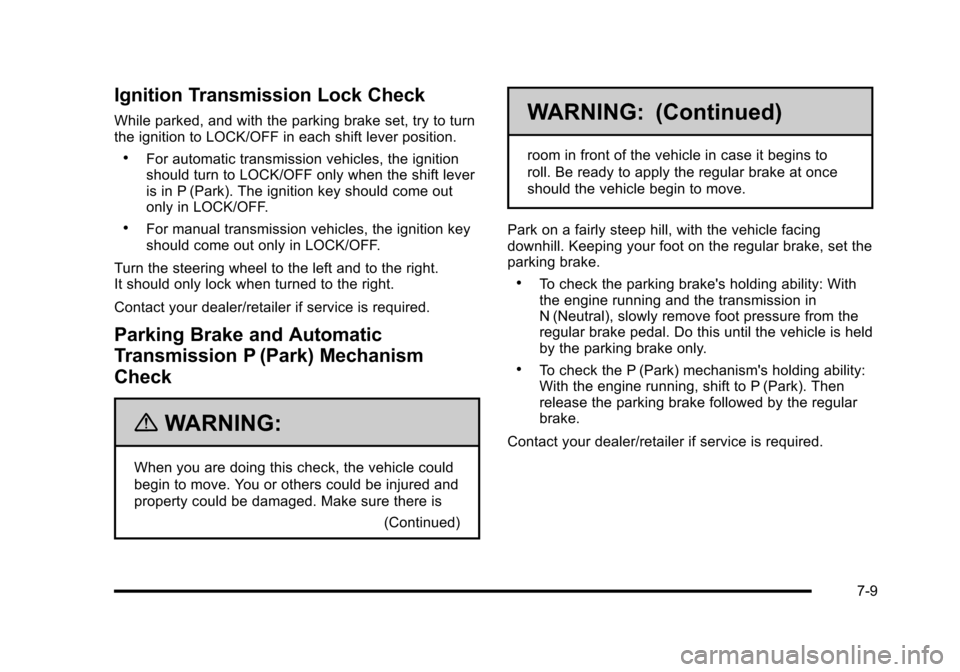

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turn

the ignition to LOCK/OFF in each shift lever position.

.For automatic transmission vehicles, the ignition

should turn to LOCK/OFF only when the shift lever

is in P (Park). The ignition key should come out

only in LOCK/OFF.

.For manual transmission vehicles, the ignition key

should come out only in LOCK/OFF.

Turn the steering wheel to the left and to the right.

It should only lock when turned to the right.

Contact your dealer/retailer if service is required.

Parking Brake and Automatic

Transmission P (Park) Mechanism

Check

{WARNING:

When you are doing this check, the vehicle could

begin to move. You or others could be injured and

property could be damaged. Make sure there is (Continued)

WARNING: (Continued)

room in front of the vehicle in case it begins to

roll. Be ready to apply the regular brake at once

should the vehicle begin to move.

Park on a fairly steep hill, with the vehicle facing

downhill. Keeping your foot on the regular brake, set the

parking brake.

.To check the parking brake's holding ability: With

the engine running and the transmission in

N (Neutral), slowly remove foot pressure from the

regular brake pedal. Do this until the vehicle is held

by the parking brake only.

.To check the P (Park) mechanism's holding ability:

With the engine running, shift to P (Park). Then

release the parking brake followed by the regular

brake.

Contact your dealer/retailer if service is required.

7-9

Page 461 of 480

Navigation System

If your vehicle has a navigation system, use of the

system may result in the storage of destinations,

addresses, telephone numbers, and other trip

information. Refer to the navigation system operating

manual for information on stored data and for deletion

instructions.

Radio Frequency

Identification (RFID)

RFID technology is used in some vehicles for functions

such as tire pressure monitoring and ignition system

security, as well as in connection with conveniences

such as key fobs for remote door locking/unlocking and

starting, and in-vehicle transmitters for garage door

openers. RFID technology in GM vehicles does not

use or record personal information or link with any other

GM system containing personal information.

Radio Frequency Statement

This vehicle has systems that operate on a radio

frequency that comply with Part 15 of the Federal

Communications Commission (FCC) Rules and with

RSS-210/211 of Industry Canada.

Operation is subject to the following two conditions:1. The device may not cause interference.

2. The device must accept any interference received, including interference that may cause undesired

operation of the device.

Changes or modifications to any of these systems by

other than an authorized service facility could void

authorization to use this equipment.

8-17

Page 469 of 480

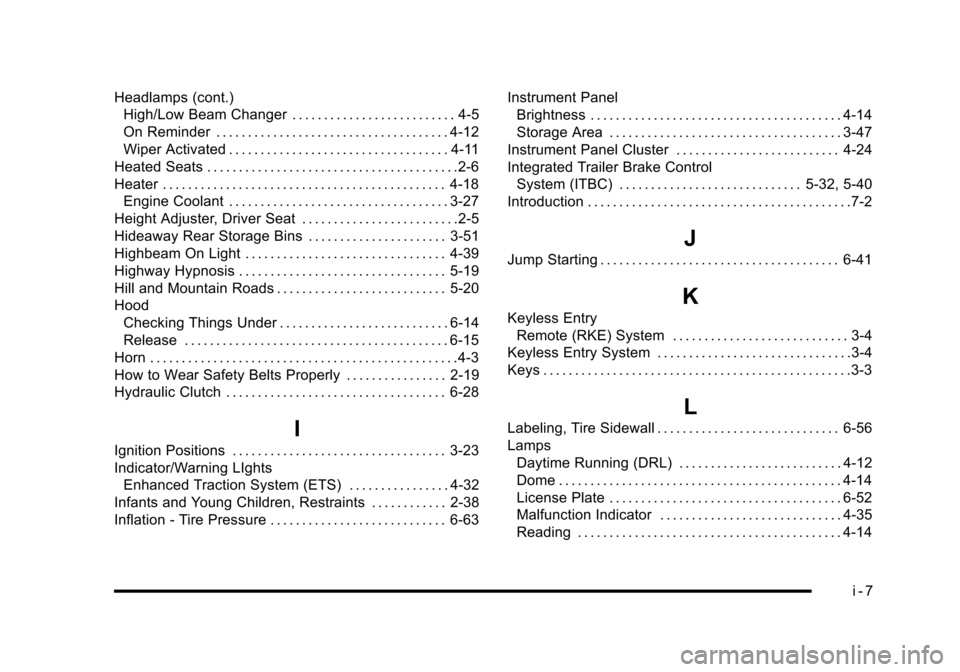

Headlamps (cont.)High/Low Beam Changer . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

On Reminder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Wiper Activated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Heated Seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18 Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Height Adjuster, Driver Seat . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Hideaway Rear Storage Bins . . . . . . . . . . . . . . . . . . . . . . 3-51

Highbeam On Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Highway Hypnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Hill and Mountain Roads . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Hood Checking Things Under . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

How to Wear Safety Belts Properly . . . . . . . . . . . . . . . . 2-19

Hydraulic Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

I

Ignition Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Indicator/Warning LIghts Enhanced Traction System (ETS) . . . . . . . . . . . . . . . . 4-32

Infants and Young Children, Restraints . . . . . . . . . . . . 2-38

Inflation - Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-63 Instrument Panel

Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Storage Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Instrument Panel Cluster . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Integrated Trailer Brake Control System (ITBC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32, 5-40

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

J

Jump Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-41

K

Keyless Entry

Remote (RKE) System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Keyless Entry System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

L

Labeling, Tire Sidewall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-56

Lamps Daytime Running (DRL) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

License Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-52

Malfunction Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

i - 7