CHEVROLET IMPALA 2007 9.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2007, Model line: IMPALA, Model: CHEVROLET IMPALA 2007 9.GPages: 460, PDF Size: 2.56 MB

Page 341 of 460

{CAUTION:

Fans or other moving engine parts can

injure you badly. Keep your hands away

from moving parts once the engine is

running.

5. Check that the jumper cables do not have

loose or missing insulation. If they do, you

could get a shock. The vehicles could

be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+)

will go to positive (+) or to a remote

positive (+) terminal if the vehicle has one.

Negative (−) will go to a heavy, unpainted

metal engine part or to a remote negative (−)

terminal if the vehicle has one.

Do not connect positive (+) to negative (−),

or you will get a short that would damage the

battery and maybe other parts too. And do

not connect the negative (−) cable to the

negative (−) terminal on the dead battery

because this can cause sparks.6. Connect the red positive (+) cable to the

positive (+) terminal location of the vehicle

with the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect

it to the positive (+) terminal location of the

vehicle with the good battery. Use a remote

positive (+) terminal if the vehicle has one.

8. Now connect the black negative (−) cable

to the negative (−) terminal location of the

vehicle with the good battery. Use a remote

negative (−) terminal if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−)

cable does not go to the dead battery. It goes

to a heavy, unpainted metal engine part or to a

remote negative (−) terminal on the vehicle with

the dead battery.

341

Page 342 of 460

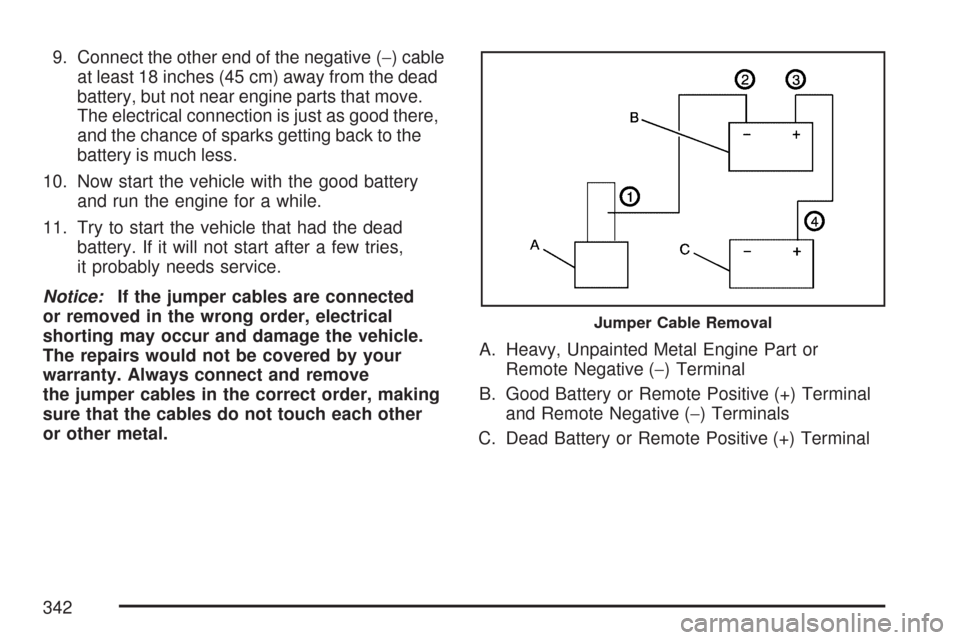

9. Connect the other end of the negative (−) cable

at least 18 inches (45 cm) away from the dead

battery, but not near engine parts that move.

The electrical connection is just as good there,

and the chance of sparks getting back to the

battery is much less.

10. Now start the vehicle with the good battery

and run the engine for a while.

11. Try to start the vehicle that had the dead

battery. If it will not start after a few tries,

it probably needs service.

Notice:If the jumper cables are connected

or removed in the wrong order, electrical

shorting may occur and damage the vehicle.

The repairs would not be covered by your

warranty. Always connect and remove

the jumper cables in the correct order, making

sure that the cables do not touch each other

or other metal.A. Heavy, Unpainted Metal Engine Part or

Remote Negative (−) Terminal

B. Good Battery or Remote Positive (+) Terminal

and Remote Negative (−) Terminals

C. Dead Battery or Remote Positive (+) Terminal

Jumper Cable Removal

342

Page 343 of 460

To disconnect the jumper cables from both

vehicles, do the following:

1. Disconnect the black negative (−) cable from

the vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from

the vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the

other vehicle.

5. Return the fuse block cover to its original

position.Headlamp Aiming

Headlamp aim has been preset at the factory and

should need no further adjustment.

However, if your vehicle is damaged in an accident,

the headlamp aim may be affected. Aim adjustment

to the low-beam headlamps may be necessary if it

is difficult to see the lane markers (for horizontal

aim), or if oncoming drivers �ash their high-beam

headlamps at you (for vertical aim).

If you believe your headlamps need to be

re-aimed, it is recommend that you take the vehicle

to your dealer for service.

Bulb Replacement

For the proper type of replacement bulbs,

seeReplacement Bulbs on page 349.

For any bulb changing procedure not listed in this

section, contact your dealer.

343

Page 344 of 460

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas

inside and can burst if you drop or

scratch the bulb. You or others could be

injured. Be sure to read and follow the

instructions on the bulb package.

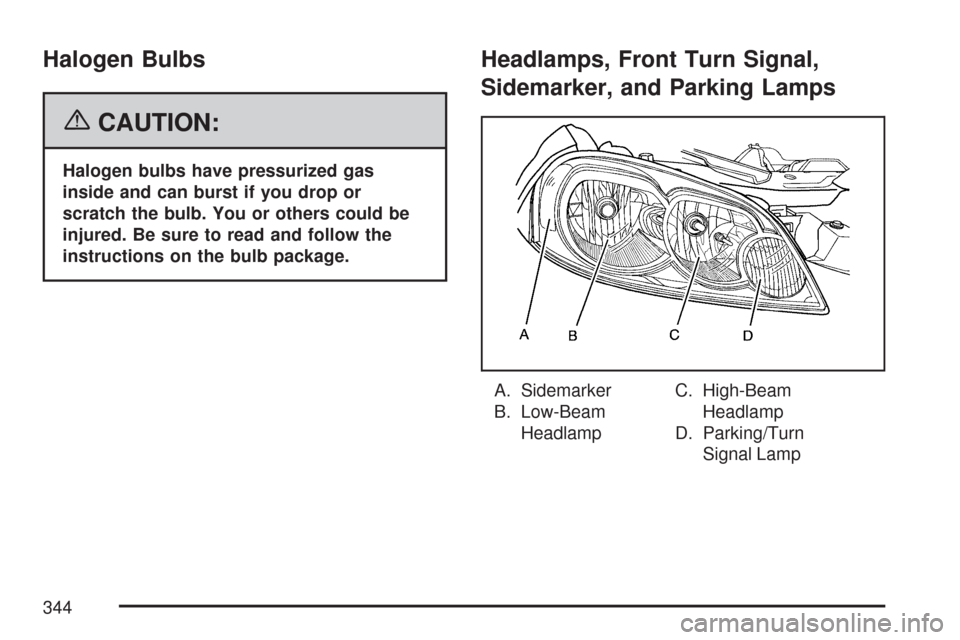

Headlamps, Front Turn Signal,

Sidemarker, and Parking Lamps

A. Sidemarker

B. Low-Beam

HeadlampC. High-Beam

Headlamp

D. Parking/Turn

Signal Lamp

344

Page 345 of 460

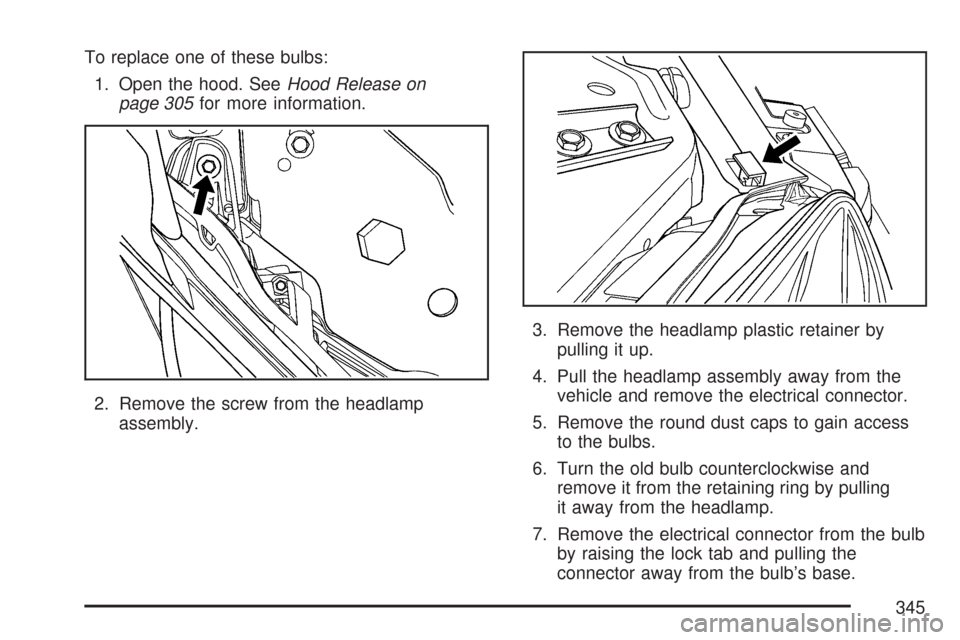

To replace one of these bulbs:

1. Open the hood. SeeHood Release on

page 305for more information.

2. Remove the screw from the headlamp

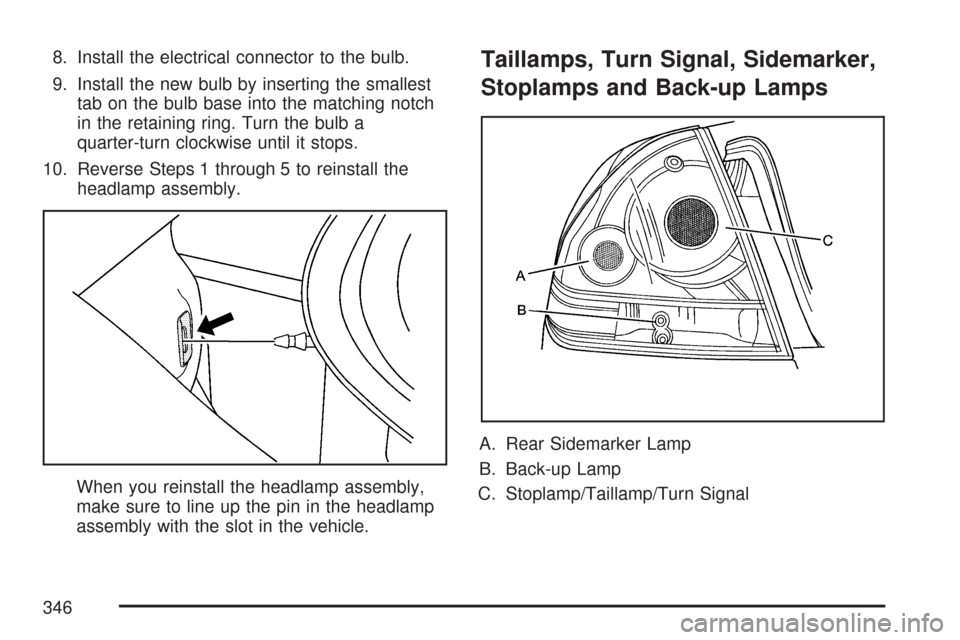

assembly.3. Remove the headlamp plastic retainer by

pulling it up.

4. Pull the headlamp assembly away from the

vehicle and remove the electrical connector.

5. Remove the round dust caps to gain access

to the bulbs.

6. Turn the old bulb counterclockwise and

remove it from the retaining ring by pulling

it away from the headlamp.

7. Remove the electrical connector from the bulb

by raising the lock tab and pulling the

connector away from the bulb’s base.

345

Page 346 of 460

8. Install the electrical connector to the bulb.

9. Install the new bulb by inserting the smallest

tab on the bulb base into the matching notch

in the retaining ring. Turn the bulb a

quarter-turn clockwise until it stops.

10. Reverse Steps 1 through 5 to reinstall the

headlamp assembly.

When you reinstall the headlamp assembly,

make sure to line up the pin in the headlamp

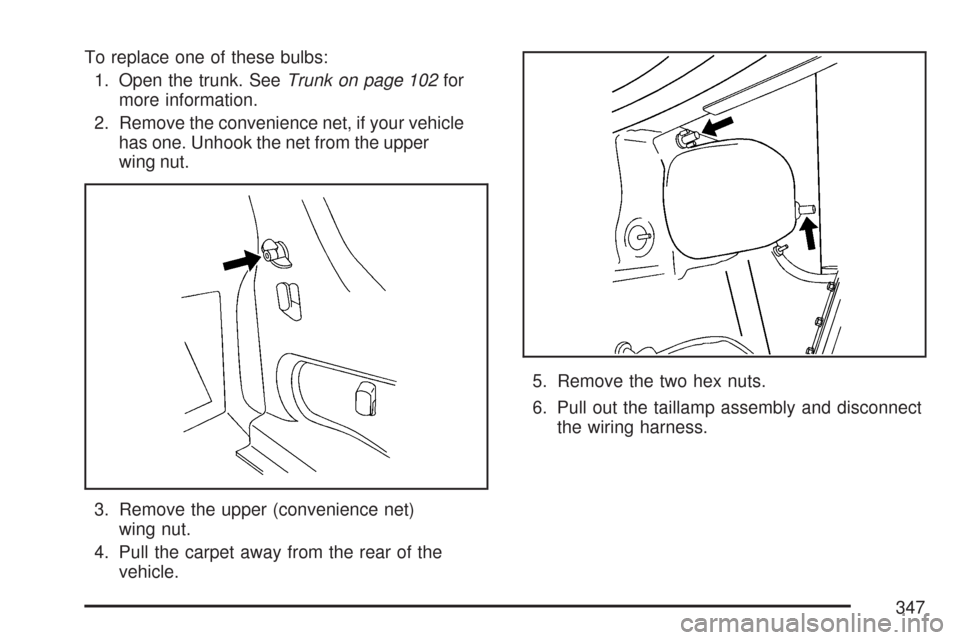

assembly with the slot in the vehicle.Taillamps, Turn Signal, Sidemarker,

Stoplamps and Back-up Lamps

A. Rear Sidemarker Lamp

B. Back-up Lamp

C. Stoplamp/Taillamp/Turn Signal

346

Page 347 of 460

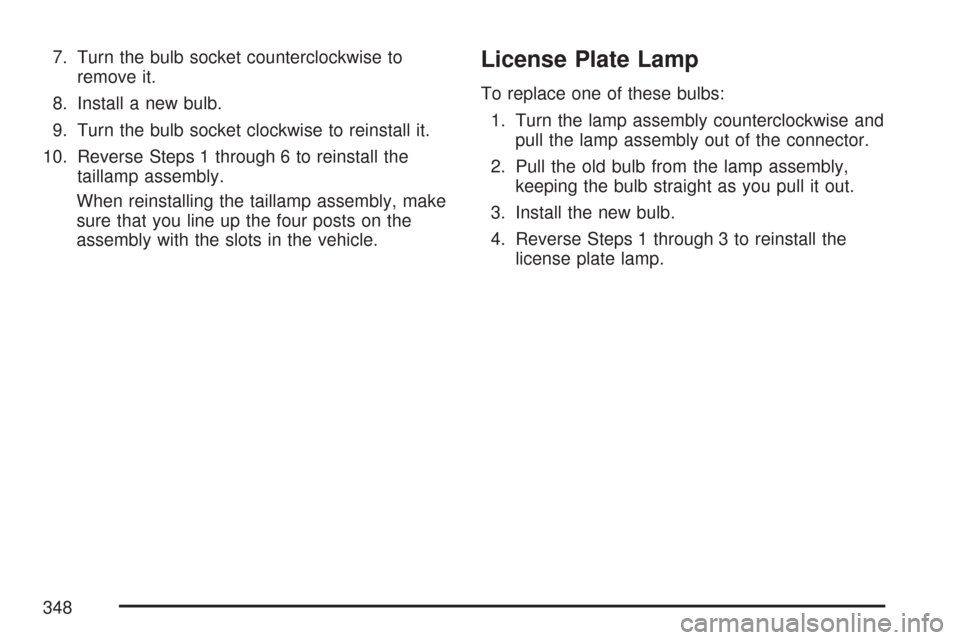

To replace one of these bulbs:

1. Open the trunk. SeeTrunk on page 102for

more information.

2. Remove the convenience net, if your vehicle

has one. Unhook the net from the upper

wing nut.

3. Remove the upper (convenience net)

wing nut.

4. Pull the carpet away from the rear of the

vehicle.5. Remove the two hex nuts.

6. Pull out the taillamp assembly and disconnect

the wiring harness.

347

Page 348 of 460

7. Turn the bulb socket counterclockwise to

remove it.

8. Install a new bulb.

9. Turn the bulb socket clockwise to reinstall it.

10. Reverse Steps 1 through 6 to reinstall the

taillamp assembly.

When reinstalling the taillamp assembly, make

sure that you line up the four posts on the

assembly with the slots in the vehicle.License Plate Lamp

To replace one of these bulbs:

1. Turn the lamp assembly counterclockwise and

pull the lamp assembly out of the connector.

2. Pull the old bulb from the lamp assembly,

keeping the bulb straight as you pull it out.

3. Install the new bulb.

4. Reverse Steps 1 through 3 to reinstall the

license plate lamp.

348

Page 349 of 460

Replacement Bulbs

Exterior Lamp Bulb Number

Back-Up 921

Front Parking/Turn Signal 3157NAK

License Plate Lamp 194

Headlamps

High-Beam H9

Low-Beam H11

Sidemarker 194

Stoplamp, Taillamp, and

Turn Signal3057

For replacement bulbs not listed here, contact

your dealer/retailer.

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for

wear or cracking. SeeScheduled Maintenance

on page 408for more information on wiper blade

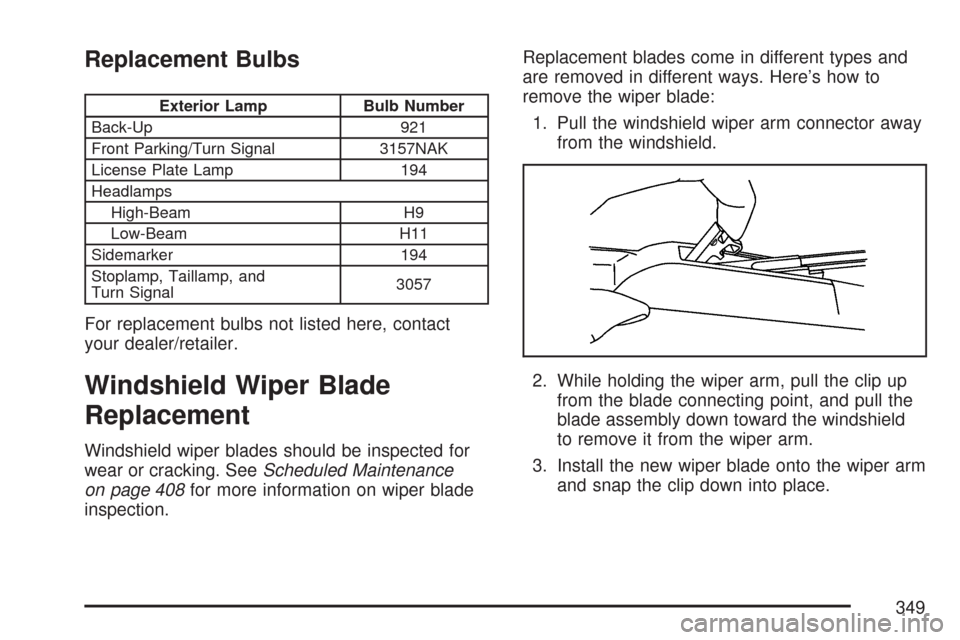

inspection.Replacement blades come in different types and

are removed in different ways. Here’s how to

remove the wiper blade:

1. Pull the windshield wiper arm connector away

from the windshield.

2. While holding the wiper arm, pull the clip up

from the blade connecting point, and pull the

blade assembly down toward the windshield

to remove it from the wiper arm.

3. Install the new wiper blade onto the wiper arm

and snap the clip down into place.

349

Page 350 of 460

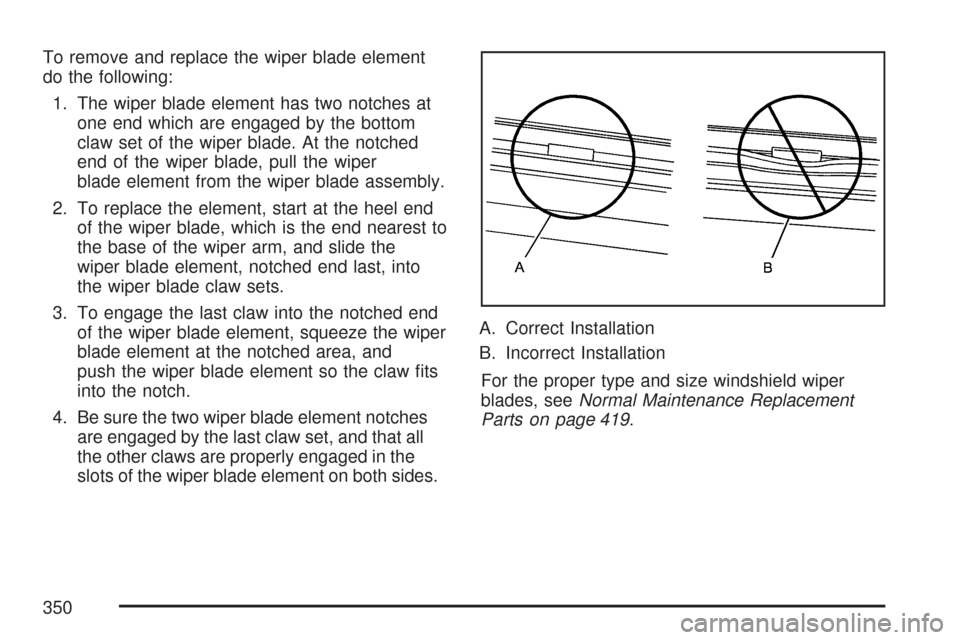

To remove and replace the wiper blade element

do the following:

1. The wiper blade element has two notches at

one end which are engaged by the bottom

claw set of the wiper blade. At the notched

end of the wiper blade, pull the wiper

blade element from the wiper blade assembly.

2. To replace the element, start at the heel end

of the wiper blade, which is the end nearest to

the base of the wiper arm, and slide the

wiper blade element, notched end last, into

the wiper blade claw sets.

3. To engage the last claw into the notched end

of the wiper blade element, squeeze the wiper

blade element at the notched area, and

push the wiper blade element so the claw �ts

into the notch.

4. Be sure the two wiper blade element notches

are engaged by the last claw set, and that all

the other claws are properly engaged in the

slots of the wiper blade element on both sides.A. Correct Installation

B. Incorrect Installation

For the proper type and size windshield wiper

blades, seeNormal Maintenance Replacement

Parts on page 419.

350