engine CHEVROLET IMPALA 2010 9.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: IMPALA, Model: CHEVROLET IMPALA 2010 9.GPages: 432, PDF Size: 1.89 MB

Page 311 of 432

{

WARNING:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing this,

and some have been blinded. Use a flashlight if

you need more light.

Be sure the battery has enough water. You do not

need to add water to the battery installed in your

new vehicle. But if a battery has filler caps, be

sure the right amount of fluid is there. If it is low,

add water to take care of that first. If you do not,

explosive gas could be present.

Battery fluid contains acid that can burn you.

Do not get it on you. If you accidentally get it in

your eyes or on your skin, flush the place with

water and get medical help immediately.

{

WARNING:

Fans or other moving engine parts can injure you

badly. Keep your hands away from moving parts

once the engine is running.

5. Check that the jumper cables do not have loose

or missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (−) will go to a heavy,

unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−), or you

will get a short that would damage the battery

and maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

the dead battery because this can cause sparks.

6-41

Page 312 of 432

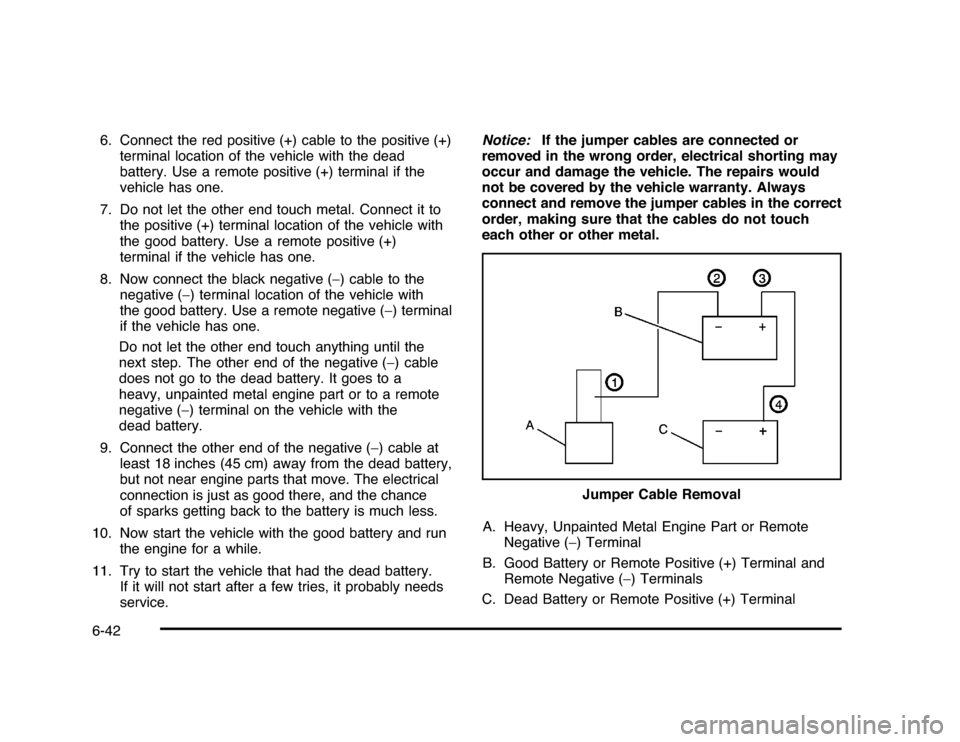

6. Connect the red positive (+) cable to the positive (+)

terminal location of the vehicle with the dead

battery. Use a remote positive (+) terminal if the

vehicle has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal location of the vehicle with

the good battery. Use a remote positive (+)

terminal if the vehicle has one.

8. Now connect the black negative (−) cable to the

negative (−) terminal location of the vehicle with

the good battery. Use a remote negative (−) terminal

if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (−) cable

does not go to the dead battery. It goes to a

heavy, unpainted metal engine part or to a remote

negative (−) terminal on the vehicle with the

dead battery.

9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably needs

service.Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by the vehicle warranty. Always

connect and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal

B. Good Battery or Remote Positive (+) Terminal and

Remote Negative (−) Terminals

C. Dead Battery or Remote Positive (+) TerminalJumper Cable Removal6-42

Page 325 of 432

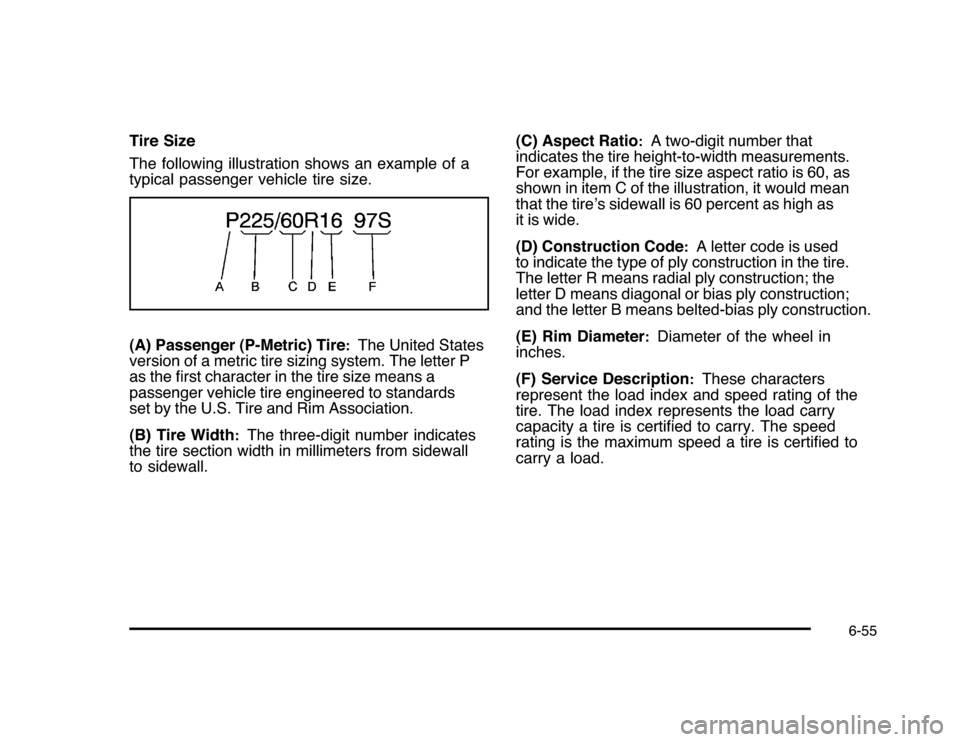

Tire Size

The following illustration shows an example of a

typical passenger vehicle tire size.

(A) Passenger (P-Metric) Tire

:

The United States

version of a metric tire sizing system. The letter P

as the first character in the tire size means a

passenger vehicle tire engineered to standards

set by the U.S. Tire and Rim Association.

(B) Tire Width

:

The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.(C) Aspect Ratio

:

A two-digit number that

indicates the tire height-to-width measurements.

For example, if the tire size aspect ratio is 60, as

shown in item C of the illustration, it would mean

that the tire’s sidewall is 60 percent as high as

it is wide.

(D) Construction Code

:

A letter code is used

to indicate the type of ply construction in the tire.

The letter R means radial ply construction; the

letter D means diagonal or bias ply construction;

and the letter B means belted-bias ply construction.

(E) Rim Diameter

:

Diameter of the wheel in

inches.

(F) Service Description

:

These characters

represent the load index and speed rating of the

tire. The load index represents the load carry

capacity a tire is certified to carry. The speed

rating is the maximum speed a tire is certified to

carry a load.

6-55

Page 334 of 432

TPMS Sensor Matching ProcessEach TPMS sensor has a unique identification code.

Any time you rotate your vehicle’s tires or replace one or

more of the TPMS sensors, the identification codes

will need to be matched to the new tire/wheel position.

The sensors are matched to the tire/wheel positions

in the following order: driver side front tire, passenger

side front tire, passenger side rear tire, and driver

side rear tire using a TPMS diagnostic tool. See your

dealer/retailer for service.

The TPMS sensors can also be matched to each

tire/wheel position by increasing or decreasing the tire’s

air pressure. If increasing the tire’s air pressure, do

not exceed the maximum inflation pressure indicated on

the tire’s sidewall.

To decrease air-pressure out of a tire you can use the

pointed end of the valve cap, a pencil-style air pressure

gage, or a key.

You have two minutes to match the first tire/wheel

position, and five minutes overall to match all four

tire/wheel positions. If it takes longer than two minutes, to

match the first tire and wheel, or more than five minutes

to match all four tire and wheel positions the matching

process stops and you need to start over.The TPMS sensor matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with the

engine off.

3. Press the Remote Keyless Entry (RKE) transmitter’s

lock and unlock buttons at the same time for

approximately five seconds. The horn sounds twice

to signal the receiver is in relearn mode and TIRE

LEARNING ACTIVE message displays on the DIC

screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPMS sensor by increasing or

decreasing the tire’s air pressure for five seconds,

or until a horn chirp sounds. The horn chirp,

which may take up to 30 seconds to sound,

confirms that the sensor identification code has

been matched to this tire and wheel position.

6. Proceed to the passenger side front tire, and repeat

the procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeat

the procedure in Step 5.

6-64

Page 345 of 432

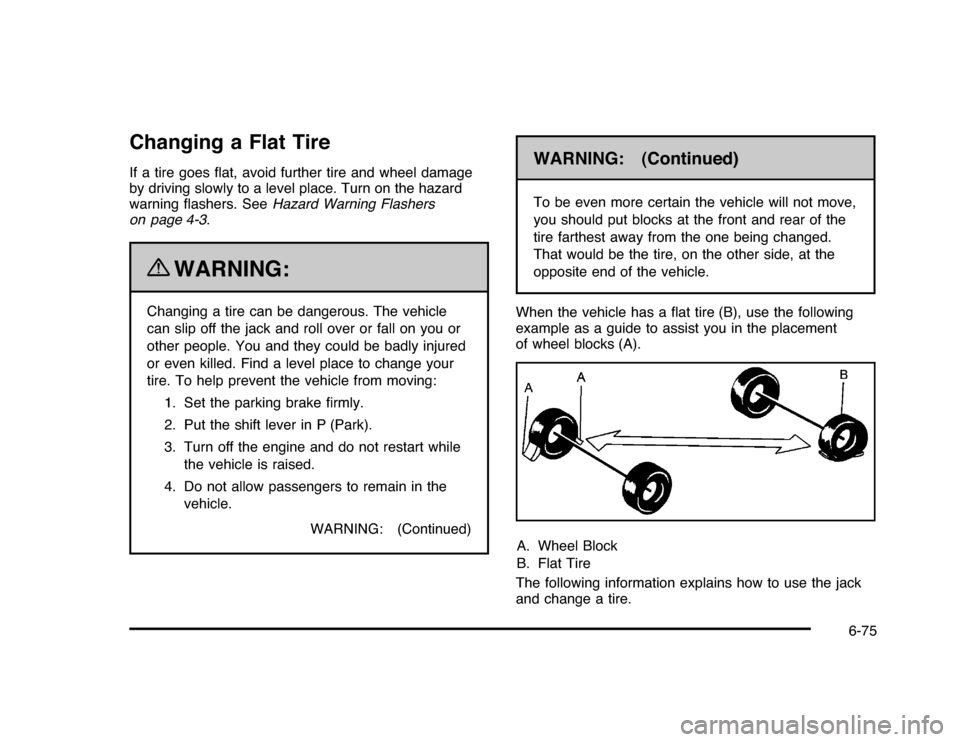

Changing a Flat TireIf a tire goes flat, avoid further tire and wheel damage

by driving slowly to a level place. Turn on the hazard

warning flashers. SeeHazard Warning Flashers

on page 4-3.

{

WARNING:

Changing a tire can be dangerous. The vehicle

can slip off the jack and roll over or fall on you or

other people. You and they could be badly injured

or even killed. Find a level place to change your

tire. To help prevent the vehicle from moving:

1. Set the parking brake firmly.

2. Put the shift lever in P (Park).

3. Turn off the engine and do not restart while

the vehicle is raised.

4. Do not allow passengers to remain in the

vehicle.

WARNING: (Continued)

WARNING: (Continued)To be even more certain the vehicle will not move,

you should put blocks at the front and rear of the

tire farthest away from the one being changed.

That would be the tire, on the other side, at the

opposite end of the vehicle.

When the vehicle has a flat tire (B), use the following

example as a guide to assist you in the placement

of wheel blocks (A).

A. Wheel Block

B. Flat Tire

The following information explains how to use the jack

and change a tire.

6-75

Page 365 of 432

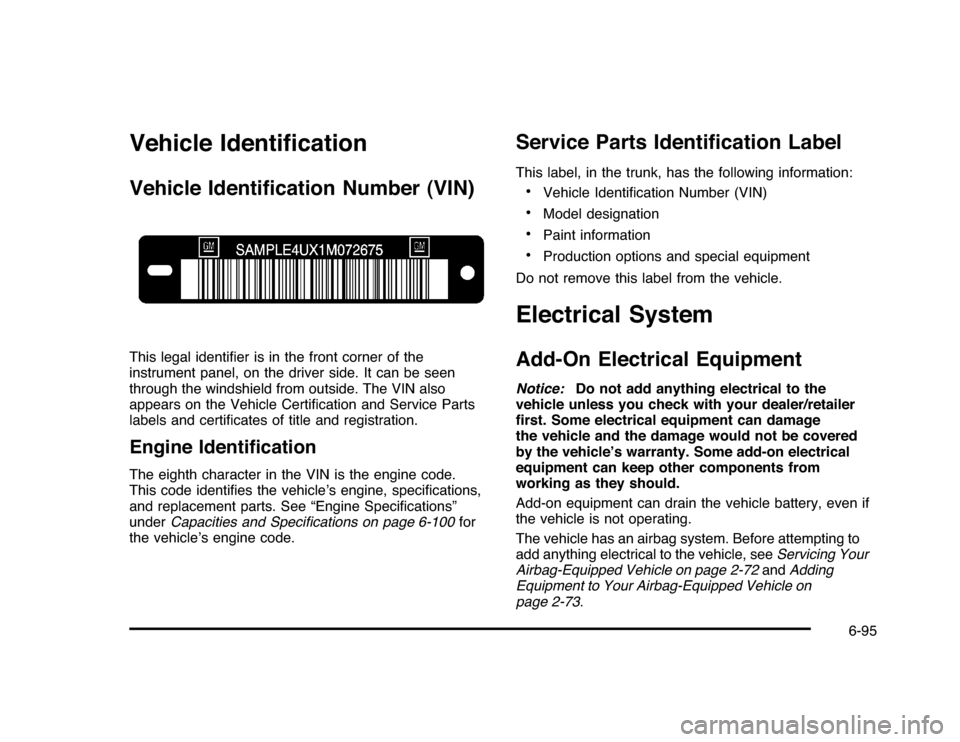

Vehicle IdentificationVehicle Identification Number (VIN)This legal identifier is in the front corner of the

instrument panel, on the driver side. It can be seen

through the windshield from outside. The VIN also

appears on the Vehicle Certification and Service Parts

labels and certificates of title and registration.Engine IdentificationThe eighth character in the VIN is the engine code.

This code identifies the vehicle’s engine, specifications,

and replacement parts. See “Engine Specifications”

underCapacities and Specifications on page 6-100for

the vehicle’s engine code.

Service Parts Identification LabelThis label, in the trunk, has the following information:•

Vehicle Identification Number (VIN)

•

Model designation

•

Paint information

•

Production options and special equipment

Do not remove this label from the vehicle.

Electrical SystemAdd-On Electrical EquipmentNotice:Do not add anything electrical to the

vehicle unless you check with your dealer/retailer

first. Some electrical equipment can damage

the vehicle and the damage would not be covered

by the vehicle’s warranty. Some add-on electrical

equipment can keep other components from

working as they should.

Add-on equipment can drain the vehicle battery, even if

the vehicle is not operating.

The vehicle has an airbag system. Before attempting to

add anything electrical to the vehicle, seeServicing Your

Airbag-Equipped Vehicle on page 2-72andAdding

Equipment to Your Airbag-Equipped Vehicle on

page 2-73.

6-95

Page 367 of 432

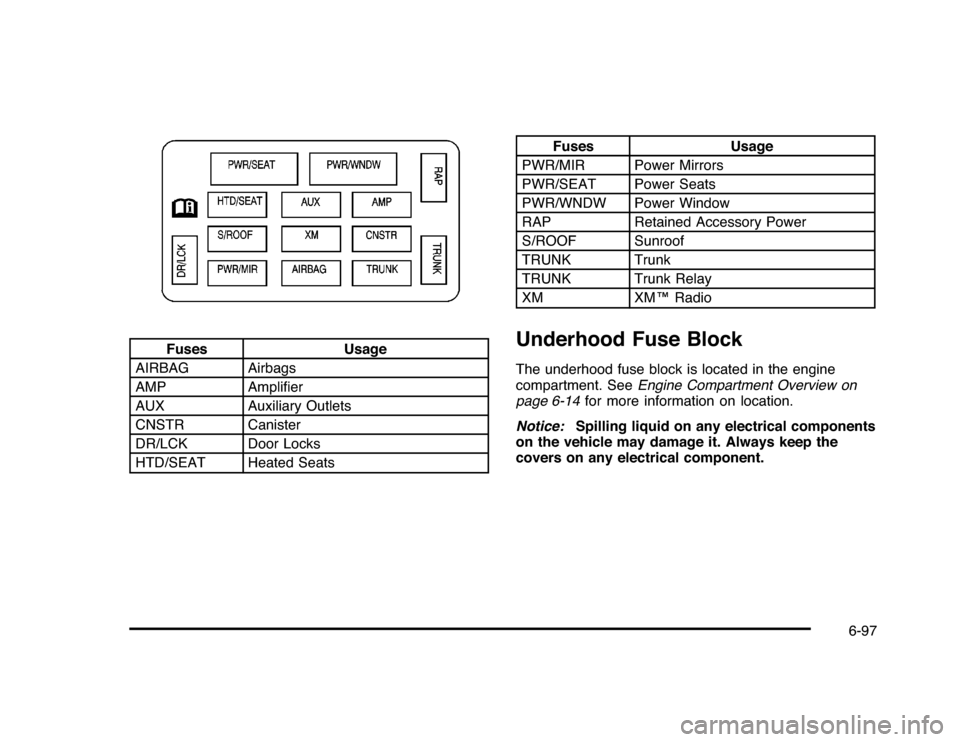

Fuses Usage

AIRBAG Airbags

AMP Amplifier

AUX Auxiliary Outlets

CNSTR Canister

DR/LCK Door Locks

HTD/SEAT Heated Seats

Fuses Usage

PWR/MIR Power Mirrors

PWR/SEAT Power Seats

PWR/WNDW Power Window

RAP Retained Accessory Power

S/ROOF Sunroof

TRUNK Trunk

TRUNK Trunk Relay

XM XM™ Radio

Underhood Fuse BlockThe underhood fuse block is located in the engine

compartment. SeeEngine Compartment Overview on

page 6-14for more information on location.

Notice:Spilling liquid on any electrical components

on the vehicle may damage it. Always keep the

covers on any electrical component.

6-97

Page 368 of 432

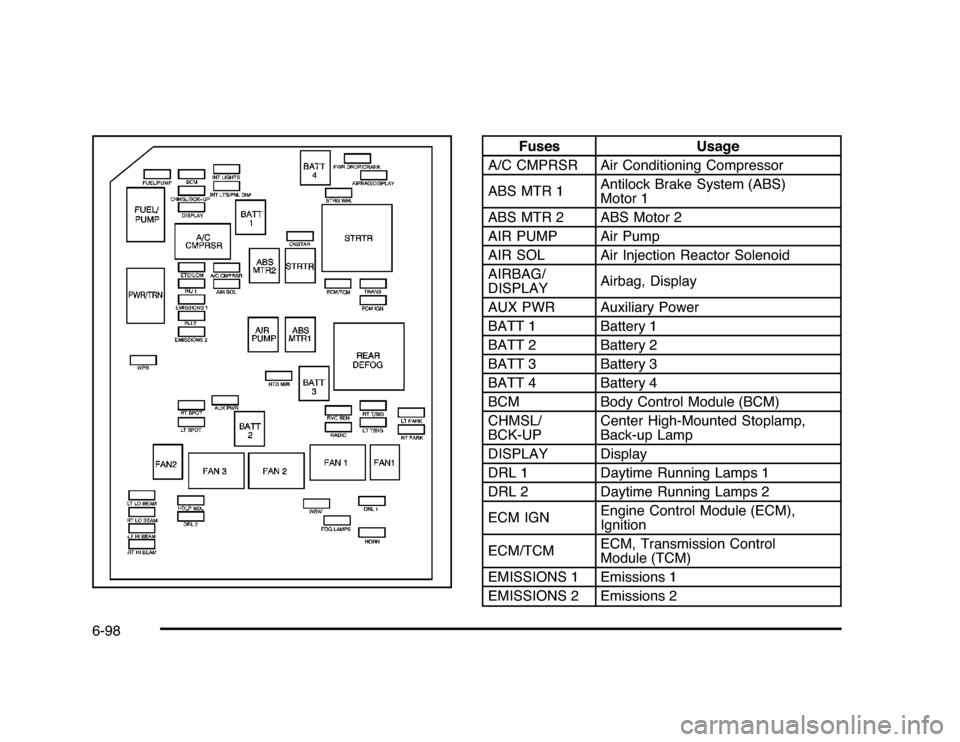

Fuses Usage

A/C CMPRSR Air Conditioning Compressor

ABS MTR 1Antilock Brake System (ABS)

Motor 1

ABS MTR 2 ABS Motor 2

AIR PUMP Air Pump

AIR SOL Air Injection Reactor Solenoid

AIRBAG/

DISPLAYAirbag, Display

AUX PWR Auxiliary Power

BATT 1 Battery 1

BATT 2 Battery 2

BATT 3 Battery 3

BATT 4 Battery 4

BCM Body Control Module (BCM)

CHMSL/

BCK-UPCenter High-Mounted Stoplamp,

Back-up Lamp

DISPLAY Display

DRL 1 Daytime Running Lamps 1

DRL 2 Daytime Running Lamps 2

ECM IGNEngine Control Module (ECM),

Ignition

ECM/TCMECM, Transmission Control

Module (TCM)

EMISSIONS 1 Emissions 1

EMISSIONS 2 Emissions 2

6-98

Page 370 of 432

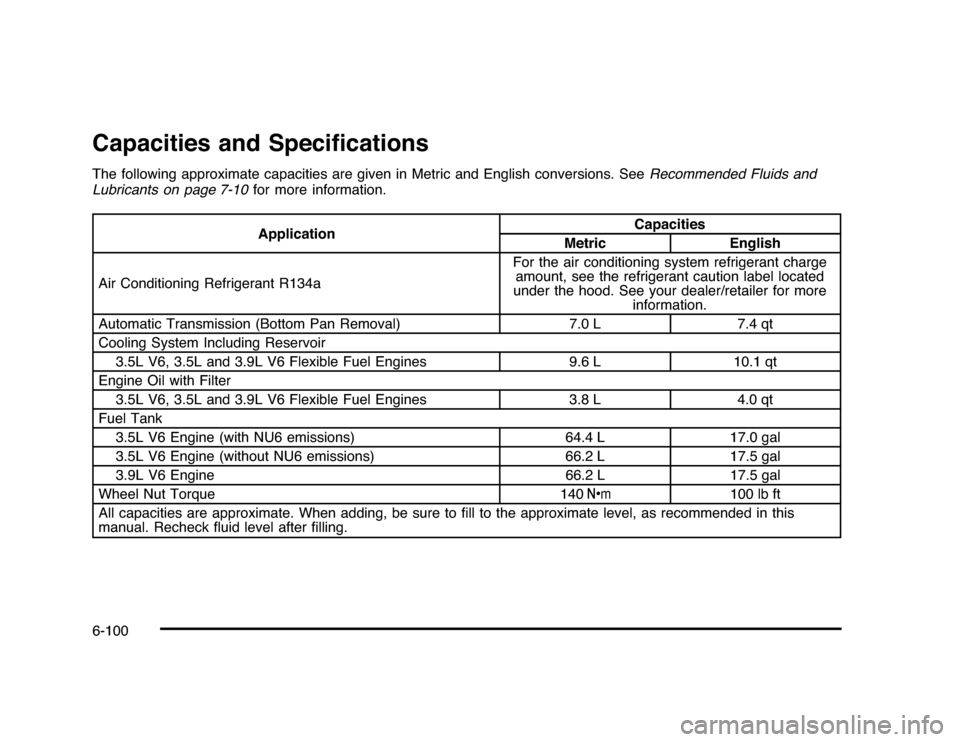

Capacities and SpecificationsThe following approximate capacities are given in Metric and English conversions. SeeRecommended Fluids and

Lubricants on page 7-10for more information.

ApplicationCapacities

Metric English

Air Conditioning Refrigerant R134aFor the air conditioning system refrigerant charge

amount, see the refrigerant caution label located

under the hood. See your dealer/retailer for more

information.

Automatic Transmission (Bottom Pan Removal) 7.0 L 7.4 qt

Cooling System Including Reservoir

3.5L V6, 3.5L and 3.9L V6 Flexible Fuel Engines 9.6 L 10.1 qt

Engine Oil with Filter

3.5L V6, 3.5L and 3.9L V6 Flexible Fuel Engines 3.8 L 4.0 qt

Fuel Tank

3.5L V6 Engine (with NU6 emissions) 64.4 L 17.0 gal

3.5L V6 Engine (without NU6 emissions) 66.2 L 17.5 gal

3.9L V6 Engine 66.2 L 17.5 gal

Wheel Nut Torque 140Y100 lb ft

All capacities are approximate. When adding, be sure to fill to the approximate level, as recommended in this

manual. Recheck fluid level after filling.

6-100

Page 371 of 432

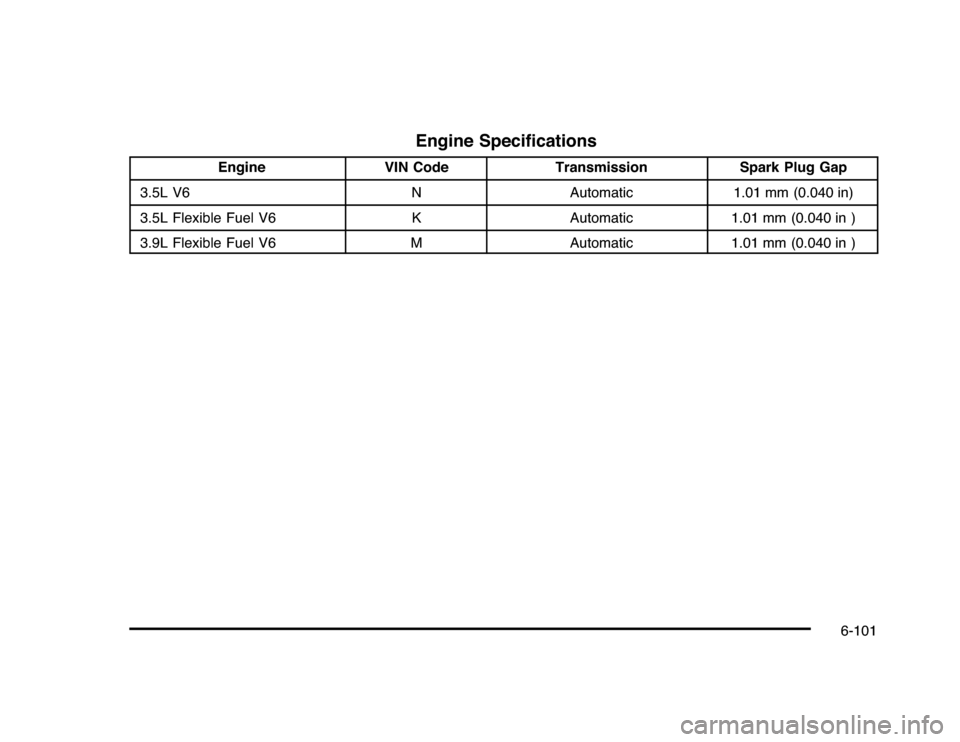

Engine Specifications

Engine VIN Code Transmission Spark Plug Gap

3.5L V6 N Automatic 1.01 mm (0.040 in)

3.5L Flexible Fuel V6 K Automatic 1.01 mm (0.040 in )

3.9L Flexible Fuel V6 M Automatic 1.01 mm (0.040 in )

6-101