low oil pressure CHEVROLET KODIAK 2004 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2004, Model line: KODIAK, Model: CHEVROLET KODIAK 2004Pages: 366, PDF Size: 6.87 MB

Page 84 of 366

Diesel Engine Warm-Up

Several factors affect how quickly your diesel engine

warms up. These can include outside temperature,

engine load, idle time and your vehicle’s option content.

Your vehicle may be equipped with some features

that can help the engine reach operating temperature

sooner. Some of these features are discussed below.

Also, remember that an automatic transmission

adds heat to the cooling system through the heat

exchanger in the radiator. Because of this, vehicles

equipped with automatic transmissions are often able to

retain engine coolant heat better than manual

transmission vehicles.

See your Caterpillar

®Operation & Maintenance manual

for additional diesel engine warm-up information.

Engine Alarm and Automatic Shutdown

Your check gages light will come on if the system

senses high engine temperature or low engine oil

pressure. If high engine temperature or low engine oil

pressure is detected, you will also hear a tone alarm at

two beats per second. The alarm and the light will

remain on until the condition is fixed. If the engine

temperature or oil pressure condition worsens, the tone

alarm will go to five beats per second.If the system senses low engine coolant, the five beat

per second alarm and the low coolant warning light

will come on.

The five beats per second tone alarm means that your

engine will shut down in about 25–30 seconds.

There is also an engine shutdown light to indicate that

the engine will shut down. SeeEngine Shutdown

Warning Light on page 3-39.

Pull off the road and shut off the engine. Don’t start it

until the reason for the problem is known, and the

problem is fixed. If the engine shuts down when you are

still in traffic, you can restart the engine and get

another 25–30 seconds of operation. Do this only if you

have to, since there is a problem that can harm the

engine if it isn’t fixed. Engine automatic shutdown, for

gasoline engines, requires activation by your dealer.

High Idle System (Caterpillar®

Diesel and Gasoline Engines)

Your vehicle has both automatic and manual high idle

capabilities.

2-16

Page 88 of 366

If you’re trying to start your engine after you’ve run out

of fuel, seeRunning Out of Fuel on page 5-15.

When your engine is cold, let it run for a few minutes

before you move your vehicle. This lets oil pressure

build up. Your engine will sound louder when it’s cold.

Notice:If you are not in an idling vehicle and

the engine overheats, you would not be there to see

the overheated engine indication. This could

damage your vehicle. Do not let your engine run

when you are not in your vehicle.

Cold Weather Starting (Diesel Engine)

The following tips will help you get good starting in

cold weather.

Use the recommended engine oil when the outside

temperature drops below freezing. SeeEngine Oil

(Caterpillar

®Diesel Engine) on page 5-20orEngine Oil

(Gasoline Engine) on page 5-20orEngine Oil

(DURAMAX™ Diesel) on page 5-25. When the outside

temperature drops below 0°F (−18°C), use of the

engine coolant heater is recommended.If you experience longer cranking times, notice an

unusual amount of exhaust smoke or are at higher

altitudes (over 7,000 ft. or 2 135 m), you may use your

engine coolant heater. SeeEngine Coolant Heater

on page 2-23.

SeeWhat Fuel to Use on page 5-8for information on

what fuel to use in cold weather.

If Your Diesel Engine Won’t Start

If you’ve run out of fuel, seeRunning Out of Fuel on

page 5-15.

If you’re not out of fuel, and your engine won’t start,

do this:

Turn your ignition key to RUN. IMMEDIATELY after

the wait to start light goes off, turn the ignition key

to START.

If the light doesn’t go off, wait a few seconds, then try

starting your engine again. And, see your dealer as soon

as you can for a starting system check.

If the light comes on and then goes off and you know

your batteries are charged, but your engine still

won’t start, your vehicle needs service.

If the light does not come on when the engine is cold,

your vehicle needs service.

2-20

Page 90 of 366

When the engine is started, it will slowly ramp up to the

high idle speed after a delay of a few seconds up to

about two minutes. For this method to work properly

there must be no throttle or brake pedal faults, and the

throttle pedal must not fall below 75 percent of wide

open throttle while pressing the brake pedal.

The engine idle speed will return to normal once the

following conditions are met:

•Once engine coolant temperature reaches

150°F (65°C).

•Air intake temperature reaches 41°F (5°C).

The high idle speed will be temporarily interrupted and

the engine speed will return to normal if any of the

following conditions occur:

•The brake pedal is applied.

•The accelerator pedal is pressed.

•The automatic transmission is shifted out of

PARK (P) or NEUTRAL (N).

•The clutch pedal on the manual transmission is

pressed.

•Vehicle speed is detected.

Once these inputs are removed, the engine idle speed

will slowly ramp back up to high idle after the normal

delay, if the conditions for engine coolant temperature

and air intake temperature are still met.

Engine Checks Before Operating

When you’ve started your engine, let it run for

20 to 30 seconds before you put a load on the engine.

Butdon’tleave the vehicle while the engine is running.

Avoid unnecessary idling of diesel engine equipped

vehicles.

If the engine idles too long, the temperature of the

engine coolant will fall below the normal operating

range. Low engine operating temperature causes

several conditions which affect engine operation and

reduce engine life.

The engine should be permitted to go through a

warm-up period. Operate the vehicle at a minimum of

600 rpm during the warm-up period. During this

period and during operation, the following observations

should be made.

During this warm-up period, check your warning lights

and gages:

•If oil pressure doesn’t begin to rise within

15 seconds of starting, stop the engine and find the

cause.

•If the engine coolant temperature gage needle goes

into the hot area on the gage, stop the engine and

find the cause of the overheating.

2-22

Page 111 of 366

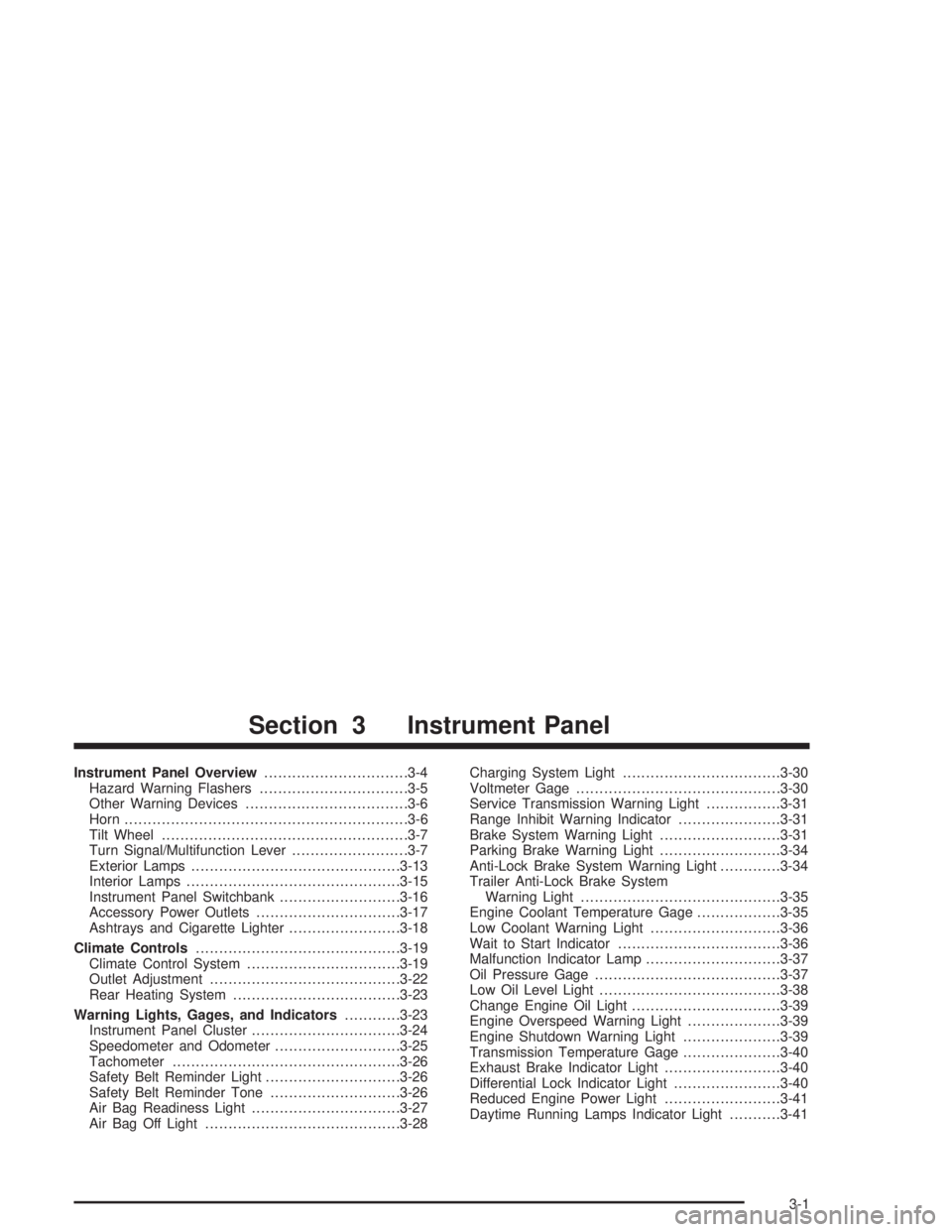

Instrument Panel Overview...............................3-4

Hazard Warning Flashers................................3-5

Other Warning Devices...................................3-6

Horn.............................................................3-6

Tilt Wheel.....................................................3-7

Turn Signal/Multifunction Lever.........................3-7

Exterior Lamps.............................................3-13

Interior Lamps..............................................3-15

Instrument Panel Switchbank..........................3-16

Accessory Power Outlets...............................3-17

Ashtrays and Cigarette Lighter........................3-18

Climate Controls............................................3-19

Climate Control System.................................3-19

Outlet Adjustment.........................................3-22

Rear Heating System....................................3-23

Warning Lights, Gages, and Indicators............3-23

Instrument Panel Cluster................................3-24

Speedometer and Odometer...........................3-25

Tachometer.................................................3-26

Safety Belt Reminder Light.............................3-26

Safety Belt Reminder Tone............................3-26

Air Bag Readiness Light................................3-27

Air Bag Off Light..........................................3-28Charging System Light..................................3-30

Voltmeter Gage............................................3-30

Service Transmission Warning Light................3-31

Range Inhibit Warning Indicator......................3-31

Brake System Warning Light..........................3-31

Parking Brake Warning Light..........................3-34

Anti-Lock Brake System Warning Light.............3-34

Trailer Anti-Lock Brake System

Warning Light...........................................3-35

Engine Coolant Temperature Gage..................3-35

Low Coolant Warning Light............................3-36

Wait to Start Indicator...................................3-36

Malfunction Indicator Lamp.............................3-37

Oil Pressure Gage........................................3-37

Low Oil Level Light.......................................3-38

Change Engine Oil Light................................3-39

Engine Overspeed Warning Light....................3-39

Engine Shutdown Warning Light.....................3-39

Transmission Temperature Gage.....................3-40

Exhaust Brake Indicator Light.........................3-40

Differential Lock Indicator Light.......................3-40

Reduced Engine Power Light.........................3-41

Daytime Running Lamps Indicator Light...........3-41

Section 3 Instrument Panel

3-1

Page 147 of 366

Malfunction Indicator Lamp

Service Engine Soon Light

If this light comes on or

flashes while you are

driving, two things may

happen.

First, you will not notice any difference in engine

performance, but your tail pipe emissions may increase.

Second, your engine may not run properly or may

stall without warning. If either of these things happen,

drive or tow your vehicle to your dealer for service.

This light should come on when the ignition is on, but

the engine is not running, as a check to show you

it is working. If it does not come on at all, have

it repaired.

Notice:If you keep driving your vehicle with this

light on, after a while, your emission controls

may not work as well, your fuel economy may not

be as good and your engine may not run as

smoothly. This could lead to costly repairs that may

not be covered by your warranty.

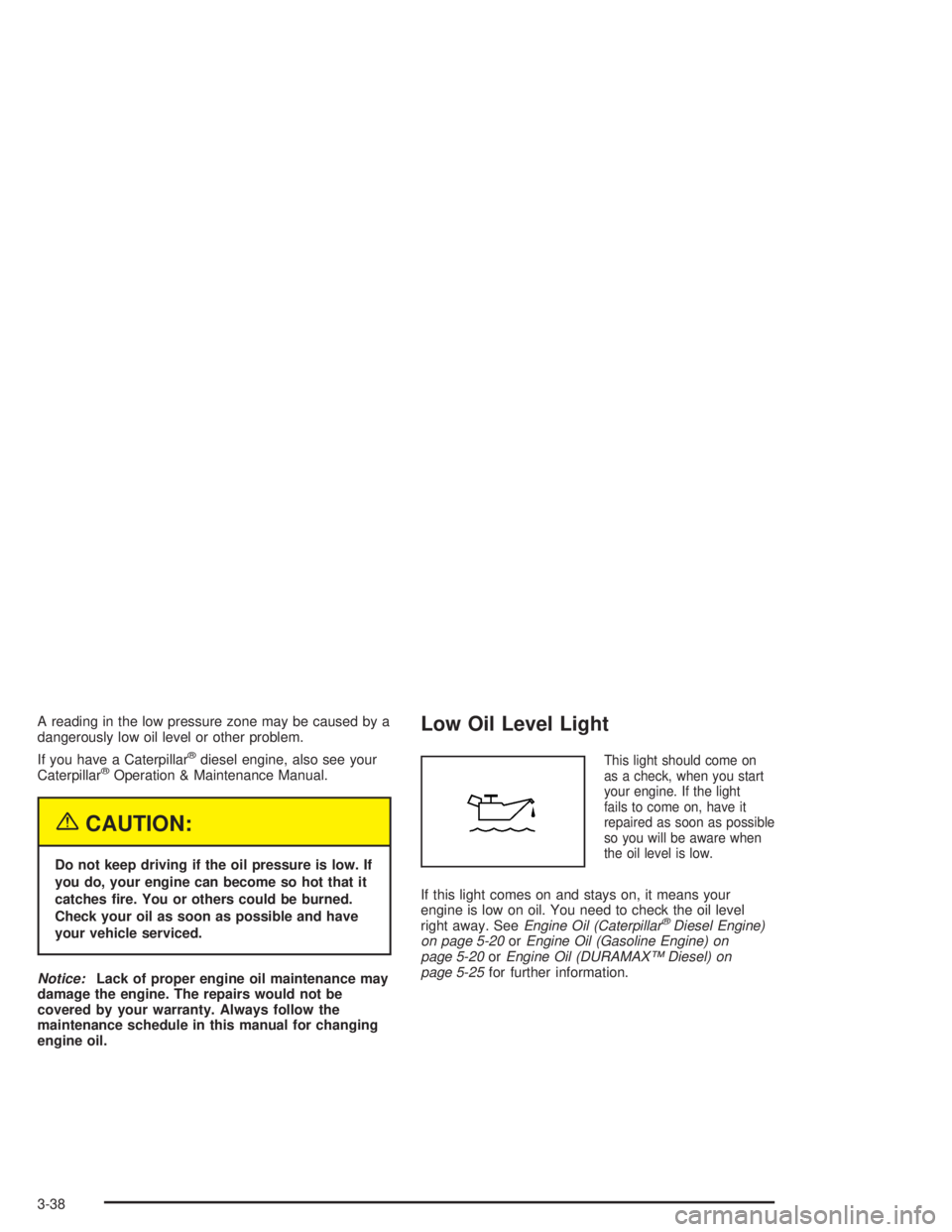

Oil Pressure Gage

The engine oil pressure gage, on the lower right portion

of your instrument panel cluster, shows engine oil

pressure in psi (pounds per square inch) or in kPa

(kilopascals). Oil pressure may vary with outside

temperature and oil viscosity, but readings of

30 to 40 psi (205 to 275 kPa) on gasoline engines at

operating temperature and moderate road speeds

are normal. If you have a diesel engine, the normal

operating range should be between 35 and 70 psi

(240 to 480 kPa).

United StatesCanada

3-37

Page 148 of 366

A reading in the low pressure zone may be caused by a

dangerously low oil level or other problem.

If you have a Caterpillar

®diesel engine, also see your

Caterpillar®Operation & Maintenance Manual.

{CAUTION:

Do not keep driving if the oil pressure is low. If

you do, your engine can become so hot that it

catches �re. You or others could be burned.

Check your oil as soon as possible and have

your vehicle serviced.

Notice:Lack of proper engine oil maintenance may

damage the engine. The repairs would not be

covered by your warranty. Always follow the

maintenance schedule in this manual for changing

engine oil.

Low Oil Level Light

This light should come on

as a check, when you start

your engine. If the light

fails to come on, have it

repaired as soon as possible

so you will be aware when

the oil level is low.

If this light comes on and stays on, it means your

engine is low on oil. You need to check the oil level

right away. SeeEngine Oil (Caterpillar

®Diesel Engine)

on page 5-20orEngine Oil (Gasoline Engine) on

page 5-20orEngine Oil (DURAMAX™ Diesel) on

page 5-25for further information.

3-38

Page 152 of 366

Low Washer Fluid Warning Light

This light will come on

when your vehicle is low

on windshield washer fluid.

For more information, seeWindshield Washer Fluid on

page 5-44.

Check Gages Warning Light

This light will come on as

you’re starting the engine,

just as a check.

If this light comes on and stays on while you are driving.

it means that either your engine coolant temperature

gage or your engine oil pressure gage may be showing

a reading in the warning zone.When the check gages light comes on, you will also

hear a warning tone. The tone and the light will

stay activated until the problem is corrected.

This light may also come on if your vehicle is equipped

with the optional automatic engine shutdown system

and engine shutdown has begun. SeeEngine Alarm and

Automatic ShutdownunderStarting Your Diesel

Engine on page 2-14.

Fuel Gage

Your fuel gage is located

on the right side of your

instrument panel cluster.

When the ignition is on, your fuel gage lets you know

about how much fuel you have left. When the gage first

shows empty, you’ll still have a little fuel left, but you

should get more fuel soon.

3-42

Page 247 of 366

{CAUTION:

Adding only plain water to your cooling

system can be dangerous. Plain water, or

some other liquid such as alcohol, can boil

before the proper coolant mixture will. Your

vehicle’s coolant warning system is set for the

proper coolant mixture. With plain water or the

wrong mixture, your engine could get too hot

but you would not get the overheat warning.

Your engine could catch �re and you or others

could be burned. Use a 50/50 mixture of clean,

drinkable water and DEX-COOL

®coolant.

Notice:In cold weather, water can freeze and crack

the engine, radiator, heater core and other parts.

Use the recommended coolant and the proper

coolant mixture.

{CAUTION:

You can be burned if you spill coolant on hot

engine parts. Coolant contains ethylene glycol

and it will burn if the engine parts are hot

enough. Do not spill coolant on a hot engine.

1. Park the vehicle on a level surface. You can

remove the coolant surge tank pressure cap

when the cooling system, including the coolant

surge tank pressure cap and upper radiator hose, is

no longer hot. Turn the pressure cap slowly

counterclockwise (left) about one full turn. If you

hear a hiss, wait for that to stop. A hiss means there

is still some pressure left.

2. Then keep turning the pressure cap slowly, and

remove it.

5-41

Page 330 of 366

(11)= Inspect rear axle air shift motor for fluid leaks.

Remove plug to check fluid level. Inspect air lines

and hoses for proper hook-up, binding, leaks, etc.

Inspect at 1,000 miles (1 600 km) and 22,500 miles

(36 000 km) and then every 22,500 miles (36 000 km)

thereafter.

(12)= Chassis Lubrication Service: Lubricate all grease

fittings in front suspension, front axle and steering

linkage. DO NOT lubricate kingpin bushings with air

pressure equipment; instead, use a hand grease gun to

ensure complete purge and eliminate sealer cap

distortion. Front axle tie rod ends, both upper and lower

kingpin fittings and both steering linkage relay rod

ends should be greased with the vehicle loaded on the

ground and wheels turned straight ahead, NOT with

the vehicle on a hoist. Apply kingpin bushing lubricant to

both upper and lower kingpin grease fittings until new

lubricant purges from between the upper shim pack and

thrust bearing. Lubricate transmission and shift

linkage, hood latches and hood hinges, parking brake

lever pivot, clevis pins and linkage, disc brake caliper

rails, clutch linkage and release bearing (if equipped),

bearing pads, propshaft universal joints, brake camshaft

bracket, slack adjusters, pedal shaft, clutch cross

shaft, clutch pedal springs and clutch cable bushing at

transmission. Lubricate suspension, axle and steeringlinkage more often when operating under dusty or

muddy conditions and in excessive off-road use.

Frequently power-washed vehicles will require more

frequent lubrication.

(13)= Check steering system:

•Look for damaged, loose or missing parts. Inspect

the steering linkage relay rod and tie rod ends for

looseness or lack of lubricant. Also look for

parts showing signs of wear or lack of lubrication.

Replace parts as needed. Also check steering gear

mounting bolts, pitman arm nut, gear housing

upper cover and side cover attaching bolts, steering

column mounting bolts and cardan joint clamp

bolts; tighten if necessary. (See service manual.)

•Inspect power steering hoses, tubes and fittings for

leaks. Hoses and lines must not be twisted, kinked

or tightly bent. Make sure clips, clamps, supporting

tubes and hoses are in place and properly

secured.

•Check steering gear for leakage around pitman

shaft and housing. If leakage is evident (lubricant

oozing out, not just oily film), leak should be

corrected immediately.

6-20

Page 331 of 366

(14)= Check front and rear suspension. Look for

damaged, loose or missing parts or parts showing signs

of wear or lack of lubrication. Replace parts as

needed.

(15)= Adjust tire pressures as indicated on the GVW

Rating label for optimum tire life. SeeTires on page 5-68

for further details. Check tires for excessive or

abnormal wear or damage. Also check for damaged

wheels. Replace wheels and/or tires as needed.

(16)= Check spring-to-axle U-bolts and shackle bolts

for proper torque. See the service manual for torque

sequence and specifications. When parts are replaced,

the torque must be checked and adjusted more often

during the first 6,000 miles (10 000 km). Check torque at

500 miles (800 km) and 2,000 miles (3 000 km) after

first use of parts.

(17)= Check complete exhaust system and cab areas

near the exhaust system for broken, damaged,

missing or out-of-position parts. Also inspect for open

seams, holes, loose connections or other conditions

which could let exhaust fumes seep into the driver

compartment. Needed repairs should be made at once.

To help maintain system integrity, replace exhaust

pipes whenever a new muffler is put on.(18)= Check all gasoline engine drive belts for cracks,

fraying and wear. Replace as needed.

(20)= With the engine off and below normal operating

temperature, check to see that the thermostatically

controlled engine cooling fan can be rotated by hand on

viscous-operated drives. Replace as needed.

(21)= Check shields and underhood insulation for

damage or looseness. Adjust or replace as needed.

23)= Wheel bearing service:

•Grease type – Clean, inspect and lubricate with the

proper wheel bearing grease at designated intervals

or when hubs are removed. SeePart C:

Recommended Fluids and Lubricants on page 6-29.

•Oil-filled type – Some wheel bearings are lubricated

by rear axle lubricant. When you have oil-filled

hubs, use lubricant identical to that used in your rear

axle. Lubricant change intervals are the same for

front and rear axles. However, you must maintain oil

level at the OIL LEVEL mark between change

intervals. SeePart C: Recommended Fluids and

Lubricants on page 6-29.

6-21