maintenance CHEVROLET KODIAK 2008 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2008, Model line: KODIAK, Model: CHEVROLET KODIAK 2008Pages: 384, PDF Size: 5.4 MB

Page 264 of 384

Hydraulic Brake Pads

Brake pad lining life will vary depending on vehicle

application, working environment, equipment

maintenance, and style of driving. The brake pad lining

wear rate has to be monitored for individual driving

habits — original equipment linings have mechanical

wear indicators to help with this. When you are down to

the last 10% of the brake lining, the brake lining wear

indicator will rub on the rotor, causing a scratching or

chirping sound. When you hear this sound, it is time to

service the brake pads. SeeScheduled Maintenance on

page 6-5.

Aftermarket brake linings might not meet the same

stringent requirements as the original equipment linings.

Using aftermarket brake linings can affect braking

performance, pedal feel, noise, and lining wear.

Air Brake Systems

If your vehicle has air brakes, it is important to get rid of

moisture in the system. Moisture will damage the

system if it is not removed daily.

There are two ways to do this. One is automatic through

the air brake vehicle’s air dryer with integral automatic

moisture ejector that purges air from the system through

a self-contained reservoir. The other way to drain

moisture from the air brake system is to manually activate

drain valves at each reservoir. Drain the air reservoirs

occasionally to be sure the air dryer is working properly.Drain the air brakes at full system pressure. To be sure

you are at full pressure, check the air pressure gage.

It should read at least 100 psi (692 kPa).

Air Dryer

If your vehicle has air brakes, it has an air dryer

mounted on the passenger side frame rail. This collects

and removes dirt, moisture, or other foreign matter

from the air prior to entering the brake system. The dryer

also acts as a moisture ejector. It automatically ejects

the moisture when the compressor cycles. The

purge tank has a manual drain valve that must be

drained every day. See “Air Brake Systems” for the

manual drain procedure.

The dryer has a filter that you need to change at

intervals. SeeScheduled Maintenance on page 6-5for

more about servicing this filter.

Electric Air Compressor

Your vehicle might have an electric air compressor. This

compressor is used to run options that require

pressurized air, such as an air horn or air seat.

The air compressor is used when vehicles do not have

an air brake system.

5-60

Page 265 of 384

The air supply for this

system must be

maintained by releasing

the drain valve to eject any

moisture that could have

built up in the system.

It is recommended that this system be drained on a

weekly basis.Clutch Pedal Free Travel

If you have a V8 engine and a manual transmission, the

clutch will need adjustment when pedal free travel gets

down to about 1/4 inch (6 mm), as measured at the clutch

pedal pad. You should have 1 1/2 to 2 inches

(38 to 51 mm) of clutch pedal free travel.

If the clutch ever needs service, be sure to use only

approved clutch replacement parts.

Chassis Lubrication

Your Maintenance Schedule provides all of the required

chassis lubrication intervals and identifies proper

lubricants to use. Be sure to see the Maintenance

Schedule before performing any chassis lubrication

service. To determine location of chassis lubrication

items, use the following charts.

5-61

Page 270 of 384

Battery

Your vehicle has two or more maintenance free

batteries. When it is time for a new battery, see your

dealer/retailer for one that has the replacement number

shown on the original battery’s label.

Warning:Battery posts, terminals, and related

accessories contain lead and lead compounds,

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

Vehicle Storage

{CAUTION:

Batteries have acid that can burn you and gas

that can explode. You can be badly hurt if you

are not careful. SeeJump Starting on

page 5-67for tips on working around a battery

without getting hurt.

Infrequent Usage: If you drive your vehicle infrequently,

remove the black, negative (−) cable from each battery.

This will help keep the batteries from running down.

Extended Storage: For extended storage of your vehicle,

remove the black, negative (−) cable from each battery

or use a battery trickle charger. This will help maintain

the charge of the batteries over an extended period

of time.

When you are ready to use the vehicle again, refer to

the engine starting procedure in the Index.

5-66

Page 276 of 384

Rear Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant and when to change it.

SeeScheduled Maintenance on page 6-5.

Notice:If you drive your vehicle through deep

water that is higher than the front or rear axle, water

may enter the axle housing and cause the axle

lubricant to break down. This could damage

the gears inside. Avoid driving your vehicle through

deep water.

You should avoid driving your vehicle through deep

puddles or standing water. If you must drive through

water that is higher than the front or rear axle, see your

dealer immediately afterward to have the condition of

the axle lubricant checked.

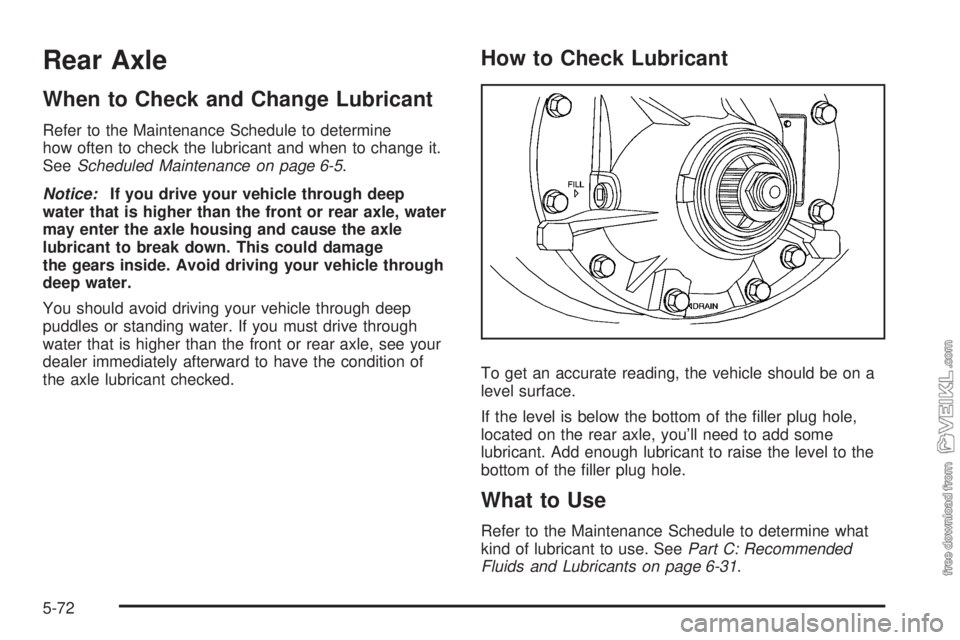

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

located on the rear axle, you’ll need to add some

lubricant. Add enough lubricant to raise the level to the

bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart C: Recommended

Fluids and Lubricants on page 6-31.

5-72

Page 277 of 384

Rear Axle Shift Motor

When to Check and Change Fluid

If you have an optional air-shift two-speed, controlled

traction, or locking differential type rear axle, a good time

to check the fluid level in the axle shift motor is when

the rear axle lubricant is checked.

How to Check Fluid

Remove the plug on the front plate of the axle shift

motor, add enough fluid to raise the level to the bottom

of the filler plug hole, then replace the plug.

What to Use

Refer to your Maintenance Schedule to determine what

kind of lubricant to use. SeePart C: Recommended

Fluids and Lubricants on page 6-31.

Four-Wheel Drive

Transfer Case

When to Check Lubricant

It is not necessary to regularly check transfer case fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

A. Fill Plug

B. Drain Plug

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the fill plug hole,

located on the transfer case, you’ll need to add some

lubricant. Add enough lubricant to raise the level to

the bottom of the fill plug hole. Use care not to

overtighten the plug.

5-73

Page 278 of 384

When to Change Lubricant

Refer to the Maintenance Schedule to determine how

often to change the lubricant. SeeScheduled

Maintenance on page 6-5.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart C: Recommended

Fluids and Lubricants on page 6-31.

Front Axle

When to Check Lubricant

It is not necessary to regularly check front axle fluid

unless you suspect there is a leak or you hear an

unusual noise. A fluid loss could indicate a problem.

Have it inspected and repaired.

Notice:If you drive your vehicle through deep

water that is higher than the front or rear axle, water

may enter the axle housing and cause the axle

lubricant to break down. This could damage the

gears inside. Avoid driving your vehicle through

deep water.You should avoid driving your vehicle through deep

puddles or standing water. If you must drive through

water that is higher than the front or rear axle, see your

dealer immediately afterward to have the condition of

the axle lubricant checked.

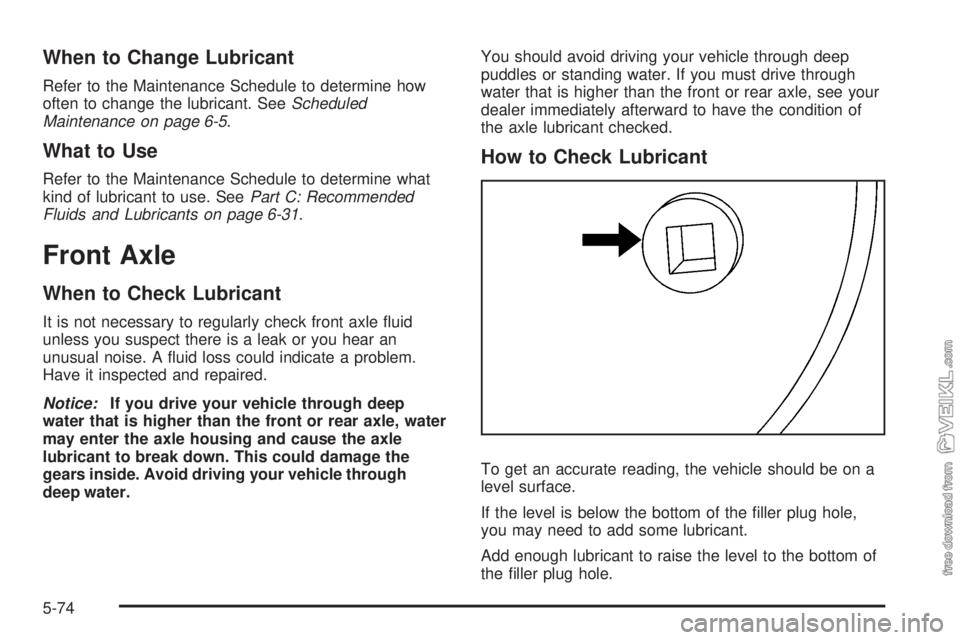

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the filler plug hole,

you may need to add some lubricant.

Add enough lubricant to raise the level to the bottom of

the filler plug hole.

5-74

Page 279 of 384

What to Use

To determine what kind of lubricant to use seePart C:

Recommended Fluids and Lubricants on page 6-31.

Noise Control System

Tampering with Noise Control

System Prohibited

The following information relates to compliance with

federal noise emission standards for vehicles with

a Gross Vehicle Weight Rating (GVWR) of more than

10,000 lbs (4 536 kg). The Maintenance Schedule

provides information on maintaining the noise control

system to minimize degradation of the noise emission

control system during the life of your vehicle. The noise

control system warranty is given in your warranty

booklet.These standards apply only to vehicles sold in the

United States.

Federal law prohibits the following acts or the causing

thereof:

1. The removal or rendering inoperative by any

person, other than for purposes of maintenance,

repair or replacement, of any device or element of

design incorporated into any new vehicle for the

purpose of noise control, prior to its sale or delivery

to the ultimate purchaser or while it is in use; or

2. The use of the vehicle after such device or element

of design has been removed or rendered inoperative

by any person.

Among those acts presumed to constitute tampering are

the acts listed below.

Insulation:

•

Removal of the noise shields or any underhood

insulation.

Engine:

•

Removal or rendering engine speed governor, if the

vehicle has one, inoperative so as to allow engine

speed to exceed manufacturer specifications.

5-75

Page 282 of 384

Other Service Items

Fuel Filter

Fuel Filter/Pressure Regulator

(Gasoline Engines)

The steel fuel filter/pressure regulator is located near

the engine compartment on the driver’s side frame rail.

If your vehicle has a rear steel fuel tank, the fuel

filter/pressure regulator is located near the rear fuel tank,

on the driver’s side frame rail. SeeScheduled

Maintenance on page 6-5for recommended service

intervals.

If your vehicle is equipped with the optional Davco

spin-on type filter, it is located on the driver’s side

frame rail.

Fuel Filter (Diesel Engines)

If you have a diesel engine, your fuel filter is located in

the engine compartment on the driver’s side of the

vehicle, or along the driver’s side frame rail. See “Fuel

Filter Replacement” earlier in this section for further

information.

Also seeScheduled Maintenance on page 6-5for

recommended service intervals.

5-78

Page 285 of 384

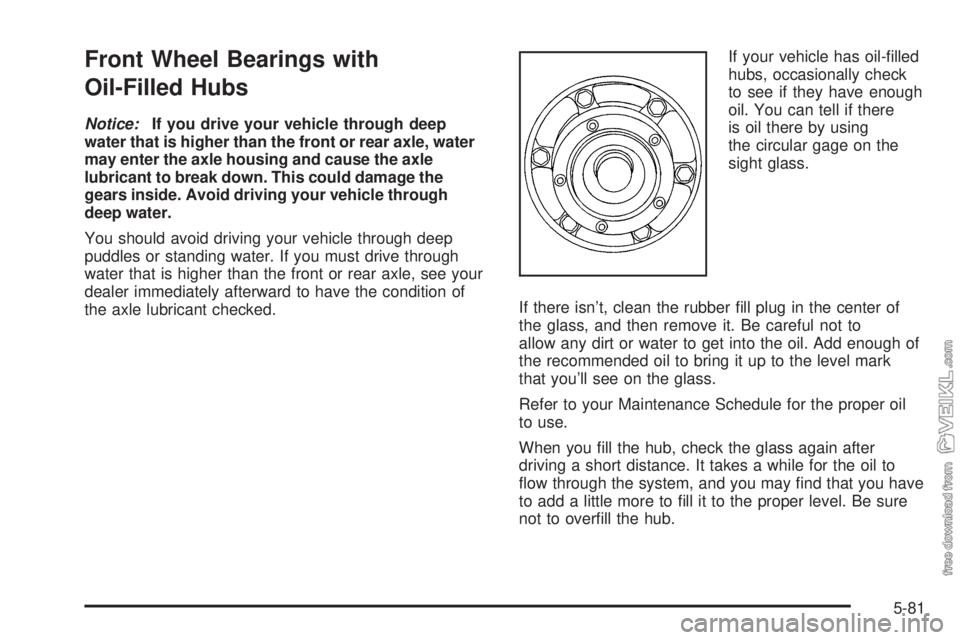

Front Wheel Bearings with

Oil-Filled Hubs

Notice:If you drive your vehicle through deep

water that is higher than the front or rear axle, water

may enter the axle housing and cause the axle

lubricant to break down. This could damage the

gears inside. Avoid driving your vehicle through

deep water.

You should avoid driving your vehicle through deep

puddles or standing water. If you must drive through

water that is higher than the front or rear axle, see your

dealer immediately afterward to have the condition of

the axle lubricant checked.If your vehicle has oil-filled

hubs, occasionally check

to see if they have enough

oil. You can tell if there

is oil there by using

the circular gage on the

sight glass.

If there isn’t, clean the rubber fill plug in the center of

the glass, and then remove it. Be careful not to

allow any dirt or water to get into the oil. Add enough of

the recommended oil to bring it up to the level mark

that you’ll see on the glass.

Refer to your Maintenance Schedule for the proper oil

to use.

When you fill the hub, check the glass again after

driving a short distance. It takes a while for the oil to

flow through the system, and you may find that you have

to add a little more to fill it to the proper level. Be sure

not to overfill the hub.

5-81

Page 288 of 384

Dual Tire Operation

When the vehicle is new, check the wheel nut tightness

on all wheels with a torque wrench after your first

100 miles (160 km) and then 1,000 miles (1 600 km)

after that. Whenever a wheel, wheel bolt or wheel nut is

removed or serviced, repeat the 100 miles (160 km),

and then 1,000 mile (1 600 km) wheel nut tightness

check.

SeeTightening the Wheel Nuts on page 5-86for wheel

nut tightening information and proper torque values.

{CAUTION:

If you operate your vehicle with a tire that is

badly underin�ated, the tire can overheat. An

overheated tire can lose air suddenly or catch

�re. You or others could be injured. Be sure all

tires (including the spare, if any) are properly

in�ated.

SeeTires on page 5-82andInflation - Tire Pressure on

page 5-82for more information on proper tire inflation.

When It Is Time for New Tires

Various factors, such as maintenance, temperatures,

driving speeds, vehicle loading, and road conditions,

influence when you need new tires.

Replace your tires when the tread depth is down to

1/8 of an inch (3.2 mm) for the front tires, or 1/16 of an

inch (1.6 mm) for a rear tire. Also, you need a new

tire if:

•You can see cord or fabric showing through the

tire’s rubber.

•The tread or sidewall is cracked, cut, or snagged

deep enough to show cord or fabric.

•The tire has a bump, bulge, or split.

•The tire has a puncture, cut, or other damage that

cannot be repaired well because of the size or

location of the damage.

The rubber in tires degrades over time, even if they are

not being used. This is also true for the spare tire, if

your vehicle has one. Multiple conditions affect how fast

this aging takes place, including temperatures, loading

conditions, and inflation pressure maintenance. With

proper care and maintenance tires will typically wear out

before they degrade due to age. If you are unsure about

the need to replace your tires as they get older, consult

the tire manufacturer for more information.

5-84