ECU CHEVROLET KODIAK 2009 Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2009, Model line: KODIAK, Model: CHEVROLET KODIAK 2009Pages: 376, PDF Size: 5.39 MB

Page 197 of 376

The Certification label also tells you the maximum

weight for the front and rear axles, called the Gross Axle

Weight Rating (GAWR). To find out the actual loads

on your front and rear axles, go to a weigh station and

weigh your vehicle. Your dealer can help you with

this. Be sure to spread out your load equally on both

sides of the center line.

Never exceed the GVWR for your vehicle, or the GAWR

for either the front or rear axle.

And, if you do have a heavy load, spread it out.

{CAUTION:

Do not load the vehicle any heavier than the

Gross Vehicle Weight Rating (GVWR), or

either the maximum front or rear Gross Axle

Weight Rating (GAWR). If you do, parts on the

vehicle can break, and it can change the way

your vehicle handles. These could cause you

to lose control and crash. Also, overloading

can shorten the life of the vehicle.

Using heavier suspension components to get added

durability might not change the weight ratings. Ask your

dealer to help you load your vehicle the right way.

Notice:Overloading your vehicle may cause

damage. Repairs would not be covered by your

warranty. Do not overload your vehicle.

If you put things inside your vehicle — like suitcases,

tools, packages, or anything else — they go as fast

as the vehicle goes. If you have to stop or turn quickly,

or if there is a crash, they keep going.

{CAUTION:

Things you put inside your vehicle can strike

and injure people in a sudden stop or turn, or

in a crash.

•Put things in the cargo area of your

vehicle. Try to spread the weight evenly.

•Never stack heavier things, like

suitcases, inside the vehicle so that some

of them are above the tops of the seats.

•Do not leave an unsecured child restraint

in your vehicle.

•When you carry something inside the

vehicle, secure it whenever you can.

•Do not leave a seat folded down unless

you need to.

4-21

Page 218 of 376

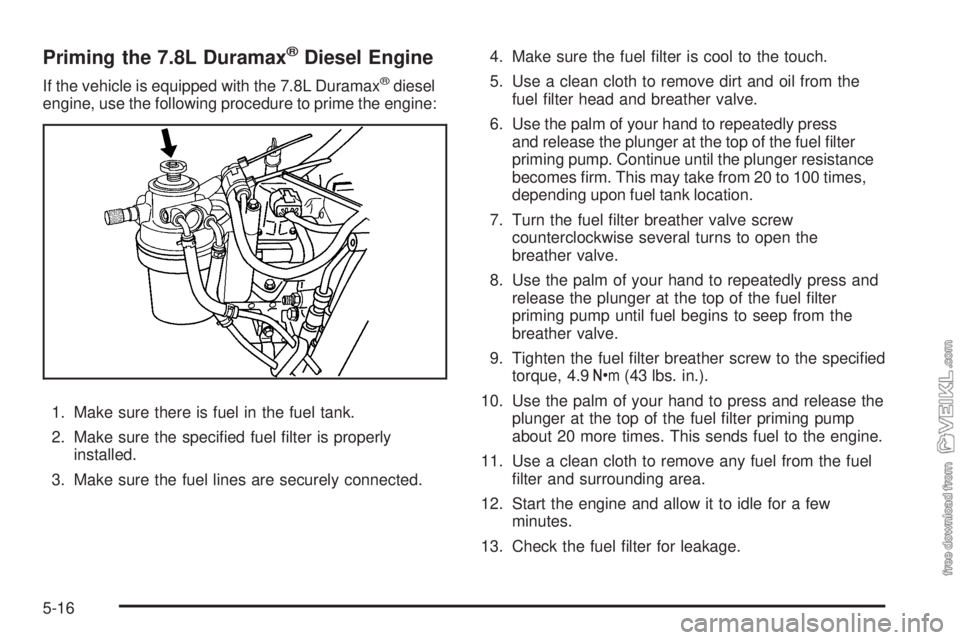

Priming the 7.8L Duramax®Diesel Engine

If the vehicle is equipped with the 7.8L Duramax®diesel

engine, use the following procedure to prime the engine:

1. Make sure there is fuel in the fuel tank.

2. Make sure the specified fuel filter is properly

installed.

3. Make sure the fuel lines are securely connected.4. Make sure the fuel filter is cool to the touch.

5. Use a clean cloth to remove dirt and oil from the

fuel filter head and breather valve.

6. Use the palm of your hand to repeatedly press

and release the plunger at the top of the fuel filter

priming pump. Continue until the plunger resistance

becomes firm. This may take from 20 to 100 times,

depending upon fuel tank location.

7. Turn the fuel filter breather valve screw

counterclockwise several turns to open the

breather valve.

8. Use the palm of your hand to repeatedly press and

release the plunger at the top of the fuel filter

priming pump until fuel begins to seep from the

breather valve.

9. Tighten the fuel filter breather screw to the specified

torque, 4.9Y(43 lbs. in.).

10. Use the palm of your hand to press and release the

plunger at the top of the fuel filter priming pump

about 20 more times. This sends fuel to the engine.

11. Use a clean cloth to remove any fuel from the fuel

filter and surrounding area.

12. Start the engine and allow it to idle for a few

minutes.

13. Check the fuel filter for leakage.

5-16

Page 225 of 376

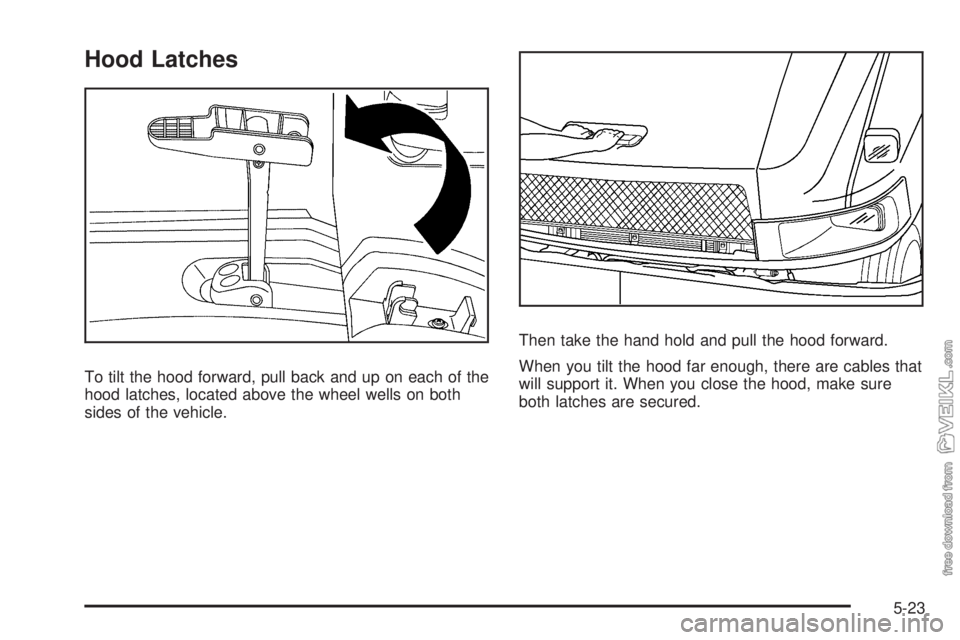

Hood Latches

To tilt the hood forward, pull back and up on each of the

hood latches, located above the wheel wells on both

sides of the vehicle.Then take the hand hold and pull the hood forward.

When you tilt the hood far enough, there are cables that

will support it. When you close the hood, make sure

both latches are secured.

5-23

Page 242 of 376

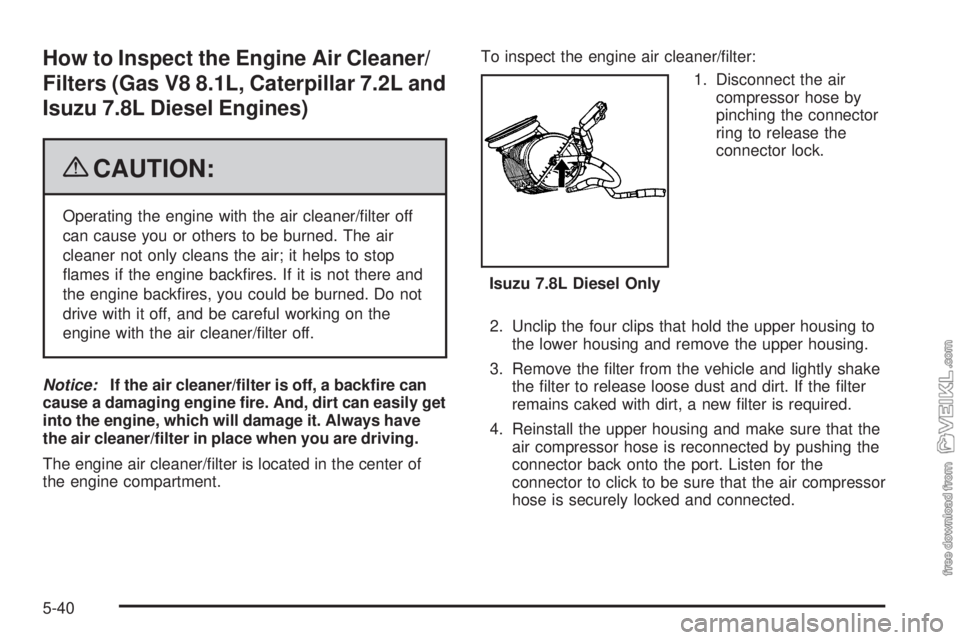

How to Inspect the Engine Air Cleaner/

Filters (Gas V8 8.1L, Caterpillar 7.2L and

Isuzu 7.8L Diesel Engines)

{CAUTION:

Operating the engine with the air cleaner/filter off

can cause you or others to be burned. The air

cleaner not only cleans the air; it helps to stop

flames if the engine backfires. If it is not there and

the engine backfires, you could be burned. Do not

drive with it off, and be careful working on the

engine with the air cleaner/filter off.

Notice:If the air cleaner/filter is off, a backfire can

cause a damaging engine fire. And, dirt can easily get

into the engine, which will damage it. Always have

the air cleaner/filter in place when you are driving.

The engine air cleaner/filter is located in the center of

the engine compartment.To inspect the engine air cleaner/filter:

1. Disconnect the air

compressor hose by

pinching the connector

ring to release the

connector lock.

2. Unclip the four clips that hold the upper housing to

the lower housing and remove the upper housing.

3. Remove the filter from the vehicle and lightly shake

the filter to release loose dust and dirt. If the filter

remains caked with dirt, a new filter is required.

4. Reinstall the upper housing and make sure that the

air compressor hose is reconnected by pushing the

connector back onto the port. Listen for the

connector to click to be sure that the air compressor

hose is securely locked and connected. Isuzu 7.8L Diesel Only

5-40

Page 249 of 376

4. With the coolant surge tank pressure cap off, start

the engine and let it run until you can feel the upper

radiator hose getting hot. Watch out for the

engine cooling fan.

By this time, the coolant level inside the coolant

surge tank may be lower. If the level is lower, add

more of the proper mixture to the coolant surge tank

until the level reaches slightly above the FULL

COLD mark.

5. Then replace the pressure cap. Be sure the

pressure cap is hand-tight and fully seated.

Engine Coolant (Caterpillar Diesel

Engines)

If your vehicle has a Caterpillar®diesel engine, see the

Caterpillar®Diesel Engine Operation & Maintenance

Manual provided with your vehicle to find out what to add,

as well as when and how to service your cooling system.

Coolant Surge Tank Pressure Cap

The coolant surge tank pressure cap is located in

the engine compartment, on the driver’s side of the

vehicle.

Notice:Your vehicle’s surge tank pressure cap is

designed for use with medium-duty cooling systems

only. If the surge tank pressure cap is not tightly

installed, coolant loss and possible engine damage

may occur. Be sure the cap is properly and tightly

secured.

5-47

Page 300 of 376

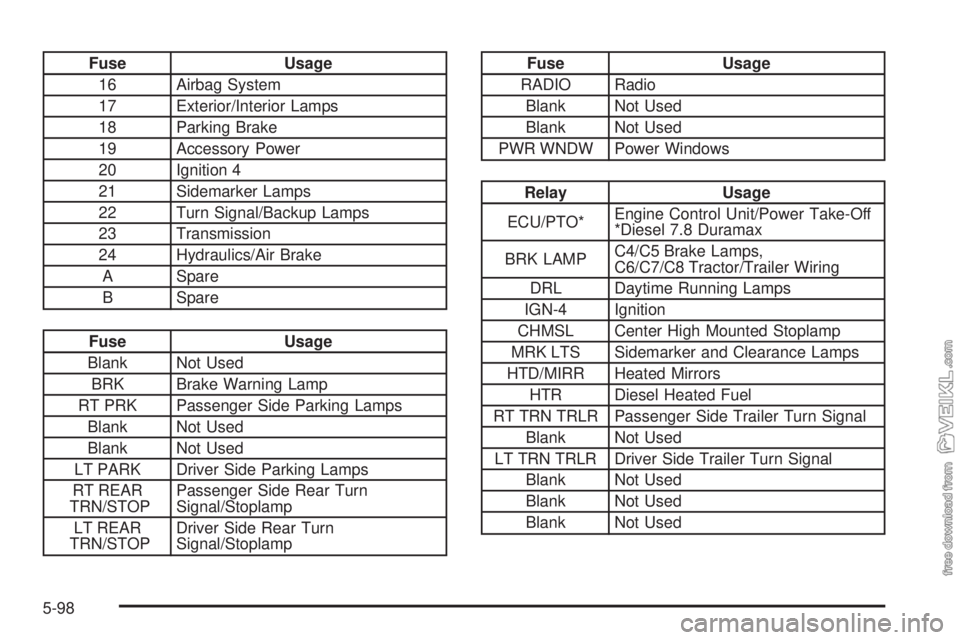

Fuse Usage

16 Airbag System

17 Exterior/Interior Lamps

18 Parking Brake

19 Accessory Power

20 Ignition 4

21 Sidemarker Lamps

22 Turn Signal/Backup Lamps

23 Transmission

24 Hydraulics/Air Brake

A Spare

B Spare

Fuse Usage

Blank Not Used

BRK Brake Warning Lamp

RT PRK Passenger Side Parking Lamps

Blank Not Used

Blank Not Used

LT PARK Driver Side Parking Lamps

RT REAR

TRN/STOPPassenger Side Rear Turn

Signal/Stoplamp

LT REAR

TRN/STOPDriver Side Rear Turn

Signal/Stoplamp

Fuse Usage

RADIO Radio

Blank Not Used

Blank Not Used

PWR WNDW Power Windows

Relay Usage

ECU/PTO*Engine Control Unit/Power Take-Off

*Diesel 7.8 Duramax

BRK LAMPC4/C5 Brake Lamps,

C6/C7/C8 Tractor/Trailer Wiring

DRL Daytime Running Lamps

IGN-4 Ignition

CHMSL Center High Mounted Stoplamp

MRK LTS Sidemarker and Clearance Lamps

HTD/MIRR Heated Mirrors

HTR Diesel Heated Fuel

RT TRN TRLR Passenger Side Trailer Turn Signal

Blank Not Used

LT TRN TRLR Driver Side Trailer Turn Signal

Blank Not Used

Blank Not Used

Blank Not Used

5-98

Page 302 of 376

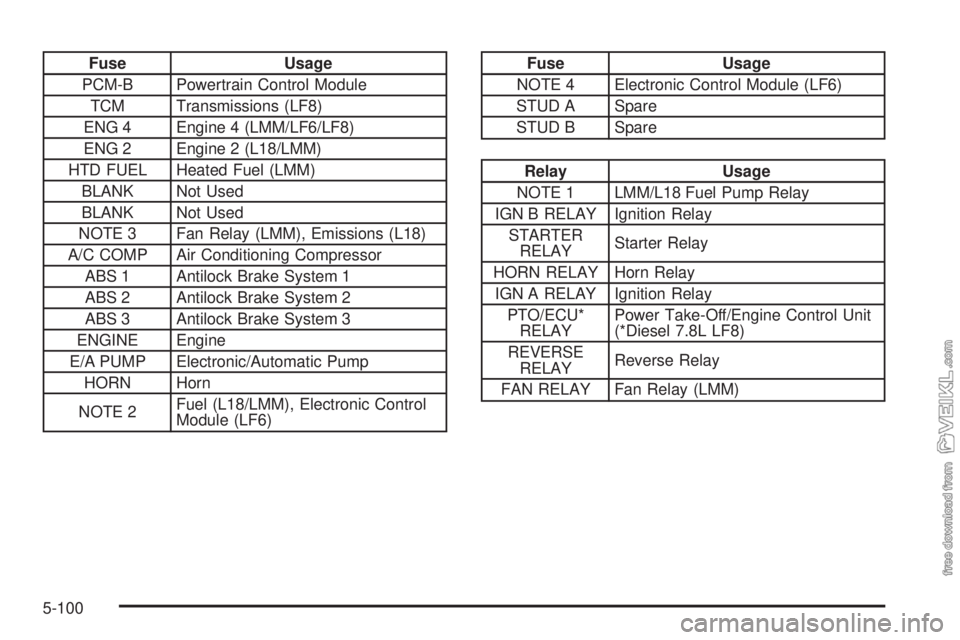

Fuse Usage

PCM-B Powertrain Control Module

TCM Transmissions (LF8)

ENG 4 Engine 4 (LMM/LF6/LF8)

ENG 2 Engine 2 (L18/LMM)

HTD FUEL Heated Fuel (LMM)

BLANK Not Used

BLANK Not Used

NOTE 3 Fan Relay (LMM), Emissions (L18)

A/C COMP Air Conditioning Compressor

ABS 1 Antilock Brake System 1

ABS 2 Antilock Brake System 2

ABS 3 Antilock Brake System 3

ENGINE Engine

E/A PUMP Electronic/Automatic Pump

HORN Horn

NOTE 2Fuel (L18/LMM), Electronic Control

Module (LF6)Fuse Usage

NOTE 4 Electronic Control Module (LF6)

STUD A Spare

STUD B Spare

Relay Usage

NOTE 1 LMM/L18 Fuel Pump Relay

IGN B RELAY Ignition Relay

STARTER

RELAYStarter Relay

HORN RELAY Horn Relay

IGN A RELAY Ignition Relay

PTO/ECU*

RELAYPower Take-Off/Engine Control Unit

(*Diesel 7.8L LF8)

REVERSE

RELAYReverse Relay

FAN RELAY Fan Relay (LMM)

5-100

Page 336 of 376

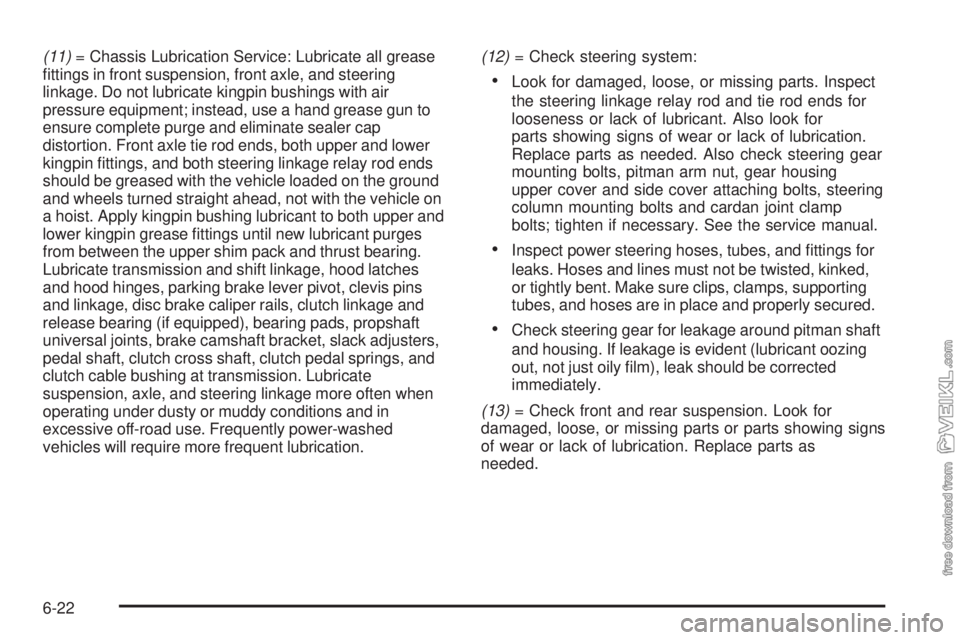

(11)= Chassis Lubrication Service: Lubricate all grease

fittings in front suspension, front axle, and steering

linkage. Do not lubricate kingpin bushings with air

pressure equipment; instead, use a hand grease gun to

ensure complete purge and eliminate sealer cap

distortion. Front axle tie rod ends, both upper and lower

kingpin fittings, and both steering linkage relay rod ends

should be greased with the vehicle loaded on the ground

and wheels turned straight ahead, not with the vehicle on

a hoist. Apply kingpin bushing lubricant to both upper and

lower kingpin grease fittings until new lubricant purges

from between the upper shim pack and thrust bearing.

Lubricate transmission and shift linkage, hood latches

and hood hinges, parking brake lever pivot, clevis pins

and linkage, disc brake caliper rails, clutch linkage and

release bearing (if equipped), bearing pads, propshaft

universal joints, brake camshaft bracket, slack adjusters,

pedal shaft, clutch cross shaft, clutch pedal springs, and

clutch cable bushing at transmission. Lubricate

suspension, axle, and steering linkage more often when

operating under dusty or muddy conditions and in

excessive off-road use. Frequently power-washed

vehicles will require more frequent lubrication.(12)= Check steering system:

•Look for damaged, loose, or missing parts. Inspect

the steering linkage relay rod and tie rod ends for

looseness or lack of lubricant. Also look for

parts showing signs of wear or lack of lubrication.

Replace parts as needed. Also check steering gear

mounting bolts, pitman arm nut, gear housing

upper cover and side cover attaching bolts, steering

column mounting bolts and cardan joint clamp

bolts; tighten if necessary. See the service manual.

•Inspect power steering hoses, tubes, and fittings for

leaks. Hoses and lines must not be twisted, kinked,

or tightly bent. Make sure clips, clamps, supporting

tubes, and hoses are in place and properly secured.

•Check steering gear for leakage around pitman shaft

and housing. If leakage is evident (lubricant oozing

out, not just oily film), leak should be corrected

immediately.

(13)= Check front and rear suspension. Look for

damaged, loose, or missing parts or parts showing signs

of wear or lack of lubrication. Replace parts as

needed.

6-22

Page 363 of 376

OnStar®(Isuzu 7.8L L6 Engine)

If your vehicle has OnStar and you subscribe to the

OnStar services, please refer to the OnStar Terms and

Conditions for information on data collection and use.

Navigation System (Isuzu

7.8L L6 Engine)

If your vehicle has a navigation system, use of the

system may result in the storage of destinations,

addresses, telephone numbers, and other trip

information. Refer to the navigation system operating

manual for information on stored data and for deletion

instructions.

Radio Frequency Identification

(RFID) (Isuzu 7.8L L6 Engine)

RFID technology is used in some vehicles for functions

such as tire pressure monitoring and ignition system

security, as well as in connection with conveniences

such as key fobs for remote door locking/unlocking and

starting, and in-vehicle transmitters for garage door

openers. RFID technology in GM vehicles does not use

or record personal information or link with any other

GM system containing personal information.

7-13

Page 366 of 376

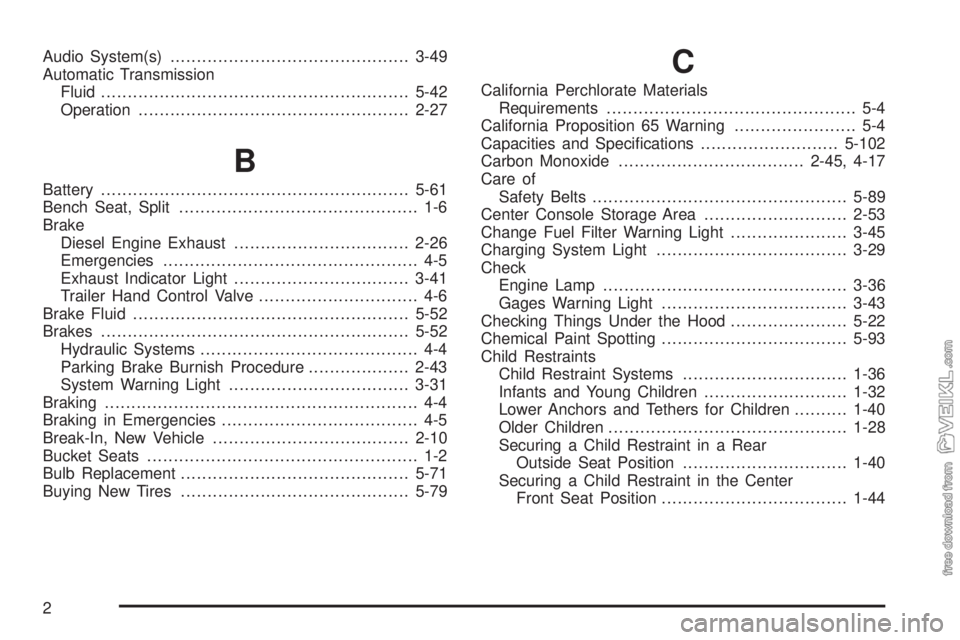

Audio System(s).............................................3-49

Automatic Transmission

Fluid..........................................................5-42

Operation...................................................2-27

B

Battery..........................................................5-61

Bench Seat, Split............................................. 1-6

Brake

Diesel Engine Exhaust.................................2-26

Emergencies................................................ 4-5

Exhaust Indicator Light.................................3-41

Trailer Hand Control Valve.............................. 4-6

Brake Fluid....................................................5-52

Brakes..........................................................5-52

Hydraulic Systems......................................... 4-4

Parking Brake Burnish Procedure...................2-43

System Warning Light..................................3-31

Braking........................................................... 4-4

Braking in Emergencies..................................... 4-5

Break-In, New Vehicle.....................................2-10

Bucket Seats................................................... 1-2

Bulb Replacement...........................................5-71

Buying New Tires...........................................5-79

C

California Perchlorate Materials

Requirements............................................... 5-4

California Proposition 65 Warning....................... 5-4

Capacities and Specifications..........................5-102

Carbon Monoxide...................................2-45, 4-17

Care of

Safety Belts................................................5-89

Center Console Storage Area...........................2-53

Change Fuel Filter Warning Light......................3-45

Charging System Light....................................3-29

Check

Engine Lamp..............................................3-36

Gages Warning Light...................................3-43

Checking Things Under the Hood......................5-22

Chemical Paint Spotting...................................5-93

Child Restraints

Child Restraint Systems...............................1-36

Infants and Young Children...........................1-32

Lower Anchors and Tethers for Children..........1-40

Older Children.............................................1-28

Securing a Child Restraint in a Rear

Outside Seat Position...............................1-40

Securing a Child Restraint in the Center

Front Seat Position...................................1-44

2