CHEVROLET OPTRA 2005 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2005, Model line: OPTRA, Model: CHEVROLET OPTRA 2005 1.GPages: 336, PDF Size: 2.21 MB

Page 241 of 336

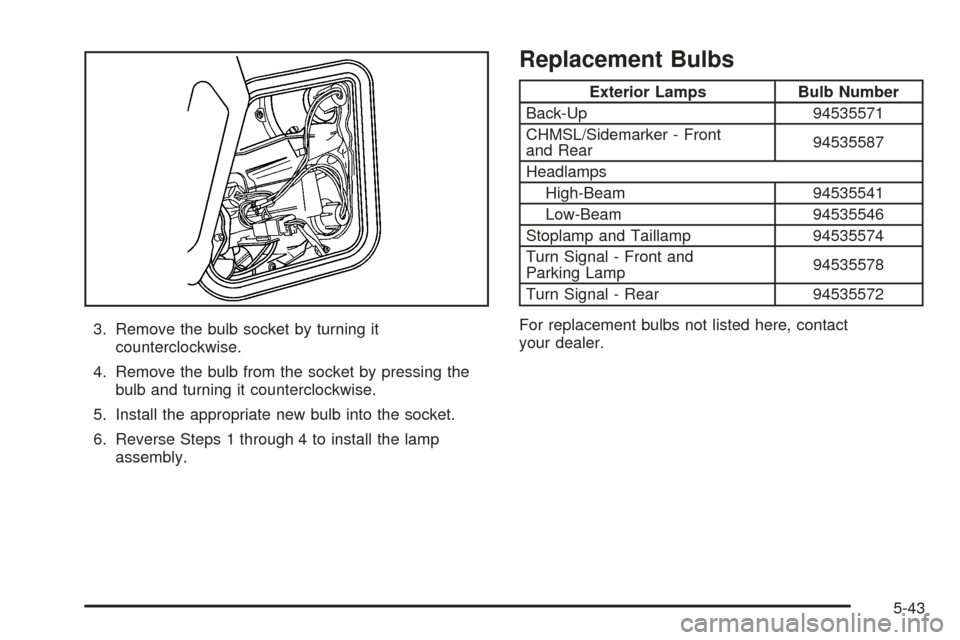

3. Remove the bulb socket by turning it

counterclockwise.

4. Remove the bulb from the socket by pressing the

bulb and turning it counterclockwise.

5. Install the appropriate new bulb into the socket.

6. Reverse Steps 1 through 4 to install the lamp

assembly.

Replacement Bulbs

Exterior Lamps Bulb Number

Back-Up 94535571

CHMSL/Sidemarker - Front

and Rear94535587

Headlamps

High-Beam 94535541

Low-Beam 94535546

Stoplamp and Taillamp 94535574

Turn Signal - Front and

Parking Lamp94535578

Turn Signal - Rear 94535572

For replacement bulbs not listed here, contact

your dealer.

5-43

Page 242 of 336

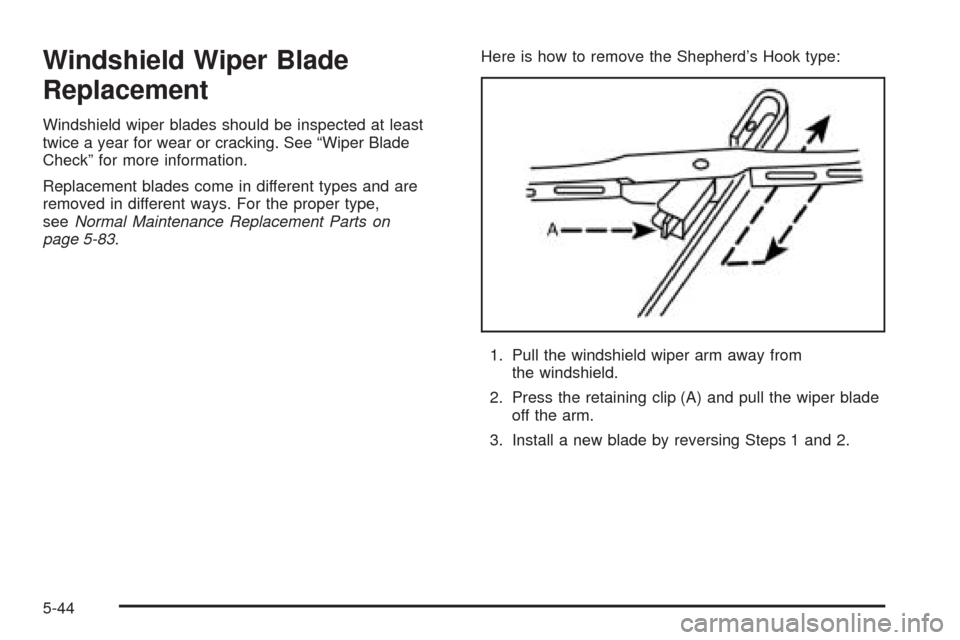

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking. See “Wiper Blade

Check” for more information.

Replacement blades come in different types and are

removed in different ways. For the proper type,

seeNormal Maintenance Replacement Parts on

page 5-83.Here is how to remove the Shepherd’s Hook type:

1. Pull the windshield wiper arm away from

the windshield.

2. Press the retaining clip (A) and pull the wiper blade

off the arm.

3. Install a new blade by reversing Steps 1 and 2.

5-44

Page 243 of 336

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your GM Warranty booklet for details. For additional

information refer to the tire manufacturer’s booklet

included with your vehicle’s Owner Manual.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. SeeLoading Your

Vehicle on page 4-28.

CAUTION: (Continued)

CAUTION: (Continued)

Underin�ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold. SeeInflation - Tire

Pressure on page 5-51.

Overin�ated tires are more likely to be

cut, punctured or broken by a sudden

impact —such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents. If your

tread is badly worn, or if your tires have

been damaged, replace them.

5-45

Page 244 of 336

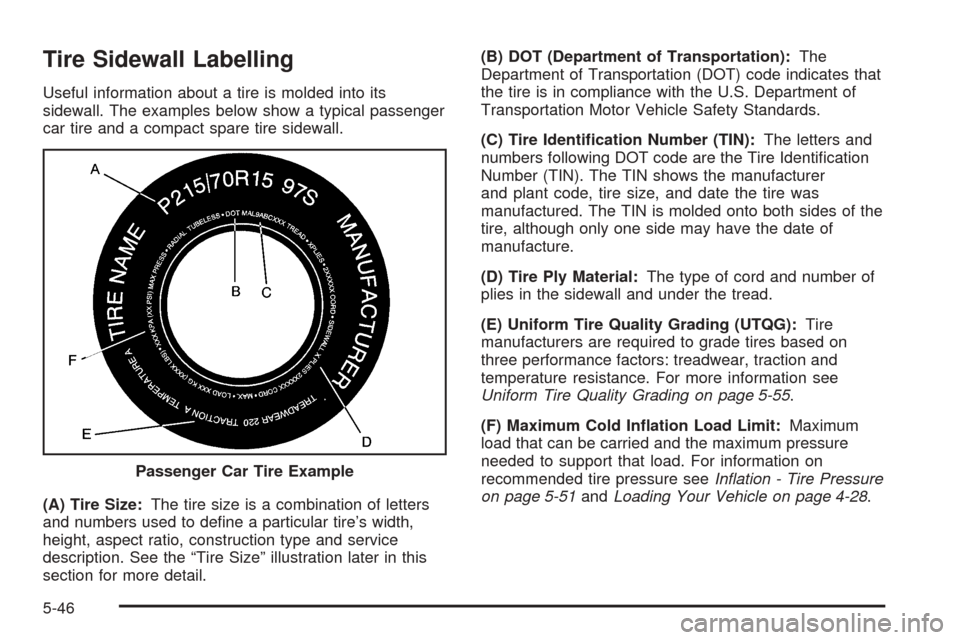

Tire Sidewall Labelling

Useful information about a tire is molded into its

sidewall. The examples below show a typical passenger

car tire and a compact spare tire sidewall.

(A) Tire Size:The tire size is a combination of letters

and numbers used to define a particular tire’s width,

height, aspect ratio, construction type and service

description. See the “Tire Size” illustration later in this

section for more detail.(B) DOT (Department of Transportation):The

Department of Transportation (DOT) code indicates that

the tire is in compliance with the U.S. Department of

Transportation Motor Vehicle Safety Standards.

(C) Tire Identi�cation Number (TIN):The letters and

numbers following DOT code are the Tire Identification

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides of the

tire, although only one side may have the date of

manufacture.

(D) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(E) Uniform Tire Quality Grading (UTQG):Tire

manufacturers are required to grade tires based on

three performance factors: treadwear, traction and

temperature resistance. For more information see

Uniform Tire Quality Grading on page 5-55.

(F) Maximum Cold In�ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load. For information on

recommended tire pressure seeInflation - Tire Pressure

on page 5-51andLoading Your Vehicle on page 4-28. Passenger Car Tire Example

5-46

Page 245 of 336

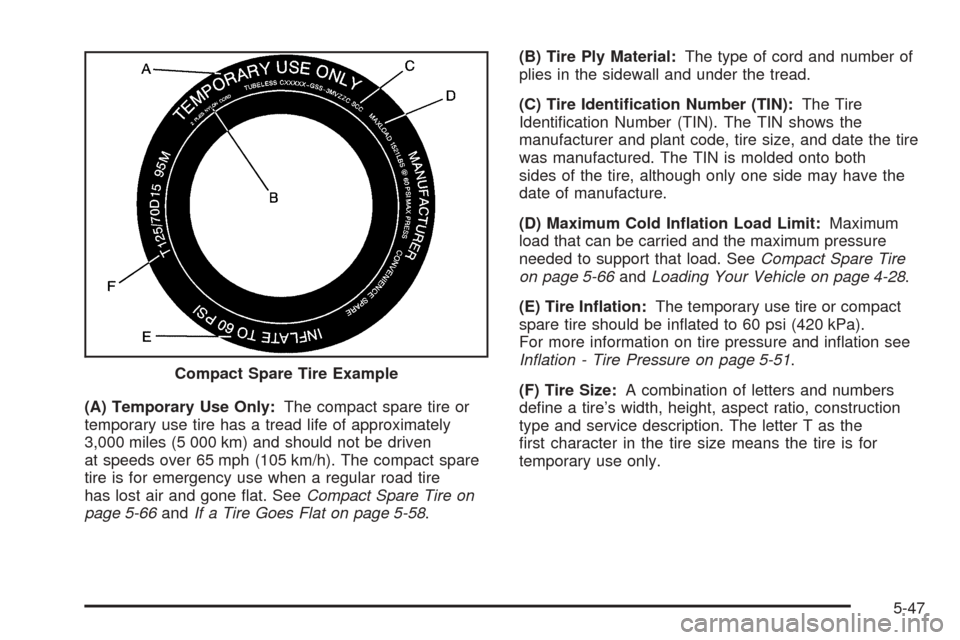

(A) Temporary Use Only:The compact spare tire or

temporary use tire has a tread life of approximately

3,000 miles (5 000 km) and should not be driven

at speeds over 65 mph (105 km/h). The compact spare

tire is for emergency use when a regular road tire

has lost air and gone flat. SeeCompact Spare Tire on

page 5-66andIf a Tire Goes Flat on page 5-58.(B) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(C) Tire Identi�cation Number (TIN):The Tire

Identification Number (TIN). The TIN shows the

manufacturer and plant code, tire size, and date the tire

was manufactured. The TIN is molded onto both

sides of the tire, although only one side may have the

date of manufacture.

(D) Maximum Cold In�ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load. SeeCompact Spare Tire

on page 5-66andLoading Your Vehicle on page 4-28.

(E) Tire In�ation:The temporary use tire or compact

spare tire should be inflated to 60 psi (420 kPa).

For more information on tire pressure and inflation see

Inflation - Tire Pressure on page 5-51.

(F) Tire Size:A combination of letters and numbers

define a tire’s width, height, aspect ratio, construction

type and service description. The letter T as the

first character in the tire size means the tire is for

temporary use only. Compact Spare Tire Example

5-47

Page 246 of 336

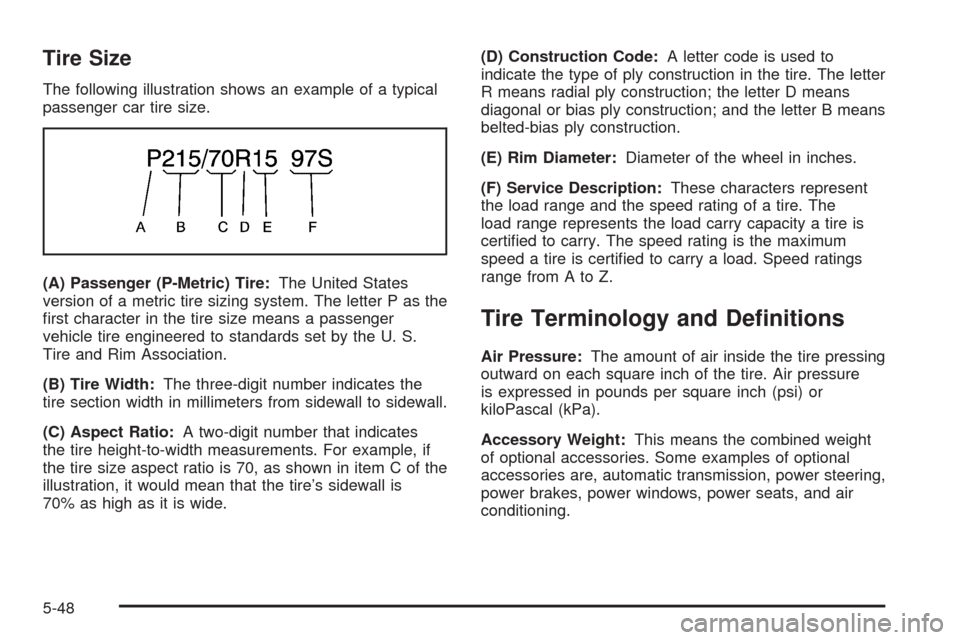

Tire Size

The following illustration shows an example of a typical

passenger car tire size.

(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter P as the

first character in the tire size means a passenger

vehicle tire engineered to standards set by the U. S.

Tire and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example, if

the tire size aspect ratio is 70, as shown in item C of the

illustration, it would mean that the tire’s sidewall is

70% as high as it is wide.(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The letter

R means radial ply construction; the letter D means

diagonal or bias ply construction; and the letter B means

belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:These characters represent

the load range and the speed rating of a tire. The

load range represents the load carry capacity a tire is

certified to carry. The speed rating is the maximum

speed a tire is certified to carry a load. Speed ratings

range from A to Z.

Tire Terminology and De�nitions

Air Pressure:The amount of air inside the tire pressing

outward on each square inch of the tire. Air pressure

is expressed in pounds per square inch (psi) or

kiloPascal (kPa).

Accessory Weight:This means the combined weight

of optional accessories. Some examples of optional

accessories are, automatic transmission, power steering,

power brakes, power windows, power seats, and air

conditioning.

5-48

Page 247 of 336

Aspect Ratio:The relationship of a tire’s height to

its width.

Belt:A rubber coated layer of cords that is located

between the plies and the tread. Cords may be made

from steel or other reinforcing materials.

Bead:The tire bead contains steel wires wrapped by

steel cords that hold the tire onto the rim.

Bias Ply Tire:A pneumatic tire in which the plies are

laid at alternate angles less than 90 degrees to the

centerline of the tread.

Cold In�ation Pressure:The amount of air pressure in

a tire, measured in pounds per square inch (psi) or

kiloPascals (kPa) before a tire has built up heat from

driving. SeeInflation - Tire Pressure on page 5-51.

Curb Weight:This means the weight of a motor vehicle

with standard and optional equipment including the

maximum capacity of fuel, oil and coolant, but without

passengers and cargo.

DOT Markings:A code molded into the sidewall of a

tire signifying that the tire is in compliance with the U.S.

Department of Transportation (DOT) motor vehicle

safety standards. The DOT code includes the Tire

Identification Number (TIN), an alphanumeric designator

which can also identify the tire manufacturer, production

plant, brand and date of production.

GVWR:Gross Vehicle Weight Rating, seeLoading

Your Vehicle on page 4-28.GAWR FRT:Gross Axle Weight Rating for the front

axle, seeLoading Your Vehicle on page 4-28.

GAWR RR:Gross Axle Weight Rating for the rear axle,

seeLoading Your Vehicle on page 4-28.

Intended Outboard Sidewall:The side of an

asymmetrical tire, that must always face outward when

mounted on a vehicle.

KiloPascal (kPa):The metric unit for air pressure.

Light Truck (LT-Metric) Tire:A tire used on light duty

trucks and some multipurpose passenger vehicles.

Load Index:An assigned number ranging from

1 to 279 that corresponds to the load carrying capacity

of a tire.

Maximum In�ation Pressure:The maximum air

pressure to which a cold tire may be inflated. The

maximum air pressure is molded onto the sidewall.

Maximum Load Rating:The load rating for a tire at the

maximum permissible inflation pressure for that tire.

Maximum Loaded Vehicle Weight:The sum of curb

weight; accessory weight; vehicle capacity weight;

and production options weight.

Normal Occupant Weight:The number of occupants a

vehicle is designed to seat multiplied by 150 lbs (68 kg).

SeeLoading Your Vehicle on page 4-28.

5-49

Page 248 of 336

Occupant Distribution:Designated seating positions.

Outward Facing Sidewall:The side of an

asymmetrical tire that has a particular side that faces

outward when mounted on a vehicle. The side of the tire

that contains a whitewall, bears white lettering or

bears manufacturer, brand, and/or model name molding

that is higher or deeper than the same moldings on

the other sidewall of the tire.

Passenger (P-Metric) Tire:A tire used on passenger

cars and some light duty trucks and multipurpose

vehicles.

Recommended In�ation Pressure:Vehicle

manufacturer’s recommended tire inflation pressure and

shown on the tire placard. SeeInflation - Tire Pressure

on page 5-51andLoading Your Vehicle on page 4-28.

Radial Ply Tire:A pneumatic tire in which the ply cords

that extend to the beads are laid at 90 degrees to the

centerline of the tread.

Rim:A metal support for a tire and upon which the tire

beads are seated.

Sidewall:The portion of a tire between the tread and

the bead.

Speed Rating:An alphanumeric code assigned to a

tire indicating the maximum speed at which a tire

can operate.Traction:The friction between the tire and the road

surface. The amount of grip provided.

Tread:The portion of a tire that comes into contact

with the road.

Treadwear Indicators:Narrow bands, sometimes

called “wear bars,” that show across the tread of a tire

when only 1/16 inch (1.6 mm) of tread remains. See

When It Is Time for New Tires on page 5-53.

UTQGS (Uniform Tire Quality Grading Standards):A

tire information system that provides consumers with

ratings for a tire’s traction, temperature, and treadwear.

Ratings are determined by tire manufacturers using

government testing procedures. The ratings are molded

into the sidewall of the tire. SeeUniform Tire Quality

Grading on page 5-55.

Vehicle Capacity Weight:The number of designated

seating positions multiplied by 150 lbs (68 kg) plus

the rated cargo load. SeeLoading Your Vehicle

on page 4-28.

Vehicle Maximum Load on the Tire:Load on an

individual tire due to curb weight, accessory weight,

occupant weight, and cargo weight.

Vehicle Placard:A label permanently attached to a

vehicle showing the vehicle’s capacity weight and

the original equipment tire size and recommended

inflation pressure. See “Tire and Loading Information

Label” underLoading Your Vehicle on page 4-28.

5-50

Page 249 of 336

In�ation - Tire Pressure

Tires need the correct amount of air pressure to

operate effectively.

Notice:Do not let anyone tell you that

under-in�ation or over-in�ation is all right. It is not.

If your tires do not have enough air (under-in�ation),

you can get the following:

Too much �exing

Too much heat

Tire overloading

Premature or irregular wear

Poor handling

Reduced fuel economy

If your tires have too much air (over-in�ation), you

can get the following:

Unusual wear

Poor handling

Rough ride

Needless damage from road hazardsA vehicle specific tire and loading information label is

attached to your vehicle. This label shows your vehicle’s

original equipment tires and the correct inflation

pressures for your tires when they are cold. The

recommended cold tire inflation pressure, shown on the

label, is the minimum amount of air pressure needed to

support your vehicle’s maximum load carrying capacity.

For additional information regarding how much weight

your vehicle can carry, and an example of the tire

and loading information label, seeLoading Your Vehicle

on page 4-28. How you load your vehicle affects

vehicle handling and ride comfort, never load your

vehicle with more weight than it was designed to carry.

When to Check

Check your tires once a month or more. Do not forget to

check the compact spare tire. For additional information

regarding the compact spare tire, seeCompact

Spare Tire on page 5-66.

How to Check

Use a good quality pocket-type gage to check tire

pressure. You cannot tell if your tires are properly

inflated simply by looking at them. Radial tires may look

properly inflated even when they are under-inflated.

Check the tire’s inflation pressure when the tires

are cold. Cold means your vehicle has been sitting

for at least three hours or driven no more than

1 mile (1.6 km).

5-51

Page 250 of 336

Remove the valve cap from the tire valve stem. Press

the tire gage firmly onto the valve to get a pressure

measurement. If the cold tire inflation pressure matches

the recommended pressure on the Tire and Loading

Information label, no further adjustment is necessary. If

the inflation pressure is low, add air until you reach

the recommended amount.

If you overfill the tire, release air by pushing on the

metal stem in the center of the tire valve. Re-check the

tire pressure with the tire gage.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out dirt and

moisture.

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. SeeWhen It Is Time

for New Tires on page 5-53andWheel Replacement

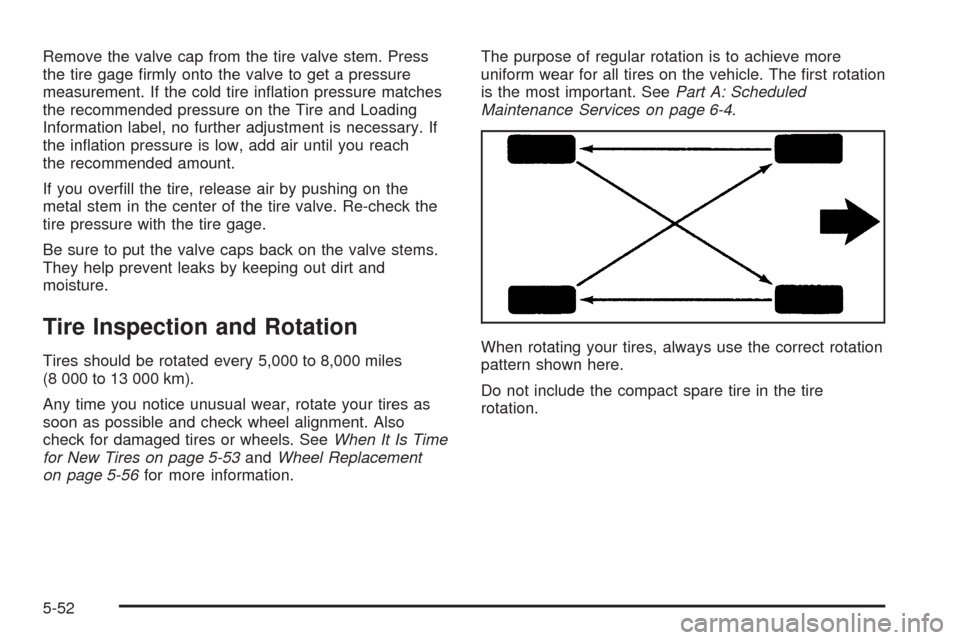

on page 5-56for more information.The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first rotation

is the most important. SeePart A: Scheduled

Maintenance Services on page 6-4.

When rotating your tires, always use the correct rotation

pattern shown here.

Do not include the compact spare tire in the tire

rotation.

5-52