brake fluid CHEVROLET PLYMOUTH ACCLAIM 1993 User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 156 of 2438

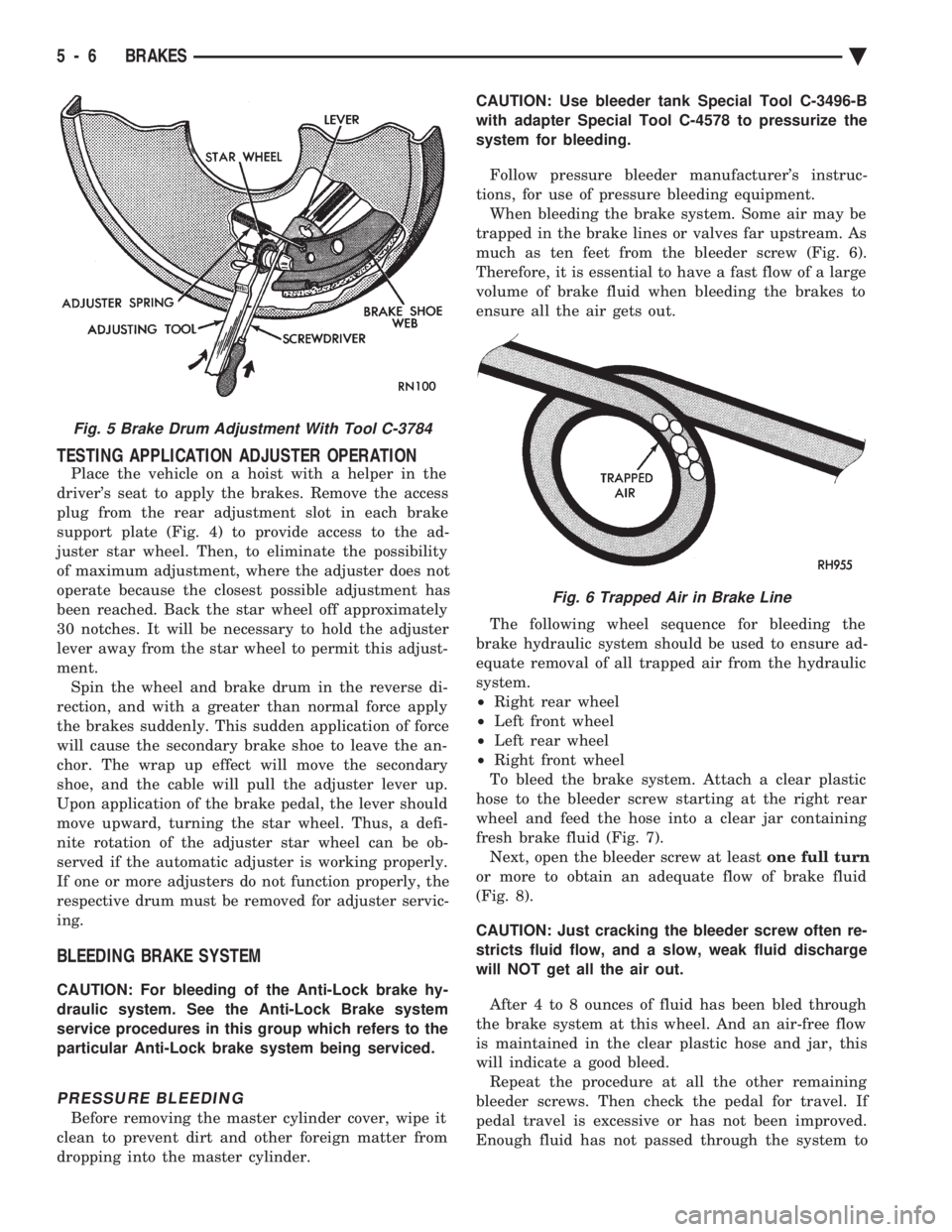

TESTING APPLICATION ADJUSTER OPERATION

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the rear adjustment slot in each brake

support plate (Fig. 4) to provide access to the ad-

juster star wheel. Then, to eliminate the possibility

of maximum adjustment, where the adjuster does not

operate because the closest possible adjustment has

been reached. Back the star wheel off approximately

30 notches. It will be necessary to hold the adjuster

lever away from the star wheel to permit this adjust-

ment. Spin the wheel and brake drum in the reverse di-

rection, and with a greater than normal force apply

the brakes suddenly. This sudden application of force

will cause the secondary brake shoe to leave the an-

chor. The wrap up effect will move the secondary

shoe, and the cable will pull the adjuster lever up.

Upon application of the brake pedal, the lever should

move upward, turning the star wheel. Thus, a defi-

nite rotation of the adjuster star wheel can be ob-

served if the automatic adjuster is working properly.

If one or more adjusters do not function properly, the

respective drum must be removed for adjuster servic-

ing.

BLEEDING BRAKE SYSTEM

CAUTION: For bleeding of the Anti-Lock brake hy-

draulic system. See the Anti-Lock Brake system

service procedures in this group which refers to the

particular Anti-Lock brake system being serviced.

PRESSURE BLEEDING

Before removing the master cylinder cover, wipe it

clean to prevent dirt and other foreign matter from

dropping into the master cylinder. CAUTION: Use bleeder tank Special Tool C-3496-B

with adapter Special Tool C-4578 to pressurize the

system for bleeding.

Follow pressure bleeder manufacturer's instruc-

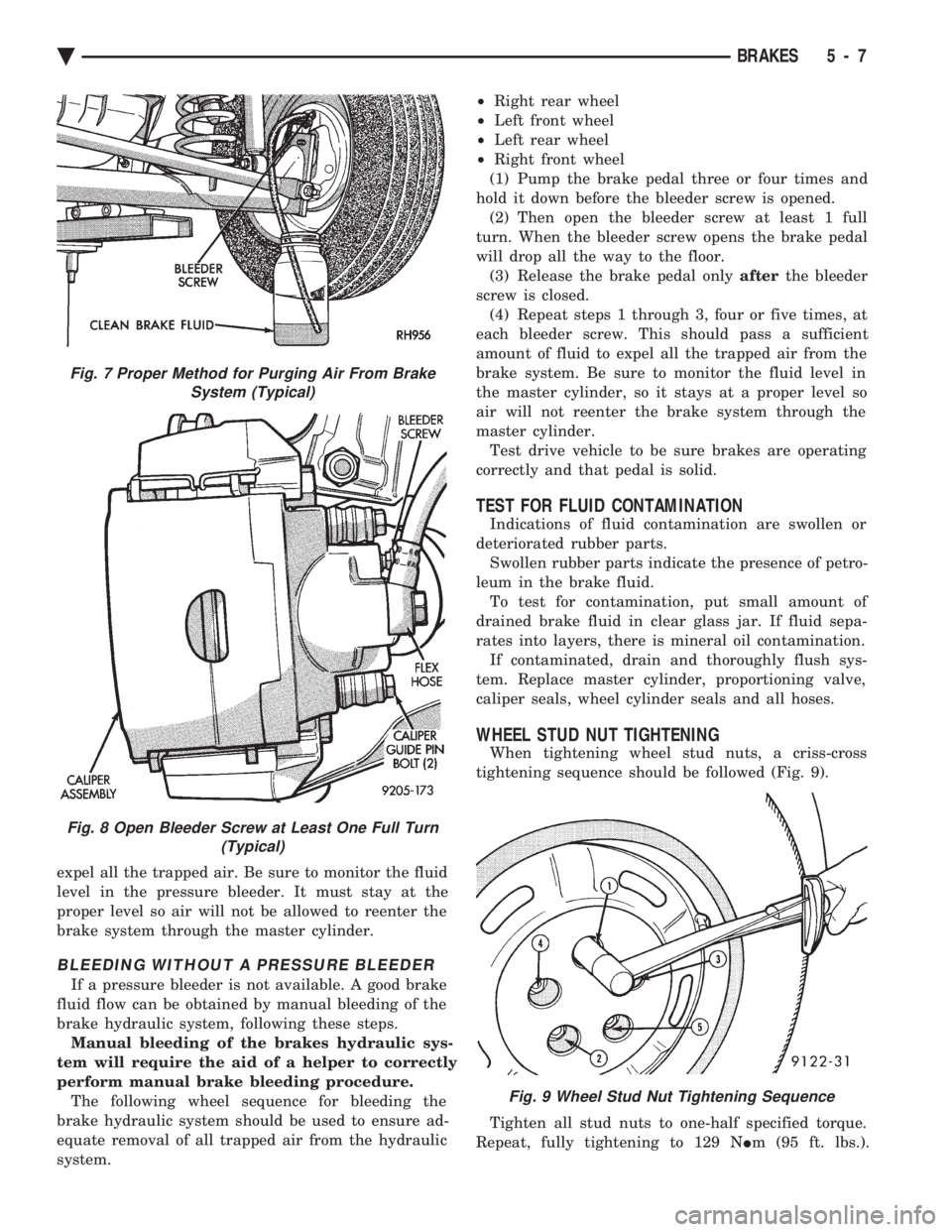

tions, for use of pressure bleeding equipment. When bleeding the brake system. Some air may be

trapped in the brake lines or valves far upstream. As

much as ten feet from the bleeder screw (Fig. 6).

Therefore, it is essential to have a fast flow of a large

volume of brake fluid when bleeding the brakes to

ensure all the air gets out.

The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure ad-

equate removal of all trapped air from the hydraulic

system.

² Right rear wheel

² Left front wheel

² Left rear wheel

² Right front wheel

To bleed the brake system. Attach a clear plastic

hose to the bleeder screw starting at the right rear

wheel and feed the hose into a clear jar containing

fresh brake fluid (Fig. 7). Next, open the bleeder screw at least one full turn

or more to obtain an adequate flow of brake fluid

(Fig. 8).

CAUTION: Just cracking the bleeder screw often re-

stricts fluid flow, and a slow, weak fluid discharge

will NOT get all the air out.

After 4 to 8 ounces of fluid has been bled through

the brake system at this wheel. And an air-free flow

is maintained in the clear plastic hose and jar, this

will indicate a good bleed. Repeat the procedure at all the other remaining

bleeder screws. Then check the pedal for travel. If

pedal travel is excessive or has not been improved.

Enough fluid has not passed through the system to

Fig. 5 Brake Drum Adjustment With Tool C-3784

Fig. 6 Trapped Air in Brake Line

5 - 6 BRAKES Ä

Page 157 of 2438

expel all the trapped air. Be sure to monitor the fluid

level in the pressure bleeder. It must stay at the

proper level so air will not be allowed to reenter the

brake system through the master cylinder.

BLEEDING WITHOUT A PRESSURE BLEEDER

If a pressure bleeder is not available. A good brake

fluid flow can be obtained by manual bleeding of the

brake hydraulic system, following these steps. Manual bleeding of the brakes hydraulic sys-

tem will require the aid of a helper to correctly

perform manual brake bleeding procedure. The following wheel sequence for bleeding the

brake hydraulic system should be used to ensure ad-

equate removal of all trapped air from the hydraulic

system. ²

Right rear wheel

² Left front wheel

² Left rear wheel

² Right front wheel

(1) Pump the brake pedal three or four times and

hold it down before the bleeder screw is opened. (2) Then open the bleeder screw at least 1 full

turn. When the bleeder screw opens the brake pedal

will drop all the way to the floor. (3) Release the brake pedal only afterthe bleeder

screw is closed. (4) Repeat steps 1 through 3, four or five times, at

each bleeder screw. This should pass a sufficient

amount of fluid to expel all the trapped air from the

brake system. Be sure to monitor the fluid level in

the master cylinder, so it stays at a proper level so

air will not reenter the brake system through the

master cylinder. Test drive vehicle to be sure brakes are operating

correctly and that pedal is solid.

TEST FOR FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swollen rubber parts indicate the presence of petro-

leum in the brake fluid. To test for contamination, put small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil contamination. If contaminated, drain and thoroughly flush sys-

tem. Replace master cylinder, proportioning valve,

caliper seals, wheel cylinder seals and all hoses.

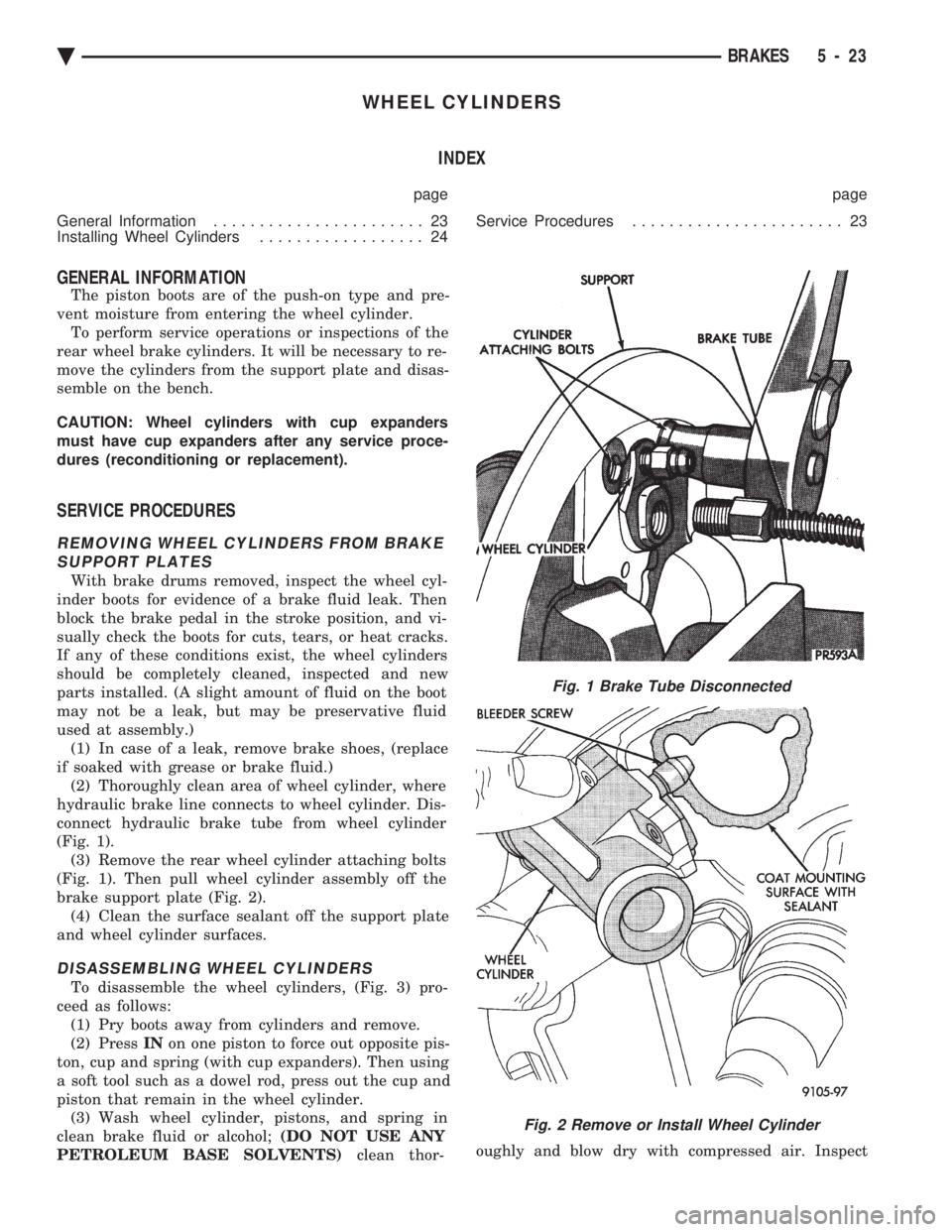

WHEEL STUD NUT TIGHTENING

When tightening wheel stud nuts, a criss-cross

tightening sequence should be followed (Fig. 9).

Tighten all stud nuts to one-half specified torque.

Repeat, fully tightening to 129 N Im (95 ft. lbs.).

Fig. 9 Wheel Stud Nut Tightening Sequence

Fig. 7 Proper Method for Purging Air From Brake

System (Typical)

Fig. 8 Open Bleeder Screw at Least One Full Turn (Typical)

Ä BRAKES 5 - 7

Page 173 of 2438

WHEEL CYLINDERS INDEX

page page

General Information ....................... 23

Installing Wheel Cylinders .................. 24 Service Procedures

....................... 23

GENERAL INFORMATION

The piston boots are of the push-on type and pre-

vent moisture from entering the wheel cylinder. To perform service operations or inspections of the

rear wheel brake cylinders. It will be necessary to re-

move the cylinders from the support plate and disas-

semble on the bench.

CAUTION: Wheel cylinders with cup expanders

must have cup expanders after any service proce-

dures (reconditioning or replacement).

SERVICE PROCEDURES

REMOVING WHEEL CYLINDERS FROM BRAKE SUPPORT PLATES

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Then

block the brake pedal in the stroke position, and vi-

sually check the boots for cuts, tears, or heat cracks.

If any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed. (A slight amount of fluid on the boot

may not be a leak, but may be preservative fluid

used at assembly.) (1) In case of a leak, remove brake shoes, (replace

if soaked with grease or brake fluid.) (2) Thoroughly clean area of wheel cylinder, where

hydraulic brake line connects to wheel cylinder. Dis-

connect hydraulic brake tube from wheel cylinder

(Fig. 1). (3) Remove the rear wheel cylinder attaching bolts

(Fig. 1). Then pull wheel cylinder assembly off the

brake support plate (Fig. 2). (4) Clean the surface sealant off the support plate

and wheel cylinder surfaces.

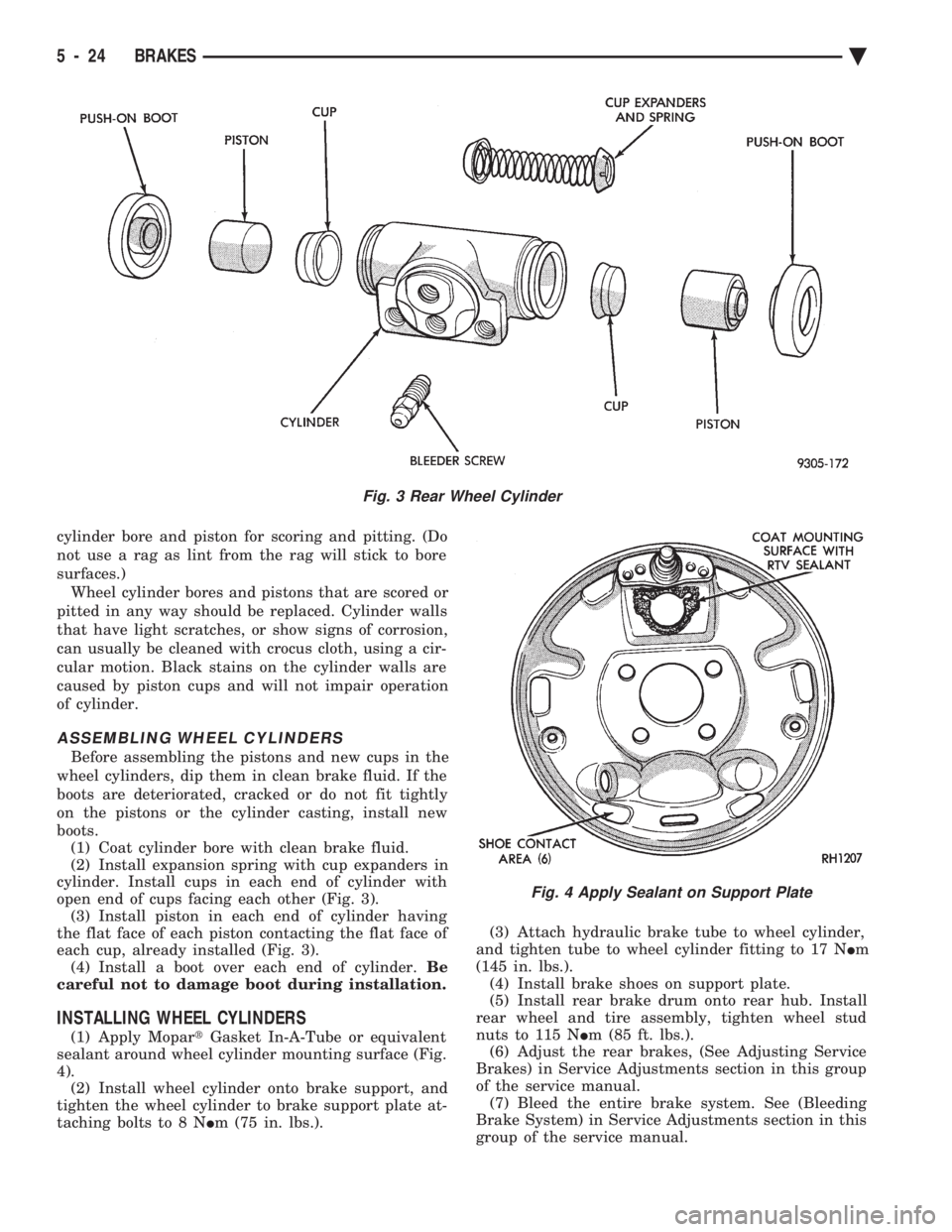

DISASSEMBLING WHEEL CYLINDERS

To disassemble the wheel cylinders, (Fig. 3) pro-

ceed as follows: (1) Pry boots away from cylinders and remove.

(2) Press INon one piston to force out opposite pis-

ton, cup and spring (with cup expanders). Then using

a soft tool such as a dowel rod, press out the cup and

piston that remain in the wheel cylinder. (3) Wash wheel cylinder, pistons, and spring in

clean brake fluid or alcohol; (DO NOT USE ANY

PETROLEUM BASE SOLVENTS) clean thor- oughly and blow dry with compressed air. Inspect

Fig. 1 Brake Tube Disconnected

Fig. 2 Remove or Install Wheel Cylinder

Ä

BRAKES 5 - 23

Page 174 of 2438

cylinder bore and piston for scoring and pitting. (Do

not use a rag as lint from the rag will stick to bore

surfaces.) Wheel cylinder bores and pistons that are scored or

pitted in any way should be replaced. Cylinder walls

that have light scratches, or show signs of corrosion,

can usually be cleaned with crocus cloth, using a cir-

cular motion. Black stains on the cylinder walls are

caused by piston cups and will not impair operation

of cylinder.

ASSEMBLING WHEEL CYLINDERS

Before assembling the pistons and new cups in the

wheel cylinders, dip them in clean brake fluid. If the

boots are deteriorated, cracked or do not fit tightly

on the pistons or the cylinder casting, install new

boots. (1) Coat cylinder bore with clean brake fluid.

(2) Install expansion spring with cup expanders in

cylinder. Install cups in each end of cylinder with

open end of cups facing each other (Fig. 3). (3) Install piston in each end of cylinder having

the flat face of each piston contacting the flat face of

each cup, already installed (Fig. 3). (4) Install a boot over each end of cylinder. Be

careful not to damage boot during installation.

INSTALLING WHEEL CYLINDERS

(1) Apply Mopar tGasket In-A-Tube or equivalent

sealant around wheel cylinder mounting surface (Fig.

4). (2) Install wheel cylinder onto brake support, and

tighten the wheel cylinder to brake support plate at-

taching bolts to 8 N Im (75 in. lbs.). (3) Attach hydraulic brake tube to wheel cylinder,

and tighten tube to wheel cylinder fitting to 17 N Im

(145 in. lbs.). (4) Install brake shoes on support plate.

(5) Install rear brake drum onto rear hub. Install

rear wheel and tire assembly, tighten wheel stud

nuts to 115 N Im (85 ft. lbs.).

(6) Adjust the rear brakes, (See Adjusting Service

Brakes) in Service Adjustments section in this group

of the service manual. (7) Bleed the entire brake system. See (Bleeding

Brake System) in Service Adjustments section in this

group of the service manual.

Fig. 3 Rear Wheel Cylinder

Fig. 4 Apply Sealant on Support Plate

5 - 24 BRAKES Ä

Page 177 of 2438

to the rear will be lower than the front brakes. This will

prevent premature rear wheel lock-up and skid. If

hydraulic pressure is lost in one half of the diagonally

split system, the operation of the proportioning valve

in the remaining half is not effected.

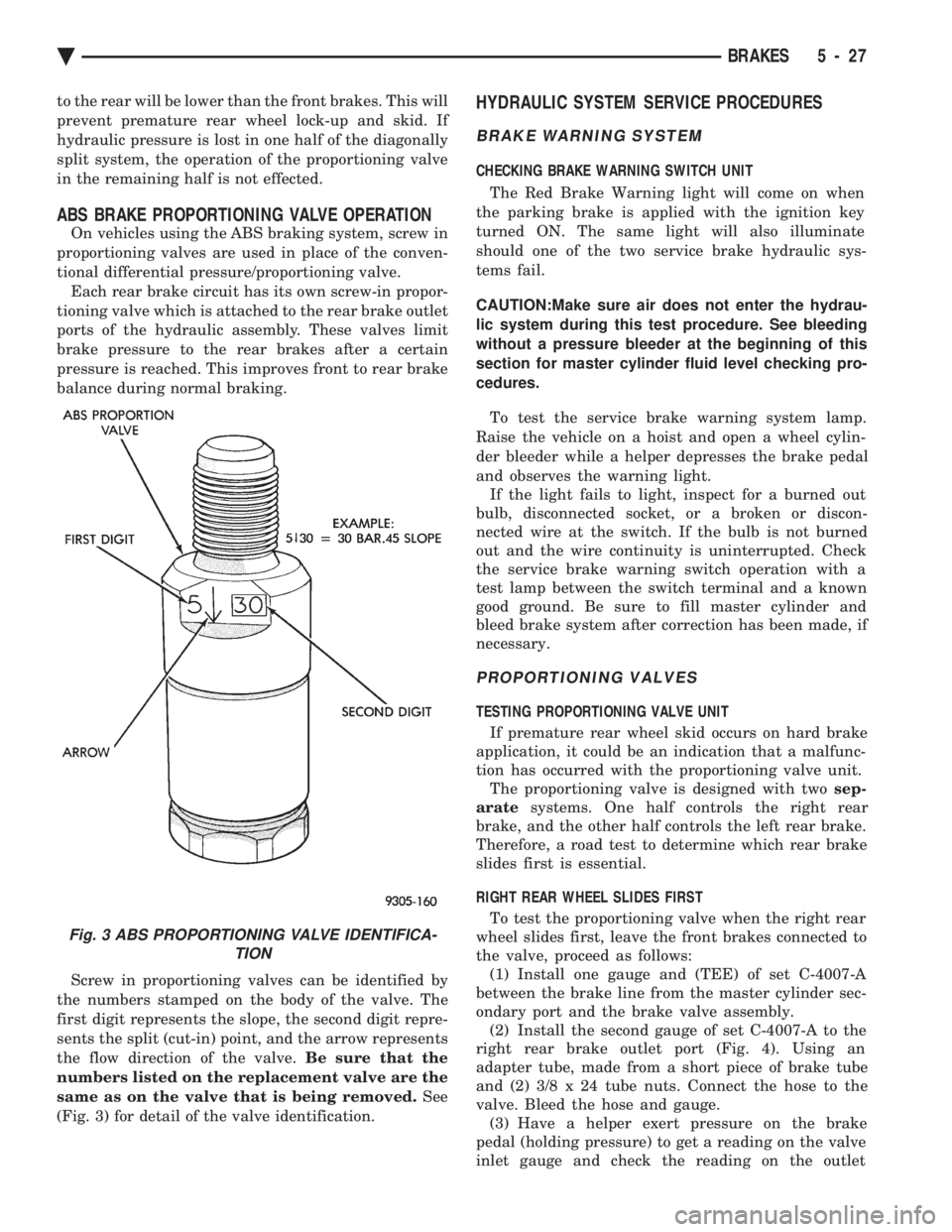

ABS BRAKE PROPORTIONING VALVE OPERATION

On vehicles using the ABS braking system, screw in

proportioning valves are used in place of the conven-

tional differential pressure/proportioning valve. Each rear brake circuit has its own screw-in propor-

tioning valve which is attached to the rear brake outlet

ports of the hydraulic assembly. These valves limit

brake pressure to the rear brakes after a certain

pressure is reached. This improves front to rear brake

balance during normal braking.

Screw in proportioning valves can be identified by

the numbers stamped on the body of the valve. The

first digit represents the slope, the second digit repre-

sents the split (cut-in) point, and the arrow represents

the flow direction of the valve. Be sure that the

numbers listed on the replacement valve are the

same as on the valve that is being removed. See

(Fig. 3) for detail of the valve identification.

HYDRAULIC SYSTEM SERVICE PROCEDURES

BRAKE WARNING SYSTEM

CHECKING BRAKE WARNING SWITCH UNIT

The Red Brake Warning light will come on when

the parking brake is applied with the ignition key

turned ON. The same light will also illuminate

should one of the two service brake hydraulic sys-

tems fail.

CAUTION:Make sure air does not enter the hydrau-

lic system during this test procedure. See bleeding

without a pressure bleeder at the beginning of this

section for master cylinder fluid level checking pro-

cedures.

To test the service brake warning system lamp.

Raise the vehicle on a hoist and open a wheel cylin-

der bleeder while a helper depresses the brake pedal

and observes the warning light. If the light fails to light, inspect for a burned out

bulb, disconnected socket, or a broken or discon-

nected wire at the switch. If the bulb is not burned

out and the wire continuity is uninterrupted. Check

the service brake warning switch operation with a

test lamp between the switch terminal and a known

good ground. Be sure to fill master cylinder and

bleed brake system after correction has been made, if

necessary.

PROPORTIONING VALVES

TESTING PROPORTIONING VALVE UNIT

If premature rear wheel skid occurs on hard brake

application, it could be an indication that a malfunc-

tion has occurred with the proportioning valve unit. The proportioning valve is designed with two sep-

arate systems. One half controls the right rear

brake, and the other half controls the left rear brake.

Therefore, a road test to determine which rear brake

slides first is essential.

RIGHT REAR WHEEL SLIDES FIRST To test the proportioning valve when the right rear

wheel slides first, leave the front brakes connected to

the valve, proceed as follows: (1) Install one gauge and (TEE) of set C-4007-A

between the brake line from the master cylinder sec-

ondary port and the brake valve assembly. (2) Install the second gauge of set C-4007-A to the

right rear brake outlet port (Fig. 4). Using an

adapter tube, made from a short piece of brake tube

and (2) 3/8 x 24 tube nuts. Connect the hose to the

valve. Bleed the hose and gauge. (3) Have a helper exert pressure on the brake

pedal (holding pressure) to get a reading on the valve

inlet gauge and check the reading on the outlet

Fig. 3 ABS PROPORTIONING VALVE IDENTIFICA- TION

Ä BRAKES 5 - 27

Page 182 of 2438

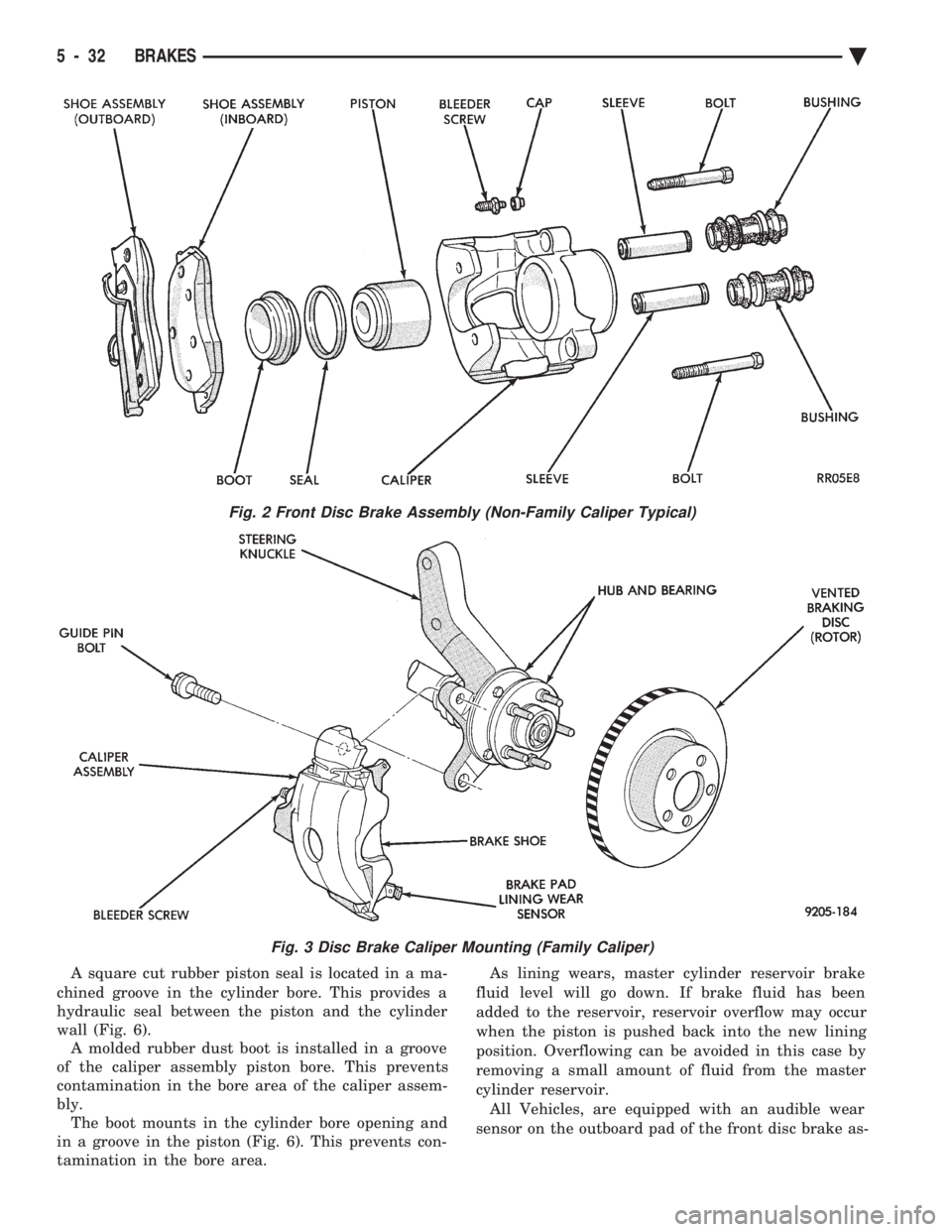

A square cut rubber piston seal is located in a ma-

chined groove in the cylinder bore. This provides a

hydraulic seal between the piston and the cylinder

wall (Fig. 6). A molded rubber dust boot is installed in a groove

of the caliper assembly piston bore. This prevents

contamination in the bore area of the caliper assem-

bly. The boot mounts in the cylinder bore opening and

in a groove in the piston (Fig. 6). This prevents con-

tamination in the bore area. As lining wears, master cylinder reservoir brake

fluid level will go down. If brake fluid has been

added to the reservoir, reservoir overflow may occur

when the piston is pushed back into the new lining

position. Overflowing can be avoided in this case by

removing a small amount of fluid from the master

cylinder reservoir. All Vehicles, are equipped with an audible wear

sensor on the outboard pad of the front disc brake as-

Fig. 2 Front Disc Brake Assembly (Non-Family Caliper Typical)

Fig. 3 Disc Brake Caliper Mounting (Family Caliper)

5 - 32 BRAKES Ä

Page 189 of 2438

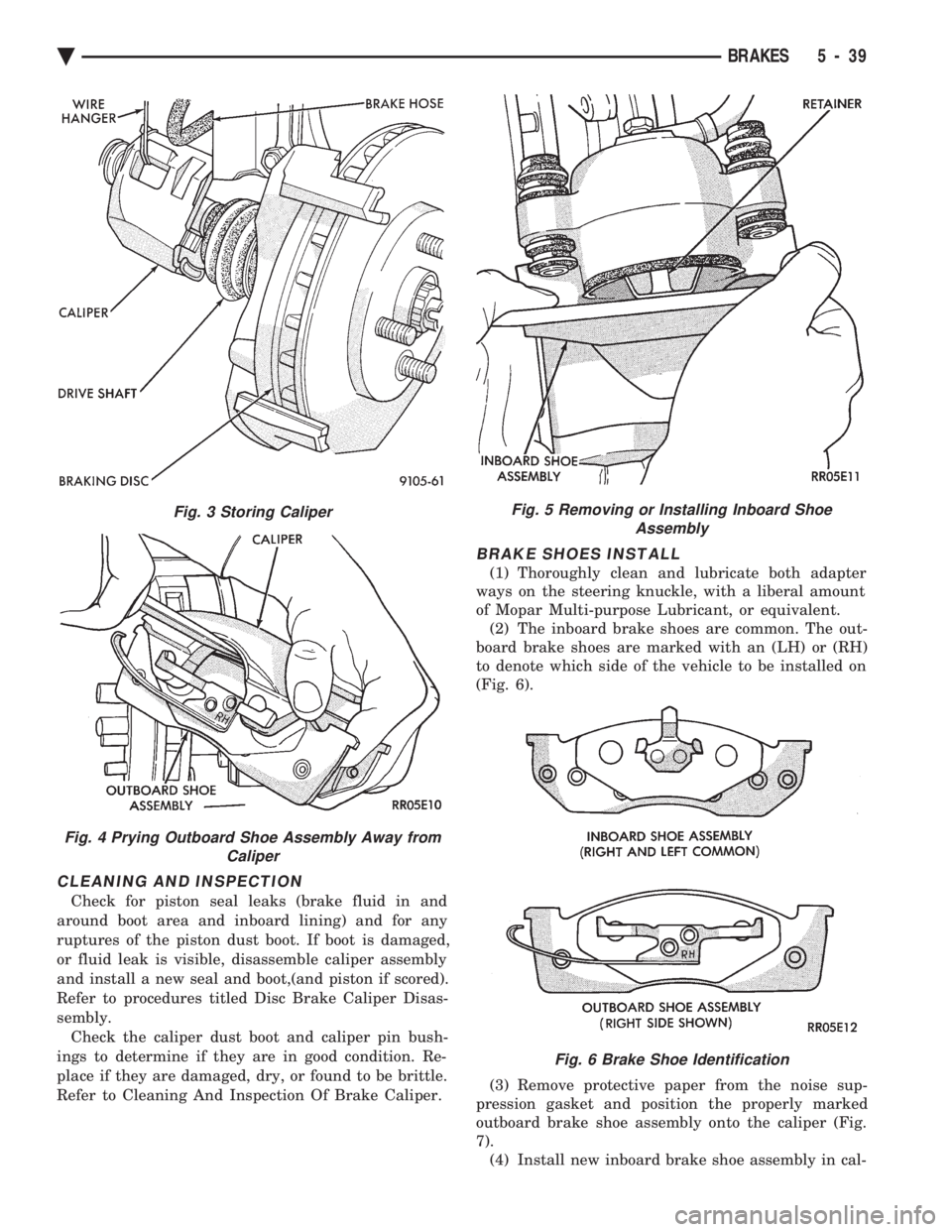

CLEANING AND INSPECTION

Check for piston seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of the piston dust boot. If boot is damaged,

or fluid leak is visible, disassemble caliper assembly

and install a new seal and boot,(and piston if scored).

Refer to procedures titled Disc Brake Caliper Disas-

sembly. Check the caliper dust boot and caliper pin bush-

ings to determine if they are in good condition. Re-

place if they are damaged, dry, or found to be brittle.

Refer to Cleaning And Inspection Of Brake Caliper.

BRAKE SHOES INSTALL

(1) Thoroughly clean and lubricate both adapter

ways on the steering knuckle, with a liberal amount

of Mopar Multi-purpose Lubricant, or equivalent. (2) The inboard brake shoes are common. The out-

board brake shoes are marked with an (LH) or (RH)

to denote which side of the vehicle to be installed on

(Fig. 6).

(3) Remove protective paper from the noise sup-

pression gasket and position the properly marked

outboard brake shoe assembly onto the caliper (Fig.

7). (4) Install new inboard brake shoe assembly in cal-

Fig. 3 Storing Caliper

Fig. 4 Prying Outboard Shoe Assembly Away from Caliper

Fig. 5 Removing or Installing Inboard ShoeAssembly

Fig. 6 Brake Shoe Identification

Ä BRAKES 5 - 39

Page 190 of 2438

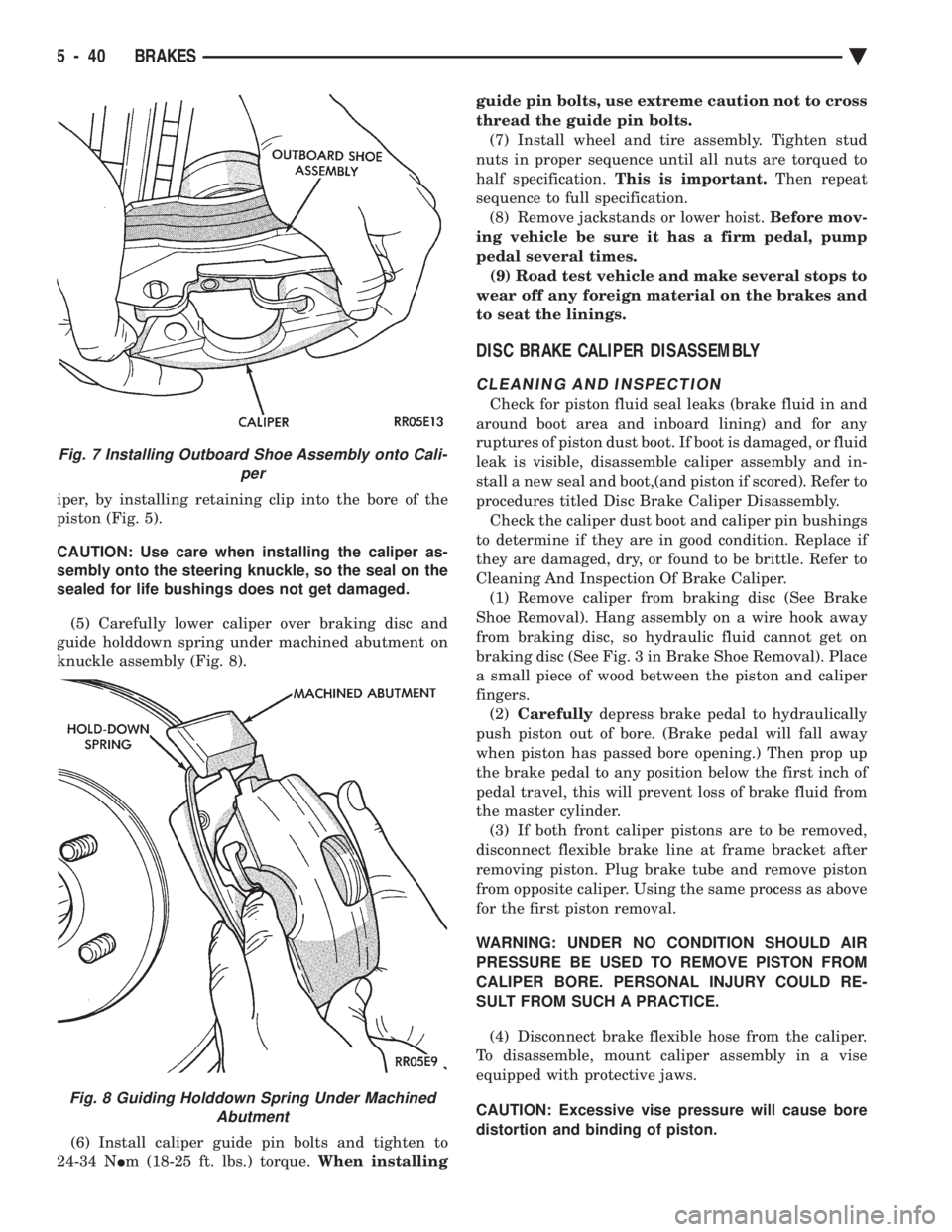

iper, by installing retaining clip into the bore of the

piston (Fig. 5).

CAUTION: Use care when installing the caliper as-

sembly onto the steering knuckle, so the seal on the

sealed for life bushings does not get damaged.

(5) Carefully lower caliper over braking disc and

guide holddown spring under machined abutment on

knuckle assembly (Fig. 8).

(6) Install caliper guide pin bolts and tighten to

24-34 N Im (18-25 ft. lbs.) torque. When installing guide pin bolts, use extreme caution not to cross

thread the guide pin bolts.

(7) Install wheel and tire assembly. Tighten stud

nuts in proper sequence until all nuts are torqued to

half specification. This is important. Then repeat

sequence to full specification. (8) Remove jackstands or lower hoist. Before mov-

ing vehicle be sure it has a firm pedal, pump

pedal several times. (9) Road test vehicle and make several stops to

wear off any foreign material on the brakes and

to seat the linings.

DISC BRAKE CALIPER DISASSEMBLY

CLEANING AND INSPECTION

Check for piston fluid seal leaks (brake fluid in and

around boot area and inboard lining) and for any

ruptures of piston dust boot. If boot is damaged, or fluid

leak is visible, disassemble caliper assembly and in-

stall a new seal and boot,(and piston if scored). Refer to

procedures titled Disc Brake Caliper Disassembly. Check the caliper dust boot and caliper pin bushings

to determine if they are in good condition. Replace if

they are damaged, dry, or found to be brittle. Refer to

Cleaning And Inspection Of Brake Caliper. (1) Remove caliper from braking disc (See Brake

Shoe Removal). Hang assembly on a wire hook away

from braking disc, so hydraulic fluid cannot get on

braking disc (See Fig. 3 in Brake Shoe Removal). Place

a small piece of wood between the piston and caliper

fingers. (2) Carefully depress brake pedal to hydraulically

push piston out of bore. (Brake pedal will fall away

when piston has passed bore opening.) Then prop up

the brake pedal to any position below the first inch of

pedal travel, this will prevent loss of brake fluid from

the master cylinder. (3) If both front caliper pistons are to be removed,

disconnect flexible brake line at frame bracket after

removing piston. Plug brake tube and remove piston

from opposite caliper. Using the same process as above

for the first piston removal.

WARNING: UNDER NO CONDITION SHOULD AIR

PRESSURE BE USED TO REMOVE PISTON FROM

CALIPER BORE. PERSONAL INJURY COULD RE-

SULT FROM SUCH A PRACTICE.

(4) Disconnect brake flexible hose from the caliper.

To disassemble, mount caliper assembly in a vise

equipped with protective jaws.

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston.

Fig. 7 Installing Outboard Shoe Assembly onto Cali- per

Fig. 8 Guiding Holddown Spring Under MachinedAbutment

5 - 40 BRAKES Ä

Page 191 of 2438

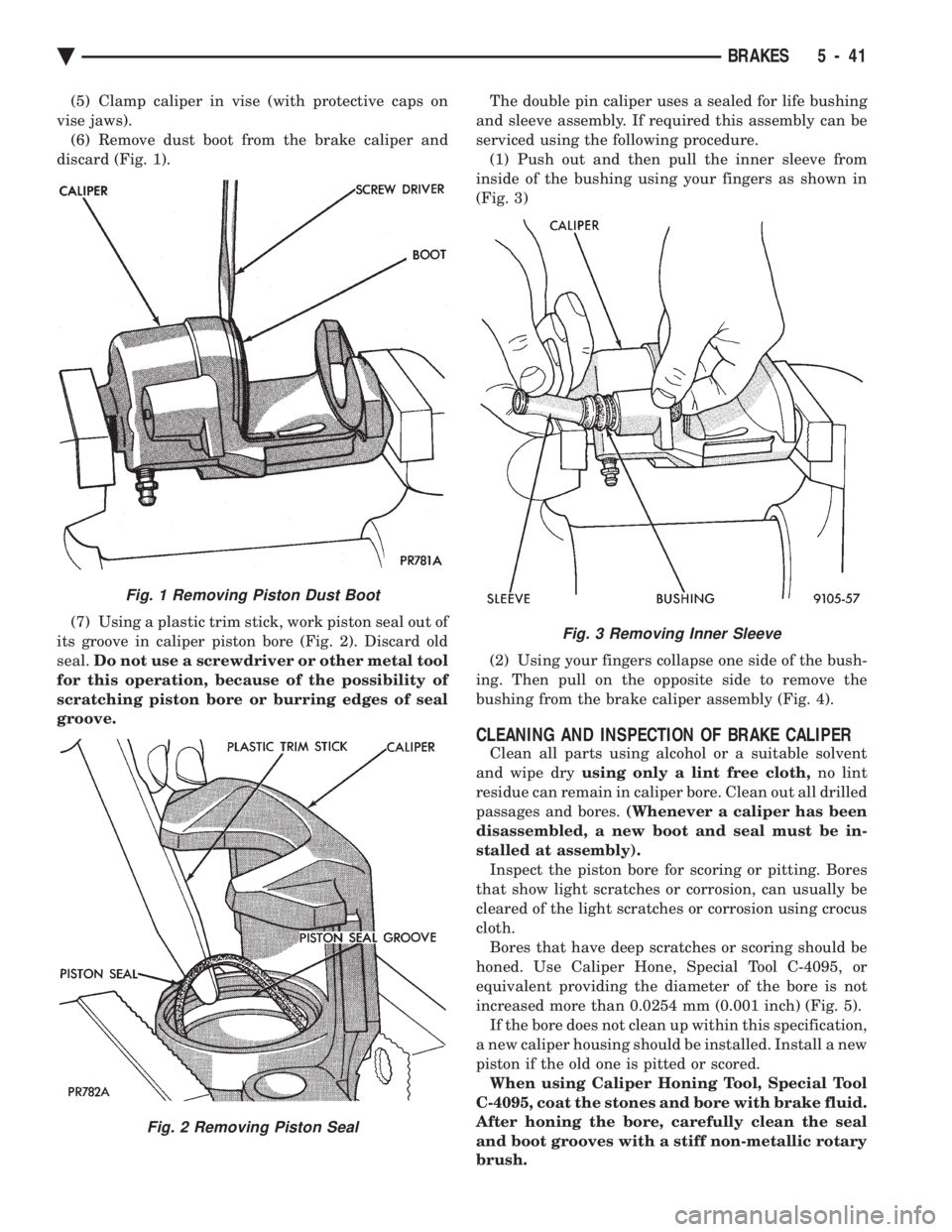

(5) Clamp caliper in vise (with protective caps on

vise jaws). (6) Remove dust boot from the brake caliper and

discard (Fig. 1).

(7) Using a plastic trim stick, work piston seal out of

its groove in caliper piston bore (Fig. 2). Discard old

seal. Do not use a screwdriver or other metal tool

for this operation, because of the possibility of

scratching piston bore or burring edges of seal

groove. The double pin caliper uses a sealed for life bushing

and sleeve assembly. If required this assembly can be

serviced using the following procedure. (1) Push out and then pull the inner sleeve from

inside of the bushing using your fingers as shown in

(Fig. 3)

(2) Using your fingers collapse one side of the bush-

ing. Then pull on the opposite side to remove the

bushing from the brake caliper assembly (Fig. 4).

CLEANING AND INSPECTION OF BRAKE CALIPER

Clean all parts using alcohol or a suitable solvent

and wipe dry using only a lint free cloth, no lint

residue can remain in caliper bore. Clean out all drilled

passages and bores. (Whenever a caliper has been

disassembled, a new boot and seal must be in-

stalled at assembly). Inspect the piston bore for scoring or pitting. Bores

that show light scratches or corrosion, can usually be

cleared of the light scratches or corrosion using crocus

cloth. Bores that have deep scratches or scoring should be

honed. Use Caliper Hone, Special Tool C-4095, or

equivalent providing the diameter of the bore is not

increased more than 0.0254 mm (0.001 inch) (Fig. 5). If the bore does not clean up within this specification,

a new caliper housing should be installed. Install a new

piston if the old one is pitted or scored. When using Caliper Honing Tool, Special Tool

C-4095, coat the stones and bore with brake fluid.

After honing the bore, carefully clean the seal

and boot grooves with a stiff non-metallic rotary

brush.

Fig. 1 Removing Piston Dust Boot

Fig. 2 Removing Piston Seal

Fig. 3 Removing Inner Sleeve

Ä BRAKES 5 - 41

Page 192 of 2438

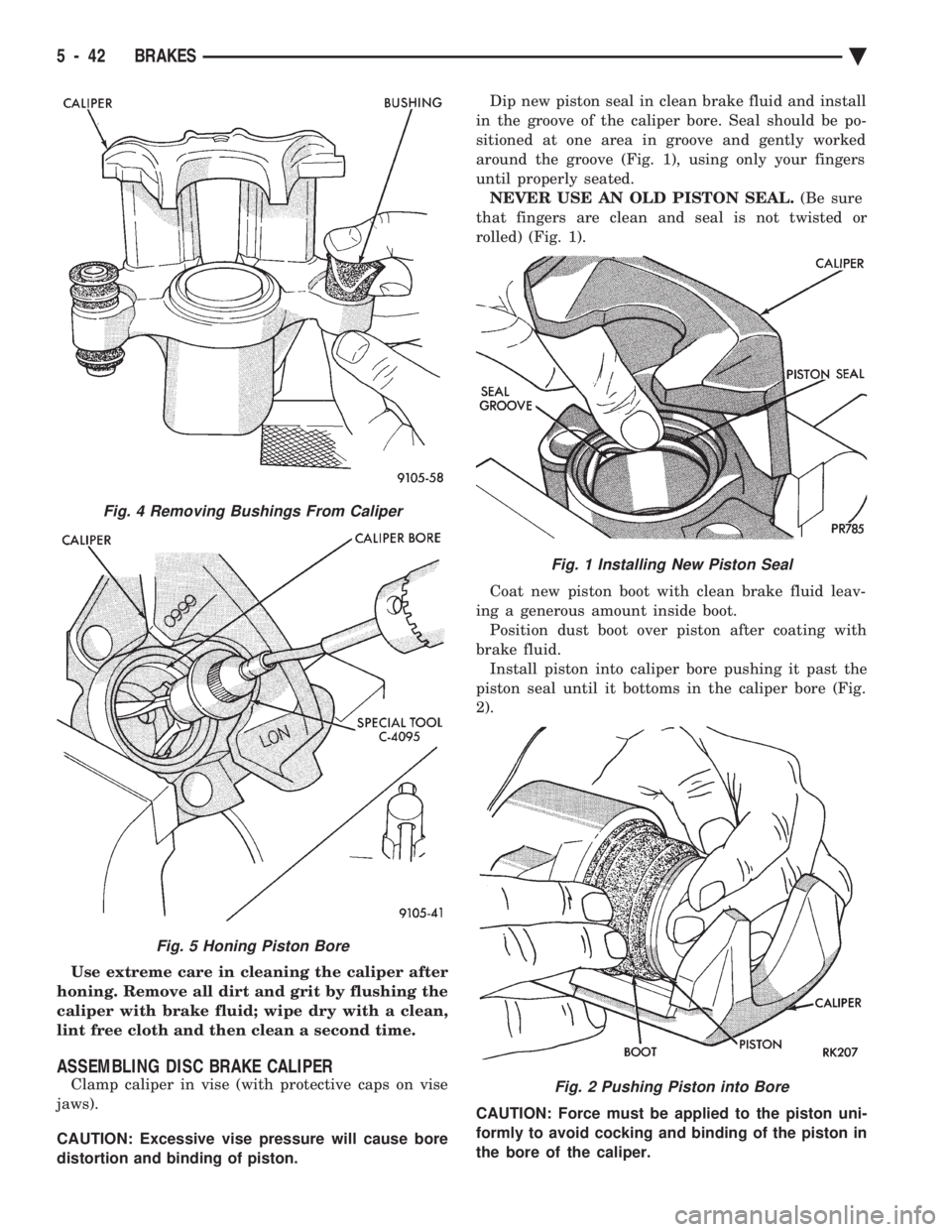

Use extreme care in cleaning the caliper after

honing. Remove all dirt and grit by flushing the

caliper with brake fluid; wipe dry with a clean,

lint free cloth and then clean a second time.

ASSEMBLING DISC BRAKE CALIPER

Clamp caliper in vise (with protective caps on vise

jaws).

CAUTION: Excessive vise pressure will cause bore

distortion and binding of piston. Dip new piston seal in clean brake fluid and install

in the groove of the caliper bore. Seal should be po-

sitioned at one area in groove and gently worked

around the groove (Fig. 1), using only your fingers

until properly seated. NEVER USE AN OLD PISTON SEAL. (Be sure

that fingers are clean and seal is not twisted or

rolled) (Fig. 1).

Coat new piston boot with clean brake fluid leav-

ing a generous amount inside boot. Position dust boot over piston after coating with

brake fluid. Install piston into caliper bore pushing it past the

piston seal until it bottoms in the caliper bore (Fig.

2).

CAUTION: Force must be applied to the piston uni-

formly to avoid cocking and binding of the piston in

the bore of the caliper.

Fig. 1 Installing New Piston Seal

Fig. 2 Pushing Piston into Bore

Fig. 4 Removing Bushings From Caliper

Fig. 5 Honing Piston Bore

5 - 42 BRAKES Ä