sensor CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 2376 of 2438

NONÐCOMPUTER AIDED DIAGNOSTIC TESTS

Determine whether the operator complaint is due

to a system failure or improper operation of the ATC

system. The system will to go into a maximum heat

or cooling mode if the operator changes the tempera-

ture setting four or more degrees. Check the following:

² Coolant level

² Refrigerant charge

² Drive belt tension

² Radiator air flow

² Radiator fan operation

² Air suction of In-car Temperature Sensor/Aspirator

To check air suction of the Aspirator, place a small

piece of tissue paper over the Aspirator opening on

the instrument panel. This opening is located to the

right of the steering column. The tissue paper should

cling to the opening if system is functioning properly. Bring the engine to normal operating temperature

and proceed with Computer Aided Diagnostic Proce-

dures. Always test the entire system after each re-

pair has been performed.

COMPUTER AIDED DIAGNOSTIC TESTS

The ATC control has a computer capable of trou-

bleshooting the entire ATC system in approximately

60 seconds. The engine must be running and at nor-

mal operating temperature during the test to provide

hot coolant for the heater. During the ATC Diagnostic Test, the computer will

calibrate the Mode and Blend Door actuators.

CAUTION: Do not remove the actuators from the

heater-A/C unit assembly with power applied. Re-

moval should only be done with the Ignition OFF.

The actuators have no mechanical stops to limit the

travel. If the actuator rotates and is not connected

to the unit assembly, it will become un-calibrated.

The Diagnostic Test is capable of checking all elec-

trical signals between the ATC Control Module, ac-

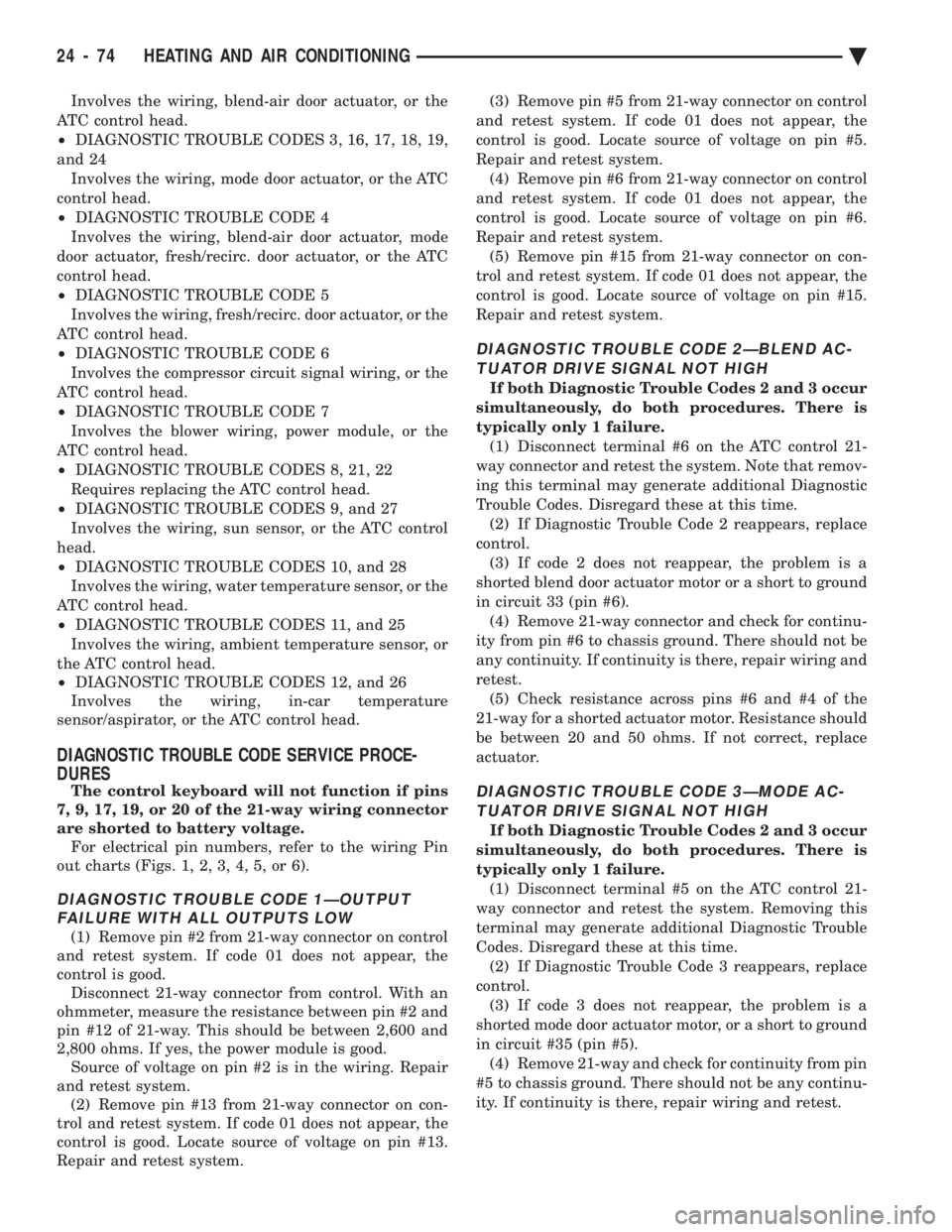

tuators, sensors and blower control. The Diagnostic Test will display two types of Diag-

nostic trouble Codes (Fig. 21). The Diagnostic Trou-

ble Codes numbered 01 through 22, have been

detected during the Diagnostic Test. Diagnostic Trou-

ble Codes numbered 23 through 28, have been de-

tected during normal ATC operation. Diagnostic

Trouble Codes 23 through 28 would then be stored in

the ATC control computer and are only being re-

trieved during the Diagnostic Test.

For electrical pin numbers, refer to the wiring Pin

out charts on the following pages in this section. (1) Start vehicle and allow engine to warm up.

(2) For two seconds, depress the DEFROST,

FLOOR and MODE buttons at the same time. The

ATC control should begin to flash on and off. (3) During the Diagnostic Test perform the follow-

ing symptom tests: (a) Do all display symbols and indicators illumi-

nate ?

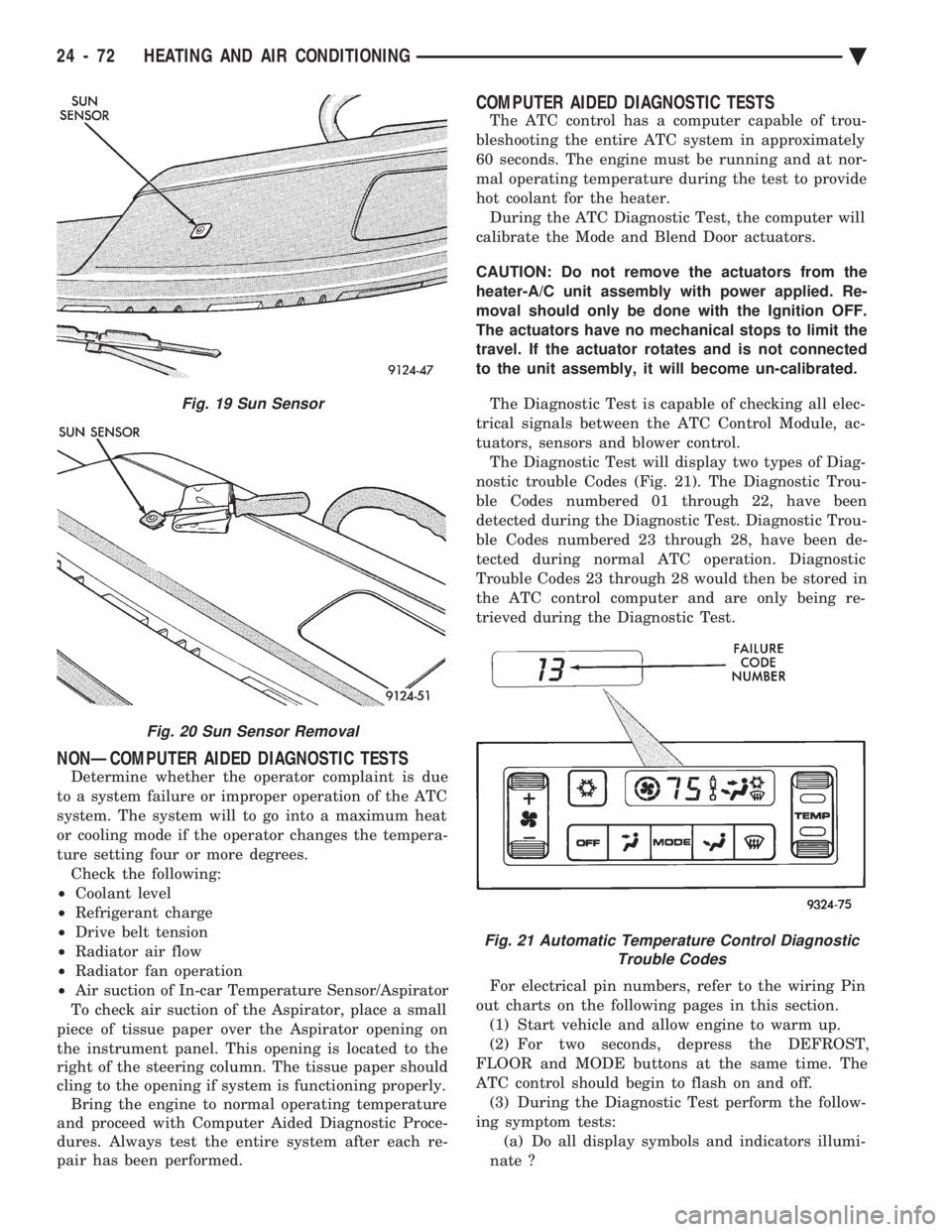

Fig. 19 Sun Sensor

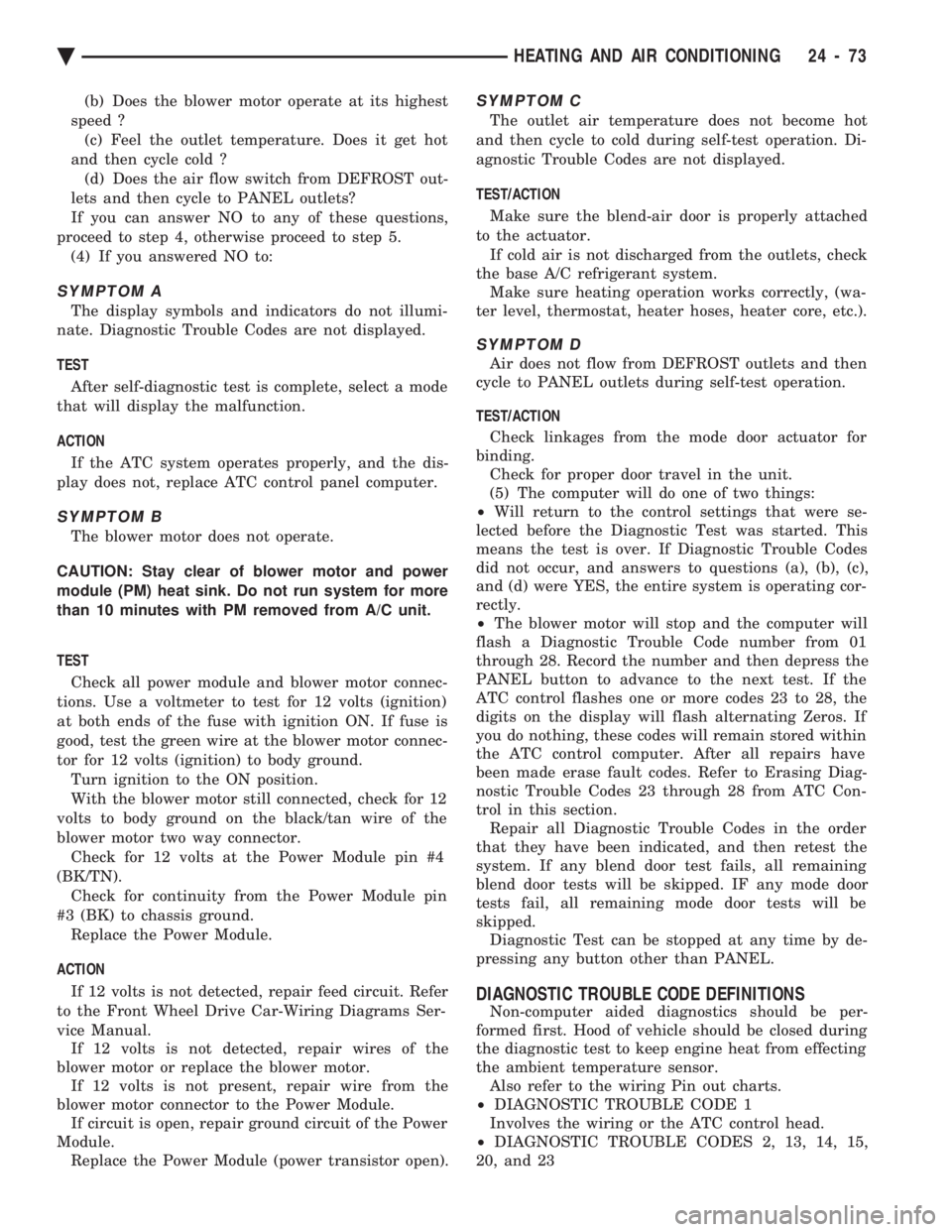

Fig. 20 Sun Sensor Removal

Fig. 21 Automatic Temperature Control Diagnostic Trouble Codes

24 - 72 HEATING AND AIR CONDITIONING Ä

Page 2377 of 2438

(b) Does the blower motor operate at its highest

speed ? (c) Feel the outlet temperature. Does it get hot

and then cycle cold ? (d) Does the air flow switch from DEFROST out-

lets and then cycle to PANEL outlets?

If you can answer NO to any of these questions,

proceed to step 4, otherwise proceed to step 5. (4) If you answered NO to:

SYMPTOM A

The display symbols and indicators do not illumi-

nate. Diagnostic Trouble Codes are not displayed.

TEST

After self-diagnostic test is complete, select a mode

that will display the malfunction.

ACTION

If the ATC system operates properly, and the dis-

play does not, replace ATC control panel computer.

SYMPTOM B

The blower motor does not operate.

CAUTION: Stay clear of blower motor and power

module (PM) heat sink. Do not run system for more

than 10 minutes with PM removed from A/C unit.

TEST Check all power module and blower motor connec-

tions. Use a voltmeter to test for 12 volts (ignition)

at both ends of the fuse with ignition ON. If fuse is

good, test the green wire at the blower motor connec-

tor for 12 volts (ignition) to body ground. Turn ignition to the ON position.

With the blower motor still connected, check for 12

volts to body ground on the black/tan wire of the

blower motor two way connector. Check for 12 volts at the Power Module pin #4

(BK/TN). Check for continuity from the Power Module pin

#3 (BK) to chassis ground. Replace the Power Module.

ACTION If 12 volts is not detected, repair feed circuit. Refer

to the Front Wheel Drive Car-Wiring Diagrams Ser-

vice Manual. If 12 volts is not detected, repair wires of the

blower motor or replace the blower motor. If 12 volts is not present, repair wire from the

blower motor connector to the Power Module. If circuit is open, repair ground circuit of the Power

Module. Replace the Power Module (power transistor open).

SYMPTOM C

The outlet air temperature does not become hot

and then cycle to cold during self-test operation. Di-

agnostic Trouble Codes are not displayed.

TEST/ACTION

Make sure the blend-air door is properly attached

to the actuator. If cold air is not discharged from the outlets, check

the base A/C refrigerant system. Make sure heating operation works correctly, (wa-

ter level, thermostat, heater hoses, heater core, etc.).

SYMPTOM D

Air does not flow from DEFROST outlets and then

cycle to PANEL outlets during self-test operation.

TEST/ACTION Check linkages from the mode door actuator for

binding. Check for proper door travel in the unit.

(5) The computer will do one of two things:

² Will return to the control settings that were se-

lected before the Diagnostic Test was started. This

means the test is over. If Diagnostic Trouble Codes

did not occur, and answers to questions (a), (b), (c),

and (d) were YES, the entire system is operating cor-

rectly.

² The blower motor will stop and the computer will

flash a Diagnostic Trouble Code number from 01

through 28. Record the number and then depress the

PANEL button to advance to the next test. If the

ATC control flashes one or more codes 23 to 28, the

digits on the display will flash alternating Zeros. If

you do nothing, these codes will remain stored within

the ATC control computer. After all repairs have

been made erase fault codes. Refer to Erasing Diag-

nostic Trouble Codes 23 through 28 from ATC Con-

trol in this section. Repair all Diagnostic Trouble Codes in the order

that they have been indicated, and then retest the

system. If any blend door test fails, all remaining

blend door tests will be skipped. IF any mode door

tests fail, all remaining mode door tests will be

skipped. Diagnostic Test can be stopped at any time by de-

pressing any button other than PANEL.

DIAGNOSTIC TROUBLE CODE DEFINITIONS

Non-computer aided diagnostics should be per-

formed first. Hood of vehicle should be closed during

the diagnostic test to keep engine heat from effecting

the ambient temperature sensor. Also refer to the wiring Pin out charts.

² DIAGNOSTIC TROUBLE CODE 1

Involves the wiring or the ATC control head.

² DIAGNOSTIC TROUBLE CODES 2, 13, 14, 15,

20, and 23

Ä HEATING AND AIR CONDITIONING 24 - 73

Page 2378 of 2438

Involves the wiring, blend-air door actuator, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 3, 16, 17, 18, 19,

and 24 Involves the wiring, mode door actuator, or the ATC

control head.

² DIAGNOSTIC TROUBLE CODE 4

Involves the wiring, blend-air door actuator, mode

door actuator, fresh/recirc. door actuator, or the ATC

control head.

² DIAGNOSTIC TROUBLE CODE 5

Involves the wiring, fresh/recirc. door actuator, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODE 6

Involves the compressor circuit signal wiring, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODE 7

Involves the blower wiring, power module, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 8, 21, 22

Requires replacing the ATC control head.

² DIAGNOSTIC TROUBLE CODES 9, and 27

Involves the wiring, sun sensor, or the ATC control

head.

² DIAGNOSTIC TROUBLE CODES 10, and 28

Involves the wiring, water temperature sensor, or the

ATC control head.

² DIAGNOSTIC TROUBLE CODES 11, and 25

Involves the wiring, ambient temperature sensor, or

the ATC control head.

² DIAGNOSTIC TROUBLE CODES 12, and 26

Involves the wiring, in-car temperature

sensor/aspirator, or the ATC control head.

DIAGNOSTIC TROUBLE CODE SERVICE PROCE-

DURES

The control keyboard will not function if pins

7, 9, 17, 19, or 20 of the 21-way wiring connector

are shorted to battery voltage. For electrical pin numbers, refer to the wiring Pin

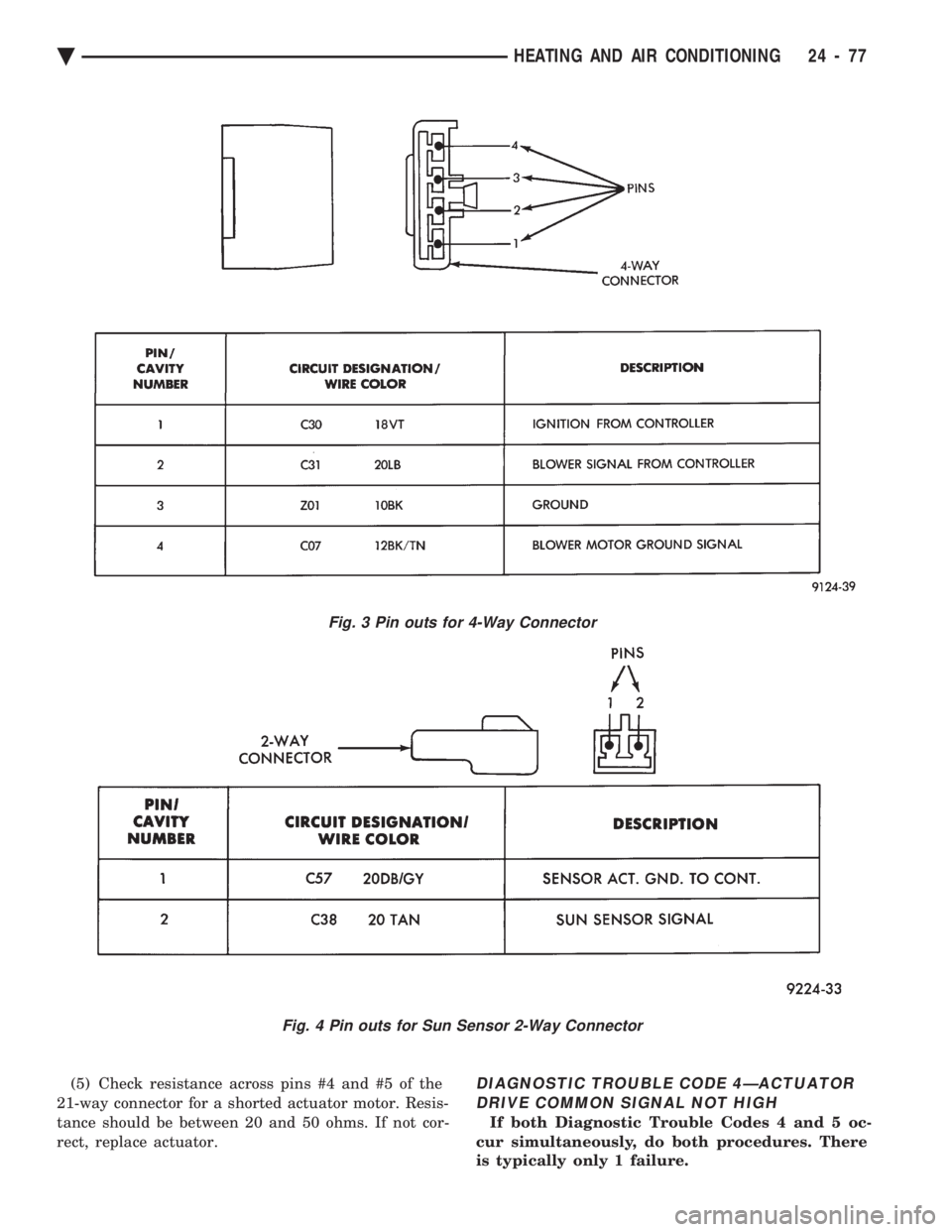

out charts (Figs. 1, 2, 3, 4, 5, or 6).

DIAGNOSTIC TROUBLE CODE 1ÐOUTPUT FAILURE WITH ALL OUTPUTS LOW

(1) Remove pin #2 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Disconnect 21-way connector from control. With an

ohmmeter, measure the resistance between pin #2 and

pin #12 of 21-way. This should be between 2,600 and

2,800 ohms. If yes, the power module is good. Source of voltage on pin #2 is in the wiring. Repair

and retest system. (2) Remove pin #13 from 21-way connector on con-

trol and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #13.

Repair and retest system. (3) Remove pin #5 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #5.

Repair and retest system. (4) Remove pin #6 from 21-way connector on control

and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #6.

Repair and retest system. (5) Remove pin #15 from 21-way connector on con-

trol and retest system. If code 01 does not appear, the

control is good. Locate source of voltage on pin #15.

Repair and retest system.

DIAGNOSTIC TROUBLE CODE 2ÐBLEND AC- TUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 2 and 3 occur

simultaneously, do both procedures. There is

typically only 1 failure. (1) Disconnect terminal #6 on the ATC control 21-

way connector and retest the system. Note that remov-

ing this terminal may generate additional Diagnostic

Trouble Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 2 reappears, replace

control. (3) If code 2 does not reappear, the problem is a

shorted blend door actuator motor or a short to ground

in circuit 33 (pin #6). (4) Remove 21-way connector and check for continu-

ity from pin #6 to chassis ground. There should not be

any continuity. If continuity is there, repair wiring and

retest. (5) Check resistance across pins #6 and #4 of the

21-way for a shorted actuator motor. Resistance should

be between 20 and 50 ohms. If not correct, replace

actuator.

DIAGNOSTIC TROUBLE CODE 3ÐMODE AC- TUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 2 and 3 occur

simultaneously, do both procedures. There is

typically only 1 failure. (1) Disconnect terminal #5 on the ATC control 21-

way connector and retest the system. Removing this

terminal may generate additional Diagnostic Trouble

Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 3 reappears, replace

control. (3) If code 3 does not reappear, the problem is a

shorted mode door actuator motor, or a short to ground

in circuit #35 (pin #5). (4) Remove 21-way and check for continuity from pin

#5 to chassis ground. There should not be any continu-

ity. If continuity is there, repair wiring and retest.

24 - 74 HEATING AND AIR CONDITIONING Ä

Page 2381 of 2438

(5) Check resistance across pins #4 and #5 of the

21-way connector for a shorted actuator motor. Resis-

tance should be between 20 and 50 ohms. If not cor-

rect, replace actuator.DIAGNOSTIC TROUBLE CODE 4ÐACTUATOR DRIVE COMMON SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 4 and 5 oc-

cur simultaneously, do both procedures. There

is typically only 1 failure.

Fig. 3 Pin outs for 4-Way Connector

Fig. 4 Pin outs for Sun Sensor 2-Way Connector

Ä HEATING AND AIR CONDITIONING 24 - 77

Page 2382 of 2438

(1) Disconnect terminal #4 on the ATC control 21-

way connector and retest the system. Removing this

terminal may generate additional Diagnostic Trouble

Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 4 reappears, replace

control. (3) If code 4 does not reappear, the problem is a

shorted actuator motor or a short to ground in circuit

#34 (pin #4). (4) Remove 21-way connector and check for conti-

nuity from pin #4 to chassis ground. There should

not be any continuity. If continuity is there, repair

wiring and retest. (5) Check resistance across pins #4 and #5, #4

and #6, and #4 and #15 of the 21-way connector for

a shorted actuator motor. Resistance should be be-

tween 20 and 50 ohms. If not correct, replace actua-

tor involved.

DIAGNOSTIC TROUBLE CODE 5ÐFRESH/ RECIRC ACTUATOR DRIVE SIGNAL NOT HIGH

If both Diagnostic Trouble Codes 4 and 5 oc-

cur simultaneously, do both procedures. There

is typically only 1 failure. (1) Disconnect terminal #15 on the ATC control

21-way connector and retest the system. Removing

this terminal may generate additional Diagnostic

Trouble Codes. Disregard these at this time. (2) If Diagnostic Trouble Code 5 reappears, replace

control. (3) If code 5 does not reappear, the problem is a

shorted fresh/recirc door actuator motor. It could also

be a short to ground in circuit #32 (pin #15). (4) Remove 21-way connector and check for conti-

nuity from pin #15 to chassis ground. There should

not be any continuity. If continuity is there, repair

wiring and retest. (5) Check resistance across pins #15 and #4 of the

21-way connector for a shorted actuator motor. Resis-

tance should be between 20 and 50 ohms. If not cor-

rect, replace actuator.

DIAGNOSTIC TROUBLE CODE 6ÐCOMPRESSOR DRIVE SIGNAL NOT HIGH

(1) Disconnect the low pressure cut out switch and

retest diagnostics. (2) If code 6 does not reappear, then the problem is

in the A/C signal circuit C02. Check for wiring prob-

lem between the low pressure cut out switch and the

engine controller, or a bad engine controller. (3) If code 6 does reappear, remove the 21-way con-

nector from the control and check for a short between

pin #13 and chassis ground. This test will check the

wire from the control to the low pressure cut out

switch for a short to ground.

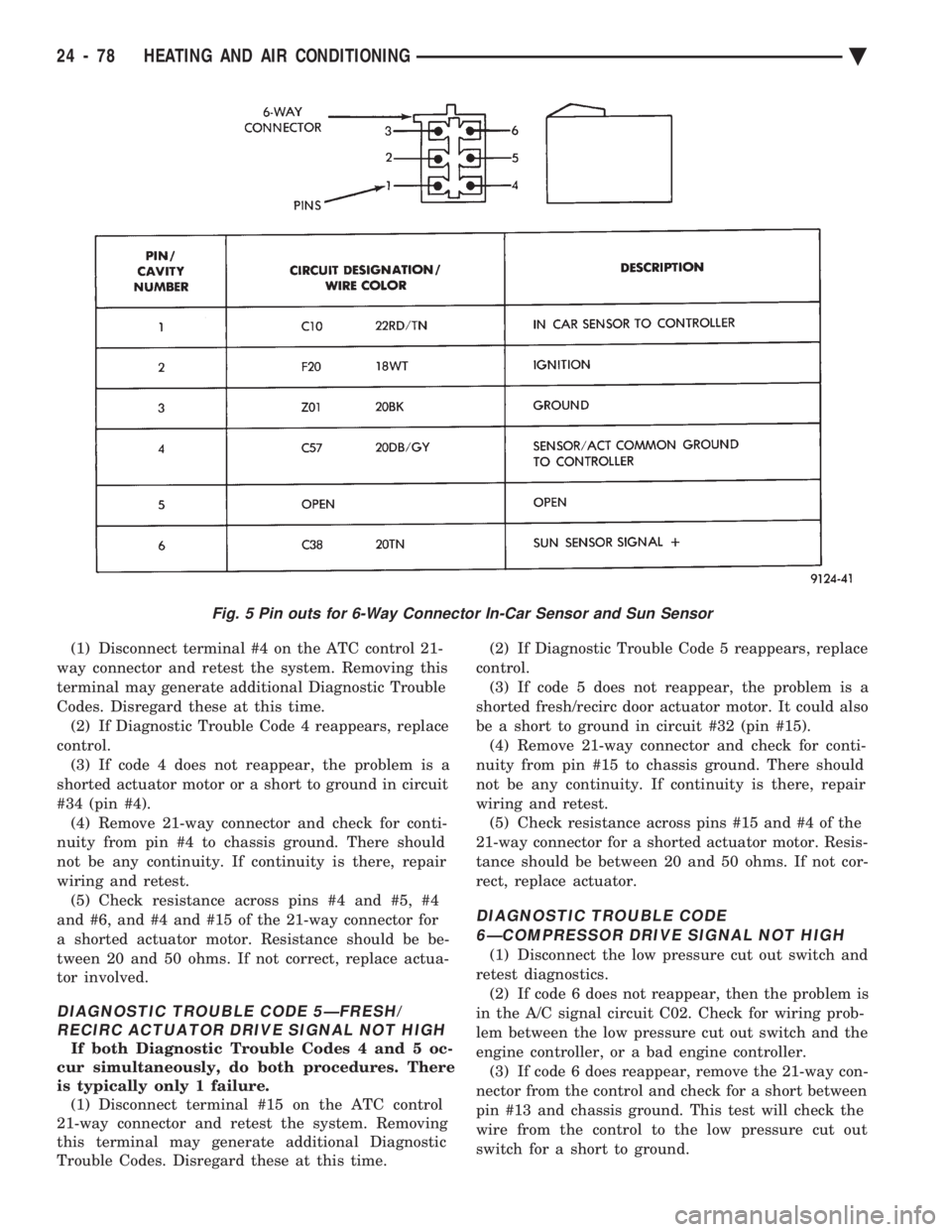

Fig. 5 Pin outs for 6-Way Connector In-Car Sensor and Sun Sensor

24 - 78 HEATING AND AIR CONDITIONING Ä

Page 2384 of 2438

(4) If pin #13 shows continuity, repair circuit C02

and retest. (5) If no continuity is shown, replace the ATC con-

trol and retest.

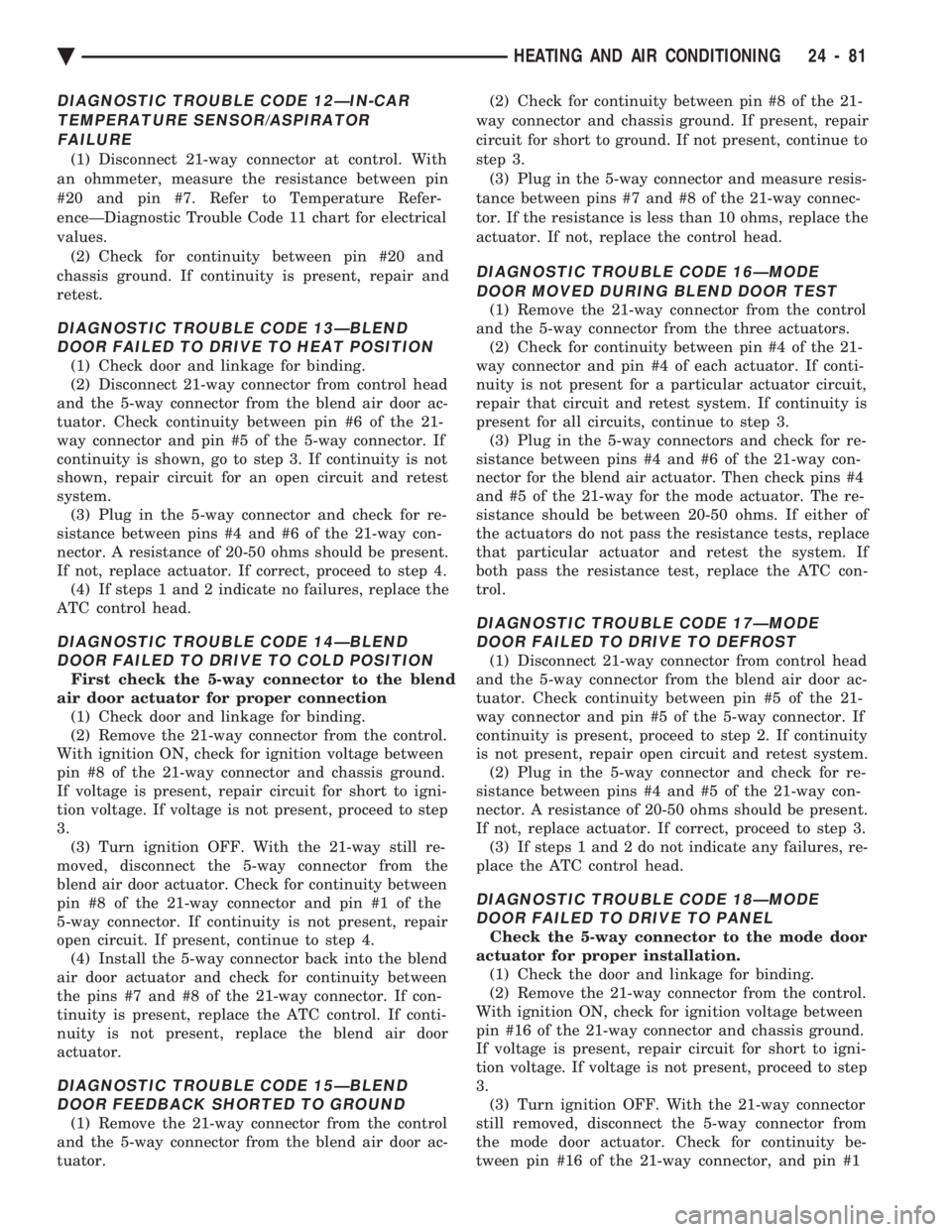

DIAGNOSTIC TROUBLE CODE 7ÐBLOWER DRIVE SIGNAL NOT HIGH

First check the 4-way connector to the power

module for correct installation (1) With the ignition ON, check for ignition volt-

age to the power module pin #1 from the ATC con-

trol. If ignition is present at the power module,

proceed to step 3. If not proceed to step 2. (2) With the 21-way connector still connected and

the ignition ON, check for power module ignition

feed at the control pin #12. If ignition is not present,

replace the control. If ignition voltage is present, re-

pair the open in the wire between the control pin

#12 and power module pin #1. Retest system. (3) Turn ignition OFF and disconnect the 21-way

connector. Measure the resistance between pins #2

and #12. The resistance should read between 2,600

and 2,800 ohms. If correct, replace the ATC control.

If not correct, proceed to step 4. (4) Remove the 4-way connector from the power

module. Check for continuity between the ATC con-

trol pin #2 and power module pin #2. If no continu-

ity is shown, repair the wire for an open. If

continuity is shown, replace the power module and

retest.

DIAGNOSTIC TROUBLE CODE 8ÐA/D CONVERTOR INTERNAL FAILURE

Diagnostics will indicate a Diagnostic Trouble Code

8 if the internal reference voltage of the A/D Conver-

tor is not correct. This Diagnostic Trouble Code is

not serviceable. If a Diagnostic Trouble Code 8 oc-

curs, the computer control head must be replaced.

DIAGNOSTIC TROUBLE CODE 9ÐSUN LOAD SENSOR FAILURE

(1) Unplug the 21-way connector from the control

and check pin #19 for continuity to chassis ground.

If continuity is present, repair the wire shorted to

ground. If no continuity is present, proceed to step 2. (2) Plug the 21-way connector back in. Remove pin

#19 from the 21 way connector and run diagnostics

again. If Diagnostic Trouble Code 9 is still present,

replace the control. If code 9 is not present, replace

the sun sensor.

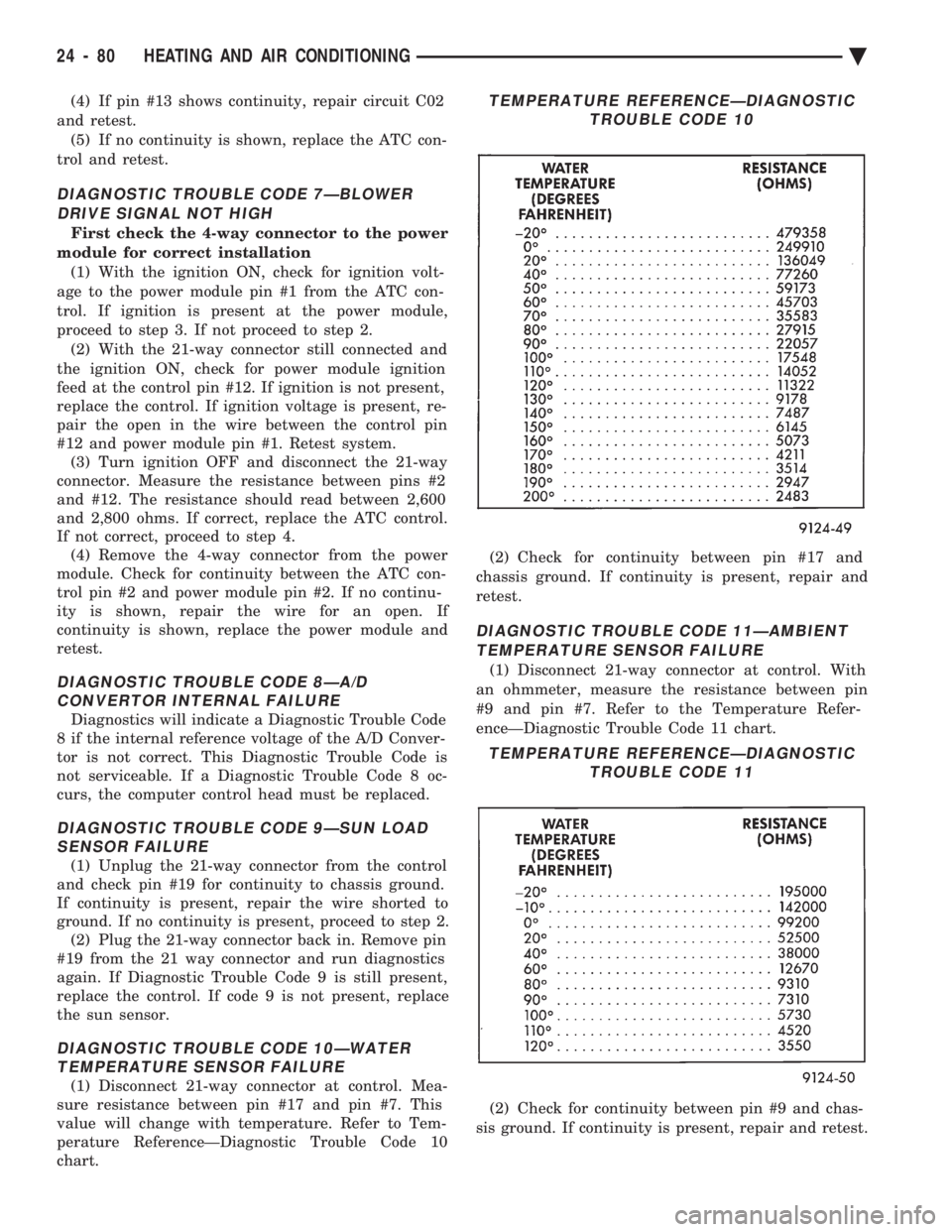

DIAGNOSTIC TROUBLE CODE 10ÐWATER TEMPERATURE SENSOR FAILURE

(1) Disconnect 21-way connector at control. Mea-

sure resistance between pin #17 and pin #7. This

value will change with temperature. Refer to Tem-

perature ReferenceÐDiagnostic Trouble Code 10

chart. (2) Check for continuity between pin #17 and

chassis ground. If continuity is present, repair and

retest.

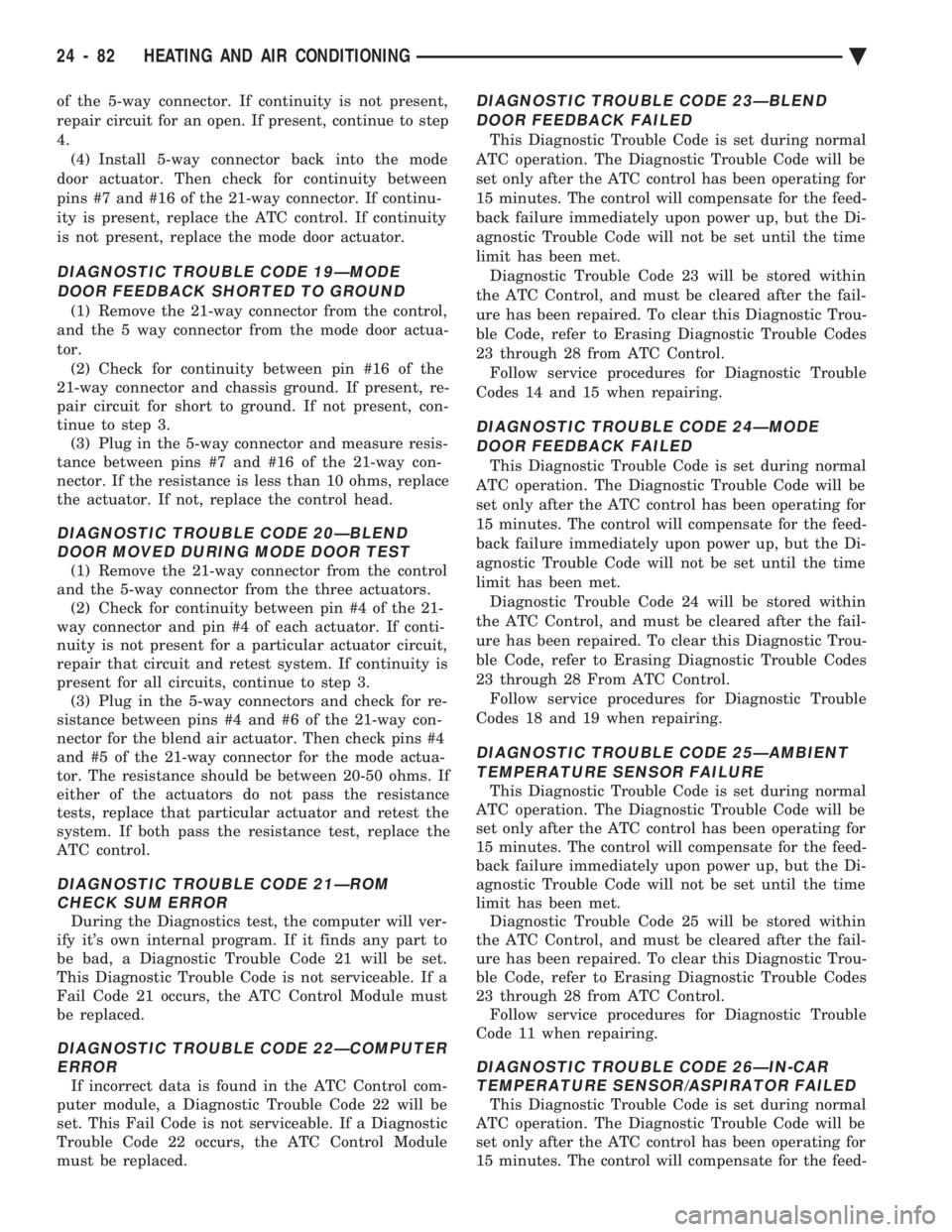

DIAGNOSTIC TROUBLE CODE 11ÐAMBIENT TEMPERATURE SENSOR FAILURE

(1) Disconnect 21-way connector at control. With

an ohmmeter, measure the resistance between pin

#9 and pin #7. Refer to the Temperature Refer-

enceÐDiagnostic Trouble Code 11 chart.

(2) Check for continuity between pin #9 and chas-

sis ground. If continuity is present, repair and retest.

TEMPERATURE REFERENCEÐDIAGNOSTIC TROUBLE CODE 10

TEMPERATURE REFERENCEÐDIAGNOSTICTROUBLE CODE 11

24 - 80 HEATING AND AIR CONDITIONING Ä

Page 2385 of 2438

DIAGNOSTIC TROUBLE CODE 12ÐIN-CAR TEMPERATURE SENSOR/ASPIRATORFAILURE

(1) Disconnect 21-way connector at control. With

an ohmmeter, measure the resistance between pin

#20 and pin #7. Refer to Temperature Refer-

enceÐDiagnostic Trouble Code 11 chart for electrical

values. (2) Check for continuity between pin #20 and

chassis ground. If continuity is present, repair and

retest.

DIAGNOSTIC TROUBLE CODE 13ÐBLEND DOOR FAILED TO DRIVE TO HEAT POSITION

(1) Check door and linkage for binding.

(2) Disconnect 21-way connector from control head

and the 5-way connector from the blend air door ac-

tuator. Check continuity between pin #6 of the 21-

way connector and pin #5 of the 5-way connector. If

continuity is shown, go to step 3. If continuity is not

shown, repair circuit for an open circuit and retest

system. (3) Plug in the 5-way connector and check for re-

sistance between pins #4 and #6 of the 21-way con-

nector. A resistance of 20-50 ohms should be present.

If not, replace actuator. If correct, proceed to step 4. (4) If steps 1 and 2 indicate no failures, replace the

ATC control head.

DIAGNOSTIC TROUBLE CODE 14ÐBLEND DOOR FAILED TO DRIVE TO COLD POSITION

First check the 5-way connector to the blend

air door actuator for proper connection (1) Check door and linkage for binding.

(2) Remove the 21-way connector from the control.

With ignition ON, check for ignition voltage between

pin #8 of the 21-way connector and chassis ground.

If voltage is present, repair circuit for short to igni-

tion voltage. If voltage is not present, proceed to step

3. (3) Turn ignition OFF. With the 21-way still re-

moved, disconnect the 5-way connector from the

blend air door actuator. Check for continuity between

pin #8 of the 21-way connector and pin #1 of the

5-way connector. If continuity is not present, repair

open circuit. If present, continue to step 4. (4) Install the 5-way connector back into the blend

air door actuator and check for continuity between

the pins #7 and #8 of the 21-way connector. If con-

tinuity is present, replace the ATC control. If conti-

nuity is not present, replace the blend air door

actuator.

DIAGNOSTIC TROUBLE CODE 15ÐBLEND DOOR FEEDBACK SHORTED TO GROUND

(1) Remove the 21-way connector from the control

and the 5-way connector from the blend air door ac-

tuator. (2) Check for continuity between pin #8 of the 21-

way connector and chassis ground. If present, repair

circuit for short to ground. If not present, continue to

step 3. (3) Plug in the 5-way connector and measure resis-

tance between pins #7 and #8 of the 21-way connec-

tor. If the resistance is less than 10 ohms, replace the

actuator. If not, replace the control head.

DIAGNOSTIC TROUBLE CODE 16ÐMODE DOOR MOVED DURING BLEND DOOR TEST

(1) Remove the 21-way connector from the control

and the 5-way connector from the three actuators. (2) Check for continuity between pin #4 of the 21-

way connector and pin #4 of each actuator. If conti-

nuity is not present for a particular actuator circuit,

repair that circuit and retest system. If continuity is

present for all circuits, continue to step 3. (3) Plug in the 5-way connectors and check for re-

sistance between pins #4 and #6 of the 21-way con-

nector for the blend air actuator. Then check pins #4

and #5 of the 21-way for the mode actuator. The re-

sistance should be between 20-50 ohms. If either of

the actuators do not pass the resistance tests, replace

that particular actuator and retest the system. If

both pass the resistance test, replace the ATC con-

trol.

DIAGNOSTIC TROUBLE CODE 17ÐMODE DOOR FAILED TO DRIVE TO DEFROST

(1) Disconnect 21-way connector from control head

and the 5-way connector from the blend air door ac-

tuator. Check continuity between pin #5 of the 21-

way connector and pin #5 of the 5-way connector. If

continuity is present, proceed to step 2. If continuity

is not present, repair open circuit and retest system. (2) Plug in the 5-way connector and check for re-

sistance between pins #4 and #5 of the 21-way con-

nector. A resistance of 20-50 ohms should be present.

If not, replace actuator. If correct, proceed to step 3. (3) If steps 1 and 2 do not indicate any failures, re-

place the ATC control head.

DIAGNOSTIC TROUBLE CODE 18ÐMODE DOOR FAILED TO DRIVE TO PANEL

Check the 5-way connector to the mode door

actuator for proper installation. (1) Check the door and linkage for binding.

(2) Remove the 21-way connector from the control.

With ignition ON, check for ignition voltage between

pin #16 of the 21-way connector and chassis ground.

If voltage is present, repair circuit for short to igni-

tion voltage. If voltage is not present, proceed to step

3. (3) Turn ignition OFF. With the 21-way connector

still removed, disconnect the 5-way connector from

the mode door actuator. Check for continuity be-

tween pin #16 of the 21-way connector, and pin #1

Ä HEATING AND AIR CONDITIONING 24 - 81

Page 2386 of 2438

of the 5-way connector. If continuity is not present,

repair circuit for an open. If present, continue to step

4.(4) Install 5-way connector back into the mode

door actuator. Then check for continuity between

pins #7 and #16 of the 21-way connector. If continu-

ity is present, replace the ATC control. If continuity

is not present, replace the mode door actuator.

DIAGNOSTIC TROUBLE CODE 19ÐMODE DOOR FEEDBACK SHORTED TO GROUND

(1) Remove the 21-way connector from the control,

and the 5 way connector from the mode door actua-

tor. (2) Check for continuity between pin #16 of the

21-way connector and chassis ground. If present, re-

pair circuit for short to ground. If not present, con-

tinue to step 3. (3) Plug in the 5-way connector and measure resis-

tance between pins #7 and #16 of the 21-way con-

nector. If the resistance is less than 10 ohms, replace

the actuator. If not, replace the control head.

DIAGNOSTIC TROUBLE CODE 20ÐBLEND DOOR MOVED DURING MODE DOOR TEST

(1) Remove the 21-way connector from the control

and the 5-way connector from the three actuators. (2) Check for continuity between pin #4 of the 21-

way connector and pin #4 of each actuator. If conti-

nuity is not present for a particular actuator circuit,

repair that circuit and retest system. If continuity is

present for all circuits, continue to step 3. (3) Plug in the 5-way connectors and check for re-

sistance between pins #4 and #6 of the 21-way con-

nector for the blend air actuator. Then check pins #4

and #5 of the 21-way connector for the mode actua-

tor. The resistance should be between 20-50 ohms. If

either of the actuators do not pass the resistance

tests, replace that particular actuator and retest the

system. If both pass the resistance test, replace the

ATC control.

DIAGNOSTIC TROUBLE CODE 21ÐROM CHECK SUM ERROR

During the Diagnostics test, the computer will ver-

ify it's own internal program. If it finds any part to

be bad, a Diagnostic Trouble Code 21 will be set.

This Diagnostic Trouble Code is not serviceable. If a

Fail Code 21 occurs, the ATC Control Module must

be replaced.

DIAGNOSTIC TROUBLE CODE 22ÐCOMPUTER ERROR

If incorrect data is found in the ATC Control com-

puter module, a Diagnostic Trouble Code 22 will be

set. This Fail Code is not serviceable. If a Diagnostic

Trouble Code 22 occurs, the ATC Control Module

must be replaced.

DIAGNOSTIC TROUBLE CODE 23ÐBLEND

DOOR FEEDBACK FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 23 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Codes 14 and 15 when repairing.

DIAGNOSTIC TROUBLE CODE 24ÐMODE DOOR FEEDBACK FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 24 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 From ATC Control. Follow service procedures for Diagnostic Trouble

Codes 18 and 19 when repairing.

DIAGNOSTIC TROUBLE CODE 25ÐAMBIENT TEMPERATURE SENSOR FAILURE

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 25 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 11 when repairing.

DIAGNOSTIC TROUBLE CODE 26ÐIN-CAR TEMPERATURE SENSOR/ASPIRATOR FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

24 - 82 HEATING AND AIR CONDITIONING Ä

Page 2387 of 2438

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 26 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 12 when repairing.

DIAGNOSTIC TROUBLE CODE 27ÐSUN LOAD SENSOR FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 27 will be stored within

the ATC Control, and must be cleared after the fail-

ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 12 when repairing.

DIAGNOSTIC TROUBLE CODE 28ÐWATER TEMPERATURE SENSOR FAILED

This Diagnostic Trouble Code is set during normal

ATC operation. The Diagnostic Trouble Code will be

set only after the ATC control has been operating for

15 minutes. The control will compensate for the feed-

back failure immediately upon power up, but the Di-

agnostic Trouble Code will not be set until the time

limit has been met. Diagnostic Trouble Code 28 will be stored within

the ATC Control and must be cleared after the fail- ure has been repaired. To clear this Diagnostic Trou-

ble Code, refer to Erasing Diagnostic Trouble Codes

23 through 28 from ATC Control. Follow service procedures for Diagnostic Trouble

Code 10 when repairing.

ERASING DIAGNOSTIC TROUBLE CODES

Diagnostic Trouble Codes 23 through 28 are stored

within the ATC in the computer memory. These

codes may be erased from the memory after the cor-

rect repairs have been made. Intermittent Diagnostic

Trouble Codes 23 through 28 will be stored until

they are erased. (1) Run the DIAGNOSTIC TEST.

(2) Depress the PANEL button to access all Diag-

nostic Trouble Codes. When the Display begins flash-

ing alternating zeros, you can do three things:

² Do nothing, and in five seconds control will return

to normal ATC operation. All codes will remain

stored in the control.

² Depress any button within five seconds, other than

A/C, and stop the test immediately. Control will re-

turn to normal ATC operation.

² Depress the A/C button within five seconds, and

proceed to the erasing procedure. By depressing the

A/C button, you will not erase any Diagnostic Trou-

ble Codes. You will only access the next part of the

procedure. Proceed to step 3. (3) After you depress the A/C button the display

will alternate E's. This is for ERASE. You can now

do two things:

² Do nothing, and in five seconds, all Diagnostic

Trouble Codes from 23 through 28 will be erased

from the ATC control.

² Depress any button within five seconds, and Diag-

nostic Trouble Codes will not be erased. Control will return to normal ATC operation.

Ä HEATING AND AIR CONDITIONING 24 - 83

Page 2405 of 2438

EXHAUST EMISSION CONTROLS INDEX

page page

Air Aspiration System ..................... 24

EGR Gas Flow Test ...................... 21

EGR System On-Board Diagnostics ........... 21

EGR Tube ServiceÐ2.2L and 2.5L TBI Engines . 22

EGR Tube ServiceÐ3.0L Engines ............ 22

EGR Tube ServiceÐ3.3L and 3.8L Engines .... 22

EGR Valve ServiceÐ2.2L and 2.5L TBI Engines . 22 EGR Valve ServiceÐ3.0L Engines

........... 22

EGR Valve ServiceÐ3.3L and 3.8L Engines .... 22

Exhaust Gas Recirculation (EGR) System ...... 20

Exhaust Gas Recirculation (EGR) System Test . . 21

Heated Inlet Air System ................... 17

Heated Oxygen Sensor (O

2Sensor) .......... 18

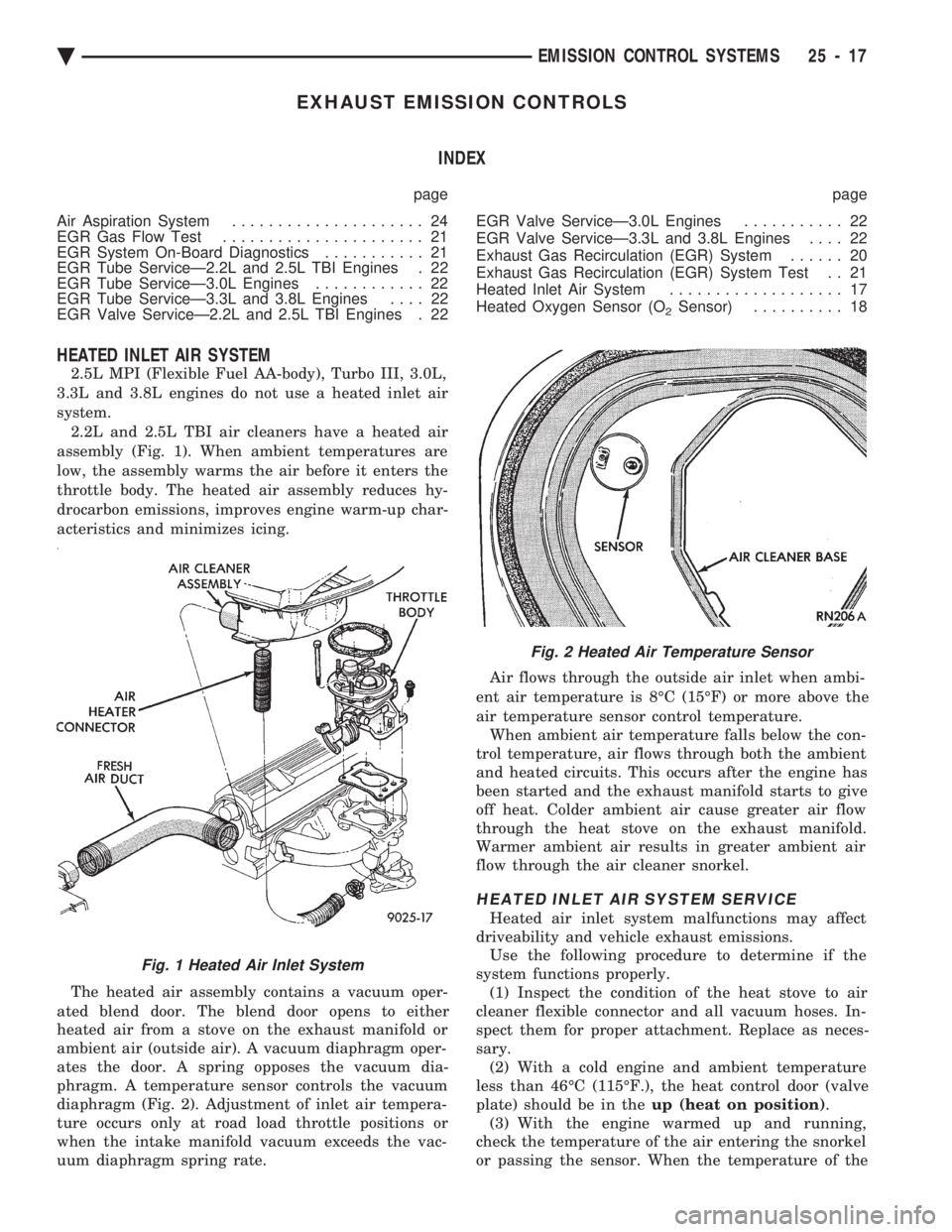

HEATED INLET AIR SYSTEM

2.5L MPI (Flexible Fuel AA-body), Turbo III, 3.0L,

3.3L and 3.8L engines do not use a heated inlet air

system. 2.2L and 2.5L TBI air cleaners have a heated air

assembly (Fig. 1). When ambient temperatures are

low, the assembly warms the air before it enters the

throttle body. The heated air assembly reduces hy-

drocarbon emissions, improves engine warm-up char-

acteristics and minimizes icing.

The heated air assembly contains a vacuum oper-

ated blend door. The blend door opens to either

heated air from a stove on the exhaust manifold or

ambient air (outside air). A vacuum diaphragm oper-

ates the door. A spring opposes the vacuum dia-

phragm. A temperature sensor controls the vacuum

diaphragm (Fig. 2). Adjustment of inlet air tempera-

ture occurs only at road load throttle positions or

when the intake manifold vacuum exceeds the vac-

uum diaphragm spring rate. Air flows through the outside air inlet when ambi-

ent air temperature is 8ÉC (15ÉF) or more above the

air temperature sensor control temperature. When ambient air temperature falls below the con-

trol temperature, air flows through both the ambient

and heated circuits. This occurs after the engine has

been started and the exhaust manifold starts to give

off heat. Colder ambient air cause greater air flow

through the heat stove on the exhaust manifold.

Warmer ambient air results in greater ambient air

flow through the air cleaner snorkel.

HEATED INLET AIR SYSTEM SERVICE

Heated air inlet system malfunctions may affect

driveability and vehicle exhaust emissions. Use the following procedure to determine if the

system functions properly. (1) Inspect the condition of the heat stove to air

cleaner flexible connector and all vacuum hoses. In-

spect them for proper attachment. Replace as neces-

sary. (2) With a cold engine and ambient temperature

less than 46ÉC (115ÉF.), the heat control door (valve

plate) should be in the up (heat on position).

(3) With the engine warmed up and running,

check the temperature of the air entering the snorkel

or passing the sensor. When the temperature of the

Fig. 1 Heated Air Inlet System

Fig. 2 Heated Air Temperature Sensor

Ä EMISSION CONTROL SYSTEMS 25 - 17