height CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 58 of 2438

BRAKE RESERVOIR LEVEL INSPECTION

WARNING: DO NOT ALLOW PETROLEUM OR WATER

BASE LIQUIDS TO CONTAMINATE BRAKE FLUID,

SEAL DAMAGE AND BRAKE FAILURE CAN RESULT.

RELIEVE PRESSURE IN ANTI-LOCK BRAKE SYS-

TEM BEFORE ADDING BRAKE FLUID TO RESER-

VOIR. IF NOT, BRAKE FLUID COULD DISCHARGED

FROM THE RESERVOIR POSSIBLY CAUSING PER-

SONAL INJURY.

The brake reservoir level should be inspected when

other under hood service is performed. It is normal

for the reservoir level to drop as disc brake pads

wear. When fluid must be added, use Mopar, Brake

Fluid or equivalent. Use only brake fluid conforming

to DOT 3, Federal, Department of Transportation

specification. To avoid brake fluid contamination, use

fluid from a properly sealed container. On vehicles with anti-lock brakes, depressurize the

system before inspecting fluid level. Turn OFF the

ignition and remove the key. Pump the brake pedal

at least 50 times to relieve the pressure in the sys-

tem.

On all vehicles, if fluid should become low after sev-

eral thousand kilometers (miles), fill the reservoir to

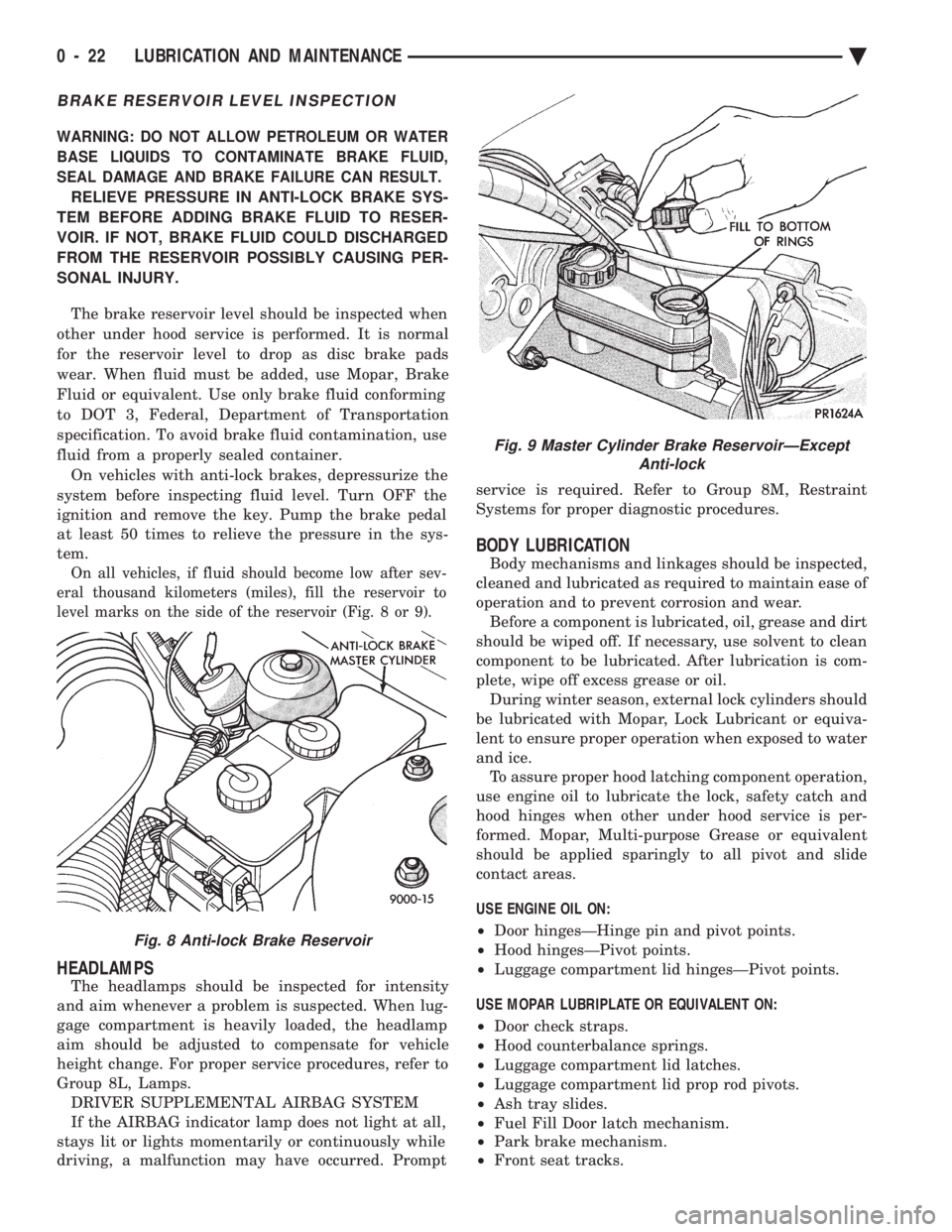

level marks on the side of the reservoir (Fig. 8 or 9).

HEADLAMPS

The headlamps should be inspected for intensity

and aim whenever a problem is suspected. When lug-

gage compartment is heavily loaded, the headlamp

aim should be adjusted to compensate for vehicle

height change. For proper service procedures, refer to

Group 8L, Lamps. DRIVER SUPPLEMENTAL AIRBAG SYSTEM

If the AIRBAG indicator lamp does not light at all,

stays lit or lights momentarily or continuously while

driving, a malfunction may have occurred. Prompt service is required. Refer to Group 8M, Restraint

Systems for proper diagnostic procedures.

BODY LUBRICATION

Body mechanisms and linkages should be inspected,

cleaned and lubricated as required to maintain ease of

operation and to prevent corrosion and wear. Before a component is lubricated, oil, grease and dirt

should be wiped off. If necessary, use solvent to clean

component to be lubricated. After lubrication is com-

plete, wipe off excess grease or oil. During winter season, external lock cylinders should

be lubricated with Mopar, Lock Lubricant or equiva-

lent to ensure proper operation when exposed to water

and ice. To assure proper hood latching component operation,

use engine oil to lubricate the lock, safety catch and

hood hinges when other under hood service is per-

formed. Mopar, Multi-purpose Grease or equivalent

should be applied sparingly to all pivot and slide

contact areas.

USE ENGINE OIL ON:

² Door hingesÐHinge pin and pivot points.

² Hood hingesÐPivot points.

² Luggage compartment lid hingesÐPivot points.

USE MOPAR LUBRIPLATE OR EQUIVALENT ON:

² Door check straps.

² Hood counterbalance springs.

² Luggage compartment lid latches.

² Luggage compartment lid prop rod pivots.

² Ash tray slides.

² Fuel Fill Door latch mechanism.

² Park brake mechanism.

² Front seat tracks.

Fig. 8 Anti-lock Brake Reservoir

Fig. 9 Master Cylinder Brake ReservoirÐExcept

Anti-lock

0 - 22 LUBRICATION AND MAINTENANCE Ä

Page 63 of 2438

FRONT SUSPENSION SERVICE PROCEDURES INDEX

page page

Ball Joints .............................. 13

Hub and Bearing Assembly ................. 20

Knuckle (Front Suspension) ................. 16

Lower Control Arm ....................... 10

Lower Control Arm Pivot Bushings ........... 11 Shock Absorbers (Strut Damper)

............. 10

Strut Damper Assembly ..................... 7

Suspension Coil Springs .................... 9

Sway Bar .............................. 14

Wheel Alignment .......................... 5

WHEEL ALIGNMENT

Front wheel alignment is the proper adjustment of

all interrelated front suspension angles. These angles

are what affects the running and steering of the

front wheels of the vehicle. The method of checking front alignment will vary

depending on the type of equipment being used. The

instructions furnished by the manufacturer of the

equipment should always be followed. With the ex-

ception that the alignment specifications recom-

mended by Chrysler Corporation be used. There are six basic factors which are the founda-

tion to front wheel alignment. These are height,

caster, camber, toe-in, steering axis inclination and

toe-out on turns. Of the six basic factors only camber

and toe in are mechanically adjustable (Fig. 1)

CAUTION: Do not attempt to modify any suspen-

sion or steering components by heating or bending

of the component.

Wheel alignment adjustments and checks should be

made in the following sequence. (1) Camber

(2) Toe

Camber is the number of degrees the top of the

wheel is tilted inward or outward from true vertical.

Inward tilt is negative camber. Outward tilt is posi-

tive camber. Excessive camber is a tire wear factor: negative

camber causes wear on the inside of the tire, while

positive camber causes wear to the outside. Toe

is measured in degrees or inches and is the

distance the front edges of the tires are closer (or far-

ther apart) than the rear edges. See Front Wheel

Drive Specifications for Toesettings.

PRE-ALIGNMENT

Before any attempt is made to change or correct

the wheel alignment factors. The following inspection

and necessary corrections must be made on those

parts which influence the steering of the vehicle. (1) Check and inflate tires to recommended pres-

sure. All tires should be the same size and in good

condition and have approximately the same wear.

Note type of tread wear which will aid in diagnosing,

see Wheels and Tires, Group 22. (2) Check front wheel and tire assembly for radial

runout. (3) Inspect lower ball joints and all steering link-

age for looseness. (4) Check for broken or sagged front and rear

springs. Front suspension must only be checked after the

vehicle has had the following checked or adjusted.

Tires set to recommended pressures, full tank of fuel,

no passenger or luggage compartment load and is on

a level floor or alignment rack. Just prior to each alignment reading. The vehicle

should be bounced (rear first, then front) by grasping

bumper at center and jouncing each end an equal

number of times. Always release bumpers at bottom

of down cycle.

Ä SUSPENSION AND DRIVESHAFTS 2 - 5

Page 69 of 2438

Inspect lower control arm for distortion. Check

bushings for severe deterioration.

INSTALLATION (ASSEMBLY)

(1) Position the lower control arm into the cross-

member. Install front and rear pivot bushing to

crossmember attaching bolts. Then loosely assemble

nuts to bolts (Fig. 2). (2) Install ball joint stud into steering knuckle and

install clamp bolt (Fig. 1). Tighten clamp bolt to 145

N Im (105 ft. lbs.).

(3) Position sway bar and bushings against the

lower control arms. Install sway bar to control arm

retainers. Install retainer bolts and tighten to 70

N Im (50 ft. lbs.).

(4) Lower vehicle so the suspension is supporting

vehicles weight (control arm at design height).

Tighten the lower control arm to crossmember at-

taching bolts to 169 N Im (125 ft. lbs.) torque.

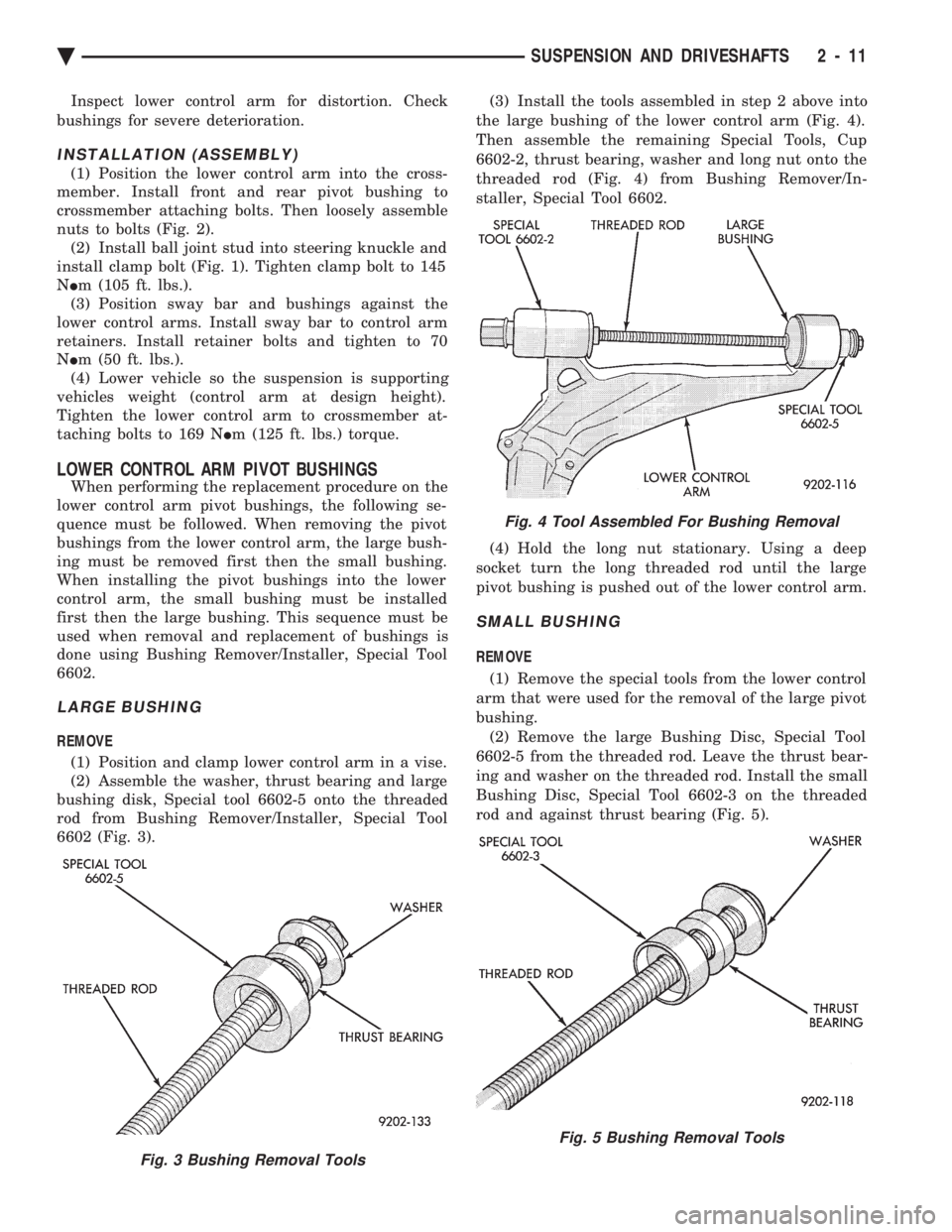

LOWER CONTROL ARM PIVOT BUSHINGS

When performing the replacement procedure on the

lower control arm pivot bushings, the following se-

quence must be followed. When removing the pivot

bushings from the lower control arm, the large bush-

ing must be removed first then the small bushing.

When installing the pivot bushings into the lower

control arm, the small bushing must be installed

first then the large bushing. This sequence must be

used when removal and replacement of bushings is

done using Bushing Remover/Installer, Special Tool

6602.

LARGE BUSHING

REMOVE

(1) Position and clamp lower control arm in a vise.

(2) Assemble the washer, thrust bearing and large

bushing disk, Special tool 6602-5 onto the threaded

rod from Bushing Remover/Installer, Special Tool

6602 (Fig. 3). (3) Install the tools assembled in step 2 above into

the large bushing of the lower control arm (Fig. 4).

Then assemble the remaining Special Tools, Cup

6602-2, thrust bearing, washer and long nut onto the

threaded rod (Fig. 4) from Bushing Remover/In-

staller, Special Tool 6602.

(4) Hold the long nut stationary. Using a deep

socket turn the long threaded rod until the large

pivot bushing is pushed out of the lower control arm.

SMALL BUSHING

REMOVE

(1) Remove the special tools from the lower control

arm that were used for the removal of the large pivot

bushing. (2) Remove the large Bushing Disc, Special Tool

6602-5 from the threaded rod. Leave the thrust bear-

ing and washer on the threaded rod. Install the small

Bushing Disc, Special Tool 6602-3 on the threaded

rod and against thrust bearing (Fig. 5).

Fig. 3 Bushing Removal Tools

Fig. 4 Tool Assembled For Bushing Removal

Fig. 5 Bushing Removal Tools

Ä SUSPENSION AND DRIVESHAFTS 2 - 11

Page 74 of 2438

the lower clamps and bolts. The center offset in the

sway bar should be oriented toward the front of the

vehicle (Fig. 16)(3) Position bushing retainers on lower control arms

and install bolts (Fig. 16). (4) With lower control arms raised to design height,

tighten all retainer attaching bolts to 70 N Im (50 ft.

lbs.) torque. (5) Lower vehicle.

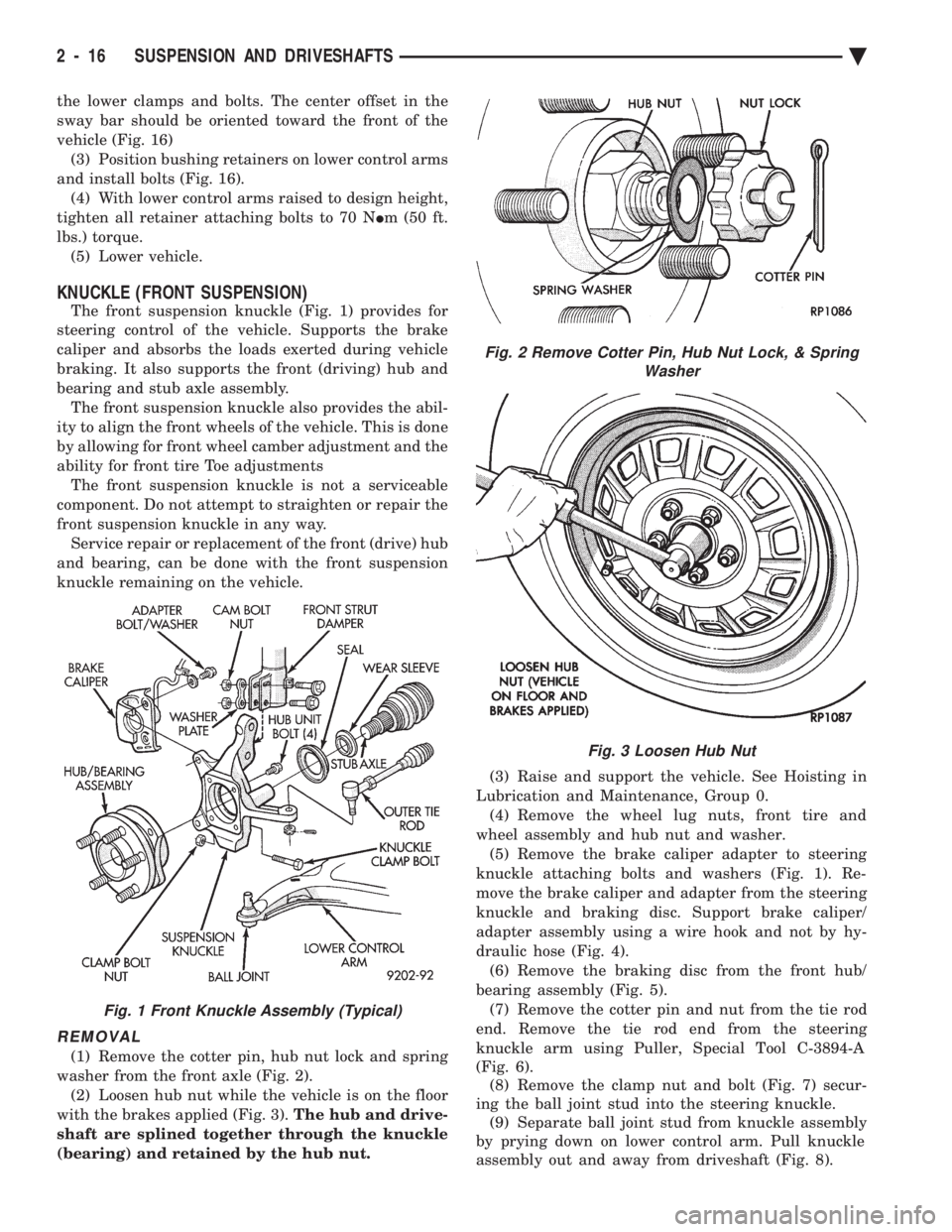

KNUCKLE (FRONT SUSPENSION)

The front suspension knuckle (Fig. 1) provides for

steering control of the vehicle. Supports the brake

caliper and absorbs the loads exerted during vehicle

braking. It also supports the front (driving) hub and

bearing and stub axle assembly. The front suspension knuckle also provides the abil-

ity to align the front wheels of the vehicle. This is done

by allowing for front wheel camber adjustment and the

ability for front tire Toe adjustments The front suspension knuckle is not a serviceable

component. Do not attempt to straighten or repair the

front suspension knuckle in any way. Service repair or replacement of the front (drive) hub

and bearing, can be done with the front suspension

knuckle remaining on the vehicle.

REMOVAL

(1) Remove the cotter pin, hub nut lock and spring

washer from the front axle (Fig. 2). (2) Loosen hub nut while the vehicle is on the floor

with the brakes applied (Fig. 3). The hub and drive-

shaft are splined together through the knuckle

(bearing) and retained by the hub nut. (3) Raise and support the vehicle. See Hoisting in

Lubrication and Maintenance, Group 0. (4) Remove the wheel lug nuts, front tire and

wheel assembly and hub nut and washer. (5) Remove the brake caliper adapter to steering

knuckle attaching bolts and washers (Fig. 1). Re-

move the brake caliper and adapter from the steering

knuckle and braking disc. Support brake caliper/

adapter assembly using a wire hook and not by hy-

draulic hose (Fig. 4). (6) Remove the braking disc from the front hub/

bearing assembly (Fig. 5). (7) Remove the cotter pin and nut from the tie rod

end. Remove the tie rod end from the steering

knuckle arm using Puller, Special Tool C-3894-A

(Fig. 6). (8) Remove the clamp nut and bolt (Fig. 7) secur-

ing the ball joint stud into the steering knuckle. (9) Separate ball joint stud from knuckle assembly

by prying down on lower control arm. Pull knuckle

assembly out and away from driveshaft (Fig. 8).

Fig. 2 Remove Cotter Pin, Hub Nut Lock, & Spring Washer

Fig. 3 Loosen Hub Nut

Fig. 1 Front Knuckle Assembly (Typical)

2 - 16 SUSPENSION AND DRIVESHAFTS Ä

Page 110 of 2438

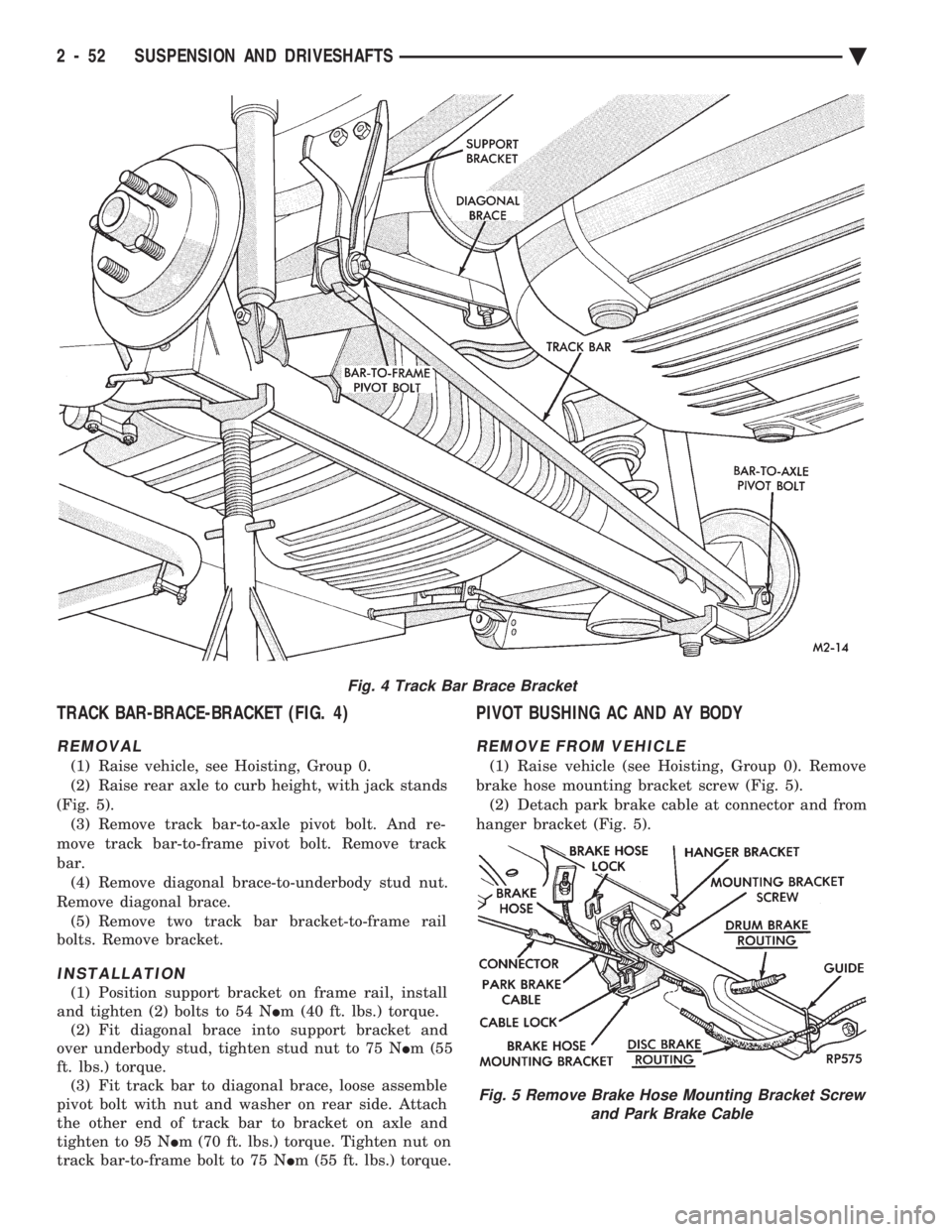

TRACK BAR-BRACE-BRACKET (FIG. 4)

REMOVAL

(1) Raise vehicle, see Hoisting, Group 0.

(2) Raise rear axle to curb height, with jack stands

(Fig. 5). (3) Remove track bar-to-axle pivot bolt. And re-

move track bar-to-frame pivot bolt. Remove track

bar. (4) Remove diagonal brace-to-underbody stud nut.

Remove diagonal brace. (5) Remove two track bar bracket-to-frame rail

bolts. Remove bracket.

INSTALLATION

(1) Position support bracket on frame rail, install

and tighten (2) bolts to 54 N Im (40 ft. lbs.) torque.

(2) Fit diagonal brace into support bracket and

over underbody stud, tighten stud nut to 75 N Im (55

ft. lbs.) torque. (3) Fit track bar to diagonal brace, loose assemble

pivot bolt with nut and washer on rear side. Attach

the other end of track bar to bracket on axle and

tighten to 95 N Im (70 ft. lbs.) torque. Tighten nut on

track bar-to-frame bolt to 75 N Im (55 ft. lbs.) torque.

PIVOT BUSHING AC AND AY BODY

REMOVE FROM VEHICLE

(1) Raise vehicle (see Hoisting, Group 0). Remove

brake hose mounting bracket screw (Fig. 5). (2) Detach park brake cable at connector and from

hanger bracket (Fig. 5).

Fig. 4 Track Bar Brace Bracket

Fig. 5 Remove Brake Hose Mounting Bracket Screw and Park Brake Cable

2 - 52 SUSPENSION AND DRIVESHAFTS Ä

Page 112 of 2438

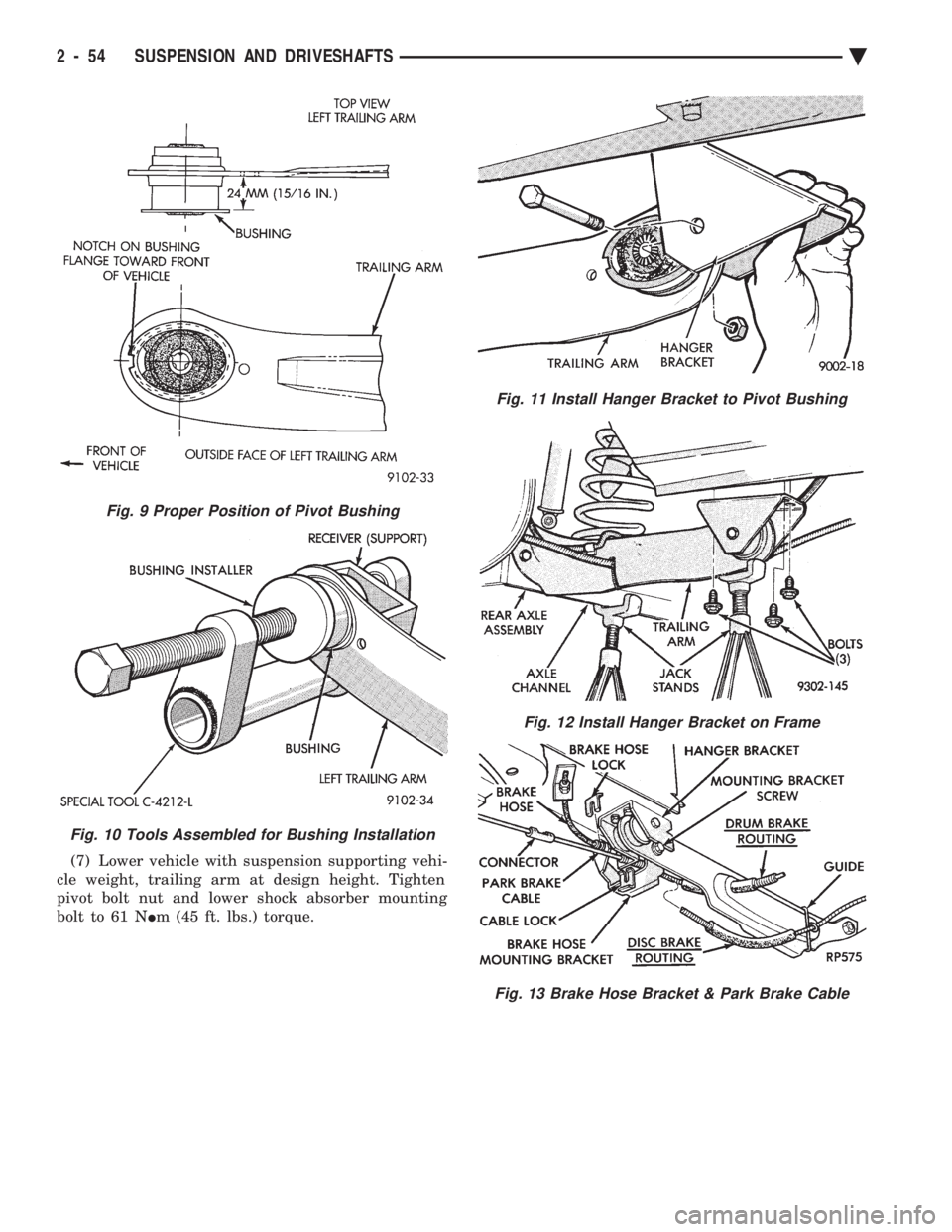

(7) Lower vehicle with suspension supporting vehi-

cle weight, trailing arm at design height. Tighten

pivot bolt nut and lower shock absorber mounting

bolt to 61 N Im (45 ft. lbs.) torque.

Fig. 9 Proper Position of Pivot Bushing

Fig. 10 Tools Assembled for Bushing Installation

Fig. 11 Install Hanger Bracket to Pivot Bushing

Fig. 12 Install Hanger Bracket on Frame

Fig. 13 Brake Hose Bracket & Park Brake Cable

2 - 54 SUSPENSION AND DRIVESHAFTS Ä

Page 114 of 2438

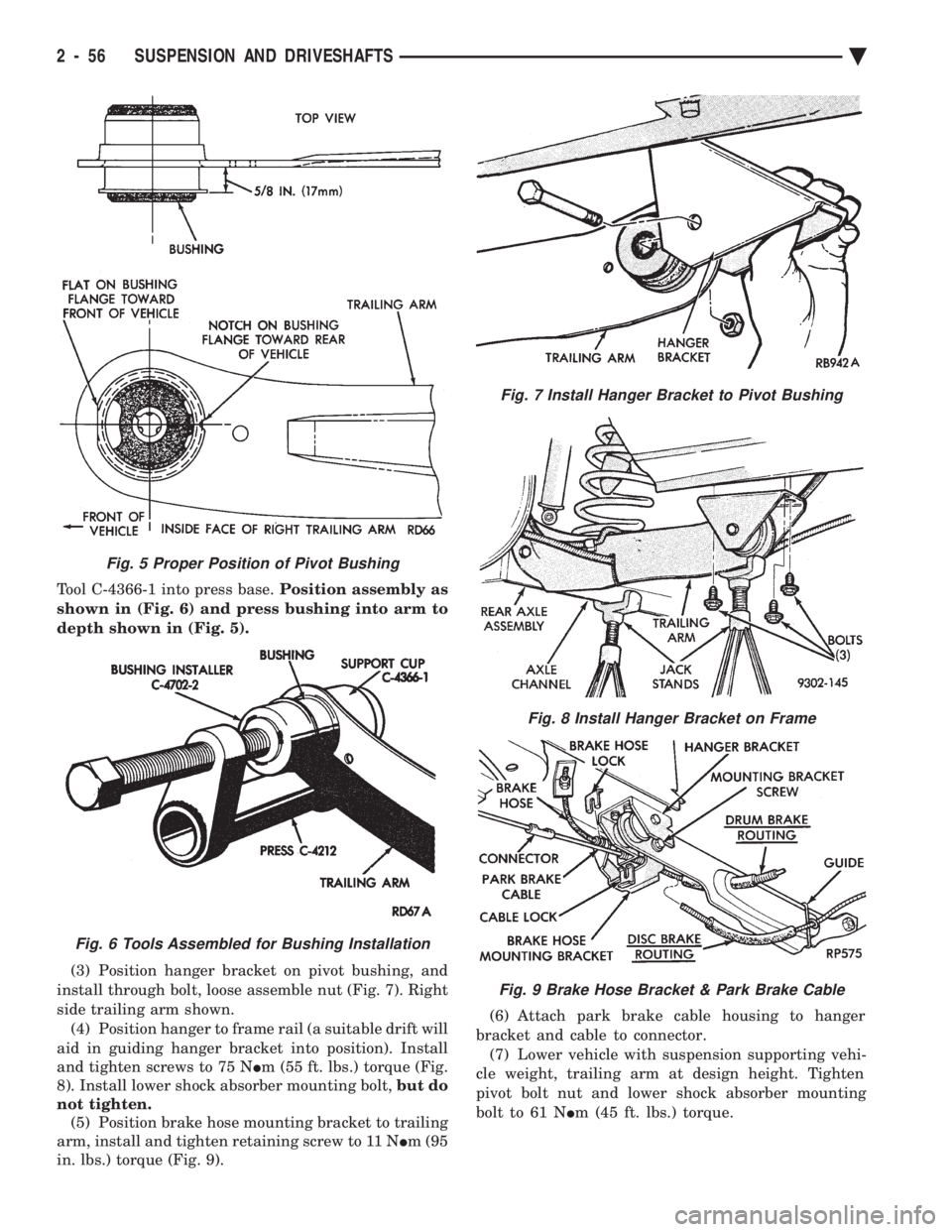

Tool C-4366-1 into press base. Position assembly as

shown in (Fig. 6) and press bushing into arm to

depth shown in (Fig. 5).

(3) Position hanger bracket on pivot bushing, and

install through bolt, loose assemble nut (Fig. 7). Right

side trailing arm shown. (4) Position hanger to frame rail (a suitable drift will

aid in guiding hanger bracket into position). Install

and tighten screws to 75 N Im (55 ft. lbs.) torque (Fig.

8). Install lower shock absorber mounting bolt, but do

not tighten. (5) Position brake hose mounting bracket to trailing

arm, install and tighten retaining screw to 11 N Im (95

in. lbs.) torque (Fig. 9). (6) Attach park brake cable housing to hanger

bracket and cable to connector. (7) Lower vehicle with suspension supporting vehi-

cle weight, trailing arm at design height. Tighten

pivot bolt nut and lower shock absorber mounting

bolt to 61 N Im (45 ft. lbs.) torque.

Fig. 7 Install Hanger Bracket to Pivot Bushing

Fig. 8 Install Hanger Bracket on Frame

Fig. 9 Brake Hose Bracket & Park Brake Cable

Fig. 5 Proper Position of Pivot Bushing

Fig. 6 Tools Assembled for Bushing Installation

2 - 56 SUSPENSION AND DRIVESHAFTS Ä

Page 117 of 2438

AUTOMATIC AIR LOAD LEVELING SYSTEM INDEX

page page

Compressor Performance Test .............. 61

Compressor Relay ........................ 72

Control Module .......................... 72

General Information ....................... 59

Major Components ....................... 59 Rear Leveling Diagnostic Procedures

......... 65

Right Shock Absorber (With Height Sensor) .... 72

Service Procedures ....................... 62

System Operation ........................ 61

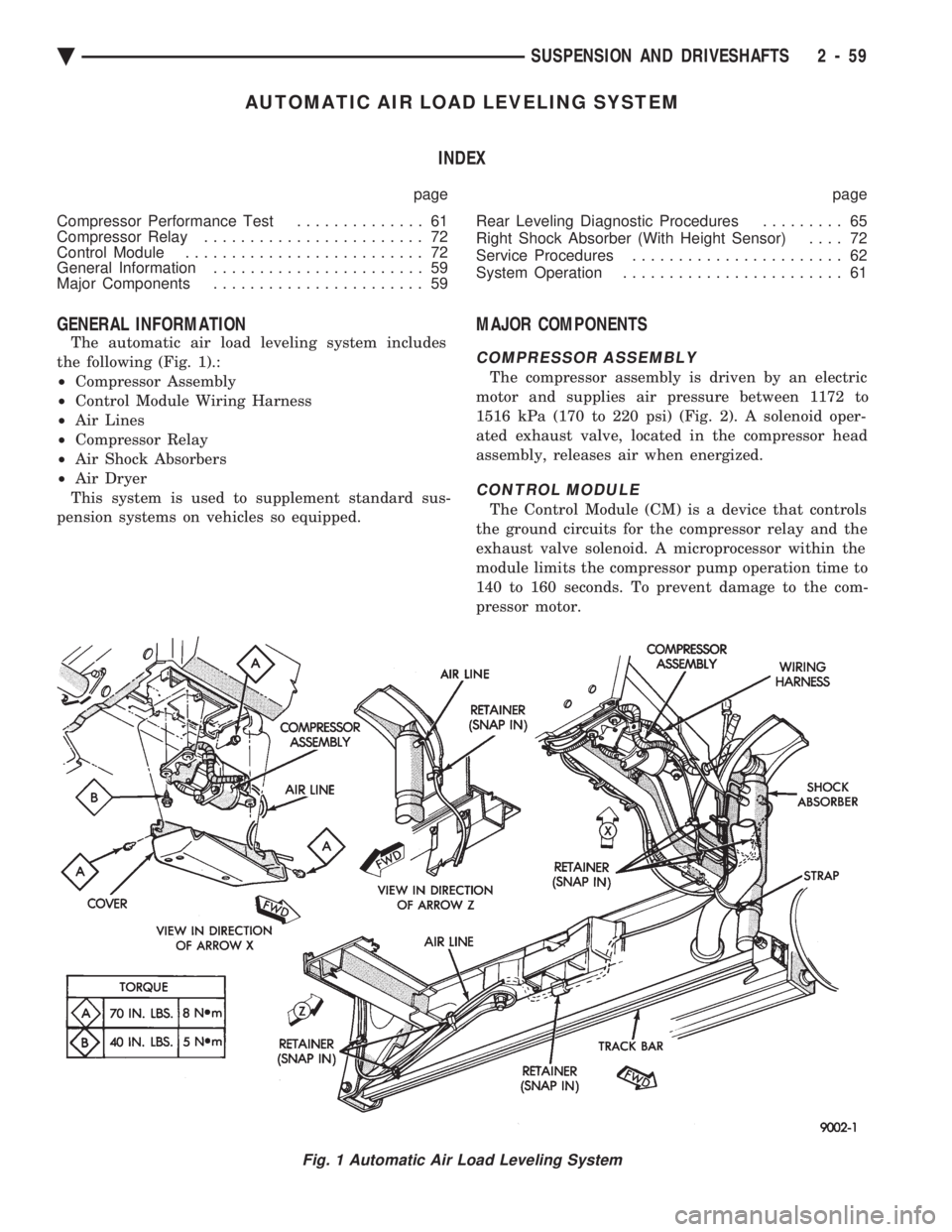

GENERAL INFORMATION

The automatic air load leveling system includes

the following (Fig. 1).:

² Compressor Assembly

² Control Module Wiring Harness

² Air Lines

² Compressor Relay

² Air Shock Absorbers

² Air Dryer

This system is used to supplement standard sus-

pension systems on vehicles so equipped.

MAJOR COMPONENTS

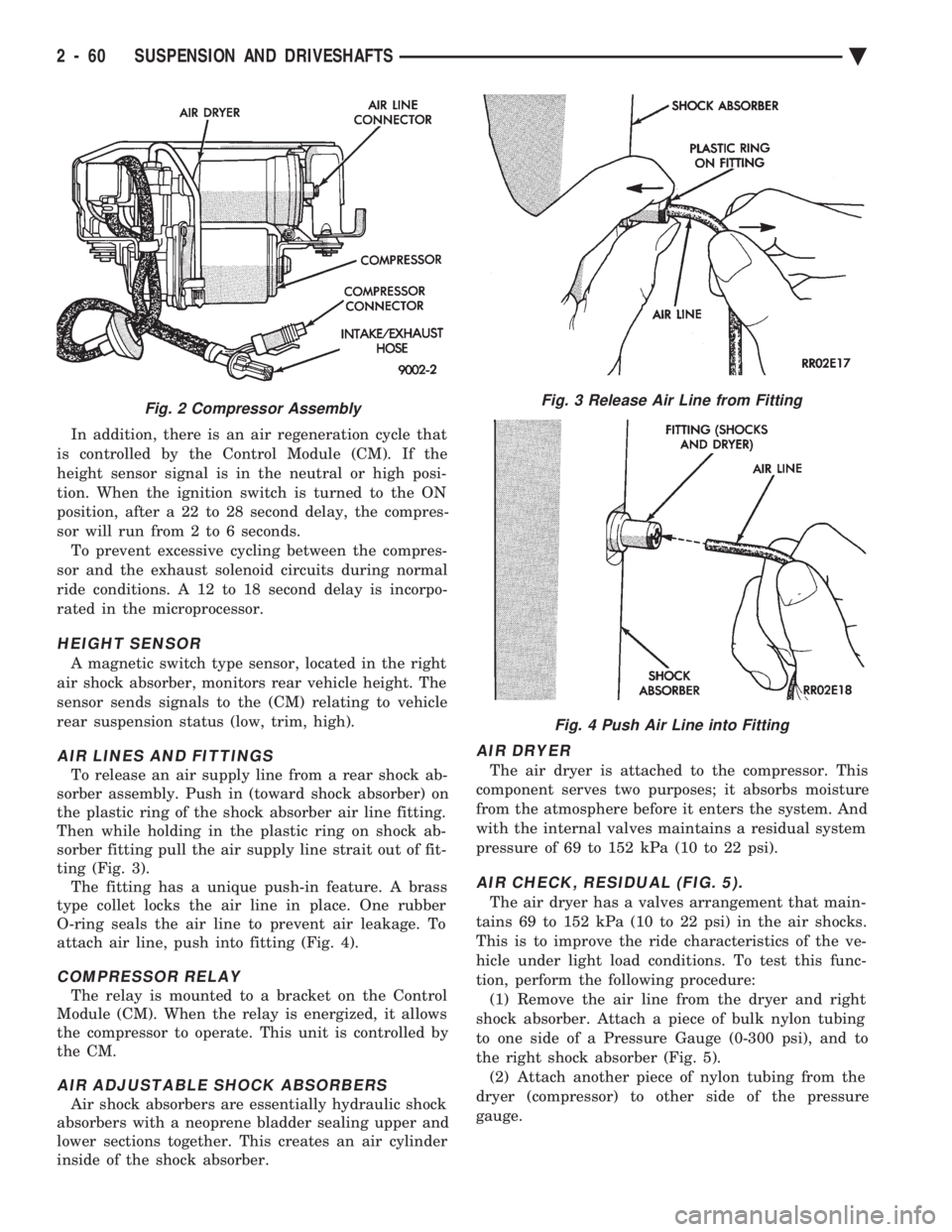

COMPRESSOR ASSEMBLY

The compressor assembly is driven by an electric

motor and supplies air pressure between 1172 to

1516 kPa (170 to 220 psi) (Fig. 2). A solenoid oper-

ated exhaust valve, located in the compressor head

assembly, releases air when energized.

CONTROL MODULE

The Control Module (CM) is a device that controls

the ground circuits for the compressor relay and the

exhaust valve solenoid. A microprocessor within the

module limits the compressor pump operation time to

140 to 160 seconds. To prevent damage to the com-

pressor motor.

Fig. 1 Automatic Air Load Leveling System

Ä SUSPENSION AND DRIVESHAFTS 2 - 59

Page 118 of 2438

In addition, there is an air regeneration cycle that

is controlled by the Control Module (CM). If the

height sensor signal is in the neutral or high posi-

tion. When the ignition switch is turned to the ON

position, after a 22 to 28 second delay, the compres-

sor will run from 2 to 6 seconds. To prevent excessive cycling between the compres-

sor and the exhaust solenoid circuits during normal

ride conditions. A 12 to 18 second delay is incorpo-

rated in the microprocessor.

HEIGHT SENSOR

A magnetic switch type sensor, located in the right

air shock absorber, monitors rear vehicle height. The

sensor sends signals to the (CM) relating to vehicle

rear suspension status (low, trim, high).

AIR LINES AND FITTINGS

To release an air supply line from a rear shock ab-

sorber assembly. Push in (toward shock absorber) on

the plastic ring of the shock absorber air line fitting.

Then while holding in the plastic ring on shock ab-

sorber fitting pull the air supply line strait out of fit-

ting (Fig. 3). The fitting has a unique push-in feature. A brass

type collet locks the air line in place. One rubber

O-ring seals the air line to prevent air leakage. To

attach air line, push into fitting (Fig. 4).

COMPRESSOR RELAY

The relay is mounted to a bracket on the Control

Module (CM). When the relay is energized, it allows

the compressor to operate. This unit is controlled by

the CM.

AIR ADJUSTABLE SHOCK ABSORBERS

Air shock absorbers are essentially hydraulic shock

absorbers with a neoprene bladder sealing upper and

lower sections together. This creates an air cylinder

inside of the shock absorber.

AIR DRYER

The air dryer is attached to the compressor. This

component serves two purposes; it absorbs moisture

from the atmosphere before it enters the system. And

with the internal valves maintains a residual system

pressure of 69 to 152 kPa (10 to 22 psi).

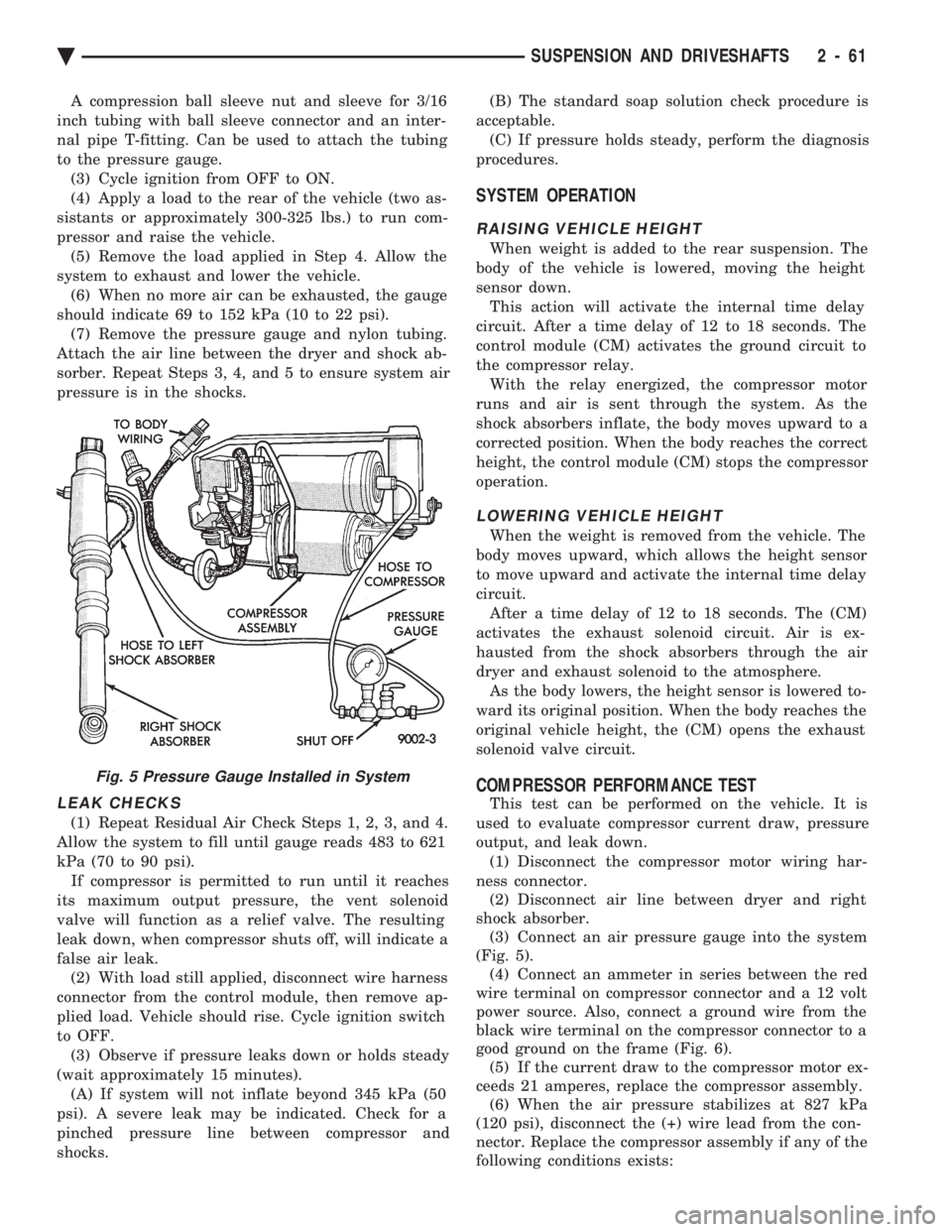

AIR CHECK, RESIDUAL (FIG. 5).

The air dryer has a valves arrangement that main-

tains 69 to 152 kPa (10 to 22 psi) in the air shocks.

This is to improve the ride characteristics of the ve-

hicle under light load conditions. To test this func-

tion, perform the following procedure: (1) Remove the air line from the dryer and right

shock absorber. Attach a piece of bulk nylon tubing

to one side of a Pressure Gauge (0-300 psi), and to

the right shock absorber (Fig. 5). (2) Attach another piece of nylon tubing from the

dryer (compressor) to other side of the pressure

gauge.

Fig. 2 Compressor AssemblyFig. 3 Release Air Line from Fitting

Fig. 4 Push Air Line into Fitting

2 - 60 SUSPENSION AND DRIVESHAFTS Ä

Page 119 of 2438

A compression ball sleeve nut and sleeve for 3/16

inch tubing with ball sleeve connector and an inter-

nal pipe T-fitting. Can be used to attach the tubing

to the pressure gauge. (3) Cycle ignition from OFF to ON.

(4) Apply a load to the rear of the vehicle (two as-

sistants or approximately 300-325 lbs.) to run com-

pressor and raise the vehicle. (5) Remove the load applied in Step 4. Allow the

system to exhaust and lower the vehicle. (6) When no more air can be exhausted, the gauge

should indicate 69 to 152 kPa (10 to 22 psi). (7) Remove the pressure gauge and nylon tubing.

Attach the air line between the dryer and shock ab-

sorber. Repeat Steps 3, 4, and 5 to ensure system air

pressure is in the shocks.

LEAK CHECKS

(1) Repeat Residual Air Check Steps 1, 2, 3, and 4.

Allow the system to fill until gauge reads 483 to 621

kPa (70 to 90 psi). If compressor is permitted to run until it reaches

its maximum output pressure, the vent solenoid

valve will function as a relief valve. The resulting

leak down, when compressor shuts off, will indicate a

false air leak. (2) With load still applied, disconnect wire harness

connector from the control module, then remove ap-

plied load. Vehicle should rise. Cycle ignition switch

to OFF. (3) Observe if pressure leaks down or holds steady

(wait approximately 15 minutes). (A) If system will not inflate beyond 345 kPa (50

psi). A severe leak may be indicated. Check for a

pinched pressure line between compressor and

shocks. (B) The standard soap solution check procedure is

acceptable. (C) If pressure holds steady, perform the diagnosis

procedures.

SYSTEM OPERATION

RAISING VEHICLE HEIGHT

When weight is added to the rear suspension. The

body of the vehicle is lowered, moving the height

sensor down. This action will activate the internal time delay

circuit. After a time delay of 12 to 18 seconds. The

control module (CM) activates the ground circuit to

the compressor relay. With the relay energized, the compressor motor

runs and air is sent through the system. As the

shock absorbers inflate, the body moves upward to a

corrected position. When the body reaches the correct

height, the control module (CM) stops the compressor

operation.

LOWERING VEHICLE HEIGHT

When the weight is removed from the vehicle. The

body moves upward, which allows the height sensor

to move upward and activate the internal time delay

circuit. After a time delay of 12 to 18 seconds. The (CM)

activates the exhaust solenoid circuit. Air is ex-

hausted from the shock absorbers through the air

dryer and exhaust solenoid to the atmosphere. As the body lowers, the height sensor is lowered to-

ward its original position. When the body reaches the

original vehicle height, the (CM) opens the exhaust

solenoid valve circuit.

COMPRESSOR PERFORMANCE TEST

This test can be performed on the vehicle. It is

used to evaluate compressor current draw, pressure

output, and leak down. (1) Disconnect the compressor motor wiring har-

ness connector. (2) Disconnect air line between dryer and right

shock absorber. (3) Connect an air pressure gauge into the system

(Fig. 5). (4) Connect an ammeter in series between the red

wire terminal on compressor connector and a 12 volt

power source. Also, connect a ground wire from the

black wire terminal on the compressor connector to a

good ground on the frame (Fig. 6). (5) If the current draw to the compressor motor ex-

ceeds 21 amperes, replace the compressor assembly. (6) When the air pressure stabilizes at 827 kPa

(120 psi), disconnect the (+) wire lead from the con-

nector. Replace the compressor assembly if any of the

following conditions exists:

Fig. 5 Pressure Gauge Installed in System

Ä SUSPENSION AND DRIVESHAFTS 2 - 61