radio antenna CHEVROLET PLYMOUTH ACCLAIM 1993 Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: PLYMOUTH ACCLAIM, Model: CHEVROLET PLYMOUTH ACCLAIM 1993Pages: 2438, PDF Size: 74.98 MB

Page 33 of 2438

COMPONENT AND SYSTEM INDEX

Name Group-page Name Group-page

AUDIO SYSTEM ............................ 8F-1

ANTENNAS ............................ 8F-20

COMPACT DISC PLAYER ................... 8F-30

RADIOS ............................... 8F-1

SPEAKERS ............................. 8F-24

BATTERY/STARTER/GENERATOR SERVICE ..........8B-1

BATTERY REMOVAL, INSTALLATION AND SERVICE . . 8B-1

GENERATOR ............................ 8B-9

SPECIFICATIONS ........................ 8B-12

STARTER .............................. 8B-4

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS ........................... 8A-1

BATTERY TEST PROCEDURES ON-VEHICLE .......8A-3

FAULT CODESÐON BOARD DIAGNOSTICS .......8A-23

GENERAL INFORMATION .................... 8A-1

GENERATOR TEST PROCEDURES ON VEHICLE ....8A-19

IGNITION OFF DRAW (IOD) ..................8A-9

SPECIFICATIONS ........................ 8A-28

STARTER TEST PROCEDURES ON VEHICLE ......8A-11

CHIME WARNING/REMINDER SYSTEM ............8U-1

EMISSION CONTROL SYSTEMS .................25-1

EVAPORATIVE EMISSION CONTROLS ...........25-1

EXHAUST EMISSION CONTROLS ..............25-17

FUEL SYSTEMS ............................ 14-1

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-95

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS ................14-100

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES .................14-107

2.2L TURBO III MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION .................... 14-83

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-35

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ ON-BOARD DIAGNOSTICS .................14-41

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SERVICE PROCEDURES .................. 14-48

2.2L/2.5L SINGLE POINT FUEL INJECTIONÐ SYSTEM OPERATION .................... 14-24

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS ..........14-66

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS ........14-70

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES .........14-77

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ...........14-55

3.0L MULTI-PORT FUEL INJECTIONÐGENERAL DIAGNOSIS .......................... 14-125

3.0L MULTI-PORT FUEL INJECTIONÐON-BOARD DIAGNOSTICS ........................ 14-130

3.0L MULTI-PORT FUEL INJECTIONÐSERVICE PROCEDURES ........................ 14-138

3.0L MULTI-PORT FUEL INJECTIONÐSYSTEM OPERATION ......................... 14-113

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ GENERAL DIAGNOSIS ................... 14-157 3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ

ON-BOARD DIAGNOSTICS ................14-162

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SERVICE PROCEDURES .................14-169

3.3L AND 3.8L MULTI-PORT FUEL INJECTIONÐ SYSTEM OPERATION ................... 14-145

ACCELERATOR PEDAL AND THROTTLE CABLE ....14-21

FUEL DELIVERY SYSTEM .................... 14-3

FUEL TANKS ........................... 14-14

GENERAL INFORMATION .................... 14-1

SPECIFICATIONS ........................ 14-178

HORNS ................................. 8G-1

IGNITION SYSTEMS ......................... 8D-1

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐDIAGNOSTIC PROCEDURES .......8D-11

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSERVICE PROCEDURES ..........8D-14

2.2L TBI, 2.5L TBI, 2.5L MPI AND 3.0L IGNITION SYSTEMSÐSYSTEM OPERATION ............8D-1

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐDIAGNOSTIC PROCEDURES ........8D-35

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMÐSYSTEM OPERATION ............8D-24

2.2L TURBO III, 3.3L AND 3.8L IGNITION SYSTEMSÐSERVICE PROCEDURES ..........8D-39

IGNITION SWITCH ....................... 8D-45

SPECIFICATIONS ........................ 8D-47

INSTRUMENT PANEL AND GAUGES ...............8E-1

AA BODY .............................. 8E-1

AC AND AY BODIES ...................... 8E-23

AG AND AJ BODIES ...................... 8E-42

AP BODY ............................. 8E-58

LAMPS .................................. 8L-1

BULB APPLICATION TABLE ..................8L-38

CONCEALED HEADLAMPS ..................8L-27

EXTERIOR LAMP SWITCHES AND HEADLAMP ALIGNMENT ........................... 8L-3

EXTERIOR LAMP SYSTEMS .................8L-25

EXTERIOR LAMPSÐAA BODY ................8L-7

EXTERIOR LAMPSÐAC BODY ...............8L-10

EXTERIOR LAMPSÐAG BODY ...............8L-14

EXTERIOR LAMPSÐAJ BODY ................8L-16

EXTERIOR LAMPSÐAP BODY ...............8L-19

EXTERIOR LAMPSÐAY-BODY ................8L-22

GENERAL INFORMATION .................... 8L-1

ILLUMINATED ENTRY SYSTEM ...............8L-33

OVERHEAD CONSOLE ........................ 8C-1

AA BODY .............................. 8C-1

AC AND AY BODY ........................ 8C-6

AG AND AJ BODIES ...................... 8C-13

AP BODY ............................. 8C-21

POWER LOCKS ............................ 8P-1

POWER MIRRORS ..........................8T-1

POWER SEATS ............................ 8R-1

POWER WINDOWS .......................... 8S-1

REAR WINDOW DEFOGGER .................... 8N-1

RESTRAINT SYSTEMS ....................... 8M-1

TURN SIGNALS AND HAZARD WARNING FLASHER ....8J-1

VEHICLE SPEED CONTROL .................... 8H-1

Page 549 of 2438

(11) Remove two screws from fuse block and lower

fuse block. (12) Remove three screws from hood release and

lower hood release handle. (13) Remove flasher relay from bracket on center

distribution duct. (14) Remove screw from ATC sensor motor assem-

bly and unhook from bracket if equipped. (15) Remove the radio ground screw above flasher

relay mount. (16) Remove center distribution duct screw from

left instrument panel lower brace, then remove four

screws to remove left lower brace.

(17) Remove five nuts on steering column and drop

column, then remove two upper column attaching studs.

(18) Remove two screws and pull out compact disc

player or cubby box, disconnect Co-Axial cable from

compact disc player. (19) Remove Electronic Vehicle Information Center

(E.V.I.C.) or Traveler from vehicle. (20) Remove radio.

(21) Remove A.T.C., A/C or heater controls. (22) Squeeze latches on side of Rear Window defog-

ger switch and remove. (23) Snap off cluster lower trim bezel, switch pod

vent grille, speaker grilles and defroster grilles. (24) Remove switch pod assembly.

(25) Remove cluster assembly.

(26) Remove dash speakers.

(27) Snap out bezel with or without message center

and disconnect wiring. (28) Open glovebox door, squeeze sides and roll

glovebox completely open. Remove glovebox light

switch, and disconnect wires. (29) Loosen right cowl side pivot bolt through

glovebox opening then close glovebox. (30) Loosen left cowl side pivot.

(31) Remove four screw attachments at top of in-

strument panel and roll panel out. (32) Pull wiring, antenna cable, A/C cable and vac-

uum lines out of instrument panel. Disconnect demis-

ter hose and remove instrument panel with ducts

attached. (33) Transfer ducts and brackets onto new panel.

(34) For instrument panel roll up, reverse

above procedures.

INTERIOR LAMP REMOVAL

The Dome, Floor Console and Door Lamps operate

when the doors are open or headlamp switch is

placed in courtesy position.

DOME LAMP

(1) Pry either the forward or rearward edge of the

dome lamp to free it from retaining bracket. (2) Pry either the forward or rearward edge of the

lens away from the bezel and replace lamp. (3) For installation reverse above procedures.

FRONT HEADER READING LAMP

Pull lamp from headliner. Disconnect wiring and

replace lamp.

FLOOR CONSOLE LAMP

Pry along top edge of lamp and pivot lamp out of

floor console, the lens does not remove. Remove lamp

and twist out lamp socket. Replace lamp.

DOOR LAMPS

Pry along bottom edge of lamp and pivot lamp out

of door trim panel, the lens does not remove. Remove

lamp and twist out lamp socket. Replace lamp.

DOOR REFLECTORS

Pry reflector away from the door trim panel, and

replace.

TRUNK LAMP

Remove lens by prying lens out of trunk trim panel

and replace bulb.

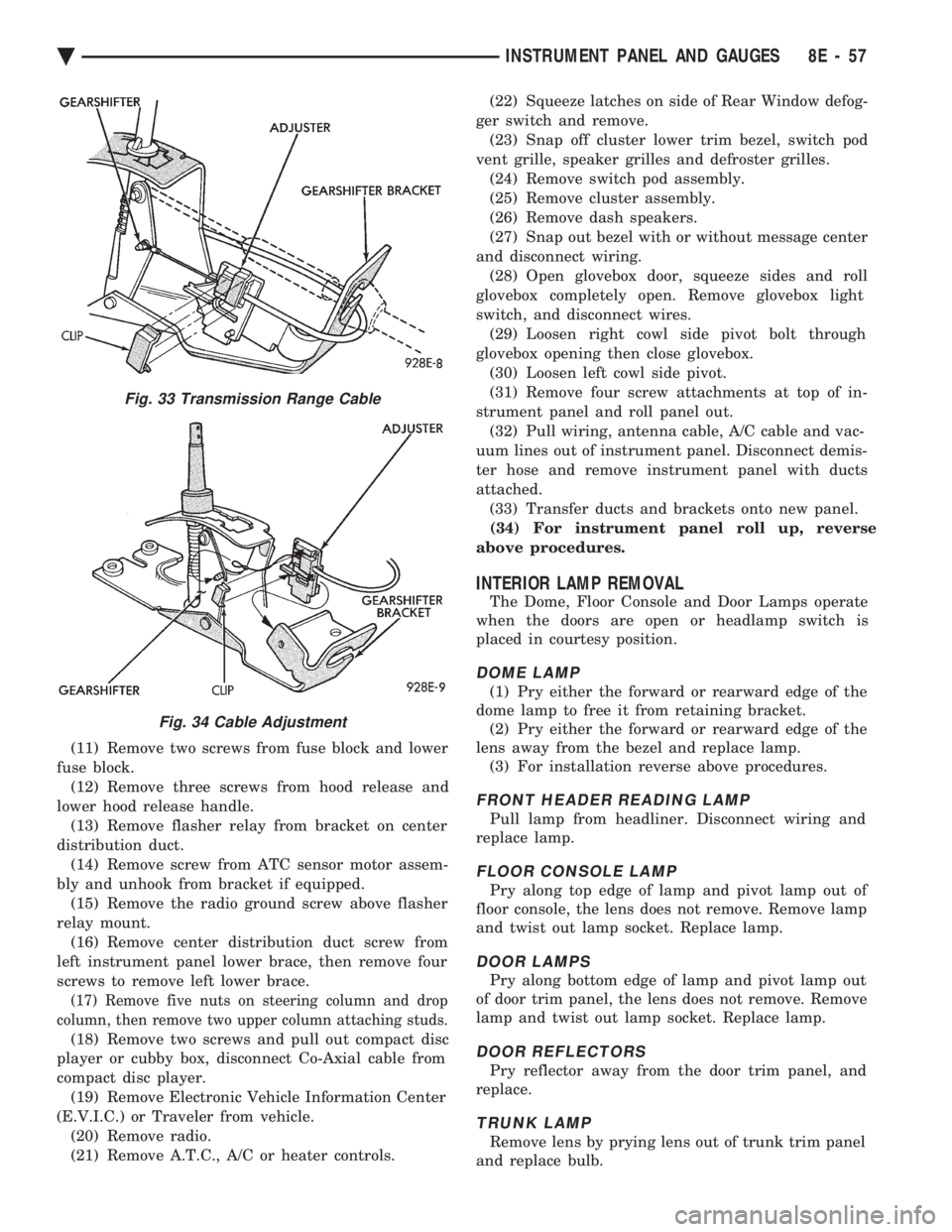

Fig. 33 Transmission Range Cable

Fig. 34 Cable Adjustment

Ä INSTRUMENT PANEL AND GAUGES 8E - 57

Page 567 of 2438

AUDIO SYSTEM

CONTENTS

page page

ANTENNAS ............................ 20

COMPACT DISC PLAYER ................. 30 RADIOS

................................ 1

SPEAKERS ............................ 24

RADIOS INDEX

page page

Audio Diagnostic Test Procedures ............. 1

Description .............................. 1

Interference Elimination ..................... 1

Radio Removal AP Body Replacement ........ 19 Radio RemovalÐAA Body

.................. 18

Radio RemovalÐAC and AY Bodies .......... 18

Radio RemovalÐAG and AJ Bodies .......... 18

DESCRIPTION

For operation of the factory installed standard and

optional radios and the optional compact disc player,

refer to the Sound Systems Operating Instructions

Manual supplied with the vehicle. All vehicles are equipped with an Ignition-Off

Draw Connector which, is used when the vehicles are

originally shipped from the factory. This connector

which, is located near the battery, helps to prevent

battery discharge during storage. For specific connec-

tor type and location, refer to Group 8W, Wiring Di-

agrams. This connector is included in the radio memory cir-

cuitry and should be checked if the memory of time

or radio station programming is inoperative.

INTERFERENCE ELIMINATION

Some components are used on vehicles equipped

with a radio capacitor, to suppress radio frequency

interference/static. Capacitors are mounted in various locations, on the

generator either internal or external, internal to the

instrument cluster, and internal to the windshield

wiper motor. Ground straps are mounted from radio chassis to

instrument panel support structure, engine to cowl,

across engine mount on right hand side. On vehicles

with air conditioning there is a strap from evapora-

tor valve to cowl. These ground straps should be se-

curely tightened to assure good metal to metal

contact. Ground straps conduct very small high fre-

quency electrical signals to ground and require clean

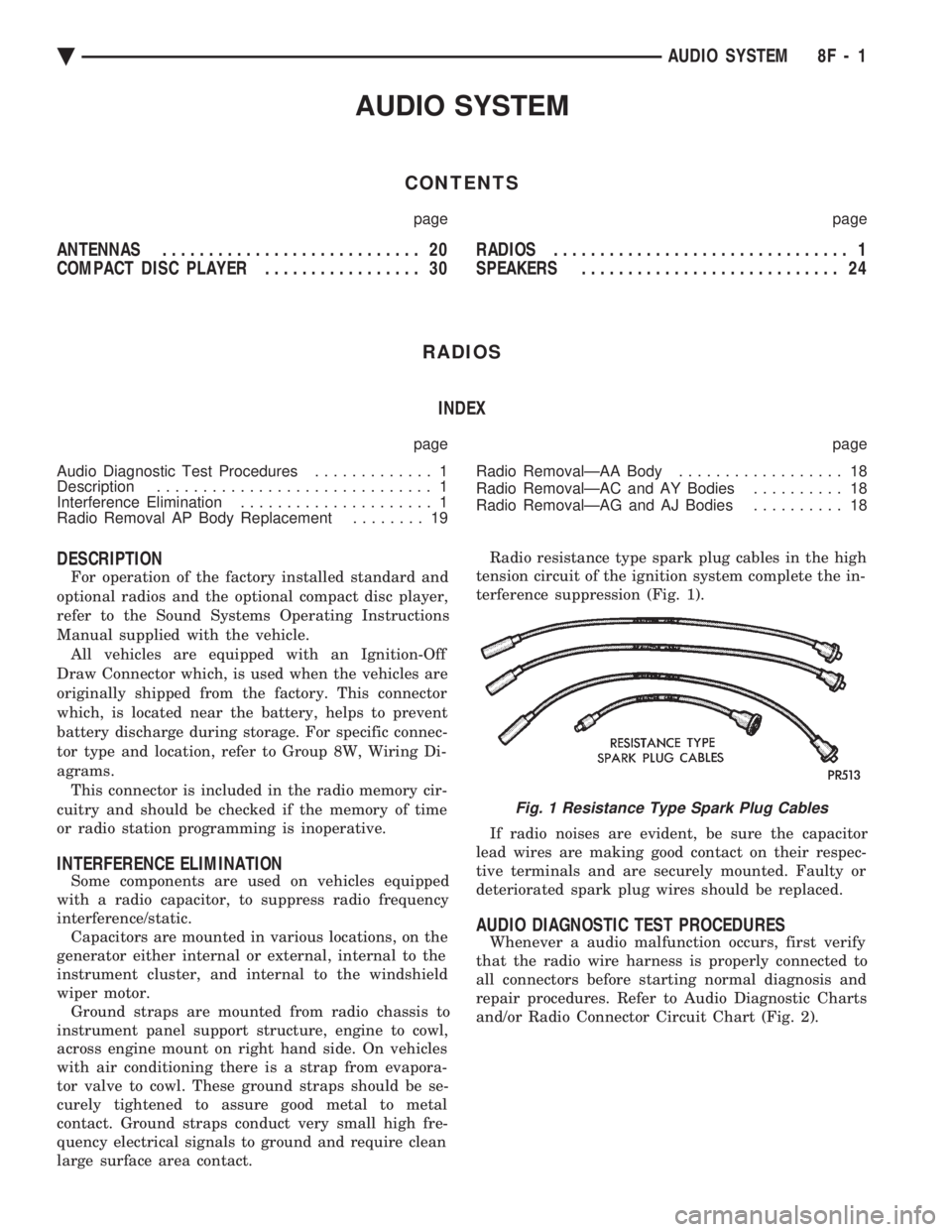

large surface area contact. Radio resistance type spark plug cables in the high

tension circuit of the ignition system complete the in-

terference suppression (Fig. 1).

If radio noises are evident, be sure the capacitor

lead wires are making good contact on their respec-

tive terminals and are securely mounted. Faulty or

deteriorated spark plug wires should be replaced.

AUDIO DIAGNOSTIC TEST PROCEDURES

Whenever a audio malfunction occurs, first verify

that the radio wire harness is properly connected to

all connectors before starting normal diagnosis and

repair procedures. Refer to Audio Diagnostic Charts

and/or Radio Connector Circuit Chart (Fig. 2).

Fig. 1 Resistance Type Spark Plug Cables

Ä AUDIO SYSTEM 8F - 1

Page 584 of 2438

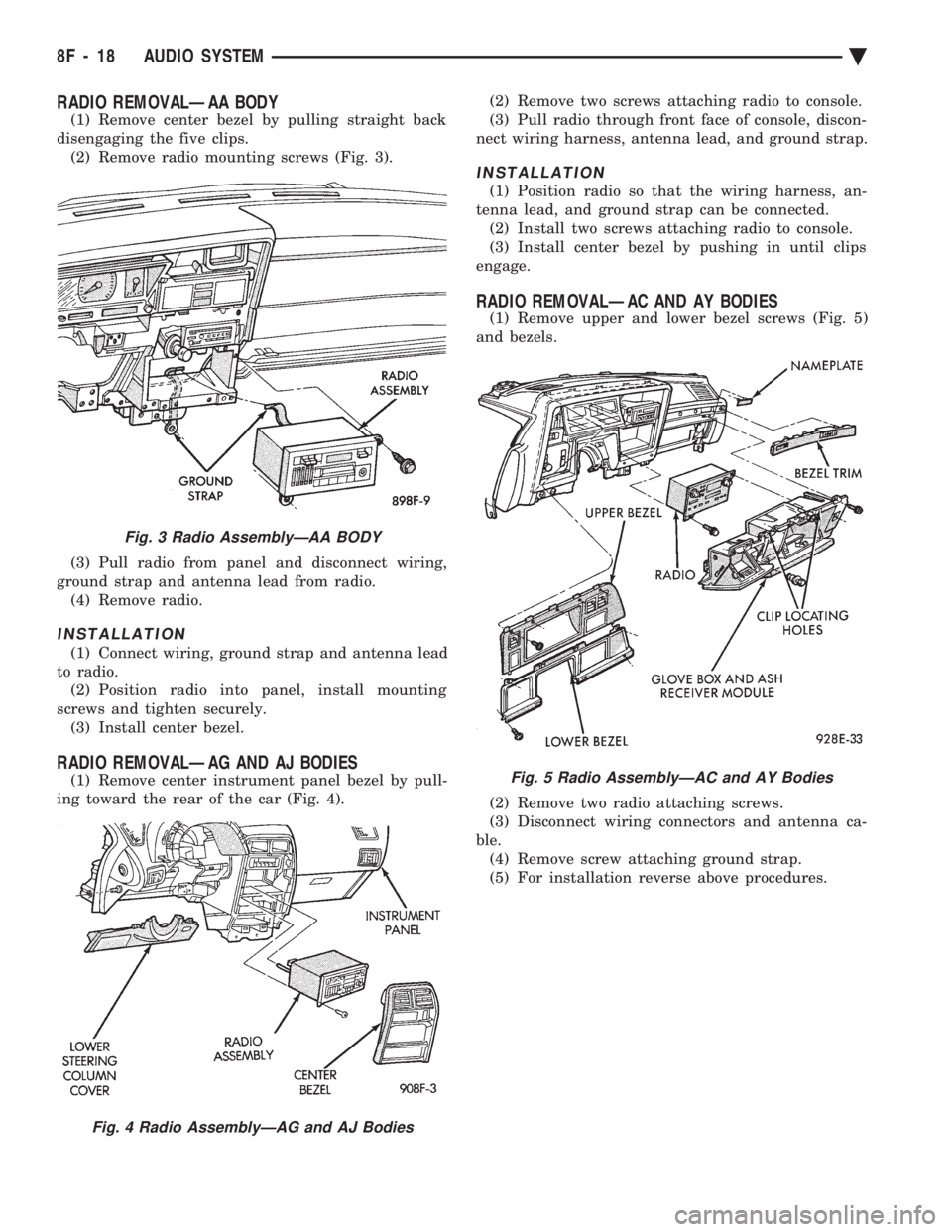

RADIO REMOVALÐAA BODY

(1) Remove center bezel by pulling straight back

disengaging the five clips. (2) Remove radio mounting screws (Fig. 3).

(3) Pull radio from panel and disconnect wiring,

ground strap and antenna lead from radio. (4) Remove radio.

INSTALLATION

(1) Connect wiring, ground strap and antenna lead

to radio. (2) Position radio into panel, install mounting

screws and tighten securely. (3) Install center bezel.

RADIO REMOVALÐAG AND AJ BODIES

(1) Remove center instrument panel bezel by pull-

ing toward the rear of the car (Fig. 4). (2) Remove two screws attaching radio to console.

(3) Pull radio through front face of console, discon-

nect wiring harness, antenna lead, and ground strap.

INSTALLATION

(1) Position radio so that the wiring harness, an-

tenna lead, and ground strap can be connected. (2) Install two screws attaching radio to console.

(3) Install center bezel by pushing in until clips

engage.

RADIO REMOVALÐAC AND AY BODIES

(1) Remove upper and lower bezel screws (Fig. 5)

and bezels.

(2) Remove two radio attaching screws.

(3) Disconnect wiring connectors and antenna ca-

ble. (4) Remove screw attaching ground strap.

(5) For installation reverse above procedures.

Fig. 3 Radio AssemblyÐAA BODY

Fig. 4 Radio AssemblyÐAG and AJ Bodies

Fig. 5 Radio AssemblyÐAC and AY Bodies

8F - 18 AUDIO SYSTEM Ä

Page 585 of 2438

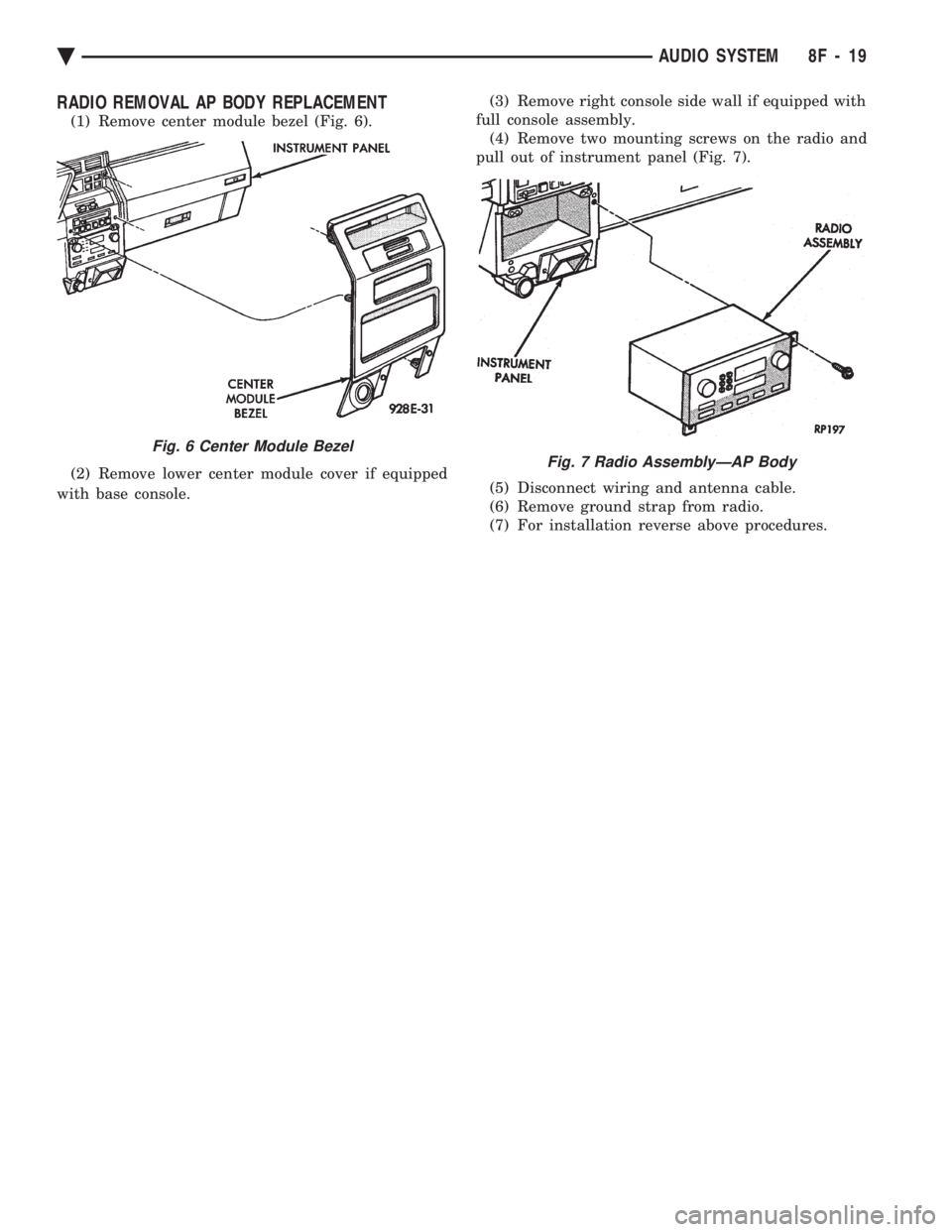

RADIO REMOVAL AP BODY REPLACEMENT

(1) Remove center module bezel (Fig. 6).

(2) Remove lower center module cover if equipped

with base console. (3) Remove right console side wall if equipped with

full console assembly. (4) Remove two mounting screws on the radio and

pull out of instrument panel (Fig. 7).

(5) Disconnect wiring and antenna cable.

(6) Remove ground strap from radio.

(7) For installation reverse above procedures.

Fig. 6 Center Module Bezel

Fig. 7 Radio AssemblyÐAP Body

Ä AUDIO SYSTEM 8F - 19

Page 586 of 2438

ANTENNAS INDEX

page page

Manual Antennas ........................ 20

Power Antenna .......................... 21 Power Antenna Mast

...................... 23

MANUAL ANTENNAS

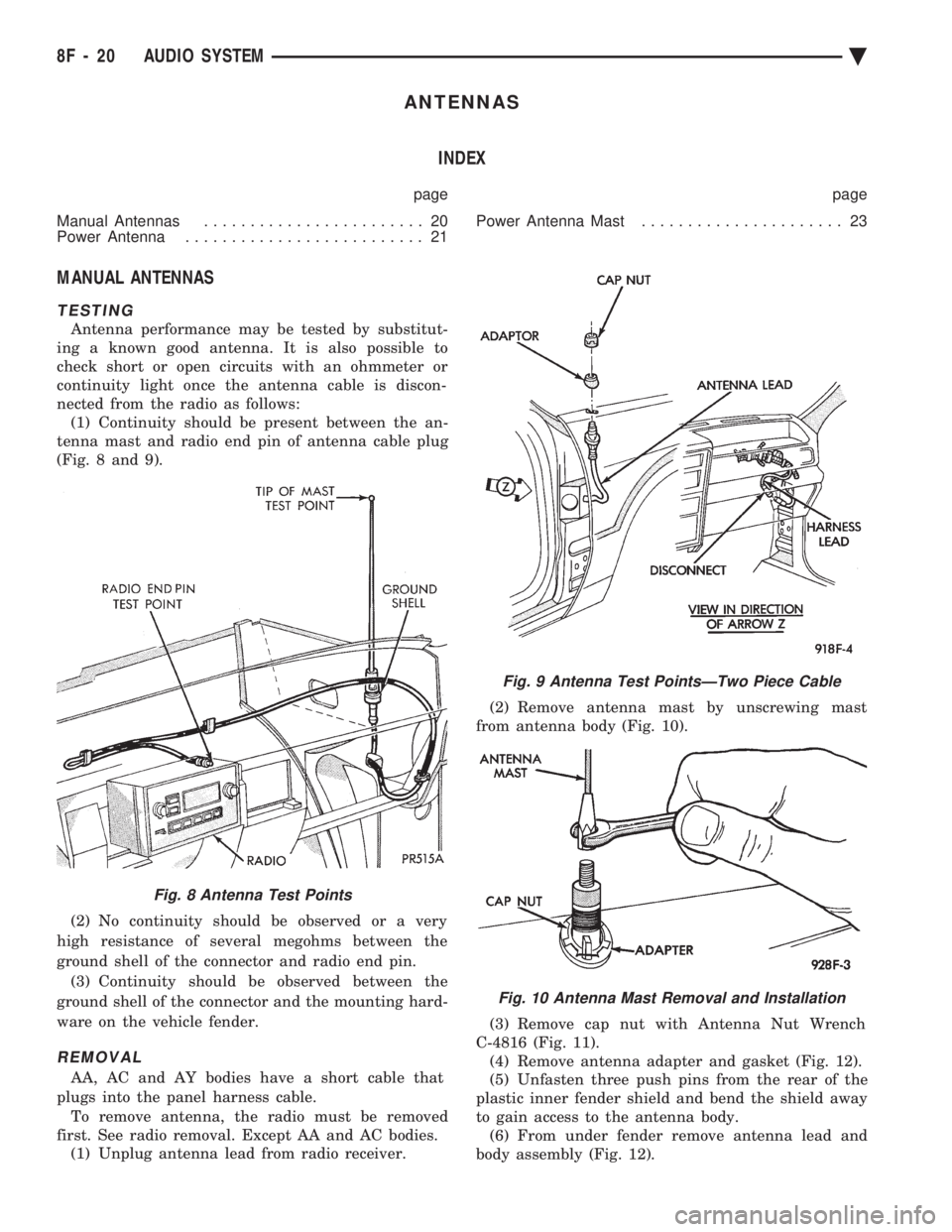

TESTING

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows: (1) Continuity should be present between the an-

tenna mast and radio end pin of antenna cable plug

(Fig. 8 and 9).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin. (3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle fender.

REMOVAL

AA, AC and AY bodies have a short cable that

plugs into the panel harness cable. To remove antenna, the radio must be removed

first. See radio removal. Except AA and AC bodies. (1) Unplug antenna lead from radio receiver. (2) Remove antenna mast by unscrewing mast

from antenna body (Fig. 10).

(3) Remove cap nut with Antenna Nut Wrench

C-4816 (Fig. 11). (4) Remove antenna adapter and gasket (Fig. 12).

(5) Unfasten three push pins from the rear of the

plastic inner fender shield and bend the shield away

to gain access to the antenna body. (6) From under fender remove antenna lead and

body assembly (Fig. 12).

Fig. 8 Antenna Test Points

Fig. 9 Antenna Test PointsÐTwo Piece Cable

Fig. 10 Antenna Mast Removal and Installation

8F - 20 AUDIO SYSTEM Ä

Page 587 of 2438

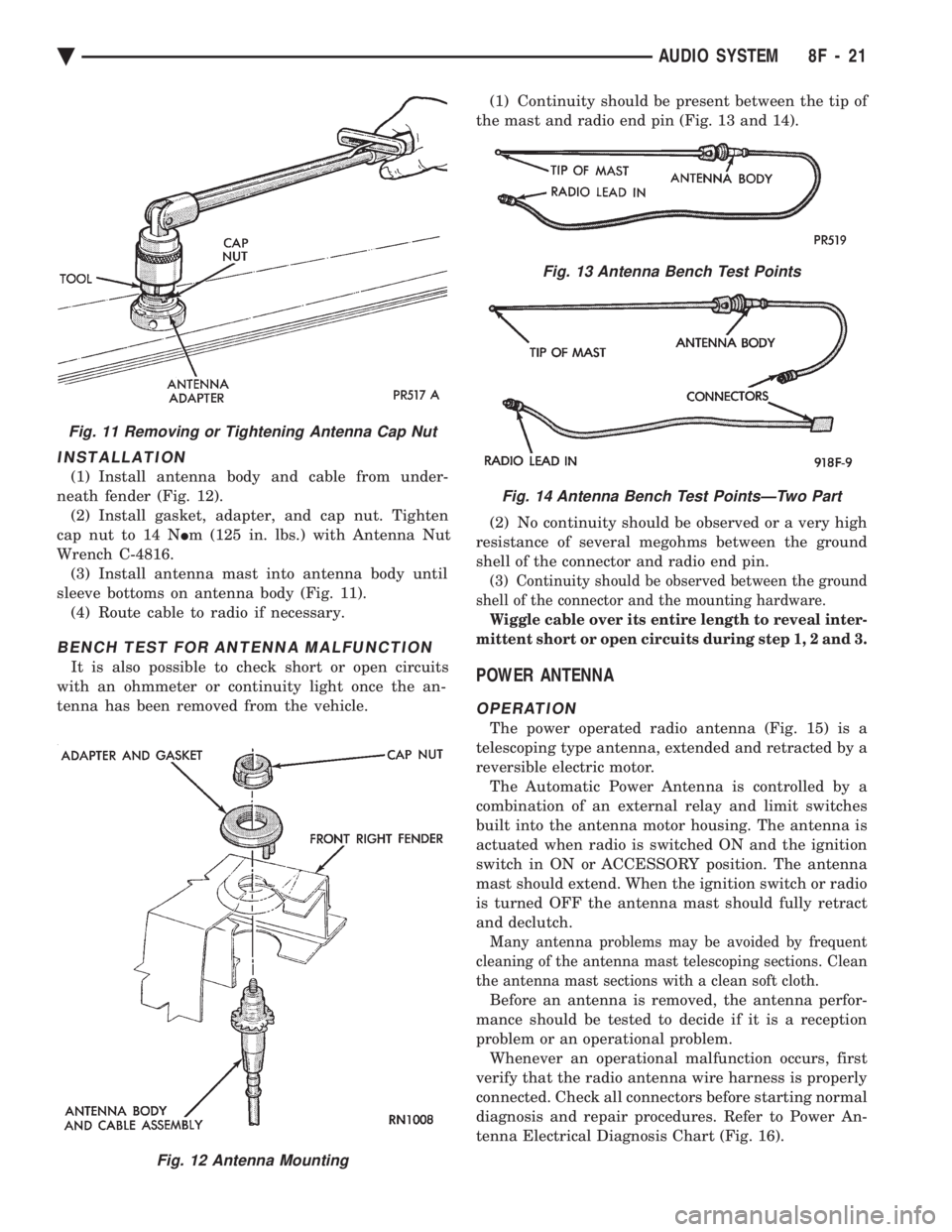

INSTALLATION

(1) Install antenna body and cable from under-

neath fender (Fig. 12). (2) Install gasket, adapter, and cap nut. Tighten

cap nut to 14 N Im (125 in. lbs.) with Antenna Nut

Wrench C-4816. (3) Install antenna mast into antenna body until

sleeve bottoms on antenna body (Fig. 11). (4) Route cable to radio if necessary.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the an-

tenna has been removed from the vehicle. (1) Continuity should be present between the tip of

the mast and radio end pin (Fig. 13 and 14).

(2) No continuity should be observed or a very high

resistance of several megohms between the ground

shell of the connector and radio end pin.

(3) Continuity should be observed between the ground

shell of the connector and the mounting hardware.

Wiggle cable over its entire length to reveal inter-

mittent short or open circuits during step 1, 2 and 3.

POWER ANTENNA

OPERATION

The power operated radio antenna (Fig. 15) is a

telescoping type antenna, extended and retracted by a

reversible electric motor. The Automatic Power Antenna is controlled by a

combination of an external relay and limit switches

built into the antenna motor housing. The antenna is

actuated when radio is switched ON and the ignition

switch in ON or ACCESSORY position. The antenna

mast should extend. When the ignition switch or radio

is turned OFF the antenna mast should fully retract

and declutch.

Many antenna problems may be avoided by frequent

cleaning of the antenna mast telescoping sections. Clean

the antenna mast sections with a clean soft cloth.

Before an antenna is removed, the antenna perfor-

mance should be tested to decide if it is a reception

problem or an operational problem. Whenever an operational malfunction occurs, first

verify that the radio antenna wire harness is properly

connected. Check all connectors before starting normal

diagnosis and repair procedures. Refer to Power An-

tenna Electrical Diagnosis Chart (Fig. 16).

Fig. 12 Antenna Mounting

Fig. 11 Removing or Tightening Antenna Cap Nut

Fig. 13 Antenna Bench Test Points

Fig. 14 Antenna Bench Test PointsÐTwo Part

Ä AUDIO SYSTEM 8F - 21

Page 589 of 2438

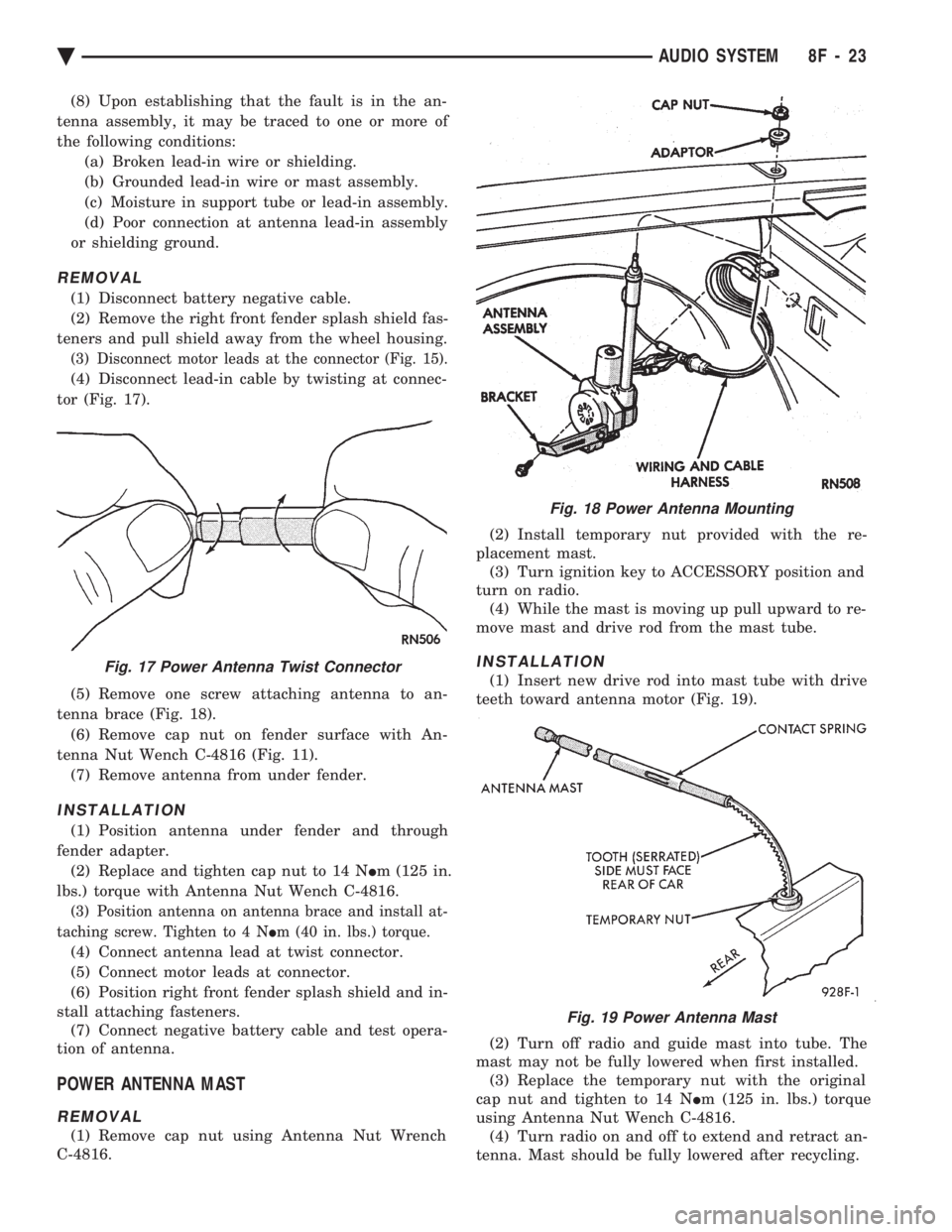

(8) Upon establishing that the fault is in the an-

tenna assembly, it may be traced to one or more of

the following conditions: (a) Broken lead-in wire or shielding.

(b) Grounded lead-in wire or mast assembly.

(c) Moisture in support tube or lead-in assembly.

(d) Poor connection at antenna lead-in assembly

or shielding ground.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the right front fender splash shield fas-

teners and pull shield away from the wheel housing.

(3) Disconnect motor leads at the connector (Fig. 15).

(4) Disconnect lead-in cable by twisting at connec-

tor (Fig. 17).

(5) Remove one screw attaching antenna to an-

tenna brace (Fig. 18). (6) Remove cap nut on fender surface with An-

tenna Nut Wench C-4816 (Fig. 11). (7) Remove antenna from under fender.

INSTALLATION

(1) Position antenna under fender and through

fender adapter. (2) Replace and tighten cap nut to 14 N Im (125 in.

lbs.) torque with Antenna Nut Wench C-4816.

(3) Position antenna on antenna brace and install at-

taching screw. Tighten to 4 N Im (40 in. lbs.) torque.

(4) Connect antenna lead at twist connector.

(5) Connect motor leads at connector.

(6) Position right front fender splash shield and in-

stall attaching fasteners. (7) Connect negative battery cable and test opera-

tion of antenna.

POWER ANTENNA MAST

REMOVAL

(1) Remove cap nut using Antenna Nut Wrench

C-4816. (2) Install temporary nut provided with the re-

placement mast. (3) Turn ignition key to ACCESSORY position and

turn on radio. (4) While the mast is moving up pull upward to re-

move mast and drive rod from the mast tube.

INSTALLATION

(1) Insert new drive rod into mast tube with drive

teeth toward antenna motor (Fig. 19).

(2) Turn off radio and guide mast into tube. The

mast may not be fully lowered when first installed. (3) Replace the temporary nut with the original

cap nut and tighten to 14 N Im (125 in. lbs.) torque

using Antenna Nut Wench C-4816. (4) Turn radio on and off to extend and retract an-

tenna. Mast should be fully lowered after recycling.

Fig. 18 Power Antenna Mounting

Fig. 17 Power Antenna Twist Connector

Fig. 19 Power Antenna Mast

Ä AUDIO SYSTEM 8F - 23

Page 595 of 2438

² If no short to ground at connector, check speaker

resistance at amplifier connector for an reading of

three to five ohms.

² If resistance is OK, refer to Radio Diagnosis. If ra-

dio checks OK, replace amplifier.

² If resistance is less than three ohms check

speaker. Check across the speaker connector if less

than three ohms replace speaker. If resistance is OK

repair wires

CONDITION: MECHANICAL NOISE DISTORTION

² Check trim for loose parts and speaker attach-

ments for buzzes

² Remove speaker still connected and listen for dis-

tortion. Distortion replace speaker.

CONDITION: ONE SPEAKER NON-OPERATIVE

² Remove output signal connector from amplifier

and check for three to five ohms resistance to the

non-operative speaker. Refer to Fig. 34 for the appro-

priate pin numbers.

² If resistance is less than three ohms, test speaker

for resistance.

² If OK repair wire. If not replace speaker.

CONDITION: ALL SPEAKERS NON-OPERATIVE

²Check radio for being ON, are the display lights

on

² Radio not ON, refer to Radio Diagnosis

² Check Amplifier Connectors and wires for proper

connection

² Check pin 9 and pin 27 for battery voltage

² If voltage OK replace amplifier ²

If pin 27 has battery voltage and pin 9 has 0 volt-

age. Refer to Power Antenna Diagnosis and test volt-

age at antenna relay.

² If pin 9 has battery voltage and pin 27 has 0 volt-

age. Check pin 27 for short to ground.

² If shorted to ground repair wire

² If no short to ground check fuse cavity number 16

for blown fuse.

² If fuse blows again replace amplifier

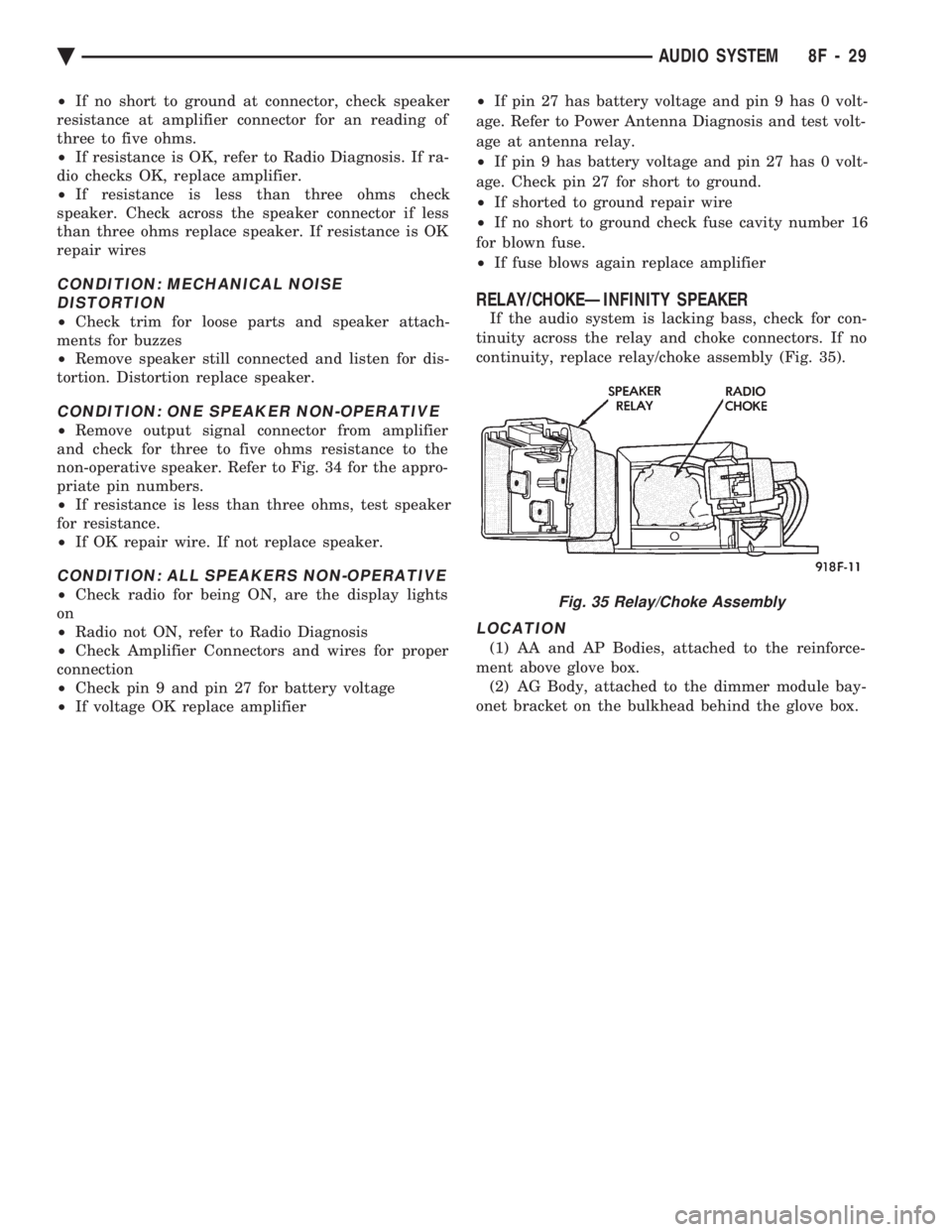

RELAY/CHOKEÐINFINITY SPEAKER

If the audio system is lacking bass, check for con-

tinuity across the relay and choke connectors. If no

continuity, replace relay/choke assembly (Fig. 35).

LOCATION

(1) AA and AP Bodies, attached to the reinforce-

ment above glove box. (2) AG Body, attached to the dimmer module bay-

onet bracket on the bulkhead behind the glove box.

Fig. 35 Relay/Choke Assembly

Ä AUDIO SYSTEM 8F - 29

Page 1064 of 2438

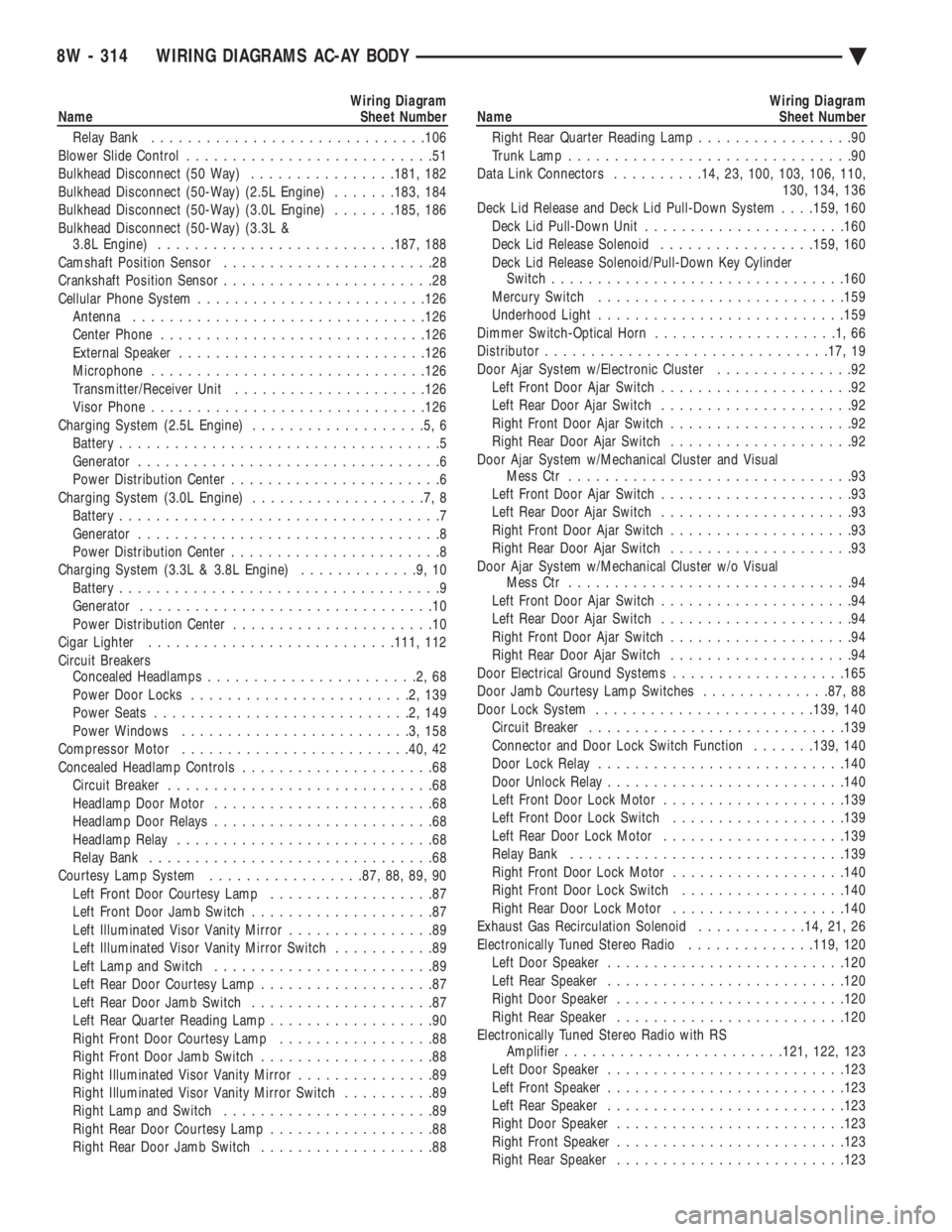

Wiring Diagram

Name Sheet Number

Relay Bank ............................. .106

Blower Slide Control ...........................51

Bulkhead Disconnect (50 Way) ................181, 182

Bulkhead Disconnect (50-Way) (2.5L Engine) .......183, 184

Bulkhead Disconnect (50-Way) (3.0L Engine) .......185, 186

Bulkhead Disconnect (50-Way) (3.3L & 3.8L Engine) ......................... .187, 188

Camshaft Position Sensor .......................28

Crankshaft Position Sensor .......................28

Cellular Phone System ........................ .126

Antenna ............................... .126

Center Phone ............................ .126

External Speaker .......................... .126

Microphone ............................. .126

Transmitter/Receiver Unit .................... .126

Visor Phone ............................. .126

Charging System (2.5L Engine) ...................5,6

Battery ...................................5

Generator .................................6

Power Distribution Center .......................6

Charging System (3.0L Engine) ...................7,8

Battery ...................................7

Generator .................................8

Power Distribution Center .......................8

Charging System (3.3L & 3.8L Engine) .............9,10

Battery ...................................9

Generator ................................10

Power Distribution Center ......................10

Cigar Lighter .......................... .111, 112

Circuit Breakers Concealed Headlamps .......................2,68

Power Door Locks ........................2,139

Power Seats ............................2,149

Power Windows .........................3,158

Compressor Motor ........................ .40, 42

Concealed Headlamp Controls .....................68

Circuit Breaker .............................68

Headlamp Door Motor ........................68

Headlamp Door Relays ........................68

Headlamp Relay ............................68

Relay Bank ...............................68

Courtesy Lamp System .................87, 88, 89, 90

Left Front Door Courtesy Lamp ..................87

Left Front Door Jamb Switch ....................87

Left Illuminated Visor Vanity Mirror ................89

Left Illuminated Visor Vanity Mirror Switch ...........89

Left Lamp and Switch ........................89

Left Rear Door Courtesy Lamp ...................87

Left Rear Door Jamb Switch ....................87

Left Rear Quarter Reading Lamp ..................90

Right Front Door Courtesy Lamp .................88

Right Front Door Jamb Switch ...................88

Right Illuminated Visor Vanity Mirror ...............89

Right Illuminated Visor Vanity Mirror Switch ..........89

Right Lamp and Switch .......................89

Right Rear Door Courtesy Lamp ..................88

Right Rear Door Jamb Switch ...................88Wiring Diagram

Name Sheet Number

Right Rear Quarter Reading Lamp .................90

Trunk Lamp ...............................90

Data Link Connectors ..........14, 23, 100, 103, 106, 110,

130, 134, 136

Deck Lid Release and Deck Lid Pull-Down System . . . .159, 160

Deck Lid Pull-Down Unit ..................... .160

Deck Lid Release Solenoid .................159, 160

Deck Lid Release Solenoid/Pull-Down Key Cylinder Switch ............................... .160

Mercury Switch .......................... .159

Underhood Light .......................... .159

Dimmer Switch-Optical Horn ....................1,66

Distributor .............................. .17, 19

Door Ajar System w/Electronic Cluster ...............92

Left Front Door Ajar Switch .....................92

Left Rear Door Ajar Switch .....................92

Right Front Door Ajar Switch ....................92

Right Rear Door Ajar Switch ....................92

Door Ajar System w/Mechanical Cluster and Visual Mess Ctr ...............................93

Left Front Door Ajar Switch .....................93

Left Rear Door Ajar Switch .....................93

Right Front Door Ajar Switch ....................93

Right Rear Door Ajar Switch ....................93

Door Ajar System w/Mechanical Cluster w/o Visual Mess Ctr ...............................94

Left Front Door Ajar Switch .....................94

Left Rear Door Ajar Switch .....................94

Right Front Door Ajar Switch ....................94

Right Rear Door Ajar Switch ....................94

Door Electrical Ground Systems ...................165

Door Jamb Courtesy Lamp Switches ..............87, 88

Door Lock System ....................... .139, 140

Circuit Breaker ........................... .139

Connector and Door Lock Switch Function .......139, 140

Door Lock Relay .......................... .140

Door Unlock Relay ......................... .140

Left Front Door Lock Motor ................... .139

Left Front Door Lock Switch ...................139

Left Rear Door Lock Motor ................... .139

Relay Bank ............................. .139

Right Front Door Lock Motor ...................140

Right Front Door Lock Switch ..................140

Right Rear Door Lock Motor ...................140

Exhaust Gas Recirculation Solenoid ............14, 21, 26

Electronically Tuned Stereo Radio ..............119, 120

Left Door Speaker ......................... .120

Left Rear Speaker ......................... .120

Right Door Speaker ........................ .120

Right Rear Speaker ........................ .120

Electronically Tuned Stereo Radio with RS Amplifier ....................... .121, 122, 123

Left Door Speaker ......................... .123

Left Front Speaker ......................... .123

Left Rear Speaker ......................... .123

Right Door Speaker ........................ .123

Right Front Speaker ........................ .123

Right Rear Speaker ........................ .123

8W - 314 WIRING DIAGRAMS AC-AY BODY Ä