belt CHEVROLET S10 1993 2.G Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1993, Model line: S10, Model: CHEVROLET S10 1993 2.GPages: 356, PDF Size: 20.85 MB

Page 216 of 356

Downloaded from www.Manualslib.com manuals search engine Your Driving and the Road

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the chocks.

Maintenance When Trailer Towing

Your vehicle will need service more often when you’re pulling a \

trailer. See

the Maintenance Schedule for more on this. Things that are esp\

ecially important in trailer operation are automatic transmission fluid (don’t ove\

rfill),

engine oil, axle lubricant, belt, cooling system, and brake adj\

ustment. Each of

these is covered in this manual, and the Index will help you find them

quickly.

If you’re trailering, it’s a good idea to review these sections before

you start your trip.

Check periodically to see that all hitch nuts and bolts are tight.

Trailer Light Wiring

See “Trailer Wiring Harness” in the Index.

Power Winches

If you wish to use a power winch on your vehicle, only use it when your

vehicle is stationary or anchored.

NOTICE

Use the regular brakes, set the parking brake Or UIWK ihe wheels IW keep

your vehicle from rolling.

4-62

Page 282 of 356

Downloaded from www.Manualslib.com manuals search engine Service & Appearance Care

Other Maintenance Items

Hydraulic Clutch Grease Fitting

If you have the 4.3L (VIN code Z) engine with a manual transmission, a

grease fitting is on the clutch housing for lubricating the cl\

utch fork ball stud.

Refer to the Maintenance Schedule for information on how to lu\

bricate the

clutch housing, and what type of lubricant to use. Be sure no\

t to over-fill

because you could

damage your clutch.

Front Suspension and Steering Linkage

Refer to the Maintenance Schedule to determine how often to lubricate the

fittings and what type of lubricant to use.

Front Wheel Bearings (Two-Wheel Drive)

If your vehicle is two-wheel drive, it has wheel bearings that mu\

st be cleaned

and repacked.

Refer

to the Maintenance Schedule to determine how often this must be

done.

Single Belt Accessory Drive

Your new vehicle uses a serpentine belt that is lighter, and more durable than

systems with several belts.

The belt runs over or around the pulleys

on the engine. A tensioner is used

to keep the belt tight at all times. The tensioner also makes replacing the

belt easier.

If you need to replace the belt, be sure to get the correct

replacement belt. Your dealership or parts supplier can help yo\

u with this.

The Accessory Drive Belt Routing label on your vehicle will sh\

ow you how to

route the belt your vehicle uses.

6-34

Page 295 of 356

Downloaded from www.Manualslib.com manuals search engine If you ever replace your tires with those not having a TPC Spec number,

make sure they are the same size, load range, speed rating an\

d construction

type (bias, bias-belted or radial) as your original tires.

Mixing tires

could cause you to lose control while driving. If you mix

tires of different types (like radial and bias-belted tires) the vehicl\

e

may nlot handle properly, an'd you could have a cras'h. Be sure to

use the same size 'and type tires on all four wheels.

It's all right to drive with your compact spare (if you have one). It

I was developed for use on your vehicle.

Uniform Tire Quality Grading

The following information relates to the system developed by th\

e United

States National Highway Traffic Safety Administration which grade\

s tires by

treadwear, traction and temperature performance. (This applies o\

nly to

vehicles

sold in the United States.)

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the

tire when tested under controlled conditions on a specified government test

course. For example, a tire graded

150 would wear one and a half (1 -1/2)

times as well on the government course as a tire graded 100. The relative

performance of tires depends upon the actual conditions of their use,

however, and may depart significantly from the norm due to var\

iations in

driving habits, service practices and differences in road charac\

teristics and

climate.

Traction-A, B, C

The traction grades, from highest to lowest are: A, B, and C. They represent

the tire's ability to stop on wet pavement as measured under controlled

conditions on specified government test surfaces of asphalt and concrete.

A

tire marked C may have poor traction performance.

Warning: The traction grade assigned to this tire is based on braking

(straight-ahead) traction tests and does not include cornering \

(turning) traction.

Temperature-A, B, C

The temperature grades are A (the highest), B, and C, representing the tire's

resistance

to the generation of heat and its ability to dissipate heat when

tested under controlled conditions on a specified indoor laboratory test wheel,

Sustained high temperature can cause the material of the tire

to degenerate

and reduce tire life, and excessive temperature can lead to sudden tire

6-47

Page 301 of 356

Downloaded from www.Manualslib.com manuals search engine If an odor lingers after cleaning vomit or urine, treat the area \

with a

watedbaking soda solution:

1 teaspoon (5 ml) of baking soda to 1 cup

(250 ml) of lukewarm water.

Finally, if needed, clean lightly with solvent-type cleaner.

Combination Stains: Like candy, ice cream, mayonnaise,

c i sauce and

unknown stains.

Carefully scrape off excess stain, then clean with cool water and allow to

dry.

If a stain remains, clean it with solvent-type cleaner.

Cleaning Vinyl or Leather

Just use warm water and a clean cloth.

Rub with a clean, damp cloth to remove dirt. You may have to do it

more than once.

Things like tar, asphalt and shoe polish will stain if you^ don’t get them

off quickly. Use a clean cloth and solvent-type vinylheather cleaner.

Cleaning the Top of the Instrument Panel

Use only mild soap and water to clean the top surfaces of the instrument

panel. Sprays containing silicones or waxes may cause annoying \

reflections in

the windshield and even make it difficult to see through the windshield under

certain conditions.

Care of Safety Belts

Keep belts clean and dry.

I

CAUTION

I

A

Do not bleach or dye safety kits. If you do, it may severely weaken

them. In a crash they might not be able to provide adequate

protection. Clean safety belts only with mild

soap and lukewarm

water.

Glass

Glass should be cleaned often. GM Glass Cleaner (GM Part No. 1050427) or

a liquid household glass cleaner will remove normal tobacco smo\

ke and dust

films.

Don’t use abrasive cleaners

on glass, because they may cause scratches.

Avoid placing decals on the inside rear window, since they may have to be

scraped off later.

6-53

Page 312 of 356

Downloaded from www.Manualslib.com manuals search engine Service & Appearance Cam

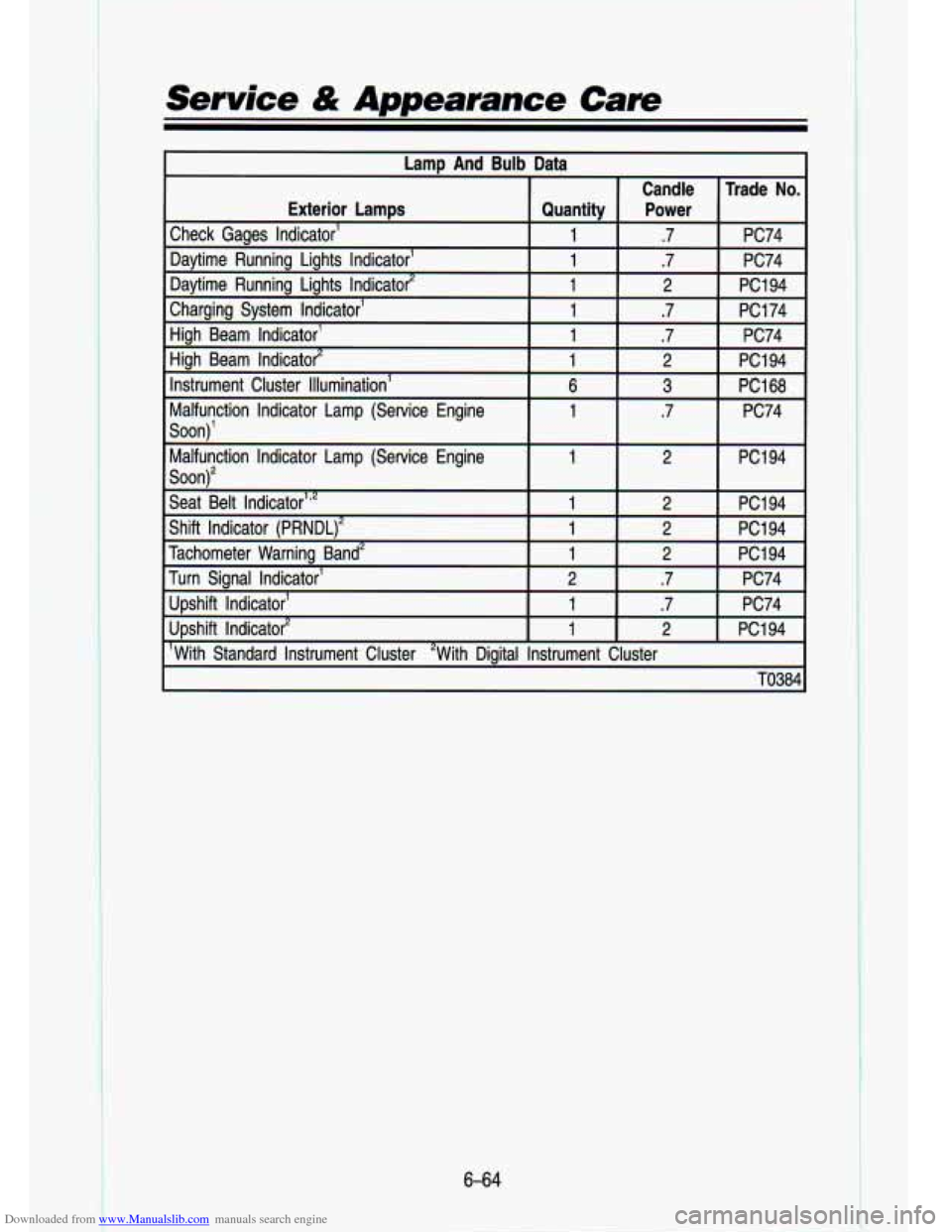

Lamp And Bulb Data

Exterior Lamps

Check Gages Indicator' Daytime Running Lights Indicator'

Daytime Running Lights Indicator2

..-

Charging System Indicator' High Beam Indicator'

High Beam lndicato?

I

Quantity 1 1

Trade No.

PC1 94

PC1 74

PC1 94

-

Instrument Cluster Illumination' 6 3 PC1 68

Malfunction Indicator Lamp (Service Engine 1 .7 PC74

Soon)'

Malfunction Indicator Lamp (Service Engine

Soon)'

I I pc194

Seat Belt Indicator'" 1 2 PC1 94

Shift Indicator (PRNDL)'

1 2 PC1 94

Tachometer Warning Band'

1 2 PC1 94

Turn Signal Indicator'

2 .7 PC74

Upshift Indicator' 1 .7 PC74

Upshift Indicator2 1

2 PC1 94

'With Standard Instrument Cluster 'With Digital Instrument Cluster

6-64

Page 315 of 356

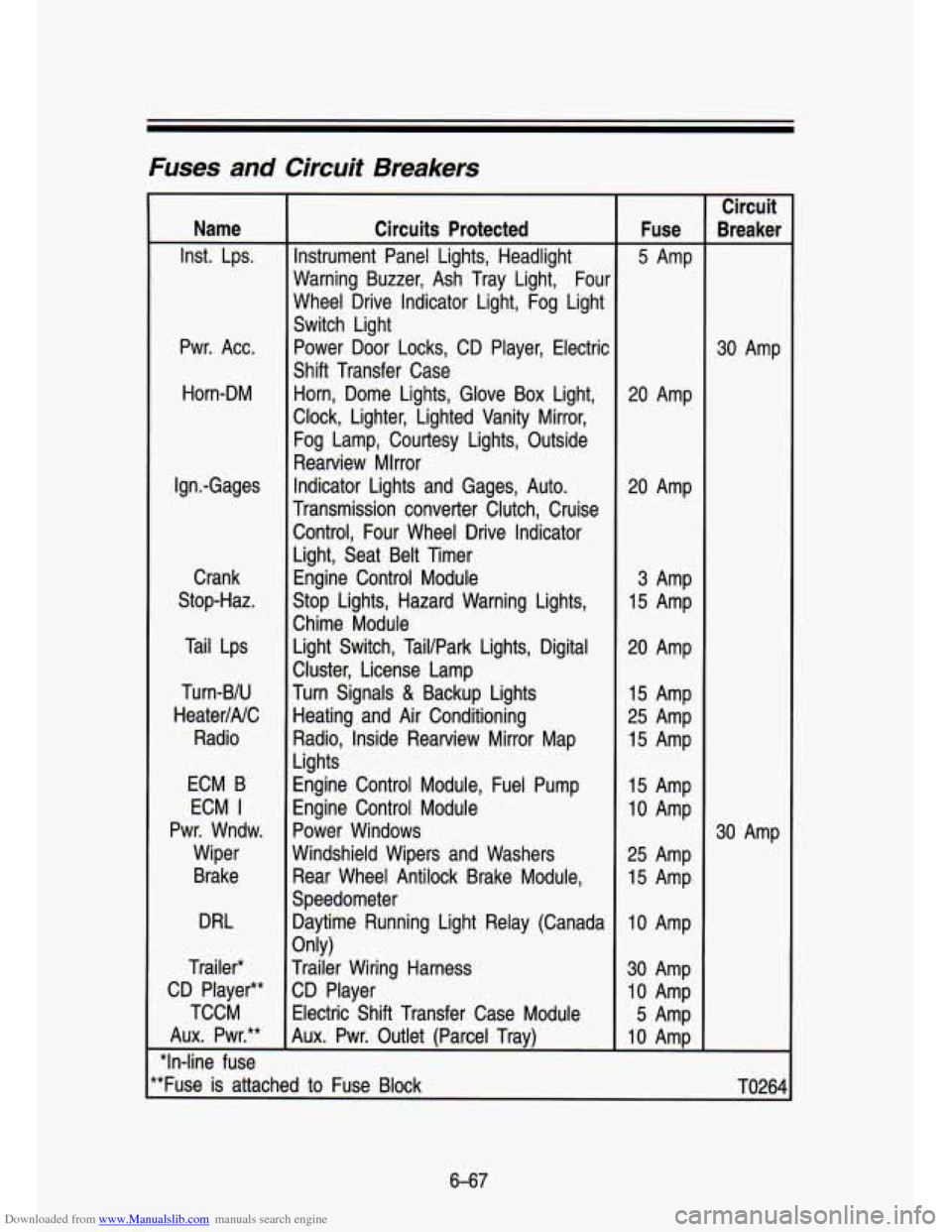

Downloaded from www.Manualslib.com manuals search engine Fuses and Circuit Breakers

Name

Inst. Lps.

Pwr. Acc. Horn-DM

Ign.-Gages Crank

Stop-Haz.

Tail Lps

Turn-BIU

HeaterINC Radio

ECM B

ECM

I

Pwr. Wndw. Wiper

Brake

DRL

Trailer*

CD Player**

TCCM

Aux. Pwr.**

"In-line fuse Circuits Protected

Instrument Panel Lights, Headlight

Warning Buzzer, Ash Tray Light, Four

Wheel Drive Indicator Light, Fog Light

Switch Light Power Door Locks, CD Player, Electric

Shift Transfer Case Horn, Dome Lights, Glove Box Light,

Clock, Lighter, Lighted Vanity Mirror,

Fog Lamp, Courtesy Lights, Outside

Rearview Mlrror

Indicator Lights and Gages, Auto.

Transmission converter Clutch, Cruise Control, Four Wheel Drive Indicator

Light, Seat Belt Timer Engine Control Module

Stop Lights, Hazard Warning Lights,

Chime Module Light Switch, Tail/Park Lights, Digital

Cluster, License Lamp

Turn Signals

& Backup Lights

Heating and Air Conditioning

Radio, Inside Rearview Mirror Map

Lights

Engine Control Module, Fuel Pump

Engine Control Module

Power Windows

Windshield Wipers and Washers Rear Wheel Antilock Brake Module,

Speedometer Daytime Running Light Relay (Canada

Trailer Wiring Harness

CD Player

Electric Shift Transfer Case Module

Aux. Pwr. Outlet (Parcel Trav)

Only) Fuse

5 Amp

20 Amp

20 Amp

3 Amp

15 Amp

20 Amp 15 Amp

25 Amp

15 Amp

15 Amp

10 Amp

25 Amp

15 Amp

10 Amp

30 Amp

10 Amp

5 Amp

10 AmD Circuit

kea ker

30 Amp

30 Amp

'*Fuse is attached to Fuse Block

TO264

6-67

Page 320 of 356

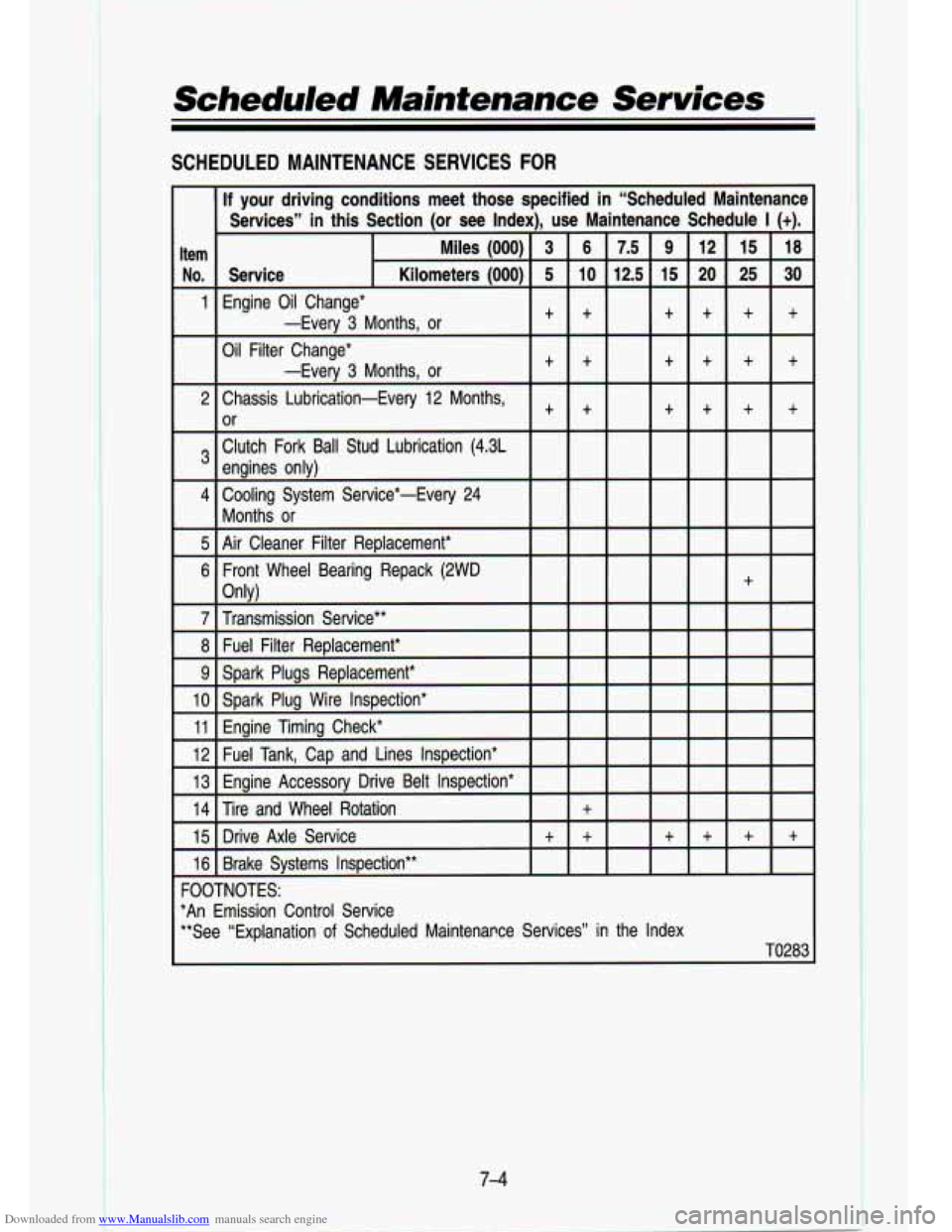

Downloaded from www.Manualslib.com manuals search engine Scheduled Maintenance Services

SCHEDULED MAINTENANCE SERVICES FOR

I

If your driving conditions meet those specified i

Services” in this Section (or see Index), use

M

Item I I Miles (000) I 3 I 6

No. Service Kilometers (000) 5 10

1 Engine Oil Change*

I -Even/ 3 Months, or

Oil Filter Change*

-Every 3 Months, or

tt

2 Chassis Lubrication-Every 12 Months,

,, Clutch Fork Ball Stud Lubrication (4.3L or J I engines only) I

4 Cooling System Service*-Every 24

1 Months or

5 I Air Cleaner Filter Replacement* I I

6 Front Wheel Bearing Repack (2WD

Only)

7 Transmission Service**

8 Fuel Filter Replacement*

9 Spark Plugs Replacement*

10 Spark Plug Wire Inspection*

11 Engine Timing Check*

12 Fuel Tank, Cap and Lines Inspection*

13 Engine Accessory Drive Belt Inspection*

14 Tire and Wheel Rotation

t

15 Drive Axle Service tt

16 Brake Systems Inspection**

FOOTNOTES:

*An Emission Control Service

**See “Explanation

of Scheduled Maintenapce Services” i n the Index

TO283

7-4

Page 322 of 356

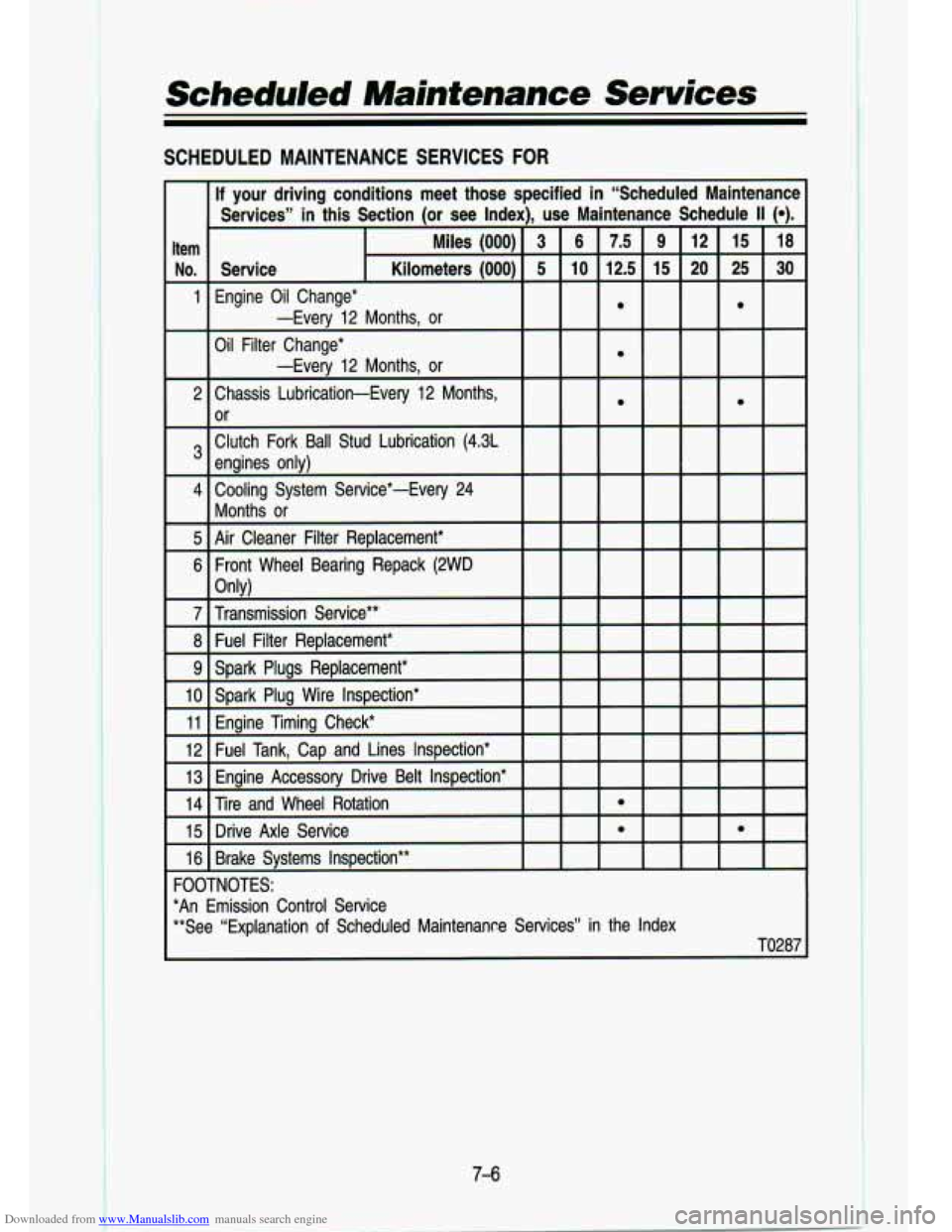

Downloaded from www.Manualslib.com manuals search engine scheduled Maintenance Services

I

SCHEDU--D MAIM 4ANCE SEf -7s FOR

If your driving conditions meet those I

Services” in this Section (or see lnde

Item Miles

(000)

No. Service Kilometers (000)

1 Engine Oil Change*

Oil Filter Change* -Every 12 Months,

or

-Every

12 Months, or

2 Chassis Lubrication-Every 12 Months, or

Clutch Fork Ball Stud Lubrication (4.3L

engines only)

Months or

3

4 Cooling System Service*-Every 24

5 Air Cleaner Filter Replacement*

6 Front Wheel Bearing Repack (2WD

7 Transmission Service**

8 Fuel Filter Replacement*

9 Spark Plugs Replacement*

10 Spark Plug Wire Inspection* 11 Engine Timing Check*

12 Fuel Tank, Cap and Lines Inspection*

13 Engine Accessory Drive Belt Inspection*

14 Tire and Wheel Rotation

15 Drive Axle Service

16 Brake Systems Inspection**

Only)

FOOTNOTES:

*An Emission Control Service

36

5 10

**See “Explanation of Scheduled Maintenance Services” in the Index

TO287

7-6

Page 326 of 356

Downloaded from www.Manualslib.com manuals search engine Scheduled Maintenance Services

13. ENGINE ACCESSORY DRIVE BELT INSPECTION*-Inspect belt. Look

for cracks, fraying, wear, and proper tension. Adjust or replac\

e as needed.

14. TIRE AND WHEEL ROTATION AND INSPECTION -For proper wear and maximum tire life, rotate tires at the first

6,000 miles (10 000

kilometers) for Schedule I or 7,500 miles (12 500 kilometers) for

Schedule

II and then every 15,000 miles (25 000 kilometers) thereafter.

Follow the instructions and patterns shown in Section

6. Check tires for

uneven wear or damage.

If irregular or premature wear is apparent,

check wheel alignment. Also, check for damaged wheels. See “\

Tires” in

the Index for more information.

15. DRIVE AXLE SERVICE -Check rear/front axle fluid level and add \

as

needed. Check constant velocity joints and axle seals for leaki\

ng.

Locking differential -Drain fluid at first oil change and refill. Check

fluid level and add as needed at subsequent oil changes. In d\

usty areas

or trailer towing applications, drain fluid at every 15,000 miles

(24

135 kilometers) and refi1l.t

Standard differential -Check fluid level and add as needed at

every oil change. In dusty areas or trailer towing applications\

, drain

fluid every

15,000 miles (24 135 kilometers) and refil1.t

More frequent lubrication may be required for off-road use.

16. BRAKE SYSTEM INSPECTION -When the engine oil is changed,

inspect the lines and hoses for proper hookup, binding, leaks, \

cracks,

chafing, etc. Check the parking brake adjustment, and the fluid\

level in

the master cylinder. A low fluid level can indicate worn disc \

brake pads

which may need to be serviced.t

When the wheels are removed for rotation, inspect disc brake p\

ads for

wear and rotors for surface condition. Also inspect drum brake \

linings for

wear and cracks. Inspect other brake parts, including drums, wh\

eel cylinders, parking brake, etc., at the same time.

Inspect brakes more often if driving habits or conditions resul\

t

in

frequent braking.

tA fluid

loss in these systems may indicate a problem. Have them inspected

and repaired at once.

7-1 0

Page 328 of 356

Downloaded from www.Manualslib.com manuals search engine Scheduled Maintenance Services

Steering column lock operation -While parked, try to turn the \

key to Lock

in each gear shift position.

With an automatic transmission, the key should turn to LOCK only when

the gear shift is in P (Park).

With manual shift, the key should turn to LOCK only when you’re in R

(Reverse).

On vehicles with a key release lever, try

to turn the key to LOCK without

pressing the lever. The key should turn to LOCK only with the key lever

depressed.

On all vehicles, the key should come out only in LOCK.

Parking brake and transmission

P (Park) mechanism operation -

CAUTION

A When you are doing this check, your vehicle could begin to move.

You or others could be injured and property could be damaged.

Make sure there is room in front of your vehicle in case you begin

to roll. Be ready to apply the regular brake at once should the

vehicle begin to move.

Park on a fairly steep hill, with the vehicle facing downhill.\

1.- )ping your foot

on the regular brake, set the manual parking brake.

To check the parking brake: With the engine running and the

transmission in

N (Neutral), slowly remove foot pressure from the regular

brake pedal.

Do this until the vehicle is held by the parking brake only.

To check the P (Park) mechanism’s holding ability: Apply the \

regular

brake and shift to

P (Park). Release the manual parking brake, then

slowly release the regular brake.

Lap and shoulder belts condition and operation -Inspect belt sy\

stem,

including: webbing, buckles, latch plates, retractors, guide loop\

s and anchors. Have a belt assembly replaced

if the webbing has been cut or otherwise

damaged.

Body Lubrication Service -Lubricate all body door hinges including th\

e

tailgate, tailgate handle pivot points, and tailgate mounted spa\

re tire carrier (if equipped), lubricate the body hood, fuel door and rear compartment hinges,

latches and locks including interior glove box and console door\

s, and any

moving seat hardware. Lubricate the hood safety lever pivot and\

prop rod

pivot. More frequent lubrication may be required when exposed to a corrosive

environment.

7-1 2