power CHEVROLET SILVERADO 1500 2021 Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2021, Model line: SILVERADO 1500, Model: CHEVROLET SILVERADO 1500 2021Pages: 463, PDF Size: 9.65 MB

Page 306 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

Driving and Operating 303

The trailer symbol on the control panel will

light amber when a trailer with electric

brakes is connected.

The ITBC control panel is on the center

stack. SeeInstrument Panel Overview 04.

The control panel allows adjustment to the

amount of output, referred to as Trailer

Gain, available to the trailer brakes and

allows manual application of the trailer

brakes. Use the ITBC control panel and the

DIC trailer brake display page to adjust and

display power output to the trailer brakes.

Trailer Brake DIC Display Page

The ITBC display page indicates:

.Trailer Gain setting

.Output to the trailer brakes

.Trailer connection

.System operational status

To display:

.Scroll through the DIC menu pages

.Press a Trailer Gain (+) or (−) button

.Activate the Manual Trailer Brake Apply

Lever

TRAILER GAIN: Press a Trailer Gain button to

recall the current Trailer Gain setting. Each

press and release of the gain buttons will

then change the Trailer Gain setting. Press the Trailer Gain (+) or (-) to adjust. Press and

hold to continuously adjust the Trailer Gain.

To turn the output to the trailer off, adjust

the Trailer Gain setting to 0.0. This setting

can be adjusted from 0.0 to 10.0 with a

trailer connected or disconnected.

TRAILER OUTPUT: This displays anytime a

trailer with electric brakes is connected.

Output to the trailer brakes is based on the

amount of vehicle braking present and

relative to the Trailer Gain setting. Output is

displayed from 0 to 100% for each gain

setting.

The Trailer Output will indicate

“- - - - - -”on

the Trailer Brake Display Page whenever the

following occur:

.No trailer is connected.

.A trailer without electric brakes is

connected. No DIC message displays.

.A trailer with electric brakes has become

disconnected. A CHECK TRAILER WIRING

message displays on the DIC.

.There is a fault present in the wiring to

the trailer brakes. A CHECK TRAILER

WIRING message displays on the DIC.

.The ITBC system is not working due to a

fault. A SERVICE TRAILER BRAKE SYSTEM

message displays in the DIC.

Manual Trailer Brake Apply Lever

Slide this lever right to apply the trailer’s

electric brakes independent of the vehicle’s

brakes. Use this lever to adjust the Trailer

Gain to achieve proper power output to the

trailer brakes. Under certain circumstances,

this lever can also be used to apply

additional trailer braking. The trailer and

vehicle brake lamps will come on when

either the vehicle brakes or trailer brakes are

applied and properly connected.

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a specific

trailering condition and it must be

readjusted anytime vehicle loading, trailer

loading, or road surface conditions change.

{Warning

Trailer brakes that are over-gained or

under-gained may not stop the vehicle

and the trailer as intended and can result

in a crash. Always follow the instructions

to set the Trailer Gain for the proper

trailer stopping performance.

Page 340 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

Vehicle Care 337

{Warning

Steam and scalding liquids from a hot

cooling system are under pressure.

Turning the pressure cap, even a little,

can cause them to come out at high

speed and you could be burned. Never

turn the cap when the cooling system,

including the pressure cap, is hot. Wait

for the cooling system and pressure cap

to cool.

Caution

Failure to follow the specific coolant fill

procedure could cause the engine to

overheat and could cause system

damage. If coolant is not visible in the

surge tank, contact your dealer.

If no coolant is visible in the surge tank, add

coolant.

1. Remove the coolant surge tank pressure cap when the cooling system, including

the coolant surge tank pressure cap and

upper radiator hose, is no longer hot.

Turn the pressure cap slowly

counterclockwise about one full turn. If a

hiss is heard, wait for that to stop.

A hiss means there is still some

pressure left.

2. Keep turning the pressure cap slowly, and remove it.

3. Fill the coolant surge tank with the proper mixture to the full cold mark.

4. With the coolant surge tank pressure cap off, start the engine and let it run until

the engine coolant temperature gauge

indicates approximately 90 °C (195 °F).

By this time, the coolant level inside the

coolant surge tank may be lower. If the

level is lower, add more of the proper

mixture to the coolant surge tank until

the level reaches the indicated mark.

5. Replace the pressure cap tightly.

6. Verify coolant level after the engine is shut off and the coolant is cold.

If necessary, repeat coolant fill procedure

Steps 1–6.Caution

If the pressure cap is not tightly installed,

coolant loss and engine damage may

occur. Be sure the cap is properly and

tightly secured.

Engine Overheating

If the vehicle has the Duramax diesel

engine, see the Duramax diesel supplement.

Caution

Do not run the engine if there is a leak

in the engine cooling system. This can

cause a loss of all coolant and can

damage the system and vehicle. Have

any leaks fixed right away.

The vehicle has several indicators to warn of

engine overheating.

There is a coolant temperature gauge in the

vehicle's instrument cluster. See Engine

Coolant Temperature Gauge 0112.

In addition, there are ENGINE OVERHEATED

STOP ENGINE, ENGINE OVERHEATED IDLE

ENGINE, and ENGINE POWER IS REDUCED

messages in the Driver Information

Center (DIC).

Page 342 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

Vehicle Care 339

continue to drive normally and have the

cooling system checked for proper fill and

function.

If the warning continues, pull over, stop, and

park the vehicle right away.

If there is still no sign of steam and the

vehicle is equipped with an engine driven

cooling fan, push down the accelerator until

the engine speed is about twice as fast as

normal idle speed for at least five minutes

while the vehicle is parked. If the warning is

still there, turn off the engine and get

everyone out of the vehicle until it

cools down.

If there is no sign of steam, idle the engine

for five minutes while parked. If the warning

is still displayed, turn off the engine until it

cools down.

Overheated Engine Protection

Operating Mode

If an overheated engine condition exists and

the ENGINE POWER IS REDUCED message

displays, an overheat protection mode which

alternates firing groups of cylinders helps to

prevent engine damage. In this mode, a loss

in power and engine performance will be

noticed. This operating mode allows thevehicle to be driven to a safe place in an

emergency. Driving extended distances

and/or towing a trailer in the overheat

protection mode should be avoided.

If the engine or transmission detects an

impending hot fluid condition, then the

transmission may force upshifts to limit

temperatures. Downshifts may also be

prevented in this instance. Normal operation

may continue unless the display indicates

there is a hot condition and engine should

be idled.

Caution

After driving in the overheated engine

protection operating mode, the engine oil

will be severely degraded. Any repairs

performed before the engine is cool may

cause engine damage. Allow the engine

to cool before attempting any repair.

Repair the cause of coolant loss, change

the oil, and reset the oil life system. See

Engine Oil

0329.

Engine Fan

If the vehicle has the Duramax diesel

engine, see the Duramax diesel supplement. The vehicle has electric cooling fan(s). The

fans may be heard spinning at low speed

during most everyday driving. The fans may

turn off if no cooling is required. Under

heavy vehicle loading, trailer towing, high

outside temperatures, or operation of the air

conditioning system, the fans may change

to high speed and an increase in fan noise

may be heard. This is normal and indicates

that the cooling system is functioning

properly. The fans will change to low speed

when additional cooling is no longer

required.

The electric engine cooling fans may run

after the engine has been turned off. This is

normal and no service is required.

Washer Fluid

What to Use

When windshield washer fluid needs to be

added, be sure to read the manufacturer's

instructions before use. Use a fluid that has

sufficient protection against freezing in an

area where the temperature may fall below

freezing.

Page 346 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

Vehicle Care 343

Stop/Start System

Vehicles equipped with a 2.7L L3B, 3.0L LM2,

5.3L L84 or 6.2L L87 are equipped with a

Stop/Start system to shut off the engine to

help conserve fuel. SeeStop/Start System

0 233.

Vehicles with the Stop/Start system have an

Absorbed Glass Mat (AGM) 12-volt battery.

Installation of a standard 12-volt battery will

result in reduced 12-volt battery life. When

using a 12-volt battery charger on the 12-volt

AGM battery, some chargers have an AGM

battery setting on the charger. If available,

use the AGM setting on the charger to limit

charge voltage to 14.8 volts. Follow the

charger manufacturer’s instructions.

{Warning

WARNING: Battery posts, terminals, and

related accessories contain lead and lead

compounds, chemicals known to the

State of California to cause cancer and

birth defects or other reproductive harm.

Batteries also contain other chemicals

known to the State of California to cause

cancer. WASH HANDS AFTER HANDLING.

(Continued)

Warning (Continued)

For more information go to

www.P65Warnings.ca.gov/

passenger-vehicle.

See California Proposition 65 Warning 0321

and the back cover.

Vehicle Storage

{Warning

Batteries have acid that can burn you and

gas that can explode. You can be badly

hurt if you are not careful. See Jump

Starting - North America 0391 for tips on

working around a battery without

getting hurt.

Infrequent Usage: Remove the black,

negative (−) cable from the battery to keep

the battery from running down.

Extended Storage: Remove the black,

negative (−) cable from the battery or use a

battery trickle charger.

Negative Battery Cable Disconnection

{Warning

Before disconnecting the negative battery

cable, turn off all features, turn the

ignition off, and remove the key,

if equipped, from the vehicle. If this is

not done, you or others could be injured,

and the vehicle could be damaged.

Caution

If the battery is disconnected with the

ignition on or the vehicle in Retained

Accessory Power (RAP), the OnStar

back-up battery will be permanently

discharged and will need to be replaced.

1. Make sure the lamps, features, and accessories are turned off.

2. Turn the ignition off and remove the key, if equipped.

Page 347 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

344 Vehicle Care

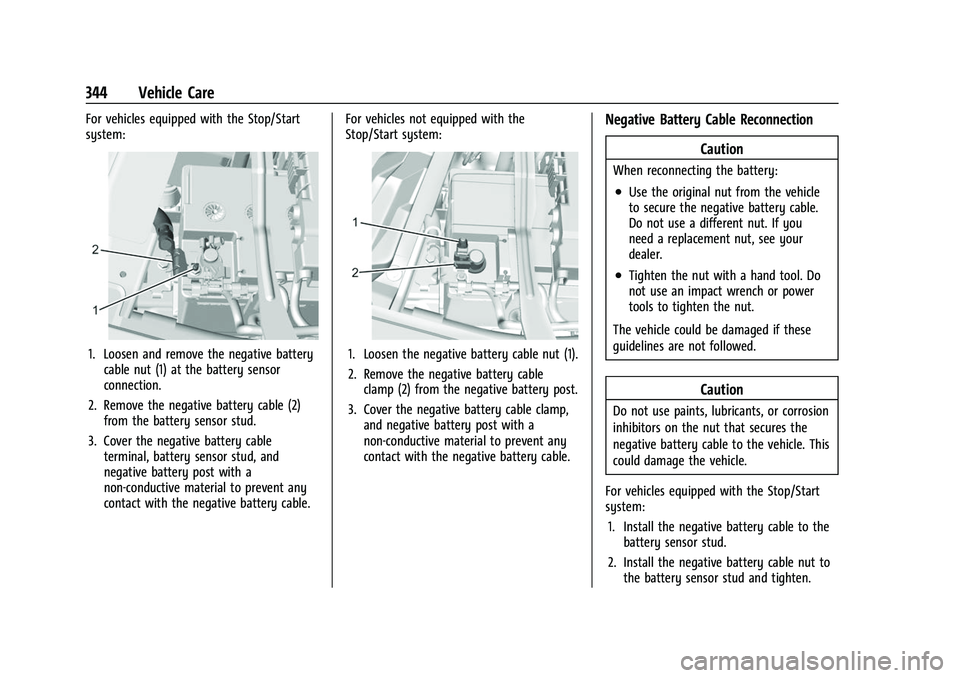

For vehicles equipped with the Stop/Start

system:

1. Loosen and remove the negative batterycable nut (1) at the battery sensor

connection.

2. Remove the negative battery cable (2) from the battery sensor stud.

3. Cover the negative battery cable terminal, battery sensor stud, and

negative battery post with a

non-conductive material to prevent any

contact with the negative battery cable. For vehicles not equipped with the

Stop/Start system:1. Loosen the negative battery cable nut (1).

2. Remove the negative battery cable

clamp (2) from the negative battery post.

3. Cover the negative battery cable clamp, and negative battery post with a

non-conductive material to prevent any

contact with the negative battery cable.

Negative Battery Cable Reconnection

Caution

When reconnecting the battery:

.Use the original nut from the vehicle

to secure the negative battery cable.

Do not use a different nut. If you

need a replacement nut, see your

dealer.

.Tighten the nut with a hand tool. Do

not use an impact wrench or power

tools to tighten the nut.

The vehicle could be damaged if these

guidelines are not followed.

Caution

Do not use paints, lubricants, or corrosion

inhibitors on the nut that secures the

negative battery cable to the vehicle. This

could damage the vehicle.

For vehicles equipped with the Stop/Start

system: 1. Install the negative battery cable to the battery sensor stud.

2. Install the negative battery cable nut to the battery sensor stud and tighten.

Page 348 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

Vehicle Care 345

3. Turn the ignition on.

For vehicles not equipped with the Stop/

Start system: 1. Install the negative battery cable clamp to the negative battery post.

2. Tighten the negative battery cable nut.

3. Turn the ignition on.

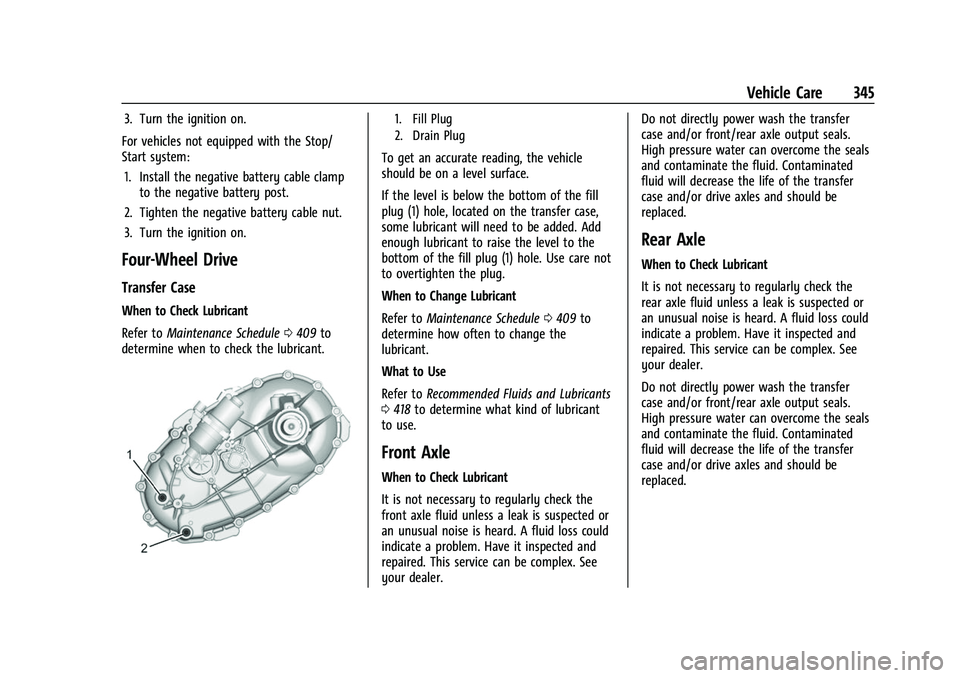

Four-Wheel Drive

Transfer Case

When to Check Lubricant

Refer to Maintenance Schedule 0409 to

determine when to check the lubricant.

1. Fill Plug

2. Drain Plug

To get an accurate reading, the vehicle

should be on a level surface.

If the level is below the bottom of the fill

plug (1) hole, located on the transfer case,

some lubricant will need to be added. Add

enough lubricant to raise the level to the

bottom of the fill plug (1) hole. Use care not

to overtighten the plug.

When to Change Lubricant

Refer to Maintenance Schedule 0409 to

determine how often to change the

lubricant.

What to Use

Refer to Recommended Fluids and Lubricants

0 418 to determine what kind of lubricant

to use.

Front Axle

When to Check Lubricant

It is not necessary to regularly check the

front axle fluid unless a leak is suspected or

an unusual noise is heard. A fluid loss could

indicate a problem. Have it inspected and

repaired. This service can be complex. See

your dealer. Do not directly power wash the transfer

case and/or front/rear axle output seals.

High pressure water can overcome the seals

and contaminate the fluid. Contaminated

fluid will decrease the life of the transfer

case and/or drive axles and should be

replaced.

Rear Axle

When to Check Lubricant

It is not necessary to regularly check the

rear axle fluid unless a leak is suspected or

an unusual noise is heard. A fluid loss could

indicate a problem. Have it inspected and

repaired. This service can be complex. See

your dealer.

Do not directly power wash the transfer

case and/or front/rear axle output seals.

High pressure water can overcome the seals

and contaminate the fluid. Contaminated

fluid will decrease the life of the transfer

case and/or drive axles and should be

replaced.

Page 355 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

352 Vehicle Care

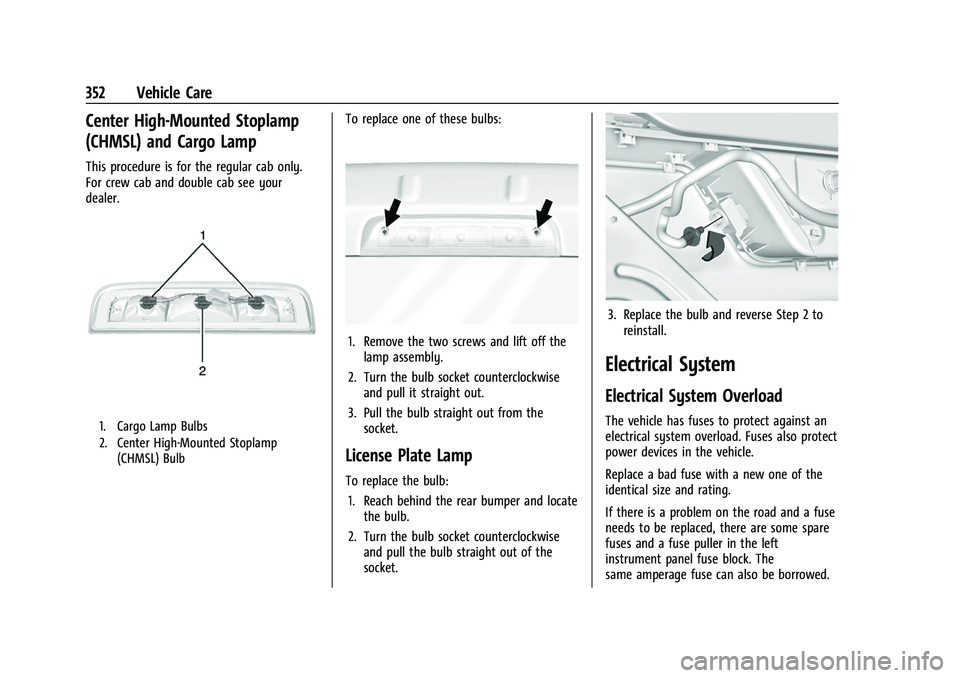

Center High-Mounted Stoplamp

(CHMSL) and Cargo Lamp

This procedure is for the regular cab only.

For crew cab and double cab see your

dealer.

1. Cargo Lamp Bulbs

2. Center High-Mounted Stoplamp(CHMSL) Bulb

To replace one of these bulbs:

1. Remove the two screws and lift off thelamp assembly.

2. Turn the bulb socket counterclockwise and pull it straight out.

3. Pull the bulb straight out from the socket.

License Plate Lamp

To replace the bulb:

1. Reach behind the rear bumper and locate the bulb.

2. Turn the bulb socket counterclockwise and pull the bulb straight out of the

socket.

3. Replace the bulb and reverse Step 2 toreinstall.

Electrical System

Electrical System Overload

The vehicle has fuses to protect against an

electrical system overload. Fuses also protect

power devices in the vehicle.

Replace a bad fuse with a new one of the

identical size and rating.

If there is a problem on the road and a fuse

needs to be replaced, there are some spare

fuses and a fuse puller in the left

instrument panel fuse block. The

same amperage fuse can also be borrowed.

Page 359 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

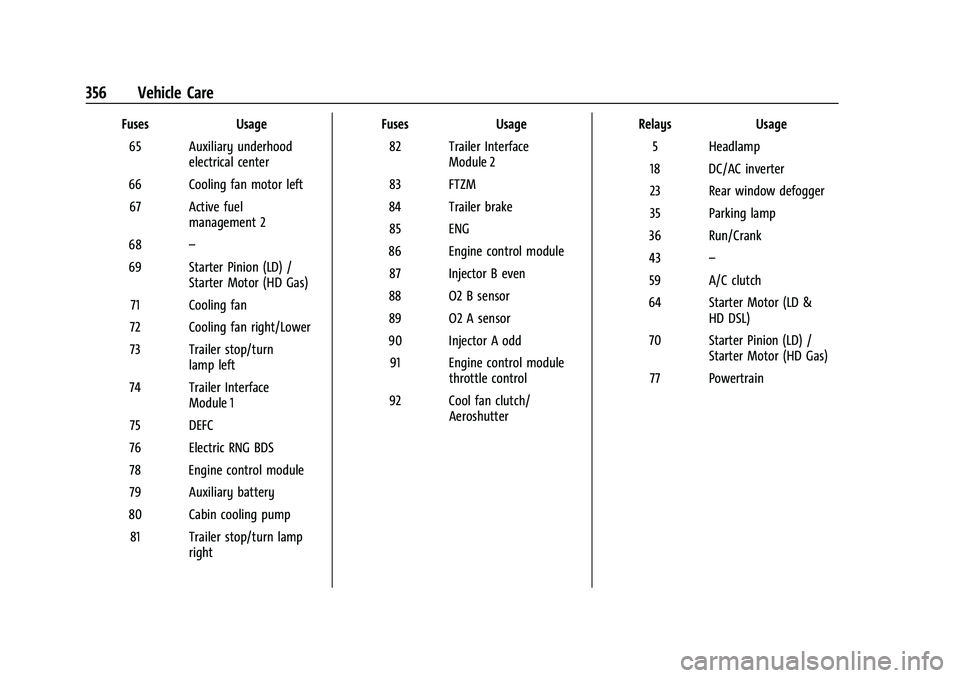

356 Vehicle Care

FusesUsage

65 Auxiliary underhood electrical center

66 Cooling fan motor left 67 Active fuel management 2

68 –

69 Starter Pinion (LD) / Starter Motor (HD Gas)

71 Cooling fan

72 Cooling fan right/Lower

73 Trailer stop/turn lamp left

74 Trailer Interface Module 1

75 DEFC

76 Electric RNG BDS

78 Engine control module

79 Auxiliary battery

80 Cabin cooling pump 81 Trailer stop/turn lamp right Fuses

Usage

82 Trailer Interface Module 2

83 FTZM

84 Trailer brake 85 ENG

86 Engine control module 87 Injector B even

88 O2 B sensor

89 O2 A sensor

90 Injector A odd 91 Engine control module throttle control

92 Cool fan clutch/ Aeroshutter Relays

Usage

5 Headlamp

18 DC/AC inverter

23 Rear window defogger

35 Parking lamp

36 Run/Crank

43 –

59 A/C clutch

64 Starter Motor (LD & HD DSL)

70 Starter Pinion (LD) / Starter Motor (HD Gas)

77 Powertrain

Page 360 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

Vehicle Care 357

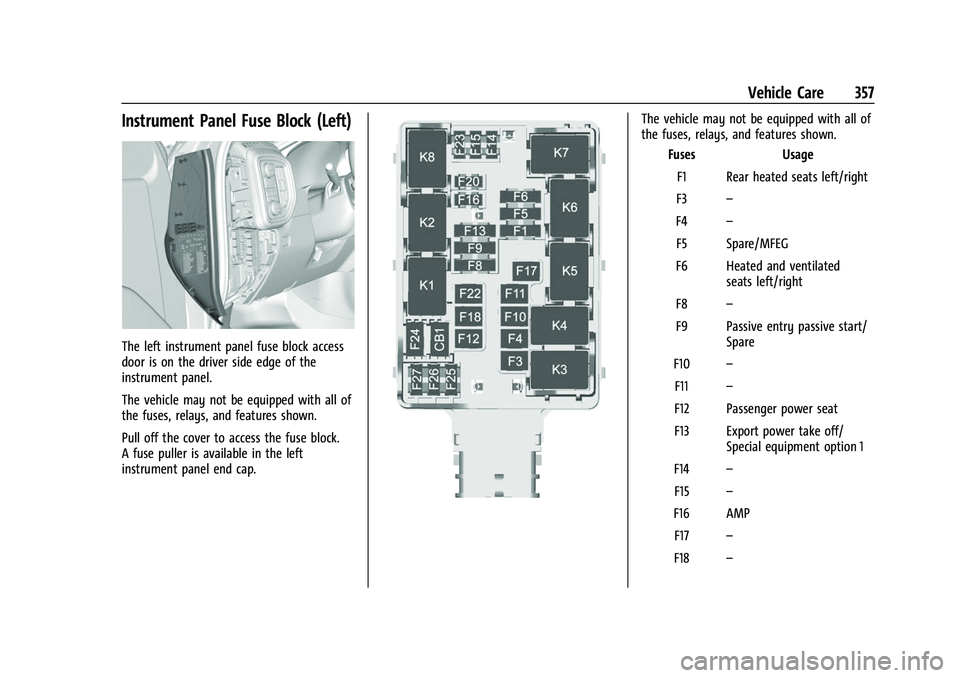

Instrument Panel Fuse Block (Left)

The left instrument panel fuse block access

door is on the driver side edge of the

instrument panel.

The vehicle may not be equipped with all of

the fuses, relays, and features shown.

Pull off the cover to access the fuse block.

A fuse puller is available in the left

instrument panel end cap.

The vehicle may not be equipped with all of

the fuses, relays, and features shown.Fuses Usage

F1 Rear heated seats left/right

F3 –

F4 –

F5 Spare/MFEG

F6 Heated and ventilated seats left/right

F8 –

F9 Passive entry passive start/ Spare

F10 –

F11 –

F12 Passenger power seat

F13 Export power take off/ Special equipment option 1

F14 –

F15 –

F16 AMP F17 –

F18 –

Page 363 of 463

Chevrolet Silverado 1500 Owner Manual (GMNA-Localizing-U.S./Canada/

Mexico/Paraguay-14632303) - 2021 - CRC - 11/9/20

360 Vehicle Care

FusesUsage

F22 Heated steering wheel

F23 MISC R/C

F24 Instrument panel cluster ignition/Overhead

F25 Heating, ventilation, and air conditioning ignition/

Heating, ventilation, and

air conditioning auxiliary

F26 USB ports/Special equipment option retained

accessory power

F27 Accessory power outlet/ retained accessory power

F28 Accessory power outlet/ Battery

F30 Sensing and diagnostic module/Parking brake

F31 Body control module 4

F32 Special equipment option/ Data link connection

F33 Body control module 8

F34 Cargo lamp

F40 CGM Fuses

Usage

F41 Infotainment 1

F42 TCP

F43 –

F44 Active vibration management

F45 Body control module 2

F46 Heating, ventilation, and air conditioning/Battery 1

F47 Instrument panel cluster/ Battery

F48 Transmission control module

F49 Body control module 1 F50 –

F51 Battery 1

F52 Battery 2

F53 –

F54 Sunroof F55 Driver power seat

F56 DC DC TRANS 1 F57 DC DC TRANS 2 Fuses

Usage

F58 Infotainment 2

Circuit

Breakers Usage

1 Accessory power outlet 2

2 Accessory power outlet 1/ Cigarette Lighter

3 Accessory power outlet 3

4 Accessory power outlet 4

Relays Usage

K1 Run/Crank

K2 Retained accessory power/ Accessory 1

K4 Retained accessory power/ Accessory 2

K5 –