lock CHEVROLET SILVERADO 2010 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2010, Model line: SILVERADO, Model: CHEVROLET SILVERADO 2010 2.GPages: 626, PDF Size: 4.8 MB

Page 472 of 626

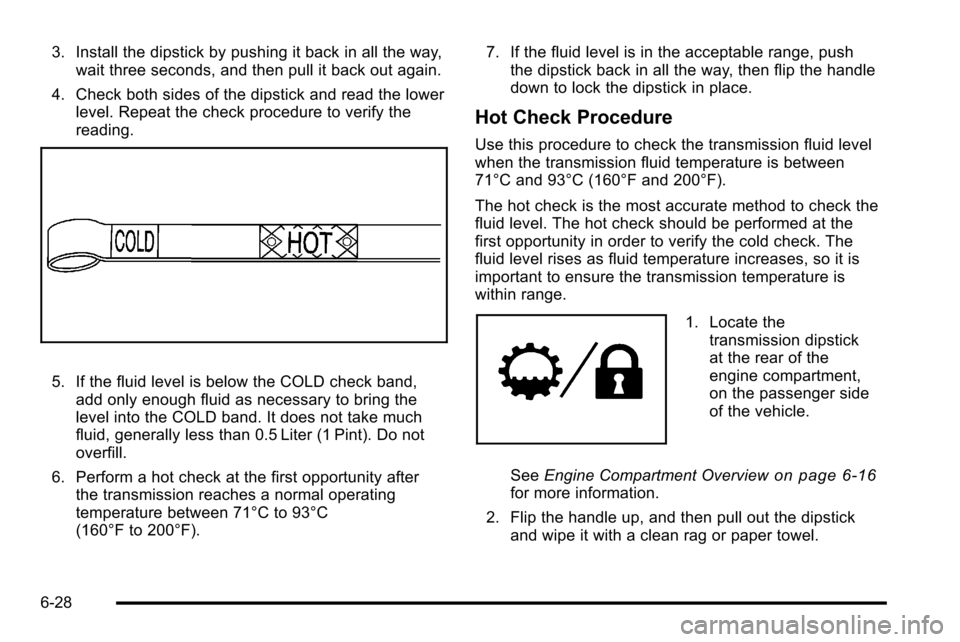

3. Install the dipstick by pushing it back in all the way,wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

5. If the fluid level is below the COLD check band,add only enough fluid as necessary to bring the

level into the COLD band. It does not take much

fluid, generally less than 0.5 Liter (1 Pint). Do not

overfill.

6. Perform a hot check at the first opportunity after the transmission reaches a normal operating

temperature between 71°C to 93°C

(160°F to 200°F). 7. If the fluid level is in the acceptable range, push

the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Hot Check Procedure

Use this procedure to check the transmission fluid level

when the transmission fluid temperature is between

71°C and 93°C (160°F and 200°F).

The hot check is the most accurate method to check the

fluid level. The hot check should be performed at the

first opportunity in order to verify the cold check. The

fluid level rises as fluid temperature increases, so it is

important to ensure the transmission temperature is

within range.

1. Locate the

transmission dipstick

at the rear of the

engine compartment,

on the passenger side

of the vehicle.

See Engine Compartment Overview

on page 6‑16for more information.

2. Flip the handle up, and then pull out the dipstick and wipe it with a clean rag or paper towel.

6-28

Page 473 of 626

3. Install the dipstick by pushing it back in all the way,wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

5. Safe operating level is within the HOT cross hatchband on the dipstick. If the fluid level is not within

the HOT band, and the transmission temperature

is between 71°C and 93°C (160°F and 200°F), add

or drain fluid as necessary to bring the level into

the HOT band. If the fluid level is low, add only

enough fluid to bring the level into the HOT band.

It does not take much fluid, generally less than

0.5 Liter (1 Pint). Do not overfill. 6. If the fluid level is in the acceptable range, push

the dipstick back in all the way, then flip the handle

down to lock the dipstick in place.

Consistency of Readings

Always check the fluid level at least twice using the

procedure described previously. Consistency

(repeatable readings) is important to maintaining proper

fluid level. If readings are still inconsistent, contact your

dealer.

Cooling System

If your vehicle has the DURAMAX®Diesel engine, see

the DURAMAX®Diesel manual for more information.

The Cooling System allows the engine to maintain the

correct working temperature.

6-29

Page 478 of 626

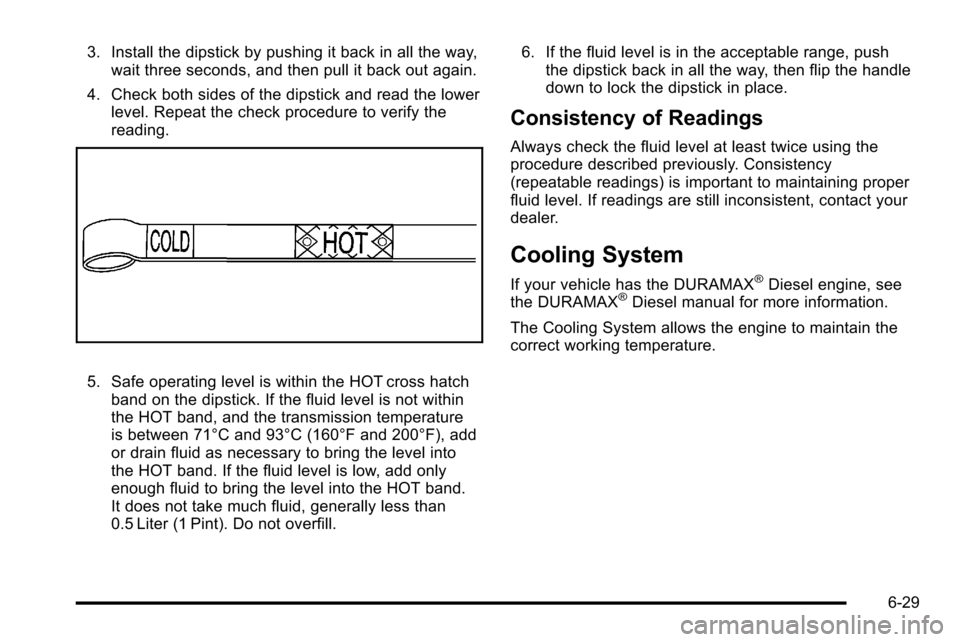

Turn the pressure cap slowly counterclockwise

about one full turn. If you hear a hiss, wait for that

to stop. A hiss means there is still some

pressure left.

2. Keep turning the pressure cap slowly, and remove it.

3. Fill the coolant surge tank with the proper mixtureto the FULL COLD mark.

4. With the coolant surge tank pressure cap off, start the engine and let it run until the engine coolant

temperature gauge indicates approximately

195°F (90°C). By this time, the coolant level inside the coolant

surge tank may be lower. If the level is lower, add

more of the proper mixture to the coolant surge

tank until the level reaches the FULL COLD mark.

5. Replace the pressure cap. Be sure the pressure cap is hand-tight and fully seated.

6. Verify coolant level after engine is shut off and the coolant is cold. If necessary, repeat coolant fill

procedure Steps 1 through 6.

Notice: If the pressure cap is not tightly installed,

coolant loss and possible engine damage may

occur. Be sure the cap is properly and tightly

secured.

Engine Overheating

If the vehicle has the DURAMAX®Diesel engine, see

the DURAMAX®Diesel manual for more information.

The vehicle has several indicators to warn of engine

overheating.

You will find a coolant temperature gauge on the

vehicle's instrument panel. See Engine Coolant

Temperature Gauge on page 4‑40.

In addition, you will find ENGINE OVERHEATED STOP

ENGINE, ENGINE OVERHEATED IDLE ENGINE, and

ENGINE POWER IS REDUCED messages in the Driver

Information Center (DIC) on the instrument panel. See

DIC Warnings and Messages on page 4‑63.

6-34

Page 500 of 626

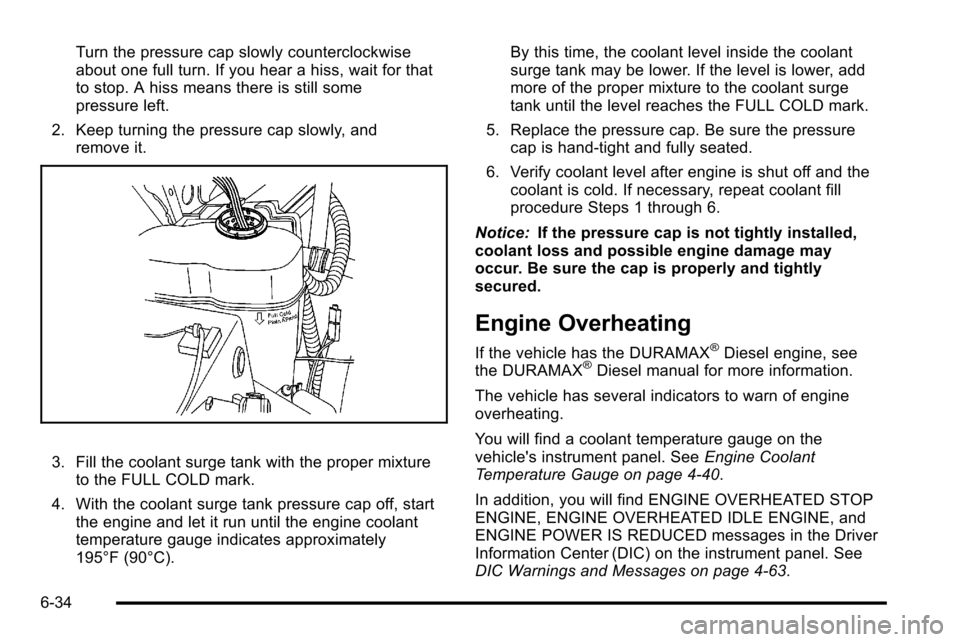

4. At a wall measure from the ground upward (A) tothe recorded distance from Step 3 and mark it.

5. Draw or tape a horizontal line (B) on the wall or flat surface the width of the vehicle at the height of the

mark in Step 4.

Notice: Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

6. Turn on the low-beam headlamps and place a piece of cardboard or equivalent in front of the

headlamp not being adjusted. This allows only the

beam of light from the headlamp being adjusted to

be seen on the flat surface.

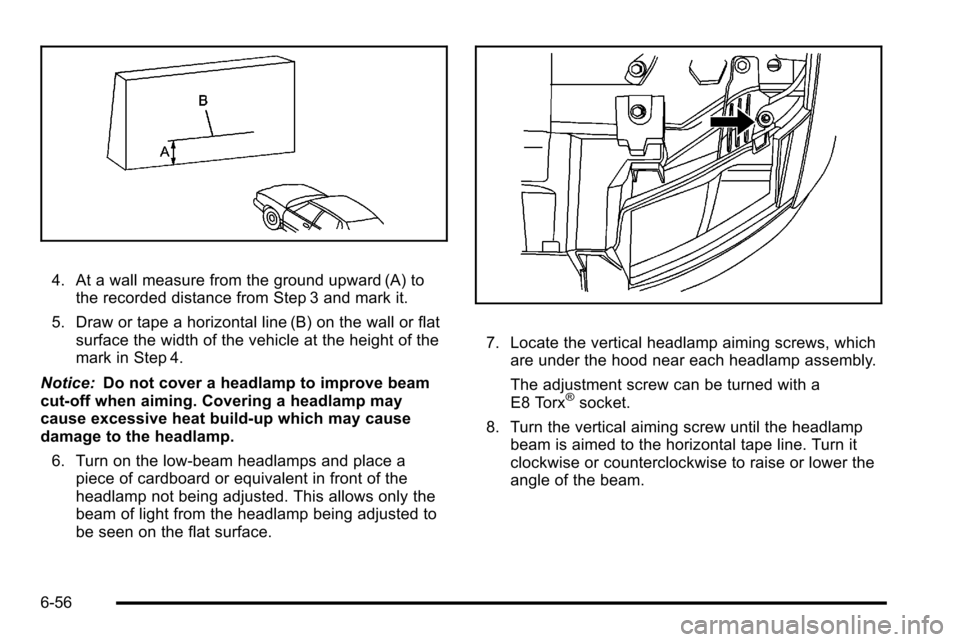

7. Locate the vertical headlamp aiming screws, whichare under the hood near each headlamp assembly.

The adjustment screw can be turned with a

E8 Torx

®socket.

8. Turn the vertical aiming screw until the headlamp beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

6-56

Page 502 of 626

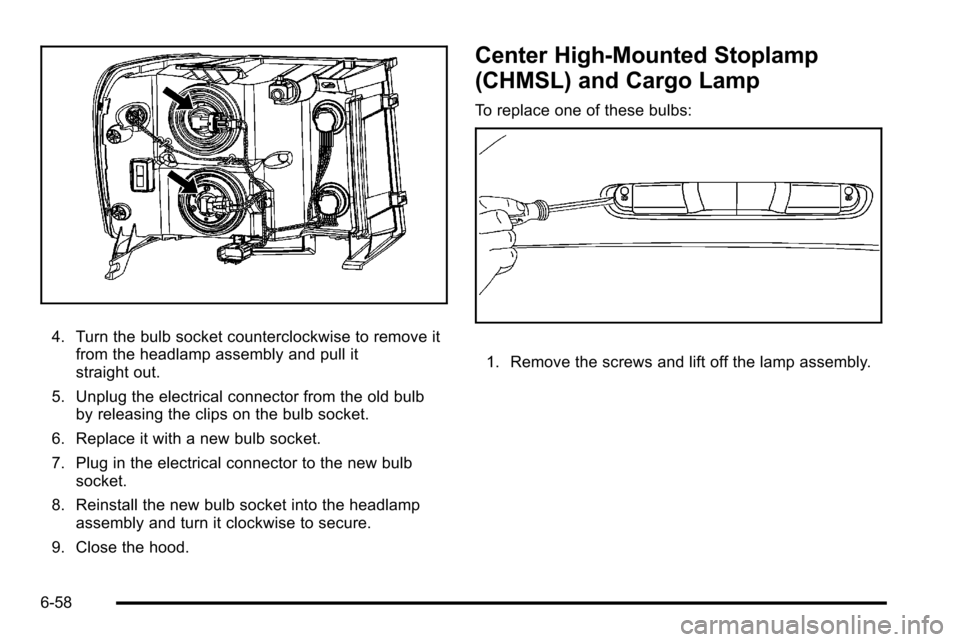

4. Turn the bulb socket counterclockwise to remove itfrom the headlamp assembly and pull it

straight out.

5. Unplug the electrical connector from the old bulb by releasing the clips on the bulb socket.

6. Replace it with a new bulb socket.

7. Plug in the electrical connector to the new bulb socket.

8. Reinstall the new bulb socket into the headlamp assembly and turn it clockwise to secure.

9. Close the hood.

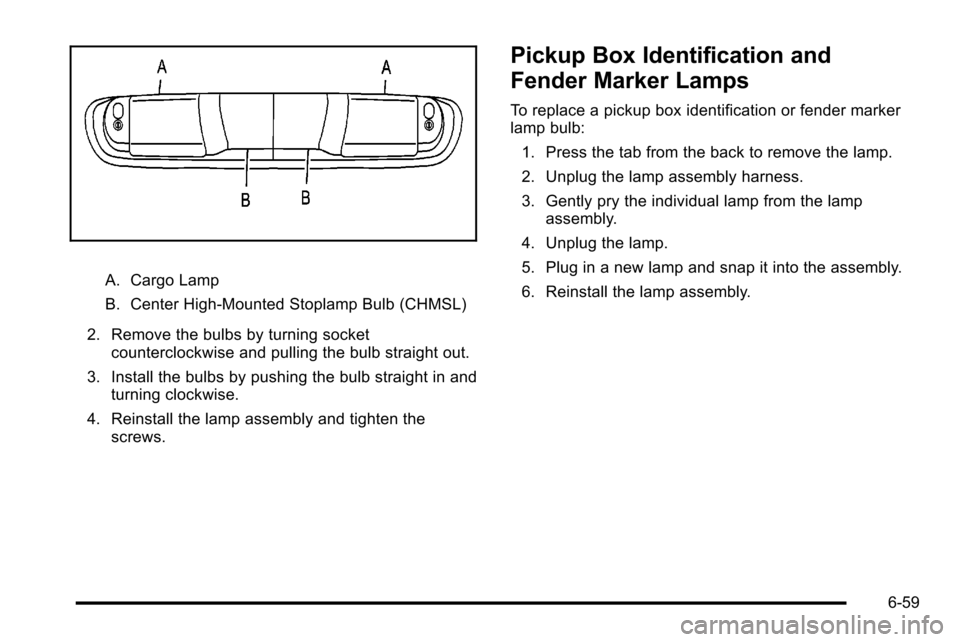

Center High-Mounted Stoplamp

(CHMSL) and Cargo Lamp

To replace one of these bulbs:

1. Remove the screws and lift off the lamp assembly.

6-58

Page 503 of 626

A. Cargo Lamp

B. Center High-Mounted Stoplamp Bulb (CHMSL)

2. Remove the bulbs by turning socket counterclockwise and pulling the bulb straight out.

3. Install the bulbs by pushing the bulb straight in and turning clockwise.

4. Reinstall the lamp assembly and tighten the screws.

Pickup Box Identification and

Fender Marker Lamps

To replace a pickup box identification or fender marker

lamp bulb:

1. Press the tab from the back to remove the lamp.

2. Unplug the lamp assembly harness.

3. Gently pry the individual lamp from the lamp assembly.

4. Unplug the lamp.

5. Plug in a new lamp and snap it into the assembly.

6. Reinstall the lamp assembly.

6-59

Page 504 of 626

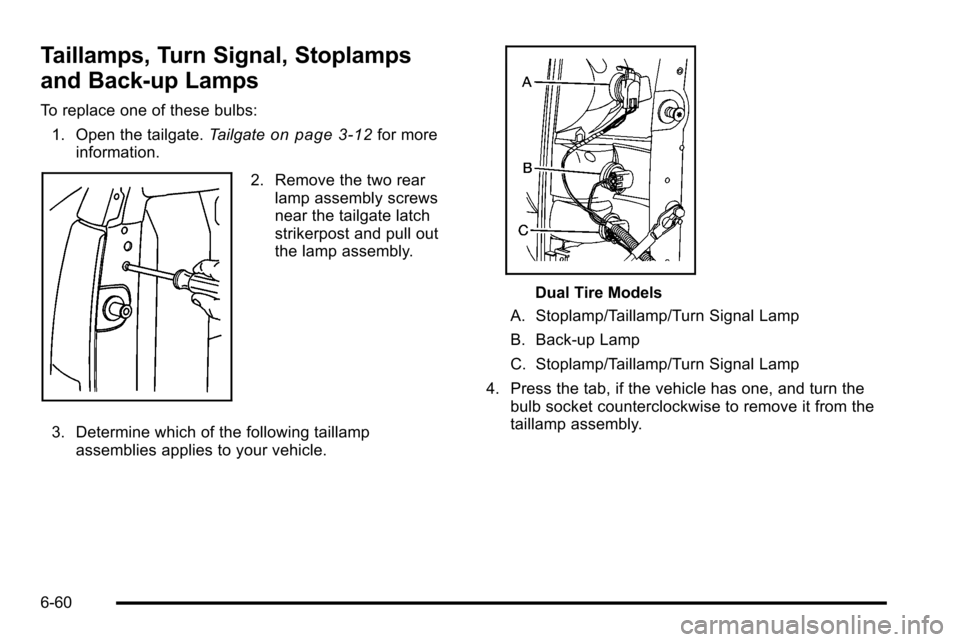

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

To replace one of these bulbs:1. Open the tailgate. Tailgate

on page 3‑12for more

information.

2. Remove the two rear lamp assembly screws

near the tailgate latch

strikerpost and pull out

the lamp assembly.

3. Determine which of the following taillamp assemblies applies to your vehicle.

Dual Tire Models

A. Stoplamp/Taillamp/Turn Signal Lamp

B. Back-up Lamp

C. Stoplamp/Taillamp/Turn Signal Lamp

4. Press the tab, if the vehicle has one, and turn the bulb socket counterclockwise to remove it from the

taillamp assembly.

6-60

Page 505 of 626

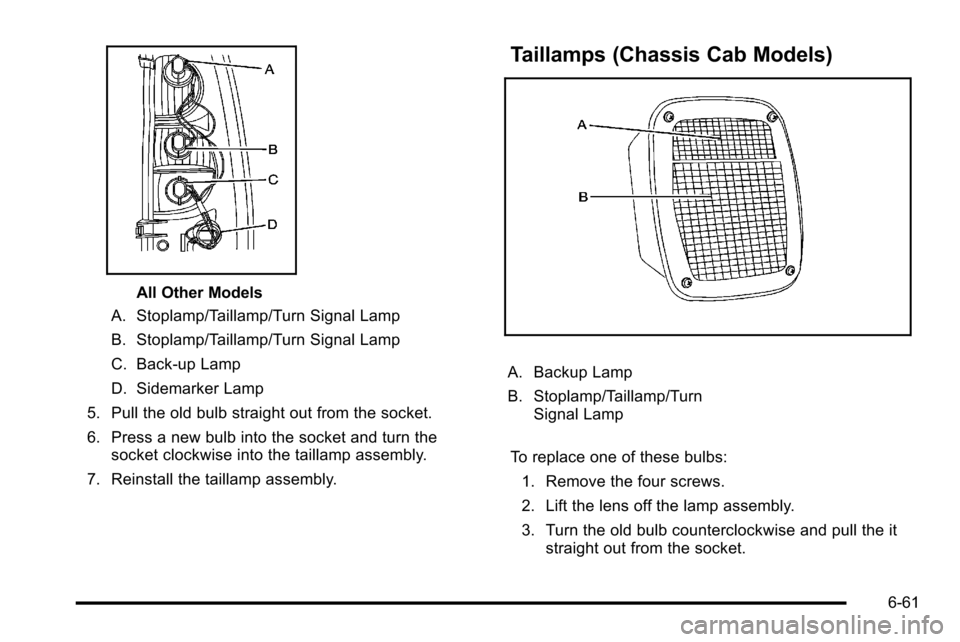

All Other Models

A. Stoplamp/Taillamp/Turn Signal Lamp

B. Stoplamp/Taillamp/Turn Signal Lamp

C. Back-up Lamp

D. Sidemarker Lamp

5. Pull the old bulb straight out from the socket.

6. Press a new bulb into the socket and turn the socket clockwise into the taillamp assembly.

7. Reinstall the taillamp assembly.

Taillamps (Chassis Cab Models)

A. Backup Lamp

B. Stoplamp/Taillamp/Turn Signal Lamp

To replace one of these bulbs: 1. Remove the four screws.

2. Lift the lens off the lamp assembly.

3. Turn the old bulb counterclockwise and pull the it straight out from the socket.

6-61

Page 506 of 626

4. Install a new bulb into the socket, turn it clockwise,and press it in until it is tight.

5. Reinstall the lens and the four screws.

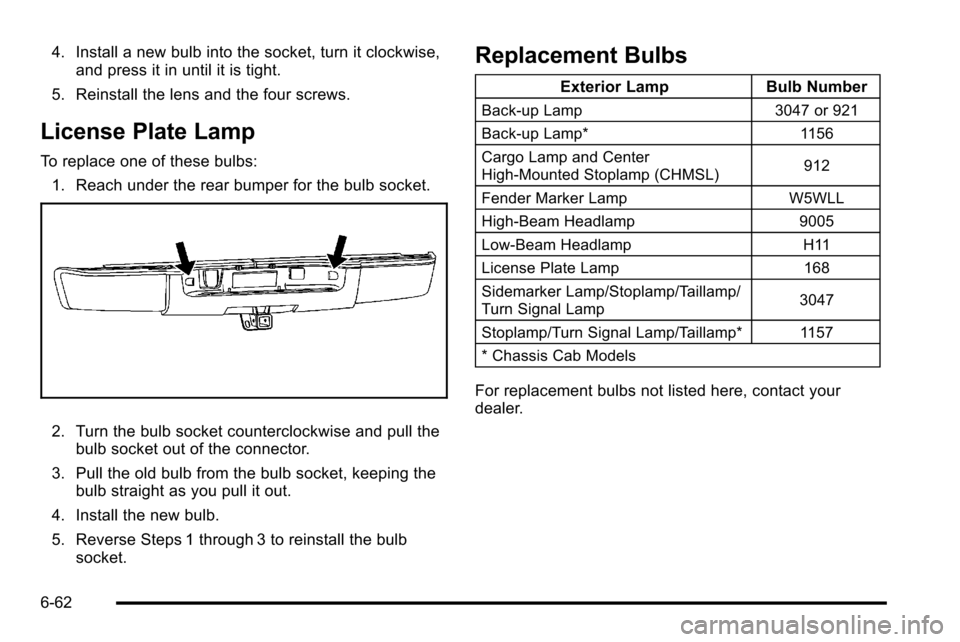

License Plate Lamp

To replace one of these bulbs: 1. Reach under the rear bumper for the bulb socket.

2. Turn the bulb socket counterclockwise and pull the bulb socket out of the connector.

3. Pull the old bulb from the bulb socket, keeping the bulb straight as you pull it out.

4. Install the new bulb.

5. Reverse Steps 1 through 3 to reinstall the bulb socket.

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp 3047 or 921

Back-up Lamp* 1156

Cargo Lamp and Center

High-Mounted Stoplamp (CHMSL) 912

Fender Marker Lamp W5WLL

High-Beam Headlamp 9005

Low-Beam Headlamp H11

License Plate Lamp 168

Sidemarker Lamp/Stoplamp/Taillamp/

Turn Signal Lamp 3047

Stoplamp/Turn Signal Lamp/Taillamp* 1157

* Chassis Cab Models

For replacement bulbs not listed here, contact your

dealer.

6-62

Page 507 of 626

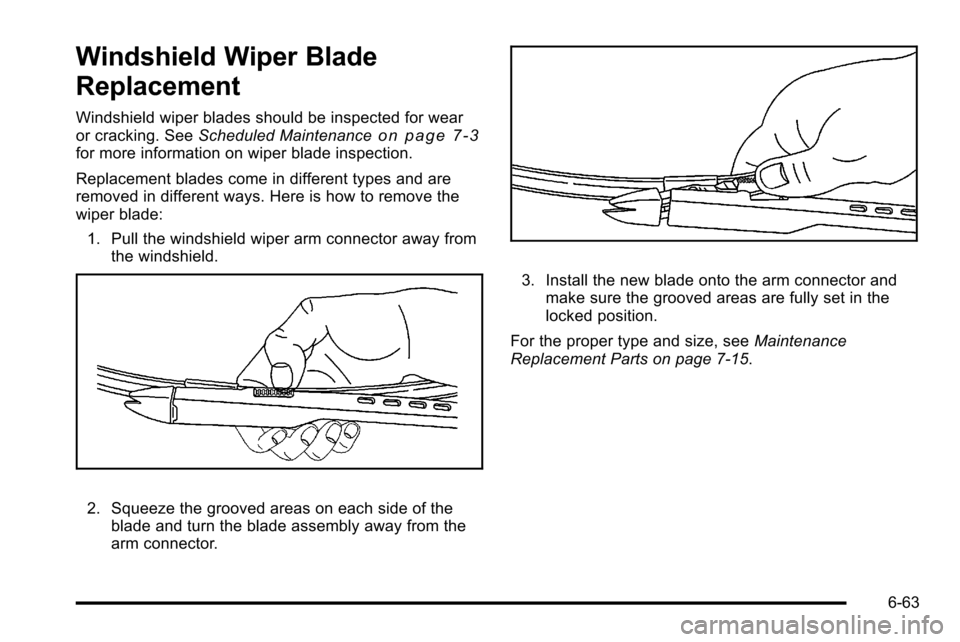

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

or cracking. SeeScheduled Maintenanceon page 7‑3for more information on wiper blade inspection.

Replacement blades come in different types and are

removed in different ways. Here is how to remove the

wiper blade:

1. Pull the windshield wiper arm connector away from the windshield.

2. Squeeze the grooved areas on each side of theblade and turn the blade assembly away from the

arm connector.

3. Install the new blade onto the arm connector and

make sure the grooved areas are fully set in the

locked position.

For the proper type and size, see Maintenance

Replacement Parts on page 7‑15.

6-63