wheel CHEVROLET SILVERADO 2011 2.G Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2011, Model line: SILVERADO, Model: CHEVROLET SILVERADO 2011 2.GPages: 588, PDF Size: 7.99 MB

Page 404 of 588

Black plate (110,1)Chevrolet Silverado Owner Manual - 2011

9-110 Driving and Operating

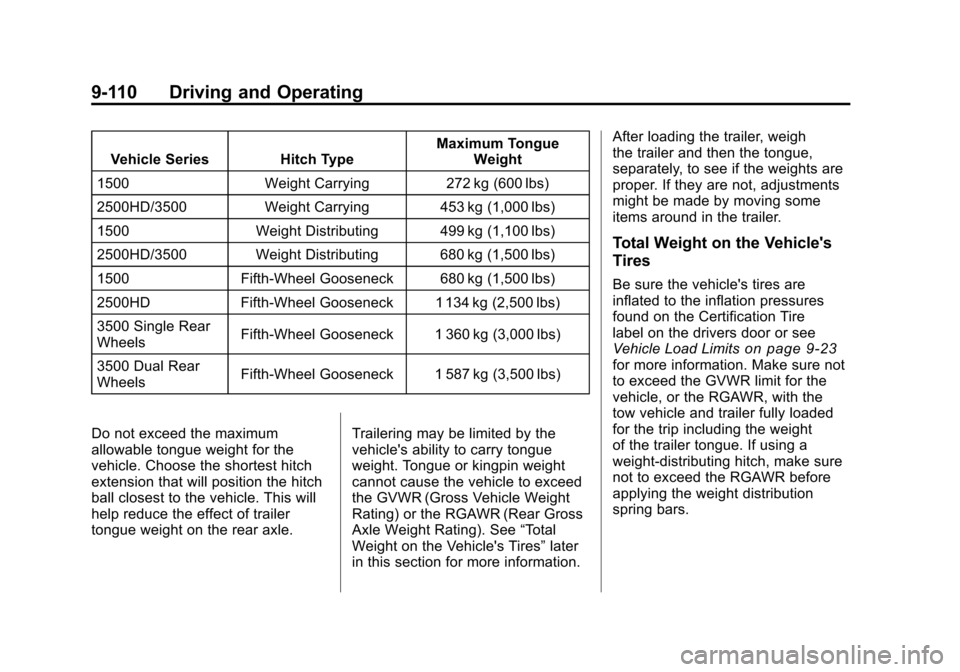

Vehicle Series Hitch TypeMaximum Tongue

Weight

1500 Weight Carrying 272 kg (600 lbs)

2500HD/3500 Weight Carrying 453 kg (1,000 lbs)

1500 Weight Distributing 499 kg (1,100 lbs)

2500HD/3500 Weight Distributing 680 kg (1,500 lbs)

1500 Fifth-Wheel Gooseneck 680 kg (1,500 lbs)

2500HD Fifth-Wheel Gooseneck 1 134 kg (2,500 lbs)

3500 Single Rear

Wheels Fifth-Wheel Gooseneck 1 360 kg (3,000 lbs)

3500 Dual Rear

Wheels Fifth-Wheel Gooseneck 1 587 kg (3,500 lbs)

Do not exceed the maximum

allowable tongue weight for the

vehicle. Choose the shortest hitch

extension that will position the hitch

ball closest to the vehicle. This will

help reduce the effect of trailer

tongue weight on the rear axle. Trailering may be limited by the

vehicle's ability to carry tongue

weight. Tongue or kingpin weight

cannot cause the vehicle to exceed

the GVWR (Gross Vehicle Weight

Rating) or the RGAWR (Rear Gross

Axle Weight Rating). See

“Total

Weight on the Vehicle's Tires” later

in this section for more information. After loading the trailer, weigh

the trailer and then the tongue,

separately, to see if the weights are

proper. If they are not, adjustments

might be made by moving some

items around in the trailer.

Total Weight on the Vehicle's

Tires

Be sure the vehicle's tires are

inflated to the inflation pressures

found on the Certification Tire

label on the drivers door or see

Vehicle Load Limits

on page 9‑23for more information. Make sure not

to exceed the GVWR limit for the

vehicle, or the RGAWR, with the

tow vehicle and trailer fully loaded

for the trip including the weight

of the trailer tongue. If using a

weight-distributing hitch, make sure

not to exceed the RGAWR before

applying the weight distribution

spring bars.

Page 405 of 588

Black plate (111,1)Chevrolet Silverado Owner Manual - 2011

Driving and Operating 9-111

Weight of the Trailering

Combination

It is important that the combination

of the tow vehicle and trailer

does not exceed any of its weight

ratings—GCWR, GVWR, RGAWR,

Trailer Weight Rating, or Tongue

Weight. The only way to be sure it is

not exceeding any of these ratings

is to weigh the tow vehicle and

trailer combination, fully loaded for

the trip, getting individual weights

for each of these items.

Towing Equipment

Hitches

The correct hitch equipment helps

maintain combination control.

Most small-to-medium trailers can

be towed with a weight-carrying

hitch which simply features a

coupler latched to the hitch ball. Larger trailers may require a

weight-distributing hitch that

uses spring bars to distribute

the trailer tongue weight among

the two vehicle and trailer axles.

Fifth-wheel and gooseneck hitches

may also be used. See

“Weight of

the Trailer Tongue” underTrailer

Towing

on page 9‑94for rating

limits with various hitch types.

If a step-bumper hitch will be used,

the bumper could be damaged

in sharp turns. Make sure there

is ample room when turning to avoid

contact between the trailer and the

bumper.

Consider using sway controls

with any trailer. Ask a trailering

professional about sway controls or

refer to the trailer manufacturer's

recommendations and instructions.

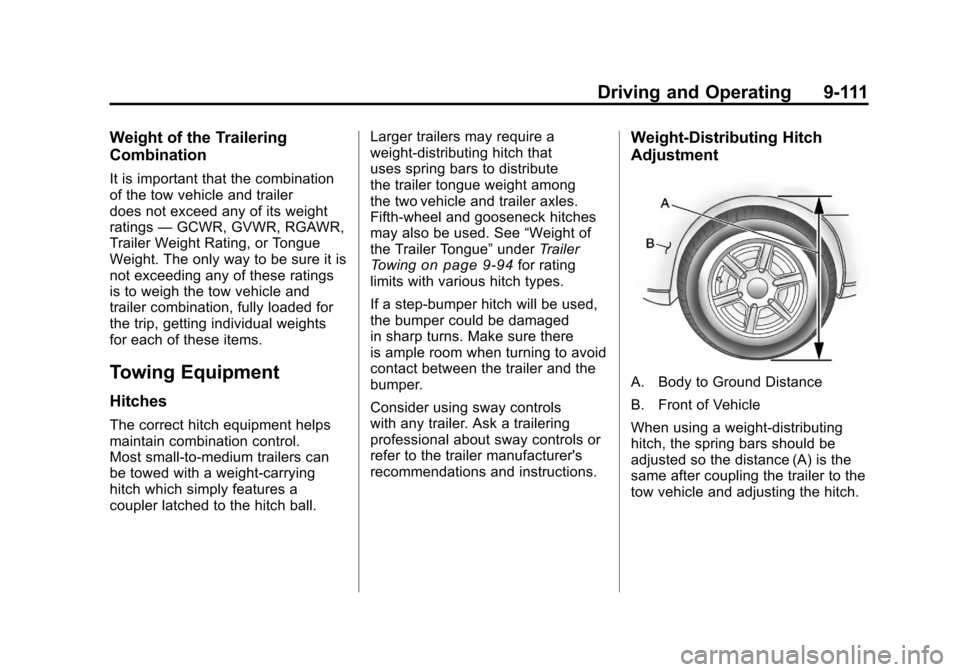

Weight‐Distributing Hitch

Adjustment

A. Body to Ground Distance

B. Front of Vehicle

When using a weight-distributing

hitch, the spring bars should be

adjusted so the distance (A) is the

same after coupling the trailer to the

tow vehicle and adjusting the hitch.

Page 406 of 588

Black plate (112,1)Chevrolet Silverado Owner Manual - 2011

9-112 Driving and Operating

Fifth-Wheel and Gooseneck

Trailering

Fifth-wheel and gooseneck trailers

can be used with many pickup

models. These trailers place a

larger percentage of the weight

(kingpin weight) on the tow vehicle

than conventional trailers. Make

sure this weight does not cause the

vehicle to exceed GAWR or GVWR.

Fifth-wheel or gooseneck kingpin

weight should be 15 to 25 percent of

the trailer weight up to the maximum

amount specified in the trailering

chart for the vehicle. See“Weight of

the Trailer” underTrailer Towing

on

page 9‑94for more information. The hitch should be located in the

pickup bed so that its centerline is

over or slightly in front of the rear

axle. Take care that it is not so far

forward that it will contact the back

of the cab in sharp turns. This is

especially important for short box

pickups. Trailer pin box extensions

and sliding fifth-wheel hitch

assemblies can help this condition.

There should be at least six inches

of clearance between the top of the

pickup box and the bottom of the

trailer shelf that extends over

the box.

Make sure the hitch is attached to

the tow vehicle frame rails. Do not

use the pickup box for support.

Safety Chains

Always attach chains between the

vehicle and the trailer. Cross the

safety chains under the tongue

of the trailer to help prevent the

tongue from contacting the road

if it becomes separated from the

hitch. Instructions about safety

chains may be provided by the

hitch manufacturer or by the trailer

manufacturer. If the trailer being

towed weighs up to 2 271 kg

(5,000 lbs) with a factory-installed

step bumper, safety chains may

be attached to the attaching points

on the bumper; otherwise, safety

chains should be attached to holes

on the trailer hitch platform. Always

leave just enough slack so the

combination can turn. Never allow

safety chains to drag on the ground.

Page 408 of 588

Black plate (114,1)Chevrolet Silverado Owner Manual - 2011

9-114 Driving and Operating

Heavy-DutyTrailer Wiring Harness

Package

For vehicles equipped with heavy

duty trailering, the harness is

connected to a bracket on the hitch

platform. The seven-wire harness

contains the following trailer circuits:

.Yellow: Left Stop/Turn Signal

.Dark Green: Right Stop/Turn

Signal

.Brown: Taillamps

.White: Ground

.Light Green: Back-up Lamps

.Red: Battery Feed*

.Dark Blue: Trailer Brake*

*The fuses for these two circuits

are installed in the underhood

electrical center, but the wires are

not connected. They should be

connected by your dealer or a

qualified service center. The fuse

and wire for the ITBC is factory

installed and connected if the

vehicle is equipped with an ITBC.

The fuse for the battery feed is

not required if the vehicle has an

auxiliary battery. If the vehicle does

not have an auxiliary battery, have

your dealer or authorized service

center install the required fuse.

If charging a remote (non-vehicle)

battery, press the Tow/Haul Mode

button, if equipped, located at the

end of the shift lever. This will

boost the vehicle system voltage

and properly charge the battery. If the trailer is too light for Tow/Haul

Mode, or the vehicle is not equipped

with Tow/Haul, turn on the

headlamps as a second way to

boost the vehicle system and

charge the battery.

Camper/Fifth-Wheel Trailer Wiring

Package

The seven-wire camper harness

is located under the front edge of

the pickup box on the driver side

of the vehicle, attached to the

frame bracket. A connector must

be added to the wiring harness

which connects to the camper.

The harness contains the following

camper/trailer circuits:

.Yellow: Left Stop/Turn Signal

.Dark Green: Right Stop/Turn

Signal

.Brown: Taillamps

.White: Ground

.Light Green: Back-up Lamps

Page 411 of 588

Black plate (117,1)Chevrolet Silverado Owner Manual - 2011

Driving and Operating 9-117

StabiliTrak systems to activate,

power sent to the trailer's brakes

will be automatically adjusted to

minimize trailer wheel lock-up.

This does not imply that the trailer

has StabiliTrak.

2500 and 3500 series vehicles with

StabiliTrak have a Trailer Sway

Control (TSC) feature. SeeTrailer

Sway Control (TSC) on page 9‑123.

2500 and 3500 series vehicles

with StabiliTrak have a Hill Start

Assist (HSA) feature. See Hill Start

Assist (HSA) on page 9‑70.

If the vehicle’s brake, antilock

brake, or StabiliTrak systems are

not functioning properly, the ITBC

system may not be fully functional

or may not function at all. Make

sure all of these systems are

fully operational to ensure full

functionality of the ITBC system.

The ITBC system is powered

through the vehicle's electrical

system. Turning the ignition off

will also turn off the ITBC system. The ITBC system is fully functional

only when the ignition is in ON or

in RUN.

The ITBC system can only be used

with trailers with electric brakes.

{WARNING

Connecting a trailer that is not

compatible with the ITBC system

may result in reduced or complete

loss of trailer braking. There may

be an increase in stopping

distance or trailer instability which

could result in personal injury or

damage to the vehicle, trailer,

or other property. An aftermarket

controller may be available for

use with trailers with surge, air,

or electric‐over‐hydraulic trailer

brake systems. To determine the

type of brakes on the trailer and

the availability of controllers,

check with your trailer

manufacturer or dealer.

When trailering, make sure of the

following:

.The ITBC system is used only

with trailers that are equipped

with electric brakes.

.All applicable local and federal

laws and regulations are

followed.

.All electrical and mechanical

connections to the trailer are

made correctly.

.The trailer

’s brakes are in proper

working condition.

.The trailer and vehicle are

properly loaded for the towing

condition.

The ITBC system is a

factory-installed item. Out‐of‐factory

installation of this system should not

be attempted. GM is not responsible

for warranty or performance of the

system resulting from out‐of‐factory

installation.

Page 415 of 588

Black plate (121,1)Chevrolet Silverado Owner Manual - 2011

Driving and Operating 9-121

.In the Trailer Output display

on the DIC,“- - - - - -”will

disappear if there is no

error present. Connecting

a trailer without electric

brakes will not clear the

six dashed lines.

4. Adjust the Trailer Gain by using the gain adjustment (+ / -)

buttons on the Trailer Brake

Control Panel.

5. Drive the vehicle with the trailer attached on a level road surface

representative of the towing

condition and free of traffic at

about 32 to 40 km/h (20 to

25 mph) and fully apply the

Manual Trailer Brake Apply

Lever.

Adjusting trailer gain at speeds

lower than 32 to 40 km/h

(20 to 25 mph) may result

in an incorrect gain setting. 6. Adjust the Trailer Gain to just

below the point of trailer wheel

lock-up, indicated by trailer

wheel squeal or tire smoke

when a trailer wheel locks.

Trailer wheel lock-up may not

occur if towing a heavily loaded

trailer. In this case, adjust the

Trailer Gain to the highest

allowable setting for the towing

condition.

7. Re-adjust Trailer Gain any time vehicle loading, trailer loading or

road surface conditions change

or if trailer wheel lock-up is

noticed at any time while towing.

Other ITBC-Related DIC Messages

In addition to displaying TRAILER

GAIN and TRAILER OUTPUT

through the DIC, trailer connection

and ITBC system status are

displayed on the DIC.

TRAILER CONNECTED: This

message will be briefly displayed

when a trailer with electric brakes

is first connected to the vehicle. This message will automatically turn

off in about 10 seconds. The driver

can also acknowledge this message

before it automatically turns off.

CHECK TRAILER WIRING: This

message will be displayed if:

1. The ITBC system first

determines connection to a

trailer with electric brakes and

then the trailer harness becomes

disconnected from the vehicle.

If the disconnect occurs while

the vehicle is stationary, this

message will automatically

turn off in about 30 seconds.

This message will also turn off if

the driver acknowledges this

message or if the trailer harness

is re-connected.

If the disconnect occurs while

the vehicle is moving, this

message will continue until

the ignition is turned off.

This message will also turn

off if the driver acknowledges

this message or if the trailer

harness is re-connected.

Page 419 of 588

Black plate (125,1)Chevrolet Silverado Owner Manual - 2011

Driving and Operating 9-125

United States

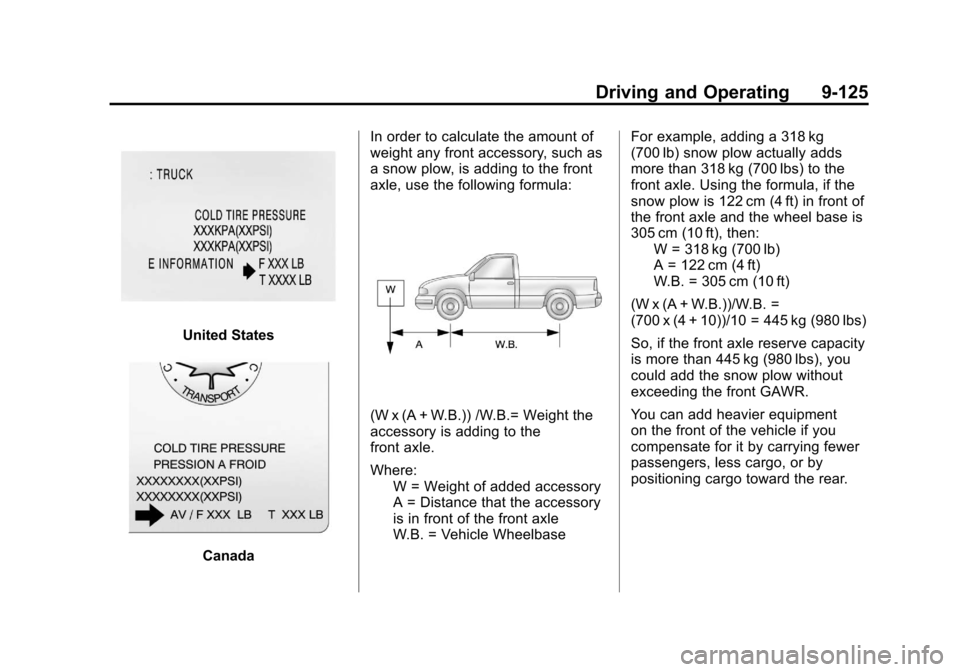

CanadaIn order to calculate the amount of

weight any front accessory, such as

a snow plow, is adding to the front

axle, use the following formula:

(W x (A + W.B.)) /W.B.= Weight the

accessory is adding to the

front axle.

Where:

W = Weight of added accessory

A = Distance that the accessory

is in front of the front axle

W.B. = Vehicle Wheelbase For example, adding a 318 kg

(700 lb) snow plow actually adds

more than 318 kg (700 lbs) to the

front axle. Using the formula, if the

snow plow is 122 cm (4 ft) in front of

the front axle and the wheel base is

305 cm (10 ft), then:

W = 318 kg (700 lb)

A = 122 cm (4 ft)

W.B. = 305 cm (10 ft)

(W x (A + W.B.))/W.B. =

(700 x (4 + 10))/10 = 445 kg (980 lbs)

So, if the front axle reserve capacity

is more than 445 kg (980 lbs), you

could add the snow plow without

exceeding the front GAWR.

You can add heavier equipment

on the front of the vehicle if you

compensate for it by carrying fewer

passengers, less cargo, or by

positioning cargo toward the rear.

Page 423 of 588

Black plate (1,1)Chevrolet Silverado Owner Manual - 2011

Vehicle Care 10-1

Vehicle Care

General Information

General Information . . . . . . . . . . 10-3

California Proposition65 Warning . . . . . . . . . . . . . . . . . 10-3

California Perchlorate Materials Requirements . . . . 10-3

Accessories and Modifications . . . . . . . . . . . . . . . 10-3

Vehicle Checks

Doing Your OwnService Work . . . . . . . . . . . . . . . 10-4

Hood . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Engine Compartment Overview . . . . . . . . . . . . . . . . . . . 10-6

Engine Oil . . . . . . . . . . . . . . . . . . . 10-7

Engine Oil Life System . . . . . . 10-9

Automatic Transmission Fluid (4-Speed Transmission) . . . 10-11

Automatic Transmission Fluid (6-Speed

Transmission) . . . . . . . . . . . . . 10-14 Manual Transmission

Fluid . . . . . . . . . . . . . . . . . . . . . . 10-17

Hydraulic Clutch . . . . . . . . . . . . 10-17

Engine Air Cleaner/Filter . . . . 10-18

Cooling System . . . . . . . . . . . . 10-19

Engine Coolant . . . . . . . . . . . . . 10-20

Engine Overheating . . . . . . . . 10-24

Overheated Engine Protection

Operating Mode . . . . . . . . . . . 10-26

Engine Fan . . . . . . . . . . . . . . . . . 10-26

Power Steering Fluid . . . . . . . 10-27

Washer Fluid . . . . . . . . . . . . . . . 10-28

Brakes . . . . . . . . . . . . . . . . . . . . . 10-29

Brake Fluid . . . . . . . . . . . . . . . . . 10-30

Battery . . . . . . . . . . . . . . . . . . . . . 10-32

Four-Wheel Drive . . . . . . . . . . . 10-32

Front Axle . . . . . . . . . . . . . . . . . . 10-34

Rear Axle . . . . . . . . . . . . . . . . . . 10-35

Noise Control System . . . . . . 10-36

Starter Switch Check . . . . . . . 10-37

Automatic Transmission Shift Lock Control Function

Check . . . . . . . . . . . . . . . . . . . . . 10-38

Ignition Transmission Lock Check . . . . . . . . . . . . . . . . . . . . . 10-38 Park Brake and P (Park)

Mechanism Check . . . . . . . . 10-39

Wiper Blade Replacement . . . . . . . . . . . . . . 10-39

Glass Replacement . . . . . . . . 10-40

Headlamp Aiming

Headlamp Aiming . . . . . . . . . . 10-40

Bulb Replacement

Bulb Replacement . . . . . . . . . . 10-43

Halogen Bulbs . . . . . . . . . . . . . . 10-43

Headlamps (Silverado) . . . . . 10-43

Pick-Up Box Identification

and Fender Marker

Lamps . . . . . . . . . . . . . . . . . . . . 10-44

Taillamps (Chassis Cab Models) . . . . . . . . . . . . . . . . . . . 10-44

Taillamps, Turn Signal, Stoplamps, and Back-Up

Lamps . . . . . . . . . . . . . . . . . . . . 10-45

Center High-Mounted Stoplamp (CHMSL) and

Cargo Lamp . . . . . . . . . . . . . . 10-45

License Plate Lamp . . . . . . . . 10-46

Replacement Bulbs . . . . . . . . . 10-46

Page 424 of 588

Black plate (2,1)Chevrolet Silverado Owner Manual - 2011

10-2 Vehicle Care

Electrical System

Electrical SystemOverload . . . . . . . . . . . . . . . . . . 10-47

Fuses and Circuit Breakers . . . . . . . . . . . . . . . . . . 10-48

Engine Compartment Fuse

Block . . . . . . . . . . . . . . . . . . . . . 10-48

Instrument Panel Fuse Block . . . . . . . . . . . . . . . . . . . . . 10-52

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . 10-55

Tire Sidewall Labeling . . . . . . 10-56

Tire Designations . . . . . . . . . . . 10-59

Tire Terminology andDefinitions . . . . . . . . . . . . . . . . 10-60

Tire Pressure . . . . . . . . . . . . . . . 10-63

Tire Pressure for High-Speed Operation . . . . . . . . . . . . . . . . . 10-65

Tire Pressure Monitor System . . . . . . . . . . . . . . . . . . . 10-65 Tire Pressure Monitor

Operation . . . . . . . . . . . . . . . . . 10-67

Tire Inspection . . . . . . . . . . . . . . 10-71

Tire Rotation . . . . . . . . . . . . . . . 10-71

Dual Tire Rotation . . . . . . . . . . 10-73

When It Is Time for New Tires . . . . . . . . . . . . . . . . . . . . . . 10-74

Buying New Tires . . . . . . . . . . . 10-75

Different Size Tires and Wheels . . . . . . . . . . . . . . . . . . . 10-77

Uniform Tire Quality Grading . . . . . . . . . . . . . . . . . . . 10-78

Wheel Alignment and Tire Balance . . . . . . . . . . . . . . . . . . . 10-79

Wheel Replacement . . . . . . . . 10-80

Tire Chains . . . . . . . . . . . . . . . . . 10-81

If a Tire Goes Flat . . . . . . . . . . 10-81

Tire Changing . . . . . . . . . . . . . . 10-83

Full-Size Spare Tire . . . . . . . . 10-95

Jump Starting

Jump Starting . . . . . . . . . . . . . . 10-96

Towing

Towing the Vehicle . . . . . . . . 10-101

Recreational Vehicle Towing . . . . . . . . . . . . . . . . . . . 10-101

Appearance Care

Exterior Care . . . . . . . . . . . . . . 10-106

Interior Care . . . . . . . . . . . . . . . 10-111

Floor Mats . . . . . . . . . . . . . . . . . 10-114

Page 451 of 588

Black plate (29,1)Chevrolet Silverado Owner Manual - 2011

Vehicle Care 10-29

Brakes

This vehicle has front disc brakes

and could have rear drum brakes or

rear disc brakes.

Disc brake pads have built-in wear

indicators that make a high-pitched

warning sound when the brake pads

are worn and new pads are needed.

The sound can come and go or be

heard all the time the vehicle is

moving, except when applying

the brake pedal firmly.

{WARNING

The brake wear warning sound

means that soon the brakes will

not work well. That could lead to

a crash. When the brake wear

warning sound is heard, have

the vehicle serviced.Notice:

Continuing to drive with

worn-out brake pads could result

in costly brake repair.

Some driving conditions or climates

can cause a brake squeal when the

brakes are first applied or lightly

applied. This does not mean

something is wrong with the brakes.

Properly torqued wheel nuts are

necessary to help prevent brake

pulsation. When tires are rotated,

inspect brake pads for wear and

evenly tighten wheel nuts in

the proper sequence to torque

specifications in Capacities and

Specifications on page 12‑2.

If the vehicle has rear drum brakes,

they do not have wear indicators,

but if a rear brake rubbing noise is

heard, have the rear brake linings

inspected immediately. Rear brake

drums should be removed and

inspected each time the tires are

removed for rotation or changing. Drum brakes have an inspection

hole to inspect lining wear during

scheduled maintenance. When the

front brake pads are replaced, have

the rear brakes inspected, too.

Brake linings should always be

replaced as complete axle sets.

Brake Pedal Travel

See your dealer if the brake pedal

does not return to normal height,

or if there is a rapid increase in

pedal travel. This could be a sign

that brake service might be

required.

Brake Adjustment

Every time the brakes are applied,

with or without the vehicle moving,

the brakes adjust for wear.