wheel CHEVROLET SILVERADO 2500 2019 Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2019, Model line: SILVERADO 2500, Model: CHEVROLET SILVERADO 2500 2019Pages: 489, PDF Size: 6.81 MB

Page 308 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

Driving and Operating 307

Vehicle SeriesTrailer WeightWeight-Distributing Hitch

Usage Hitch Distribution

1500 Up to 3 175 kg (7,000 lb) OptionalRefer to trailer

manufacturer ’s

recommendation

1500 Over 3 175 kg (7,000 lb) Required50%

2500/3500 Up to 9 080 kg (20,000 lb) Optional50%

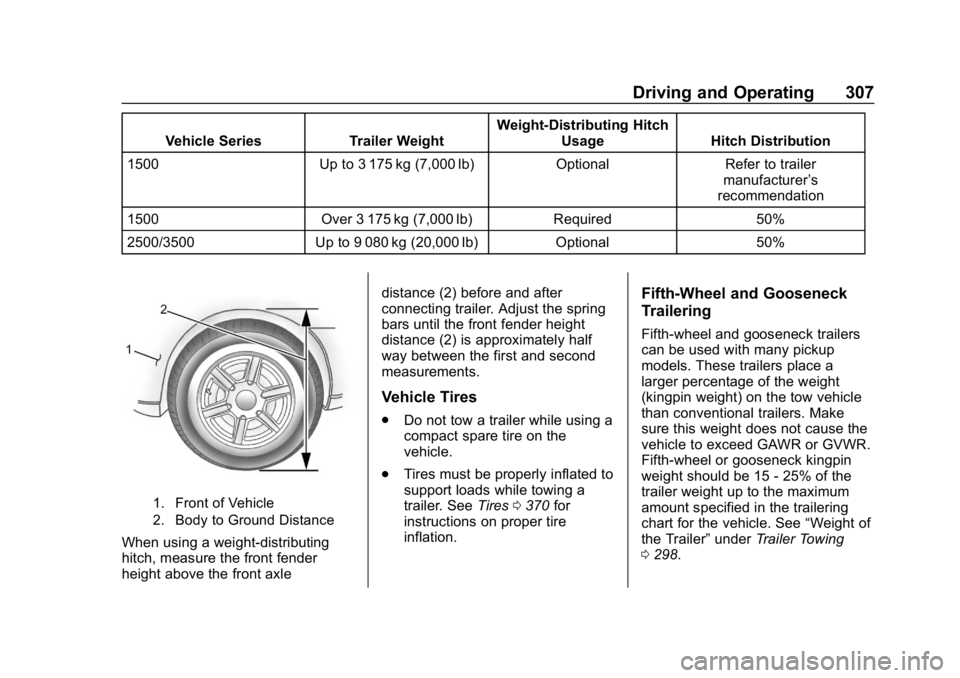

1. Front of Vehicle

2. Body to Ground Distance

When using a weight-distributing

hitch, measure the front fender

height above the front axle distance (2) before and after

connecting trailer. Adjust the spring

bars until the front fender height

distance (2) is approximately half

way between the first and second

measurements.

Vehicle Tires

.

Do not tow a trailer while using a

compact spare tire on the

vehicle.

. Tires must be properly inflated to

support loads while towing a

trailer. See Tires0370 for

instructions on proper tire

inflation.

Fifth-Wheel and Gooseneck

Trailering

Fifth-wheel and gooseneck trailers

can be used with many pickup

models. These trailers place a

larger percentage of the weight

(kingpin weight) on the tow vehicle

than conventional trailers. Make

sure this weight does not cause the

vehicle to exceed GAWR or GVWR.

Fifth-wheel or gooseneck kingpin

weight should be 15 - 25% of the

trailer weight up to the maximum

amount specified in the trailering

chart for the vehicle. See “Weight of

the Trailer” underTrailer Towing

0 298.

Page 309 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

308 Driving and Operating

The hitch should be in the pickup

bed so that its centerline is over or

slightly in front of the rear axle. Take

care that it is not so far forward that

it will contact the back of the cab in

sharp turns. This is especially

important for short box pickups.

Trailer pin box extensions and

sliding fifth-wheel hitch assemblies

may be used. There should be at

least 15 cm (6 in) of clearance

between the top of the pickup box

and the bottom of the trailer shelf

that extends over the box.

Make sure the hitch is attached to

the tow vehicle frame rails. Do not

use the pickup box for support.

Safety Chains

Always attach safety chains

between the vehicle and the trailer.

Instructions about safety chains

may be provided by the hitch

manufacturer or by the trailer

manufacturer.

If the trailer being towed weighs up

to 2 271 kg (5,000 lb) with a

factory-installed step bumper, safety

chains may be attached to theattaching points on the bumper;

otherwise, safety chains should be

attached to holes on the trailer hitch.

Cross the safety chains under the

tongue of the trailer to help prevent

the tongue from contacting the road

if it becomes separated from the

hitch. Always leave enough slack in

the safety chains to allow the

combination to turn. Never allow

safety chains to drag on the ground.

Trailer Brakes

Loaded trailers over 900 kg

(2,000 lb) must be equipped with

brake systems and with brakes for

each axle. Trailer braking equipment

conforming to Canadian Standards

Association (CSA) requirement

CAN3-D313, or its equivalent, is

recommended.

State or local regulations may

require trailers to have their own

braking system if the loaded weight

of the trailer exceeds certain

minimums that can vary from state

to state. Read and follow the

instructions for the trailer brakes so

they are installed, adjusted, andmaintained properly. Never attempt

to tap into your vehicle's hydraulic

brake system. If you do, both the

vehicle anti-lock brakes and the

trailer brakes may not function,

which could result in a crash.

Auxiliary Battery

If equipped, the vehicle's auxiliary

battery can be used to supply

electrical power to additional

equipment that may be added, such

as a slide-in camper.

Locate the auxiliary battery

connector under the hood on the

driver's side of the vehicle, next to

the underhood electrical center.

Follow the proper installation

instructions included with any

electrical equipment that is installed.

Caution

To prevent draining the auxiliary

battery, always turn off electrical

equipment when not in use and

do not use any equipment that

(Continued)

Page 311 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

310 Driving and Operating

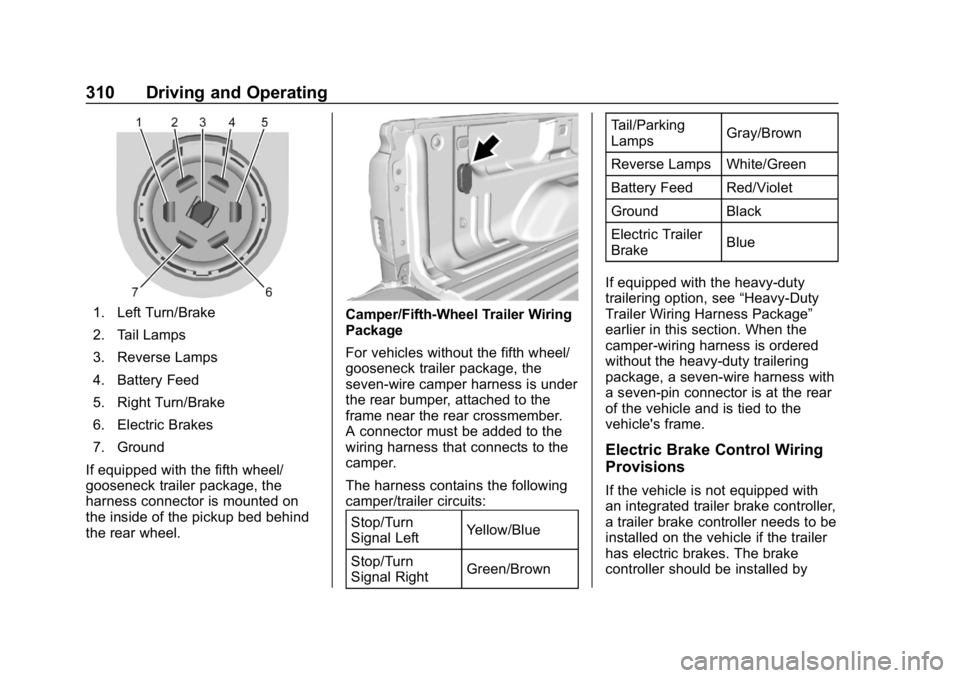

1. Left Turn/Brake

2. Tail Lamps

3. Reverse Lamps

4. Battery Feed

5. Right Turn/Brake

6. Electric Brakes

7. Ground

If equipped with the fifth wheel/

gooseneck trailer package, the

harness connector is mounted on

the inside of the pickup bed behind

the rear wheel.Camper/Fifth-Wheel Trailer Wiring

Package

For vehicles without the fifth wheel/

gooseneck trailer package, the

seven-wire camper harness is under

the rear bumper, attached to the

frame near the rear crossmember.

A connector must be added to the

wiring harness that connects to the

camper.

The harness contains the following

camper/trailer circuits: Stop/Turn

Signal Left Yellow/Blue

Stop/Turn

Signal Right Green/Brown Tail/Parking

Lamps

Gray/Brown

Reverse Lamps White/Green

Battery Feed Red/Violet

Ground Black

Electric Trailer

Brake Blue

If equipped with the heavy-duty

trailering option, see “Heavy-Duty

Trailer Wiring Harness Package”

earlier in this section. When the

camper-wiring harness is ordered

without the heavy-duty trailering

package, a seven-wire harness with

a seven-pin connector is at the rear

of the vehicle and is tied to the

vehicle's frame.

Electric Brake Control Wiring

Provisions

If the vehicle is not equipped with

an integrated trailer brake controller,

a trailer brake controller needs to be

installed on the vehicle if the trailer

has electric brakes. The brake

controller should be installed by

Page 313 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

312 Driving and Operating

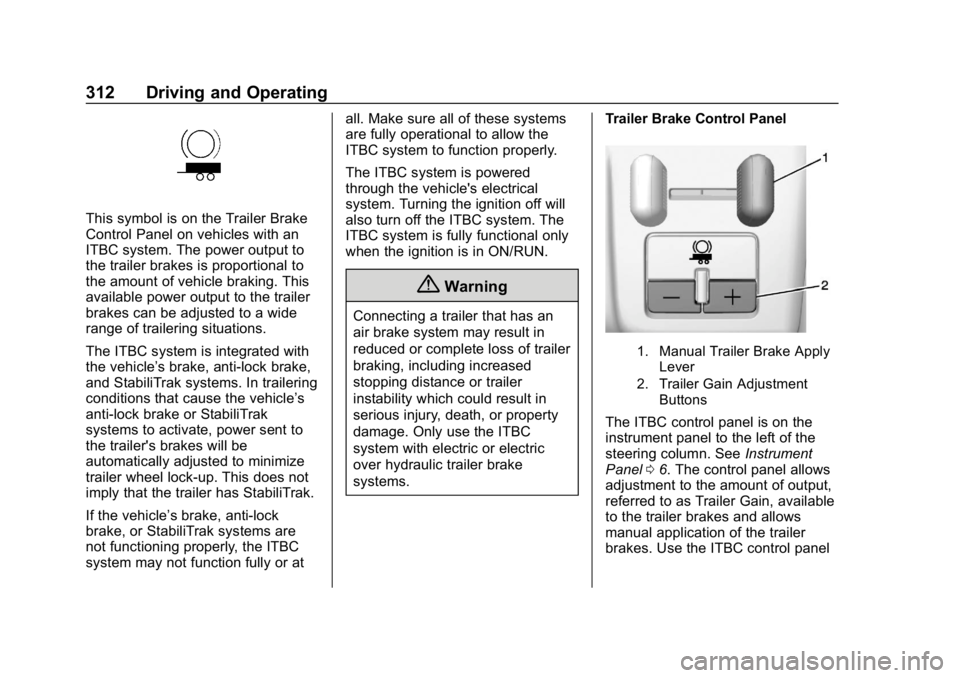

This symbol is on the Trailer Brake

Control Panel on vehicles with an

ITBC system. The power output to

the trailer brakes is proportional to

the amount of vehicle braking. This

available power output to the trailer

brakes can be adjusted to a wide

range of trailering situations.

The ITBC system is integrated with

the vehicle’s brake, anti-lock brake,

and StabiliTrak systems. In trailering

conditions that cause the vehicle’s

anti-lock brake or StabiliTrak

systems to activate, power sent to

the trailer's brakes will be

automatically adjusted to minimize

trailer wheel lock-up. This does not

imply that the trailer has StabiliTrak.

If the vehicle’s brake, anti-lock

brake, or StabiliTrak systems are

not functioning properly, the ITBC

system may not function fully or at all. Make sure all of these systems

are fully operational to allow the

ITBC system to function properly.

The ITBC system is powered

through the vehicle's electrical

system. Turning the ignition off will

also turn off the ITBC system. The

ITBC system is fully functional only

when the ignition is in ON/RUN.

{Warning

Connecting a trailer that has an

air brake system may result in

reduced or complete loss of trailer

braking, including increased

stopping distance or trailer

instability which could result in

serious injury, death, or property

damage. Only use the ITBC

system with electric or electric

over hydraulic trailer brake

systems.

Trailer Brake Control Panel

1. Manual Trailer Brake Apply

Lever

2. Trailer Gain Adjustment Buttons

The ITBC control panel is on the

instrument panel to the left of the

steering column. See Instrument

Panel 06. The control panel allows

adjustment to the amount of output,

referred to as Trailer Gain, available

to the trailer brakes and allows

manual application of the trailer

brakes. Use the ITBC control panel

Page 315 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

314 Driving and Operating

Trailer Gain Adjustment Procedure

Trailer Gain should be set for a

specific trailering condition and it

must be readjusted anytime vehicle

loading, trailer loading, or road

surface conditions change.

{Warning

Trailer brakes that are

over-gained or under-gained may

not stop the vehicle and the trailer

as intended and can result in a

crash. Always follow the

instructions to set the Trailer Gain

for the proper trailer stopping

performance.

To adjust Trailer Gain for each

towing condition: 1. Drive the vehicle with the trailer attached on a level road

surface representative of the

towing condition and free of

traffic at about 32 - 40 km/h

(20 - 25 mph) and fully apply

the Manual Trailer Brake Apply

Lever. Note

Adjusting Trailer Gain at speeds

lower than 32 to 40 km/h (20 to

25 mph) may result in an incorrect

gain setting.

2. Adjust the Trailer Gain, using the Trailer Gain (+) or (−)

adjustment Buttons, to just

below the point of trailer wheel

lock-up, indicated by trailer

wheel squeal or tire smoke

when a trailer wheel locks.

Note

Trailer wheel lock-up may not occur

if towing a heavily loaded trailer.

Adjust the Trailer Gain to the

highest allowable setting for the

towing condition.

3. Readjust Trailer Gain anytime vehicle loading, trailer loading,

or road surface conditions

change or if trailer wheel

lock-up is noticed at any time

while towing. Other ITBC-Related DIC Messages

TRAILER CONNECTED: This

message will briefly display when a

trailer with electric brakes is first

connected to the vehicle. This

message will automatically turn off

in about 10 seconds. This message

can be acknowledged before it

automatically turns off.

CHECK TRAILER WIRING: This

message will display if:

.

The ITBC system first

determines connection to a

trailer with electric brakes and

then the trailer harness becomes

disconnected the vehicle.

If the disconnect occurs while

the vehicle is stationary, this

message will automatically turn

off in about 30 seconds. This

message will also turn off if it is

acknowledged or if the trailer

harness is reconnected.

If the disconnect occurs while

the vehicle is moving, this

message will continue until the

ignition is turned off. This

Page 316 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

Driving and Operating 315

message will also turn off if it is

acknowledged or if the trailer

harness is reconnected.

. There is an electrical fault in the

wiring to the trailer brakes. This

message will continue as long

as there is an electrical fault in

the trailer wiring. This message

will also turn off if it is

acknowledged.

To determine whether the electrical

fault is on the vehicle side or trailer

side of the trailer wiring harness

connection: 1. Disconnect the trailer wiring harness from the vehicle.

2. Turn the ignition off.

3. Wait 10 seconds, then turn the ignition back to RUN.

4. If the CHECK TRAILER WIRING message reappears,

the electrical fault is on the

vehicle side. If the CHECK TRAILER WIRING

message only reappears when

connecting the trailer wiring harness

to the vehicle, the electrical fault is

on the trailer side.

SERVICE TRAILER BRAKE

SYSTEM: This message will display

when there is a problem with the

ITBC system. If this message

continues over multiple ignition

cycles, have the vehicle serviced.

If either the CHECK TRAILER

WIRING or SERVICE TRAILER

BRAKE SYSTEM message displays

while driving, the ITBC system may

not be fully functional or may not

function at all. When traffic

conditions allow, carefully pull the

vehicle over to the side of the road

and turn the ignition off. Check the

wiring connection to the trailer and

turn the ignition back on. If either of

these messages continues, either

the vehicle or trailer needs service.

A GM dealer may be able to

diagnose and repair problems with

the trailer. However, any diagnosis

and repair of the trailer is not

covered under the vehicle warranty. Contact your trailer dealer for

assistance with trailer repairs and

trailer warranty information.

Trailer Sway

Control (TSC)

Vehicles with StabiliTrak have a

Trailer Sway Control (TSC) feature.

Trailer sway is unintended

side-to-side motion of a trailer while

towing. If the vehicle is towing a

trailer and the TSC detects that

sway is increasing, the vehicle

brakes are selectively applied at

each wheel, to help reduce

excessive trailer sway. If equipped

with the Integrated Trailer Brake

Control (ITBC) system, and the

trailer has an electric brake system,

StabiliTrak may also apply the trailer

brakes.

Page 322 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

Driving and Operating 321

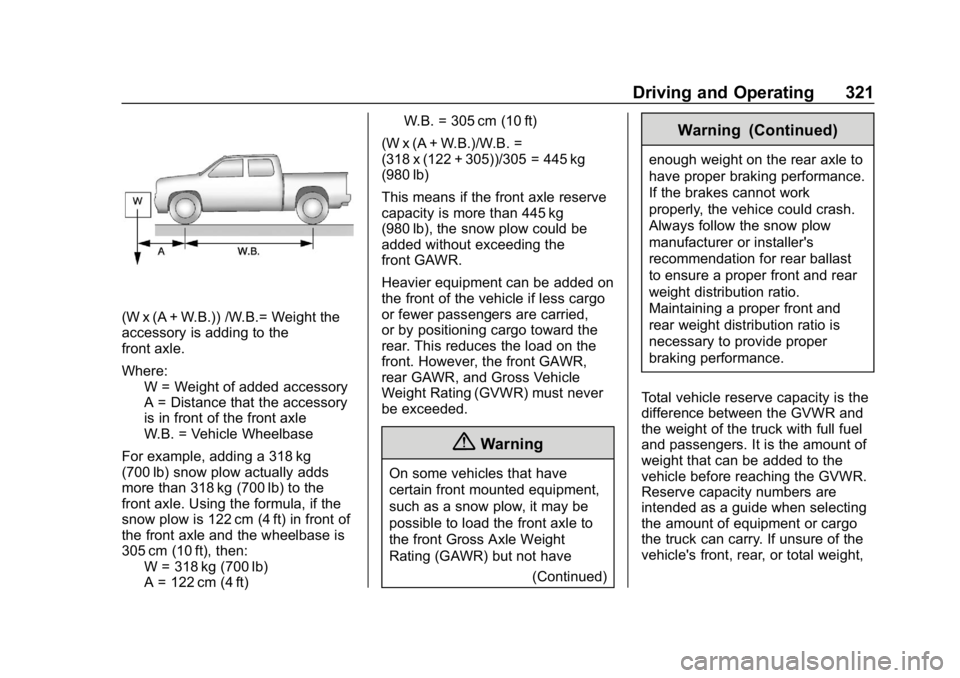

(W x (A + W.B.)) /W.B.= Weight the

accessory is adding to the

front axle.

Where:W = Weight of added accessory

A = Distance that the accessory

is in front of the front axle

W.B. = Vehicle Wheelbase

For example, adding a 318 kg

(700 lb) snow plow actually adds

more than 318 kg (700 lb) to the

front axle. Using the formula, if the

snow plow is 122 cm (4 ft) in front of

the front axle and the wheelbase is

305 cm (10 ft), then: W = 318 kg (700 lb)

A = 122 cm (4 ft) W.B. = 305 cm (10 ft)

(W x (A + W.B.)/W.B. =

(318 x (122 + 305))/305 = 445 kg

(980 lb)

This means if the front axle reserve

capacity is more than 445 kg

(980 lb), the snow plow could be

added without exceeding the

front GAWR.

Heavier equipment can be added on

the front of the vehicle if less cargo

or fewer passengers are carried,

or by positioning cargo toward the

rear. This reduces the load on the

front. However, the front GAWR,

rear GAWR, and Gross Vehicle

Weight Rating (GVWR) must never

be exceeded.

{Warning

On some vehicles that have

certain front mounted equipment,

such as a snow plow, it may be

possible to load the front axle to

the front Gross Axle Weight

Rating (GAWR) but not have (Continued)

Warning (Continued)

enough weight on the rear axle to

have proper braking performance.

If the brakes cannot work

properly, the vehice could crash.

Always follow the snow plow

manufacturer or installer's

recommendation for rear ballast

to ensure a proper front and rear

weight distribution ratio.

Maintaining a proper front and

rear weight distribution ratio is

necessary to provide proper

braking performance.

Total vehicle reserve capacity is the

difference between the GVWR and

the weight of the truck with full fuel

and passengers. It is the amount of

weight that can be added to the

vehicle before reaching the GVWR.

Reserve capacity numbers are

intended as a guide when selecting

the amount of equipment or cargo

the truck can carry. If unsure of the

vehicle's front, rear, or total weight,

Page 324 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

Vehicle Care 323

Vehicle Care

General Information

General Information . . . . . . . . . . 324

California Proposition65 Warning . . . . . . . . . . . . . . . . . 325

California Perchlorate Materials Requirements . . . . . 325

Accessories and Modifications . . . . . . . . . . . . . . . . 325

Vehicle Checks

Doing Your OwnService Work . . . . . . . . . . . . . . . 326

Hood . . . . . . . . . . . . . . . . . . . . . . . . . 326

Engine Compartment Overview . . . . . . . . . . . . . . . . . . . . 328

Engine Oil . . . . . . . . . . . . . . . . . . . . 331

Engine Oil Life System . . . . . . . 333

Automatic Transmission Fluid (6-Speed Transmission) . . . . . 335

Automatic Transmission Fluid (8-Speed Transmission) . . . . . 337

Engine Air Cleaner/Filter . . . . . . 338

Cooling System . . . . . . . . . . . . . . 339

Engine Overheating . . . . . . . . . . 343

Overheated Engine Protection Operating Mode . . . . . . . . . . . . . 344

Engine Fan . . . . . . . . . . . . . . . . . . . 345 Power Steering Fluid (1500

Series) . . . . . . . . . . . . . . . . . . . . . . 345

Power Steering Fluid (2500/ 3500 Series) . . . . . . . . . . . . . . . . 345

Washer Fluid . . . . . . . . . . . . . . . . . 346

Brakes . . . . . . . . . . . . . . . . . . . . . . . 347

Brake Fluid . . . . . . . . . . . . . . . . . . . 348

Battery - North America . . . . . . 349

Four-Wheel Drive . . . . . . . . . . . . . 350

Front Axle . . . . . . . . . . . . . . . . . . . . 350

Rear Axle . . . . . . . . . . . . . . . . . . . . 351

Noise Control System . . . . . . . . 352

Starter Switch Check . . . . . . . . . 354

Automatic Transmission Shift

Lock Control Function

Check . . . . . . . . . . . . . . . . . . . . . . . 354

Ignition Transmission Lock Check . . . . . . . . . . . . . . . . . . . . . . . 354

Park Brake and P (Park) Mechanism Check . . . . . . . . . . 354

Wiper Blade Replacement . . . . 355

Windshield Replacement . . . . . 356

Gas Strut(s) . . . . . . . . . . . . . . . . . . 356

Headlamp Aiming

Headlamp Aiming . . . . . . . . . . . . 357

Bulb Replacement

Bulb Replacement . . . . . . . . . . . . 357

Halogen Bulbs . . . . . . . . . . . . . . . . 357 High Intensity Discharge (HID)

Lighting . . . . . . . . . . . . . . . . . . . . . 358

LED Lighting . . . . . . . . . . . . . . . . . 358

Headlamps, Front Turn Signal, Sidemarker, and Parking

Lamps . . . . . . . . . . . . . . . . . . . . . . 358

Fog Lamps . . . . . . . . . . . . . . . . . . . 359

Taillamps (Chassis Cab Models) . . . . . . . . . . . . . . . . . . . . . 359

Taillamps, Turn Signal, Stoplamps, and Back-Up

Lamps . . . . . . . . . . . . . . . . . . . . . . 359

Center High-Mounted Stoplamp (CHMSL) and

Cargo Lamp . . . . . . . . . . . . . . . . . 361

Electrical System

Electrical System Overload . . . 361

Fuses and Circuit Breakers . . . 362

Engine Compartment FuseBlock . . . . . . . . . . . . . . . . . . . . . . . . 362

Instrument Panel Fuse Block (Right) . . . . . . . . . . . . . . . . . . . . . . 366

Instrument Panel Fuse Block (Left) . . . . . . . . . . . . . . . . . 367

Wheels and Tires

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . 370

All-Season Tires . . . . . . . . . . . . . . 370

Winter Tires . . . . . . . . . . . . . . . . . . 371

Low-Profile Tires . . . . . . . . . . . . . 371

Page 325 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

324 Vehicle Care

All-Terrain Tires . . . . . . . . . . . . . . . 372

Tire Sidewall Labeling . . . . . . . . 372

Tire Designations . . . . . . . . . . . . . 374

Tire Terminology andDefinitions . . . . . . . . . . . . . . . . . . 376

Tire Pressure . . . . . . . . . . . . . . . . . 378

Tire Pressure for High-Speed Operation . . . . . . . . . . . . . . . . . . . 380

Tire Pressure Monitor System . . . . . . . . . . . . . . . . . . . . . . 380

Tire Pressure Monitor Operation . . . . . . . . . . . . . . . . . . . 381

Tire Inspection . . . . . . . . . . . . . . . . 385

Tire Rotation . . . . . . . . . . . . . . . . . 386

When It Is Time for New Tires . . . . . . . . . . . . . . . . . . . . . . . . 388

Buying New Tires . . . . . . . . . . . . . 389

Different Size Tires and Wheels . . . . . . . . . . . . . . . . . . . . . . 390

Uniform Tire Quality Grading . . . . . . . . . . . . . . . . . . . . . 391

Wheel Alignment and Tire Balance . . . . . . . . . . . . . . . . . . . . . 392

Wheel Replacement . . . . . . . . . . 393

Tire Chains . . . . . . . . . . . . . . . . . . . 394

If a Tire Goes Flat . . . . . . . . . . . . 394

Tire Changing . . . . . . . . . . . . . . . . 396

Full-Size Spare Tire . . . . . . . . . . 407Jump Starting

Jump Starting - North America . . . . . . . . . . . . . . . . . . . . . 408

Towing the Vehicle

Towing the Vehicle . . . . . . . . . . . 412

Recreational VehicleTowing . . . . . . . . . . . . . . . . . . . . . . 412

Appearance Care

Exterior Care . . . . . . . . . . . . . . . . . 418

Interior Care . . . . . . . . . . . . . . . . . . 423

Floor Mats . . . . . . . . . . . . . . . . . . . . 426

General Information

For service and parts needs, visit

your dealer. You will receive

genuine GM parts and GM-trained

and supported service people.

Genuine GM parts have one of

these marks:

Page 327 of 489

Chevrolet Silverado LD 1500 and Silverado 2500/3500 Owner Manual (GMNA-

Localizing-U.S./Canada-12162993) - 2019 - crc - 4/4/18

326 Vehicle Care

Vehicle Checks

Doing Your Own

Service Work

{Warning

It can be dangerous to work on

your vehicle if you do not have

the proper knowledge, service

manual, tools, or parts. Always

follow owner’s manual procedures

and consult the service manual

for your vehicle before doing any

service work.

If doing some of your own service

work, use the proper service

manual. It tells you much more

about how to service the vehicle

than this manual can. To order the

proper service manual, see

Publication Ordering Information

0 458. This vehicle has an airbag system.

Before attempting to do your own

service work, see

Servicing the

Airbag-Equipped Vehicle 088.

If equipped with remote vehicle

start, open the hood before

performing any service work to

prevent remote starting the vehicle

accidentally. See Remote Vehicle

Start 038.

Keep a record with all parts receipts

and list the mileage and the date of

any service work performed. See

Maintenance Records 0444.

Caution

Even small amounts of

contamination can cause damage

to vehicle systems. Do not allow

contaminants to contact the fluids,

reservoir caps, or dipsticks.

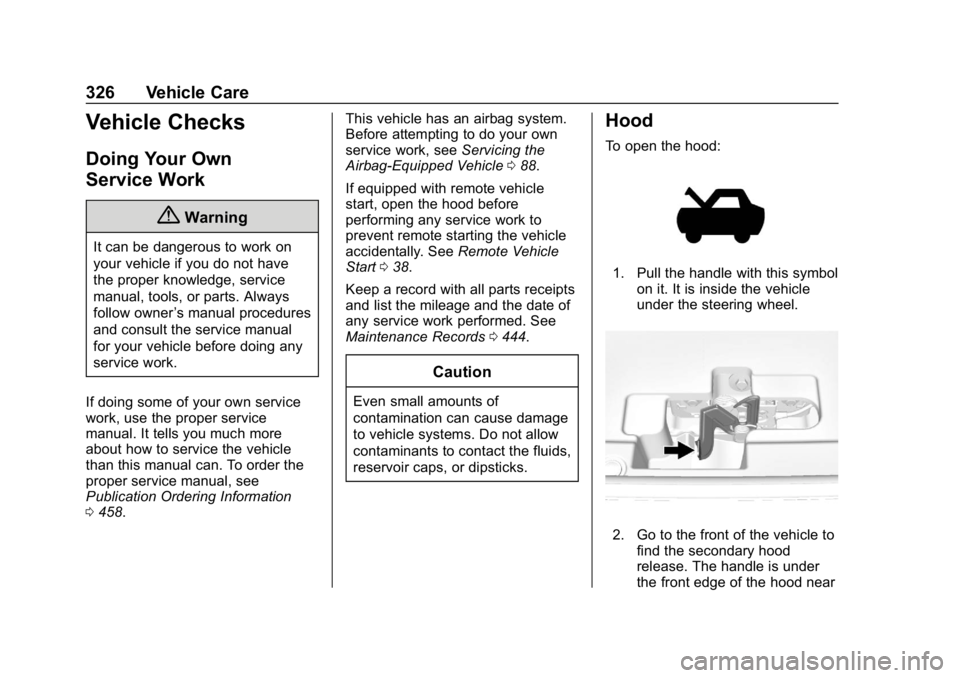

Hood

To open the hood:

1. Pull the handle with this symbol

on it. It is inside the vehicle

under the steering wheel.

2. Go to the front of the vehicle tofind the secondary hood

release. The handle is under

the front edge of the hood near