towing CHEVROLET SILVERADO 2500 2023 Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2023, Model line: SILVERADO 2500, Model: CHEVROLET SILVERADO 2500 2023Pages: 441, PDF Size: 14.4 MB

Page 278 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Driving and Operating 277

Warning (Continued)

.Do not move the vehicle if someone is

in the path of the trailer. Some parts

of the trailer might be underwater and

not visible to people who are assisting

in launching the boat.

Disconnect the wiring to the trailer before

backing the trailer into the water to prevent

damage to the electrical circuits on the

trailer. Reconnect the wiring to the trailer

after removing the trailer from the water.

If the trailer has electric brakes that can

function when the trailer is submerged, it

might help to leave the electrical trailer

connector attached to maintain trailer brake

functionality while on the boat ramp.

To back the trailer into the water: 1. If equipped, place the vehicle in four-wheel-drive high.

2. Slowly back down the boat ramp until the boat is floating, but no further than

necessary.

3. Press and hold the brake pedal, but do not shift into P (Park) yet.

4. Have someone place chocks under the front wheels of the vehicle. 5. Gradually release the brake pedal to

allow the chocks to absorb the load of

the trailer.

6. Reapply the brake pedal. Then apply the parking brake and shift into P (Park).

7. Release the brake pedal.

Pulling the Trailer from the Water

To pull the trailer out of the water: 1. Press and hold the brake pedal.

2. Start the engine and shift into gear.

3. Release the parking brake.

4. Let up on the brake pedal.

5. Drive slowly until the tires are clear of the chocks.

6. Stop and have someone pick up and store the chocks.

7. Slowly pull the trailer from the water.

8. Once the vehicle and trailer have been driven from the sloped part of the boat

ramp, the vehicle can be shifted from

four-wheel-drive high. Shift into the drive

mode that is appropriate for the road

conditions.

Caution

If the vehicle tires begin to spin and the

vehicle begins to slide toward the water,

remove your foot from the accelerator

pedal and apply the brake pedal. Seek

help to have the vehicle towed up

the ramp.

Maintenance when Trailer Towing

The vehicle needs service more often when

used to tow trailers. See Maintenance

Schedule 0392. It is especially important to

check the engine oil, axle lubricant, belts,

cooling system, and brake system before

and during each trip.

Check periodically to see that all nuts and

bolts on the trailer hitch are tight.

Engine Cooling When Trailer Towing

The cooling system may temporarily

overheat during severe operating conditions.

See Engine Overheating 0318.

Page 279 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

278 Driving and Operating

Trailer Towing

If equipped with a diesel engine, see the

Duramax diesel supplement.

Caution

Towing a trailer improperly can damage

the vehicle and result in costly repairs

not covered by the vehicle warranty. To

tow a trailer correctly, follow the

directions in this section and see your

dealer for important information about

towing a trailer with the vehicle.

Trailering is different than just driving the

vehicle by itself. Trailering means changes in

handling, acceleration, braking, durability,

and fuel economy. Successful, safe trailering

takes correct equipment, and it has to be

used properly.

The following information has many

time-tested, important trailering tips and

safety rules. Many of these are important

for your safety and that of your passengers.

Read this section carefully before pulling a

trailer.

Trailer Weight

{Warning

Never exceed the towing capacity for

your vehicle.

Safe trailering requires monitoring the

weight, speed, altitude, road grades, outside

temperature, and how frequently the vehicle

is used to tow a trailer.

Trailer Weight Ratings

When towing a trailer, the combined weight

of the vehicle, vehicle contents, trailer, and

trailer contents must be below all of the

maximum weight ratings for the vehicle,

including:

.GCWR: Gross Combined Weight Rating

.GVWR: Gross Vehicle Weight Rating

.Maximum Trailer Weight Rating

.GAWR-RR: Gross Axle Weight Rating-Rear

.Maximum Trailer Tongue Weight Rating

See “Weight-Distributing Hitch and

Adjustment” underTowing Equipment 0281

to determine if equalizer bars are required

to obtain the maximum trailer weight

rating. See

“Trailer Brakes” underTowing

Equipment 0281 to determine if brakes are

required based on your trailer's weight.

The only way to be sure the weight is not

exceeding any of these ratings is to weigh

the tow vehicle and trailer combination,

fully loaded for the trip, getting individual

weights for each of these items.

A trailering information label on the B-pillar

shows tow rating information for the

vehicle.

{Warning

You and others could be seriously injured

or killed if the trailer is too heavy or the

trailer brakes are inadequate for the load.

The vehicle may be damaged, and the

repairs would not be covered by the

vehicle warranty.

Only tow a trailer if all the steps in this

section have been followed. Ask your

dealer for advice and information about

towing a trailer.

Page 282 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Driving and Operating 281

After loading the trailer, separately weigh

the trailer and then the trailer tongue and

calculate the trailer load balance percentage

to see if the weights and distribution are

appropriate for your vehicle. If the trailer

weight is too high, it may be possible to

transfer some of the cargo into your vehicle.

If the trailer tongue weight is too high or

too low, it may be possible to rearrange

some of the cargo inside of the trailer.

Do not exceed the maximum allowable

tongue weight for your vehicle. Use the

shortest hitch extension available to position

the hitch ball closer to your vehicle. This will

help reduce the effect of the trailer tongue

weight on the trailer hitch and the rear axle.

If a cargo carrier is used in the trailer hitch

receiver, choose a carrier that positions the

load as close to the vehicle as possible.

Make sure the total weight, including the

carrier, is no more than half of the

maximum allowable tongue weight for the

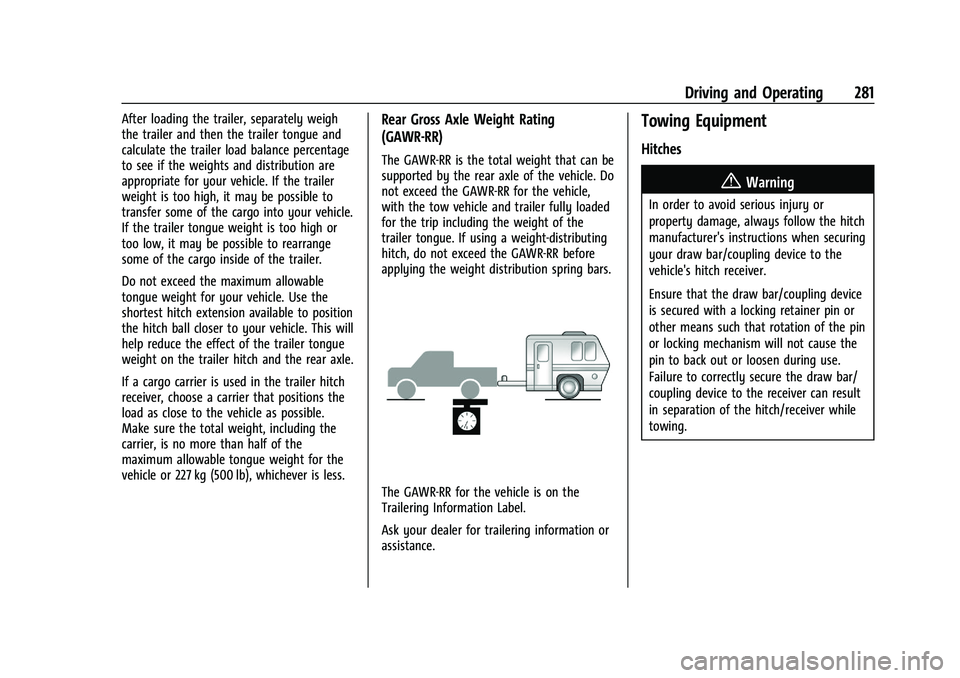

vehicle or 227 kg (500 lb), whichever is less.Rear Gross Axle Weight Rating

(GAWR-RR)

The GAWR-RR is the total weight that can be

supported by the rear axle of the vehicle. Do

not exceed the GAWR-RR for the vehicle,

with the tow vehicle and trailer fully loaded

for the trip including the weight of the

trailer tongue. If using a weight-distributing

hitch, do not exceed the GAWR-RR before

applying the weight distribution spring bars.

The GAWR-RR for the vehicle is on the

Trailering Information Label.

Ask your dealer for trailering information or

assistance.

Towing Equipment

Hitches

{Warning

In order to avoid serious injury or

property damage, always follow the hitch

manufacturer's instructions when securing

your draw bar/coupling device to the

vehicle's hitch receiver.

Ensure that the draw bar/coupling device

is secured with a locking retainer pin or

other means such that rotation of the pin

or locking mechanism will not cause the

pin to back out or loosen during use.

Failure to correctly secure the draw bar/

coupling device to the receiver can result

in separation of the hitch/receiver while

towing.

Page 283 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

282 Driving and Operating

Conventional Hitch

A conventional hitch is bolted to the frame

or cross member of the tow vehicle, and is

generally rated Class 2, 3, or 4.

Gooseneck Hitch

A gooseneck hitch is designed to be coupled

to a special hitch leveraging a hitch ball, and

is mounted over the rear axle in the

truck bed.

Fifth-Wheel Hitch

A fifth-wheel hitch is mounted over the rear

axle in the truck bed, and leverages a

hinged plate—the same type of hitch

leveraged by semi trucks. Generally,

fifth-wheel hitches accommodate large

trailers with as many as one, two, or three

axles. Always use the correct hitch equipment for

your vehicle. Crosswinds, large trucks going

by, and rough roads can affect the trailer

and the hitch.

Proper hitch equipment for your vehicle

helps maintain control of the vehicle-trailer

combination. Many trailers can be towed

using a weight-carrying hitch which has a

coupler latched to the hitch ball, or a tow

eye latched to a pintle hook. Other trailers

may require a weight-distributing hitch that

uses spring bars to distribute the trailer

tongue weight between your vehicle and

trailer axles. Fifth-wheel and gooseneck

hitches may also be used. See

“Maximum

Trailer Tongue Weight” underTrailer Towing

0 278 for weight limits with various hitch

types. Avoid sharp turns when using a step-bumper

hitch to prevent damage. Make wider turns

to prevent contact between your trailer and

your bumper.

Consider using mechanical sway controls

with any trailer. Ask a trailering professional

about sway controls or refer to the trailer

manufacturer's recommendations and

instructions.

Page 284 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Driving and Operating 283

Weight-Distributing Hitch and Adjustment

A weight-distributing hitch may be useful with some trailers. Use the following guidelines to determine if a weight-distributing hitch should

be used.Vehicle Maximum Trailer Weight GCWR* Maximum Tongue Weight

2500/3500 Up to 9 080 kg (20,000 lb) See (1) below 25%

(1) Weight distributing hitch required on vehicles equipped with On/Off Road (OOR) and Mud Terrain (MT) tires with trailers over 10,000 lbs.

Weight distributing hitch optional for other vehicles.

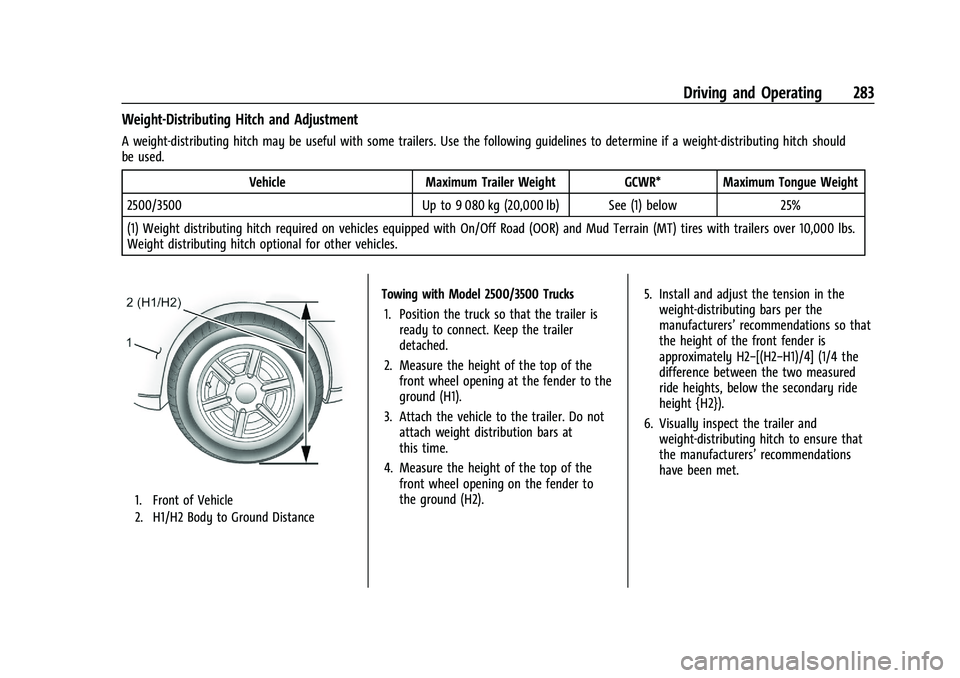

1. Front of Vehicle

2. H1/H2 Body to Ground Distance

Towing with Model 2500/3500 Trucks 1. Position the truck so that the trailer is ready to connect. Keep the trailer

detached.

2. Measure the height of the top of the front wheel opening at the fender to the

ground (H1).

3. Attach the vehicle to the trailer. Do not attach weight distribution bars at

this time.

4. Measure the height of the top of the front wheel opening on the fender to

the ground (H2). 5. Install and adjust the tension in the

weight-distributing bars per the

manufacturers’ recommendations so that

the height of the front fender is

approximately H2−[(H2−H1)/4] (1/4 the

difference between the two measured

ride heights, below the secondary ride

height {H2}).

6. Visually inspect the trailer and weight-distributing hitch to ensure that

the manufacturers’ recommendations

have been met.

Page 285 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

284 Driving and Operating

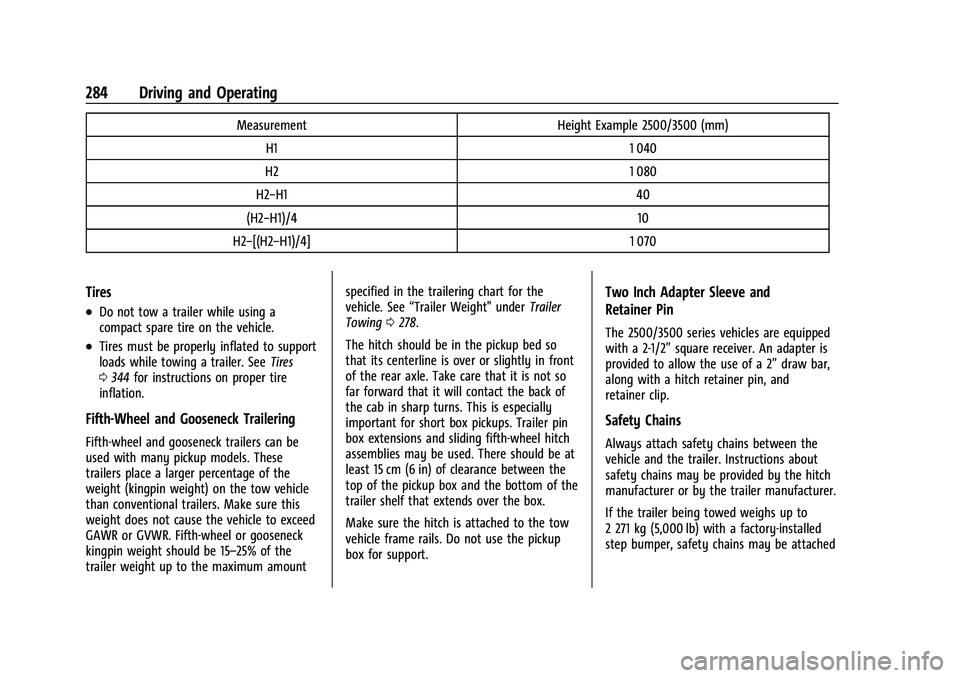

MeasurementHeight Example 2500/3500 (mm)

H1 1 040

H2 1 080

H2−H1 40

(H2−H1)/4 10

H2−[(H2−H1)/4] 1 070

Tires

.Do not tow a trailer while using a

compact spare tire on the vehicle.

.Tires must be properly inflated to support

loads while towing a trailer. SeeTires

0 344 for instructions on proper tire

inflation.

Fifth-Wheel and Gooseneck Trailering

Fifth-wheel and gooseneck trailers can be

used with many pickup models. These

trailers place a larger percentage of the

weight (kingpin weight) on the tow vehicle

than conventional trailers. Make sure this

weight does not cause the vehicle to exceed

GAWR or GVWR. Fifth-wheel or gooseneck

kingpin weight should be 15–25% of the

trailer weight up to the maximum amount specified in the trailering chart for the

vehicle. See

“Trailer Weight" under Trailer

Towing 0278.

The hitch should be in the pickup bed so

that its centerline is over or slightly in front

of the rear axle. Take care that it is not so

far forward that it will contact the back of

the cab in sharp turns. This is especially

important for short box pickups. Trailer pin

box extensions and sliding fifth-wheel hitch

assemblies may be used. There should be at

least 15 cm (6 in) of clearance between the

top of the pickup box and the bottom of the

trailer shelf that extends over the box.

Make sure the hitch is attached to the tow

vehicle frame rails. Do not use the pickup

box for support.

Two Inch Adapter Sleeve and

Retainer Pin

The 2500/3500 series vehicles are equipped

with a 2-1/2” square receiver. An adapter is

provided to allow the use of a 2” draw bar,

along with a hitch retainer pin, and

retainer clip.

Safety Chains

Always attach safety chains between the

vehicle and the trailer. Instructions about

safety chains may be provided by the hitch

manufacturer or by the trailer manufacturer.

If the trailer being towed weighs up to

2 271 kg (5,000 lb) with a factory-installed

step bumper, safety chains may be attached

Page 288 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Driving and Operating 287

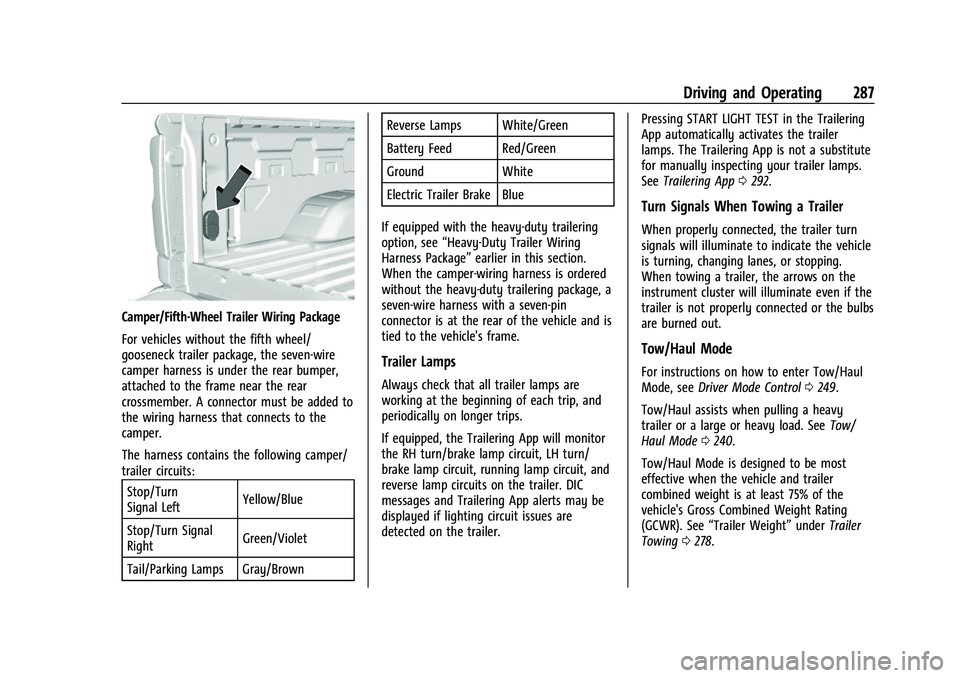

Camper/Fifth-Wheel Trailer Wiring Package

For vehicles without the fifth wheel/

gooseneck trailer package, the seven-wire

camper harness is under the rear bumper,

attached to the frame near the rear

crossmember. A connector must be added to

the wiring harness that connects to the

camper.

The harness contains the following camper/

trailer circuits:Stop/Turn

Signal Left Yellow/Blue

Stop/Turn Signal

Right Green/Violet

Tail/Parking Lamps Gray/Brown Reverse Lamps White/Green

Battery Feed Red/Green

Ground White

Electric Trailer Brake Blue

If equipped with the heavy-duty trailering

option, see “Heavy-Duty Trailer Wiring

Harness Package” earlier in this section.

When the camper-wiring harness is ordered

without the heavy-duty trailering package, a

seven-wire harness with a seven-pin

connector is at the rear of the vehicle and is

tied to the vehicle's frame.

Trailer Lamps

Always check that all trailer lamps are

working at the beginning of each trip, and

periodically on longer trips.

If equipped, the Trailering App will monitor

the RH turn/brake lamp circuit, LH turn/

brake lamp circuit, running lamp circuit, and

reverse lamp circuits on the trailer. DIC

messages and Trailering App alerts may be

displayed if lighting circuit issues are

detected on the trailer. Pressing START LIGHT TEST in the Trailering

App automatically activates the trailer

lamps. The Trailering App is not a substitute

for manually inspecting your trailer lamps.

See

Trailering App 0292.

Turn Signals When Towing a Trailer

When properly connected, the trailer turn

signals will illuminate to indicate the vehicle

is turning, changing lanes, or stopping.

When towing a trailer, the arrows on the

instrument cluster will illuminate even if the

trailer is not properly connected or the bulbs

are burned out.

Tow/Haul Mode

For instructions on how to enter Tow/Haul

Mode, see Driver Mode Control 0249.

Tow/Haul assists when pulling a heavy

trailer or a large or heavy load. See Tow/

Haul Mode 0240.

Tow/Haul Mode is designed to be most

effective when the vehicle and trailer

combined weight is at least 75% of the

vehicle's Gross Combined Weight Rating

(GCWR). See “Trailer Weight” underTrailer

Towing 0278.

Page 289 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

288 Driving and Operating

Tow/Haul Mode is most useful when towing

a heavy trailer or carrying a large or

heavy load:

.Through rolling terrain.

.In stop-and-go traffic.

.In busy parking lots.

Operating the vehicle in Tow/Haul Mode

when lightly loaded or not towing will not

cause damage; however, it is not

recommended and may result in unpleasant

engine and transmission driving

characteristics, heavy or light steering

efforts, and reduced fuel economy.

Integrated Trailer Brake Control System

The vehicle may have an Integrated Trailer

Brake Control (ITBC) system for use with

electric trailer brakes or most electric over

hydraulic trailer brake systems. These

instructions apply to both types of electric

trailer brakes.

This symbol is on the Trailer Brake Control

Panel on vehicles with an ITBC system. The

power output to the trailer brakes is

proportional to the amount of vehicle

braking. This available power output to the

trailer brakes can be adjusted to a wide

range of trailering situations.

The ITBC system is integrated with the

vehicle’s brake, antilock brake, and

StabiliTrak/Electronic Stability Control (ESC)

systems. In trailering conditions that cause

the vehicle’s antilock brake or StabiliTrak/

ESC systems to activate, power sent to the

trailer's brakes will be automatically

adjusted to minimize trailer wheel lock-up.

This does not imply that the trailer has

StabiliTrak/ESC.

If the vehicle’s brake, antilock brake,

or StabiliTrak/ESC systems are not

functioning properly, the ITBC system may

not function fully or at all. Make sure all of

these systems are fully operational to allow

the ITBC system to function properly.

The ITBC system is powered through the

vehicle's electrical system. Turning the

ignition off will also turn off the ITBC

system. The ITBC system is fully functional

only when the ignition is in on.{Warning

Connecting a trailer that has an air brake

system may result in reduced or

complete loss of trailer braking, including

increased stopping distance or trailer

instability which could result in serious

injury, death, or property damage. Only

use the ITBC system with electric or

electric over hydraulic trailer brake

systems.

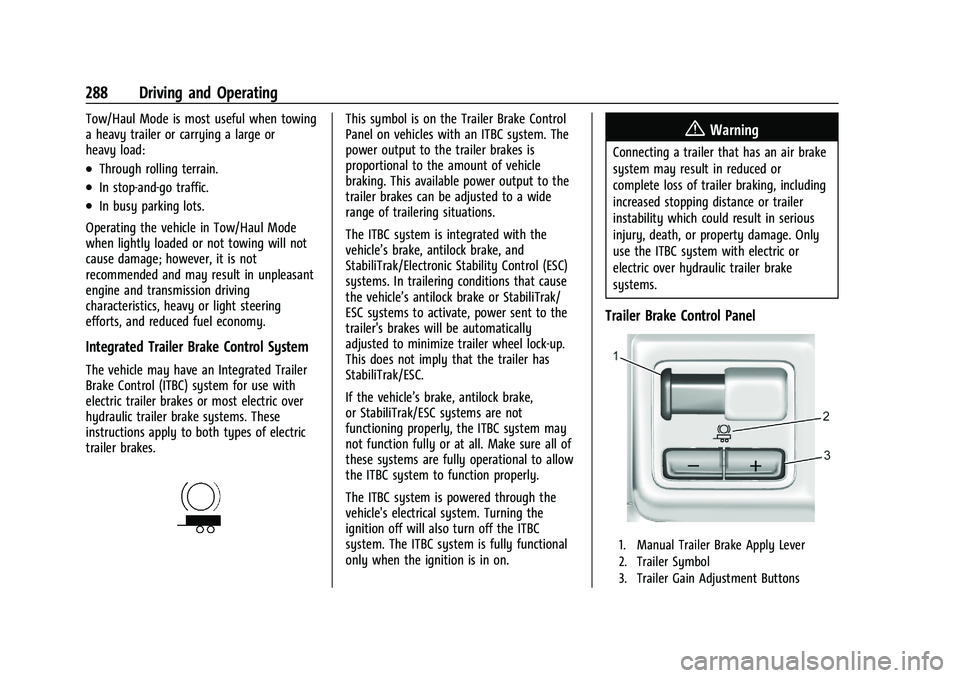

Trailer Brake Control Panel

1. Manual Trailer Brake Apply Lever

2. Trailer Symbol

3. Trailer Gain Adjustment Buttons

Page 291 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

290 Driving and Operating

To adjust Trailer Gain for each towing

condition:1. Drive the vehicle with the trailer attached on a level road surface

representative of the towing condition

and free of traffic at about 32–40 km/h

(20–25 mph) and fully apply the Manual

Trailer Brake Apply Lever.

Adjusting Trailer Gain at speeds lower

than 32–40 km/h (20–25 mph) may

result in an incorrect gain setting.

2. Adjust the Trailer Gain, using the Trailer Gain (+) or (−) adjustment buttons, to

just below the point of trailer wheel

lock-up, indicated by trailer wheel squeal

or tire smoke when a trailer wheel locks.

Trailer wheel lock-up may not occur if

towing a heavily loaded trailer. Adjust

the Trailer Gain to the highest allowable

setting for the towing condition.

3. Readjust Trailer Gain anytime vehicle loading, trailer loading, or road surface

conditions change or if trailer wheel

lock-up is noticed at any time while

towing.Other ITBC-Related DIC Messages

TRAILER CONNECTED: This message will

briefly display when a trailer with electric

brakes is first connected to the vehicle. This

message will automatically turn off in about

10 seconds. This message can be

acknowledged before it automatically

turns off.

CHECK TRAILER WIRING: This message will

display if:

.The ITBC system first determines

connection to a trailer with electric brakes

and then the trailer harness becomes

disconnected from the vehicle.

If the disconnect occurs while the vehicle

is stationary, this message will

automatically turn off in about

30 seconds. This message will also turn

off if it is acknowledged or if the trailer

harness is reconnected.

If the disconnect occurs while the vehicle

is moving, this message will continue

until the ignition is turned off. This

message will also turn off if it is

acknowledged or if the trailer harness is

reconnected.

.There is an electrical fault in the wiring to

the trailer brakes. This message will

continue as long as there is an electrical

fault in the trailer wiring. This message

will also turn off if it is acknowledged.

To determine whether the electrical fault is

on the vehicle side or trailer side of the

trailer wiring harness connection: 1. Disconnect the trailer wiring harness from the vehicle.

2. Turn the ignition off.

3. Wait 10 seconds, then turn the ignition back to RUN.

4. If the CHECK TRAILER WIRING message reappears, the electrical fault is on the

vehicle side.

If the CHECK TRAILER WIRING message only

reappears when connecting the trailer wiring

harness to the vehicle, the electrical fault is

on the trailer side.

SERVICE TRAILER BRAKE SYSTEM: This

message will display when there is a

problem with the ITBC system. If this

message continues over multiple ignition

cycles, have the vehicle serviced.

Page 292 of 441

Chevrolet Silverado 2500 HD/3500 HD Owner Manual (GMNA-Localizing-U.

S./Canada/Mexico-15546003) - 2022 - CRC - 5/5/21

Driving and Operating 291

If either the CHECK TRAILER WIRING or

SERVICE TRAILER BRAKE SYSTEM message

displays while driving, the ITBC system may

not be fully functional or may not function

at all. When traffic conditions allow,

carefully pull the vehicle over to the side of

the road and turn the ignition off. Check the

wiring connection to the trailer and turn the

ignition back on. If either of these messages

continues, either the vehicle or trailer needs

service.

A GM dealer may be able to diagnose and

repair problems with the trailer. However,

any diagnosis and repair of the trailer is not

covered under the vehicle warranty. Contact

your trailer dealer for assistance with trailer

repairs and trailer warranty information.

Trailer Sway Control (TSC)

Vehicles with StabiliTrak/Electronic Stability

Control (ESC) have a Trailer Sway Control

(TSC) feature. Trailer sway is unintended

side-to-side motion of a trailer while towing.

If the vehicle is towing a trailer and the TSC

detects that sway is increasing, the vehicle

brakes are selectively applied at each wheel,

to help reduce excessive trailer sway.

If equipped with the Integrated Trailer BrakeControl (ITBC) system, and the trailer has an

electric brake system, StabiliTrak/ESC may

also apply the trailer brakes.

If TSC is enabled, the Traction Control

System (TCS)/StabiliTrak/ESC warning light

will flash on the instrument cluster. Reduce

vehicle speed by gradually removing your

foot from the accelerator. If trailer sway

continues, StabiliTrak/ESC can reduce engine

torque to help slow the vehicle. TSC will not

function if StabiliTrak/ESC is turned off. See

Traction Control/Electronic Stability Control

0

247.

{Warning

Trailer sway can result in a crash and in

serious injury or death, even if the

vehicle is equipped with TSC.

If the trailer begins to sway, reduce

vehicle speed by gradually removing your

foot from the accelerator. Then pull over

to check the trailer and vehicle to help

correct possible causes, including an

improperly or overloaded trailer,

unrestrained cargo, improper trailer hitch

configuration, or improperly inflated or

incorrect vehicle or trailer tires. See

Towing Equipment 0281 for trailer

ratings and hitch setup recommendations.

Aftermarket Electronic Trailer Sway

Control Devices

Some trailers may come equipped with an

electronic device designed to reduce or

control trailer sway. Aftermarket equipment

manufacturers also offer similar devices that

connect to the wiring between the trailer

and the vehicle. These devices may interfere

with the vehicle’s trailer brake or other

systems, including integrated anti-sway

systems, if equipped. Messages related to