clock CHEVROLET SPARK 2013 3.G User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2013, Model line: SPARK, Model: CHEVROLET SPARK 2013 3.GPages: 350, PDF Size: 5.89 MB

Page 179 of 350

Black plate (3,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

Climate Controls 8-3

Air Vents

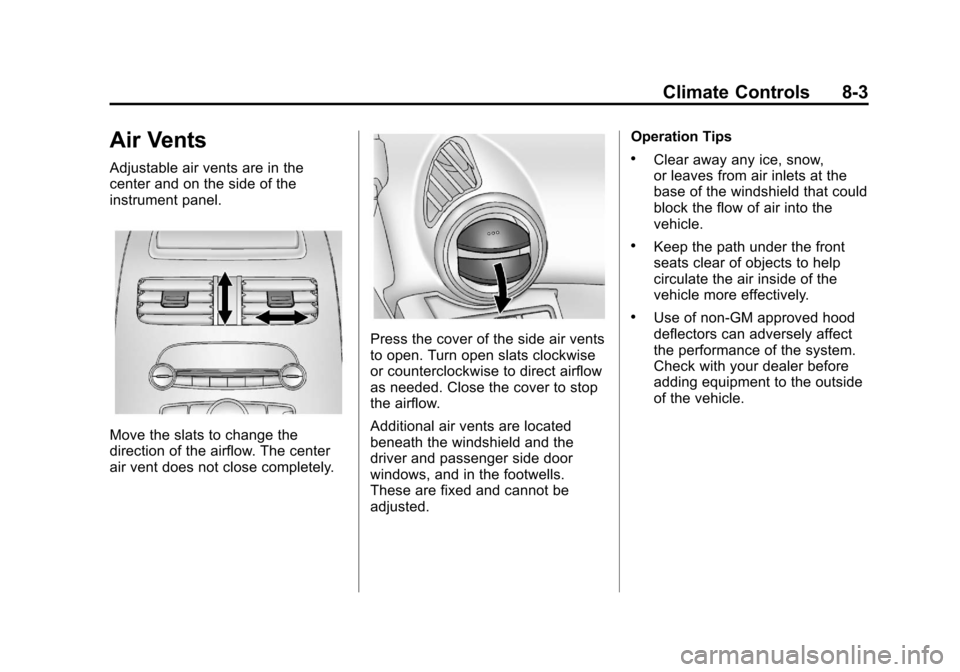

Adjustable air vents are in the

center and on the side of the

instrument panel.

Move the slats to change the

direction of the airflow. The center

air vent does not close completely.

Press the cover of the side air vents

to open. Turn open slats clockwise

or counterclockwise to direct airflow

as needed. Close the cover to stop

the airflow.

Additional air vents are located

beneath the windshield and the

driver and passenger side door

windows, and in the footwells.

These are fixed and cannot be

adjusted.Operation Tips

.Clear away any ice, snow,

or leaves from air inlets at the

base of the windshield that could

block the flow of air into the

vehicle.

.Keep the path under the front

seats clear of objects to help

circulate the air inside of the

vehicle more effectively.

.Use of non-GM approved hood

deflectors can adversely affect

the performance of the system.

Check with your dealer before

adding equipment to the outside

of the vehicle.

Page 215 of 350

Black plate (35,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

Driving and Operating 9-35

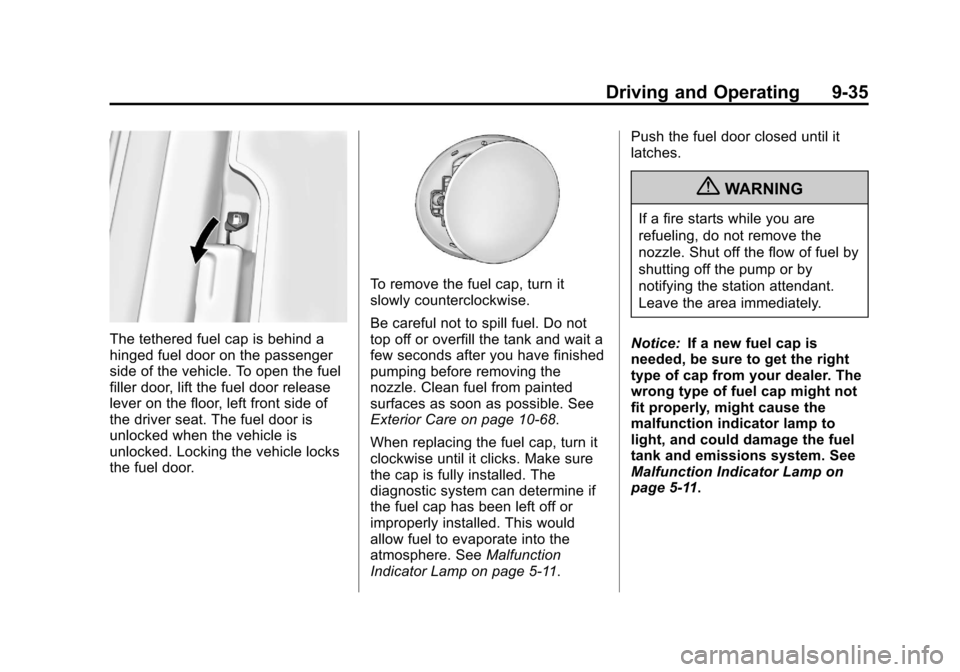

The tethered fuel cap is behind a

hinged fuel door on the passenger

side of the vehicle. To open the fuel

filler door, lift the fuel door release

lever on the floor, left front side of

the driver seat. The fuel door is

unlocked when the vehicle is

unlocked. Locking the vehicle locks

the fuel door.

To remove the fuel cap, turn it

slowly counterclockwise.

Be careful not to spill fuel. Do not

top off or overfill the tank and wait a

few seconds after you have finished

pumping before removing the

nozzle. Clean fuel from painted

surfaces as soon as possible. See

Exterior Care on page 10‑68.

When replacing the fuel cap, turn it

clockwise until it clicks. Make sure

the cap is fully installed. The

diagnostic system can determine if

the fuel cap has been left off or

improperly installed. This would

allow fuel to evaporate into the

atmosphere. SeeMalfunction

Indicator Lamp on page 5‑11. Push the fuel door closed until it

latches.

{WARNING

If a fire starts while you are

refueling, do not remove the

nozzle. Shut off the flow of fuel by

shutting off the pump or by

notifying the station attendant.

Leave the area immediately.

Notice: If a new fuel cap is

needed, be sure to get the right

type of cap from your dealer. The

wrong type of fuel cap might not

fit properly, might cause the

malfunction indicator lamp to

light, and could damage the fuel

tank and emissions system. See

Malfunction Indicator Lamp on

page 5‑11.

Page 233 of 350

Black plate (15,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

Vehicle Care 10-15

WARNING (Continued)

could catch fire and you

or others could be burned. Use a

50/50 mixture of clean, drinkable

water and DEX-COOL coolant.

Notice: In cold weather, water

can freeze and crack the engine,

radiator, heater core and other

parts. Use the recommended

coolant and the proper coolant

mixture.

{WARNING

You can be burned if you spill

coolant on hot engine parts.

Coolant contains ethylene glycol

and it will burn if the engine parts

are hot enough. Do not spill

coolant on a hot engine.

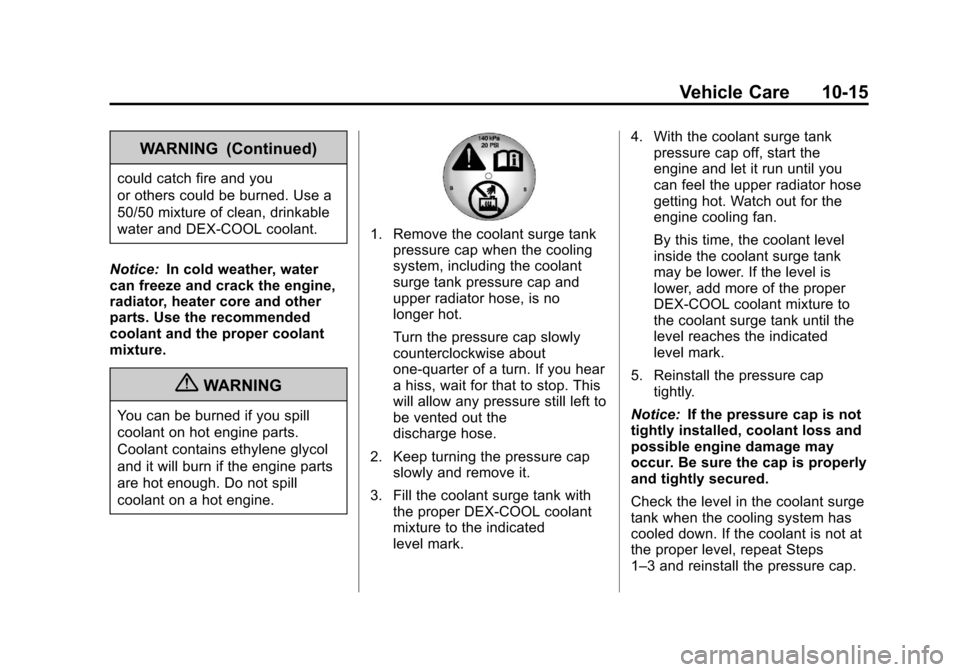

1. Remove the coolant surge tank pressure cap when the cooling

system, including the coolant

surge tank pressure cap and

upper radiator hose, is no

longer hot.

Turn the pressure cap slowly

counterclockwise about

one-quarter of a turn. If you hear

a hiss, wait for that to stop. This

will allow any pressure still left to

be vented out the

discharge hose.

2. Keep turning the pressure cap slowly and remove it.

3. Fill the coolant surge tank with the proper DEX-COOL coolant

mixture to the indicated

level mark. 4. With the coolant surge tank

pressure cap off, start the

engine and let it run until you

can feel the upper radiator hose

getting hot. Watch out for the

engine cooling fan.

By this time, the coolant level

inside the coolant surge tank

may be lower. If the level is

lower, add more of the proper

DEX-COOL coolant mixture to

the coolant surge tank until the

level reaches the indicated

level mark.

5. Reinstall the pressure cap tightly.

Notice: If the pressure cap is not

tightly installed, coolant loss and

possible engine damage may

occur. Be sure the cap is properly

and tightly secured.

Check the level in the coolant surge

tank when the cooling system has

cooled down. If the coolant is not at

the proper level, repeat Steps

1–3 and reinstall the pressure cap.

Page 242 of 350

Black plate (24,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

10-24 Vehicle Care

Bulb Replacement

For the proper type of replacement

bulbs, seeReplacement Bulbs on

page 10‑26.

For any bulb‐changing procedure

not listed in this section, contact

your dealer.

Halogen Bulbs

{WARNING

Halogen bulbs have pressurized

gas inside and can burst if you

drop or scratch the bulb. You or

others could be injured. Be sure

to read and follow the instructions

on the bulb package.

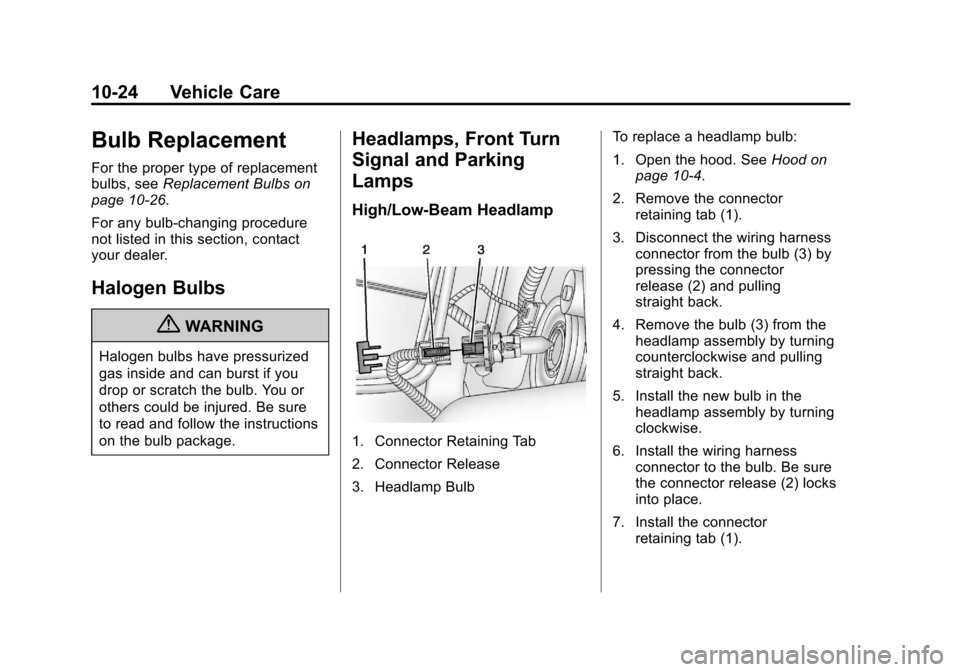

Headlamps, Front Turn

Signal and Parking

Lamps

High/Low-Beam Headlamp

1. Connector Retaining Tab

2. Connector Release

3. Headlamp Bulb To replace a headlamp bulb:

1. Open the hood. See

Hood on

page 10‑4.

2. Remove the connector retaining tab (1).

3. Disconnect the wiring harness connector from the bulb (3) by

pressing the connector

release (2) and pulling

straight back.

4. Remove the bulb (3) from the headlamp assembly by turning

counterclockwise and pulling

straight back.

5. Install the new bulb in the headlamp assembly by turning

clockwise.

6. Install the wiring harness connector to the bulb. Be sure

the connector release (2) locks

into place.

7. Install the connector retaining tab (1).

Page 243 of 350

Black plate (25,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

Vehicle Care 10-25

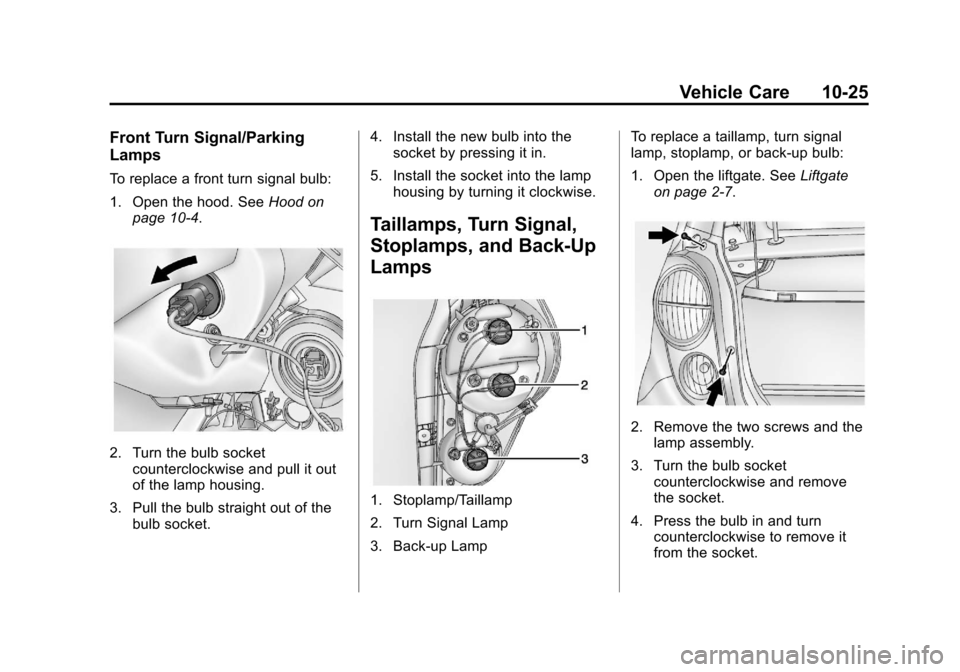

Front Turn Signal/Parking

Lamps

To replace a front turn signal bulb:

1. Open the hood. SeeHood on

page 10‑4.

2. Turn the bulb socket counterclockwise and pull it out

of the lamp housing.

3. Pull the bulb straight out of the bulb socket. 4. Install the new bulb into the

socket by pressing it in.

5. Install the socket into the lamp housing by turning it clockwise.

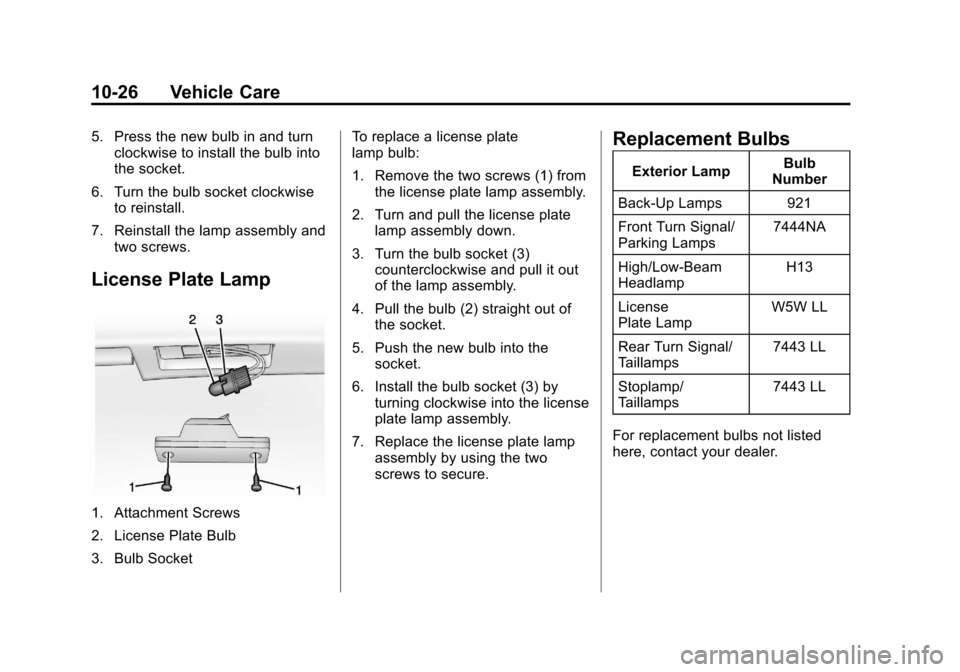

Taillamps, Turn Signal,

Stoplamps, and Back-Up

Lamps

1. Stoplamp/Taillamp

2. Turn Signal Lamp

3. Back-up Lamp To replace a taillamp, turn signal

lamp, stoplamp, or back-up bulb:

1. Open the liftgate. See

Liftgate

on page 2‑7.

2. Remove the two screws and the lamp assembly.

3. Turn the bulb socket counterclockwise and remove

the socket.

4. Press the bulb in and turn counterclockwise to remove it

from the socket.

Page 244 of 350

Black plate (26,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

10-26 Vehicle Care

5. Press the new bulb in and turnclockwise to install the bulb into

the socket.

6. Turn the bulb socket clockwise to reinstall.

7. Reinstall the lamp assembly and two screws.

License Plate Lamp

1. Attachment Screws

2. License Plate Bulb

3. Bulb Socket To replace a license plate

lamp bulb:

1. Remove the two screws (1) from

the license plate lamp assembly.

2. Turn and pull the license plate lamp assembly down.

3. Turn the bulb socket (3) counterclockwise and pull it out

of the lamp assembly.

4. Pull the bulb (2) straight out of the socket.

5. Push the new bulb into the socket.

6. Install the bulb socket (3) by turning clockwise into the license

plate lamp assembly.

7. Replace the license plate lamp assembly by using the two

screws to secure.

Replacement Bulbs

Exterior Lamp Bulb

Number

Back-Up Lamps 921

Front Turn Signal/

Parking Lamps 7444NA

High/Low-Beam

Headlamp H13

License

Plate Lamp W5W LL

Rear Turn Signal/

Taillamps 7443 LL

Stoplamp/

Taillamps 7443 LL

For replacement bulbs not listed

here, contact your dealer.

Page 275 of 350

Black plate (57,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

Vehicle Care 10-57

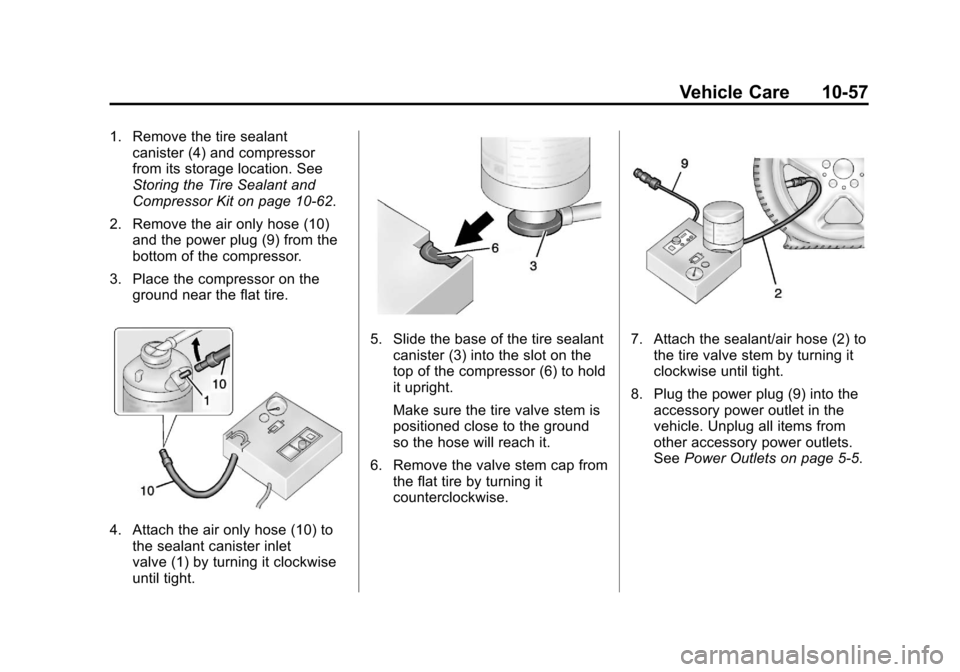

1. Remove the tire sealantcanister (4) and compressor

from its storage location. See

Storing the Tire Sealant and

Compressor Kit on page 10‑62.

2. Remove the air only hose (10) and the power plug (9) from the

bottom of the compressor.

3. Place the compressor on the ground near the flat tire.

4. Attach the air only hose (10) tothe sealant canister inlet

valve (1) by turning it clockwise

until tight.

5. Slide the base of the tire sealant

canister (3) into the slot on the

top of the compressor (6) to hold

it upright.

Make sure the tire valve stem is

positioned close to the ground

so the hose will reach it.

6. Remove the valve stem cap from the flat tire by turning it

counterclockwise.7. Attach the sealant/air hose (2) tothe tire valve stem by turning it

clockwise until tight.

8. Plug the power plug (9) into the accessory power outlet in the

vehicle. Unplug all items from

other accessory power outlets.

See Power Outlets on page 5‑5.

Page 276 of 350

Black plate (58,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

10-58 Vehicle Care

If the vehicle has an accessory

power outlet, do not use the

cigarette lighter.

If the vehicle only has a cigarette

lighter, use the cigarette lighter.

Do not pinch the power plug

cord in the door or window.

9. Start the vehicle. The vehicle must be running while using the

air compressor.

10. Press the on/off button (5) to turn the tire sealant and

compressor kit on.

The compressor will inject

sealant and air into the tire.

The pressure gauge (7) will

initially show a high pressure

while the compressor pushes

the sealant into the tire. Once

the sealant is completely

dispersed into the tire, the

pressure will quickly drop and

start to rise again as the tire

inflates with air only. 11. Inflate the tire to the

recommended inflation

pressure using the pressure

gauge (7). The recommended

inflation pressure can be found

on the Tire and Loading

Information label. See Tire

Pressure on page 10‑41.

The pressure gauge (7) may

read higher than the actual tire

pressure while the compressor

is on. Turn the compressor off

to get an accurate pressure

reading. The compressor may

be turned on/off until the

correct pressure is reached.

Notice: If the recommended

pressure cannot be reached after

approximately 25 minutes, the

vehicle should not be driven

farther. The tire is too severely

damaged and the tire sealant and

compressor kit cannot inflate the

tire. Remove the power plug from

the accessory power outlet and

unscrew the inflating hose from the tire valve. See

Roadside

Assistance Program on

page 13‑5.

12. Press the on/off button (5) to

turn the tire sealant and

compressor kit off.

The tire is not sealed and will

continue to leak air until the

vehicle is driven and the

sealant is distributed in the tire.

Therefore, Steps 13–21 must

be done immediately after

Step 12.

Be careful while handling the

tire sealant and compressor kit

as it could be warm after

usage.

13. Unplug the power plug (9) from the accessory power outlet in

the vehicle.

14. Turn the sealant/air hose (2) counterclockwise to remove it

from the tire valve stem.

Page 277 of 350

Black plate (59,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

Vehicle Care 10-59

15. Replace the tire valvestem cap.

16. Remove the tire sealant canister (4) from the slot on top

of the compressor (6).

17. Turn the air only hose (10) counterclockwise to remove it

from the tire sealant canister

inlet valve (1).

18. Turn the sealant/air hose (2) clockwise onto the sealant

canister inlet valve (1) to

prevent sealant leakage.

19. Return the air only hose (10) and power plug (9) back to

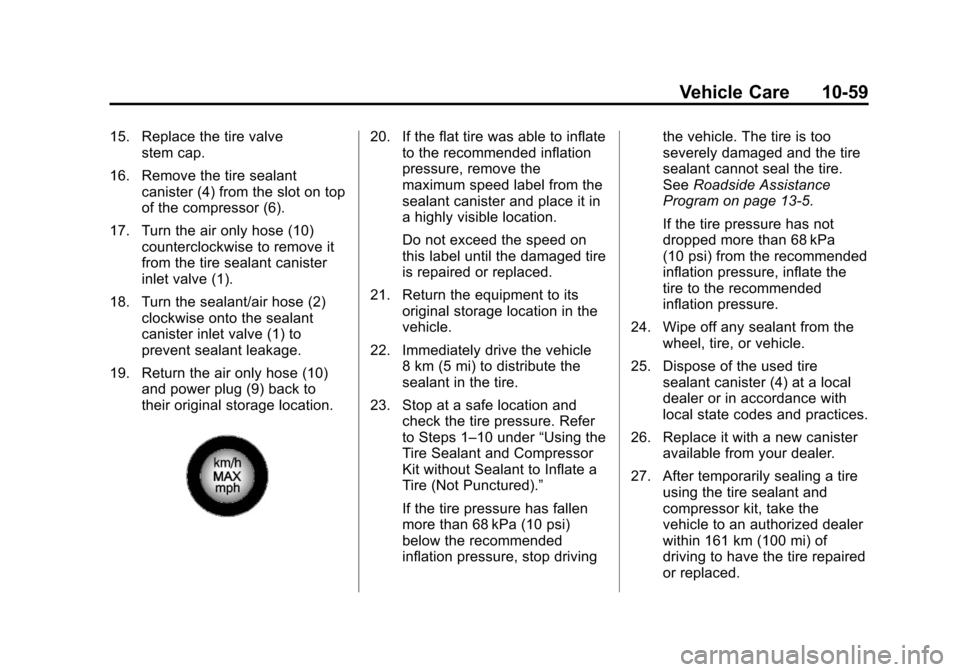

their original storage location.20. If the flat tire was able to inflateto the recommended inflation

pressure, remove the

maximum speed label from the

sealant canister and place it in

a highly visible location.

Do not exceed the speed on

this label until the damaged tire

is repaired or replaced.

21. Return the equipment to its original storage location in the

vehicle.

22. Immediately drive the vehicle 8 km (5 mi) to distribute the

sealant in the tire.

23. Stop at a safe location and check the tire pressure. Refer

to Steps 1–10 under “Using the

Tire Sealant and Compressor

Kit without Sealant to Inflate a

Tire (Not Punctured).”

If the tire pressure has fallen

more than 68 kPa (10 psi)

below the recommended

inflation pressure, stop driving the vehicle. The tire is too

severely damaged and the tire

sealant cannot seal the tire.

See

Roadside Assistance

Program on page 13‑5.

If the tire pressure has not

dropped more than 68 kPa

(10 psi) from the recommended

inflation pressure, inflate the

tire to the recommended

inflation pressure.

24. Wipe off any sealant from the wheel, tire, or vehicle.

25. Dispose of the used tire sealant canister (4) at a local

dealer or in accordance with

local state codes and practices.

26. Replace it with a new canister available from your dealer.

27. After temporarily sealing a tire using the tire sealant and

compressor kit, take the

vehicle to an authorized dealer

within 161 km (100 mi) of

driving to have the tire repaired

or replaced.

Page 278 of 350

Black plate (60,1)Chevrolet Spark Owner Manual - 2013 - crc - 9/11/12

10-60 Vehicle Care

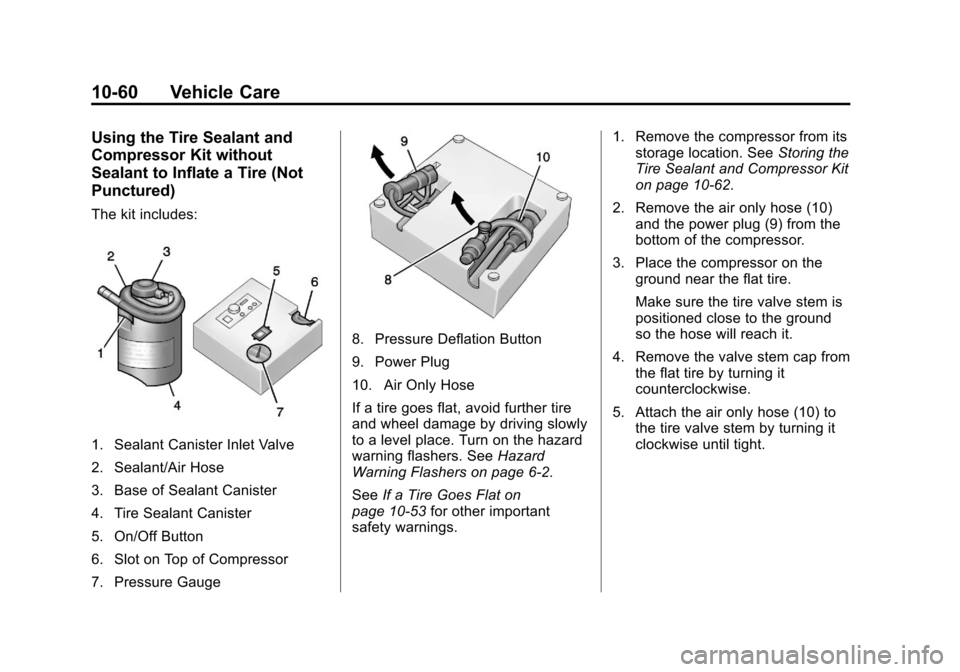

Using the Tire Sealant and

Compressor Kit without

Sealant to Inflate a Tire (Not

Punctured)

The kit includes:

1. Sealant Canister Inlet Valve

2. Sealant/Air Hose

3. Base of Sealant Canister

4. Tire Sealant Canister

5. On/Off Button

6. Slot on Top of Compressor

7. Pressure Gauge

8. Pressure Deflation Button

9. Power Plug

10. Air Only Hose

If a tire goes flat, avoid further tire

and wheel damage by driving slowly

to a level place. Turn on the hazard

warning flashers. SeeHazard

Warning Flashers on page 6‑2.

See If a Tire Goes Flat on

page 10‑53 for other important

safety warnings. 1. Remove the compressor from its

storage location. See Storing the

Tire Sealant and Compressor Kit

on page 10‑62.

2. Remove the air only hose (10) and the power plug (9) from the

bottom of the compressor.

3. Place the compressor on the ground near the flat tire.

Make sure the tire valve stem is

positioned close to the ground

so the hose will reach it.

4. Remove the valve stem cap from the flat tire by turning it

counterclockwise.

5. Attach the air only hose (10) to the tire valve stem by turning it

clockwise until tight.