engine CHEVROLET SSR 2006 1.G Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2006, Model line: SSR, Model: CHEVROLET SSR 2006 1.GPages: 390, PDF Size: 2.44 MB

Page 282 of 390

What to Add

When you do need brake fluid, use only DOT-3 brake

fluid. Use new brake fluid from a sealed container

only. SeeRecommended Fluids and Lubricants on

page 6-12.

Always clean the brake fluid reservoir cap and the area

around the cap before removing it. This will help

keep dirt from entering the reservoir.

{CAUTION:

With the wrong kind of �uid in your brake

system, your brakes may not work well, or they

may not even work at all. This could cause a

crash. Always use the proper brake �uid.Notice:

Using the wrong �uid can badly damage brake

system parts. For example, just a few drops of

mineral-based oil, such as engine oil, in your

brake system can damage brake system parts so

badly that they will have to be replaced. Do not

let someone put in the wrong kind of �uid.

If you spill brake �uid on your vehicle’s painted

surfaces, the paint �nish can be damaged. Be

careful not to spill brake �uid on your vehicle. If

you do, wash it off immediately. SeeWashing

Your Vehicle on page 5-80.

5-34

Page 286 of 390

Notice:Jump starting your vehicle’s battery using

the engine compartment fuse block battery posts

can damage your vehicle. See item K in theEngine

Compartment Overview on page 5-12.Always

use the remote positive terminal and remote

negative terminal to jump start your vehicle’s

battery. See items A and H in theEngine

Compartment Overview on page 5-12

for location.4. Open the hoods and locate the positive (+) and

negative (−) terminal locations on the other

vehicle. Your vehicle has a remote positive (+) jump

starting terminal and a remote negative (−) jump

starting terminal. You should always use these

remote terminals instead of the terminals on

the battery.

The remote positive (+)

terminal is located inside

a red cover in the

engine compartment on

the passenger’s side of

the vehicle. See item A in

theEngine Compartment

Overview on page 5-12.

Press inward on the tabs located on the outboard

sides of the remote positive (+) terminal cover

and pull outward to access the terminal.

5-38

Page 287 of 390

The remote negative (−)

terminal is located near the

power steering fluid

reservoir. It is marked

GND (−). See item H in the

Engine Compartment

Overview on page 5-12for

more information on

location.

You will not see the battery of your vehicle under

the hood. It is located on the rear underside of

the vehicle. You will not need to access the battery

for jump starting. The remote positive (+) terminal

is for that purpose.

{CAUTION:

An electric fan can start up even when the

engine is not running and can injure you. Keep

hands, clothing and tools away from any

underhood electric fan.

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

�ashlight if you need more light.

Be sure the battery has enough water. You do

not need to add water to the battery installed

in your new vehicle. But if a battery has �ller

caps, be sure the right amount of �uid is there.

If it is low, add water to take care of that �rst.

If you do not, explosive gas could be present.

Battery �uid contains acid that can burn you.

Do not get it on you. If you accidentally get it

in your eyes or on your skin, �ush the place

with water and get medical help immediately.

{CAUTION:

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

parts once the engine is running.

5-39

Page 288 of 390

5. Check that the jumper cables do not have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (−) will go to a heavy,

unpainted metal engine part or to a remote

negative (−) terminal if the vehicle has one.

Do not connect positive (+) to negative (−)oryou

will get a short that would damage the battery

and maybe other parts too. And do not connect the

negative (−) cable to the negative (−) terminal on

the dead battery because this can cause sparks.

6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

7. Do not let the other end touch metal. Connect it to

the positive (+) terminal of the good battery. Use a

remote positive (+) terminal if the vehicle has one.8. Now connect the black negative (−) cable to the

negative (−) terminal of the good battery. Use a

remote negative (−) terminal if the vehicle has one.

Do not let the other end of the cable touch

anything until the next step. The other end of the

negative (−) cabledoes notgo to the dead battery. It

goes to a heavy, unpainted metal engine part or

to a remote negative (−) terminal on the vehicle with

the dead battery.

9. Connect the other end of the negative (−) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

Use a remote negative (−) terminal if the vehicle has

one. Your vehicle’s remote negative (−) terminal

is marked GND (−).

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery.

If it will not start after a few tries, it probably

needs service.

5-40

Page 289 of 390

Notice:If the jumper cables are connected or

removed in the wrong order, electrical shorting may

occur and damage the vehicle. The repairs would

not be covered by your warranty. Always connect

and remove the jumper cables in the correct

order, making sure that the cables do not touch

each other or other metal.

A. Dead Battery or Remote Positive (+) Terminal

B. Good Battery or Remote Positive (+) and Remote

Negative (−) Terminals

C. Heavy, Unpainted Metal Engine Part or Remote

Negative (−) Terminal (GND)To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the

other vehicle.

5. Return the remote positive (+) terminal cover to its

original position.

Jumper Cable Removal

5-41

Page 302 of 390

Tire Size

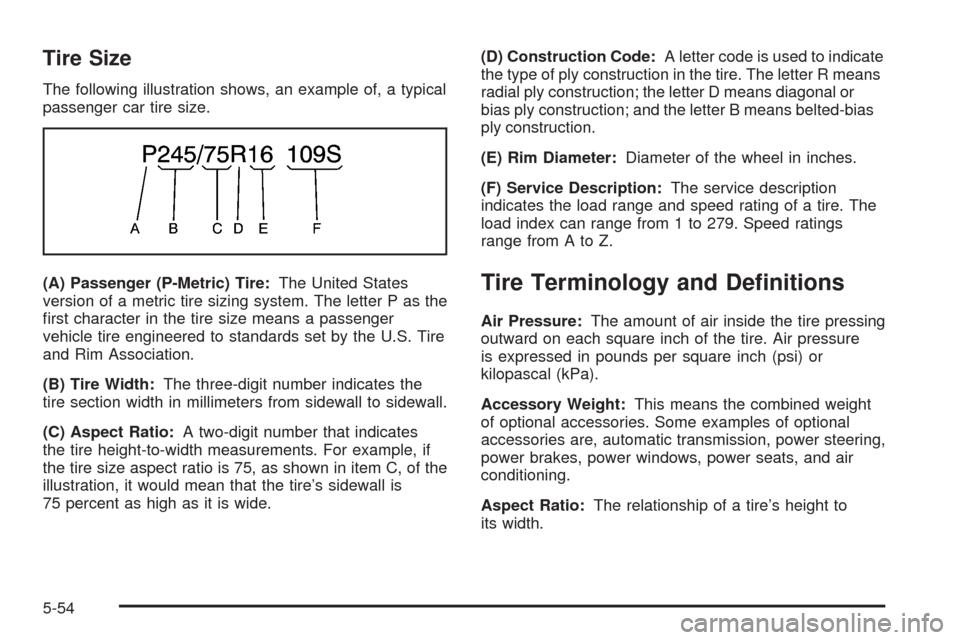

The following illustration shows, an example of, a typical

passenger car tire size.

(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter P as the

first character in the tire size means a passenger

vehicle tire engineered to standards set by the U.S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.

(C) Aspect Ratio:A two-digit number that indicates

the tire height-to-width measurements. For example, if

the tire size aspect ratio is 75, as shown in item C, of the

illustration, it would mean that the tire’s sidewall is

75 percent as high as it is wide.(D) Construction Code:A letter code is used to indicate

the type of ply construction in the tire. The letter R means

radial ply construction; the letter D means diagonal or

bias ply construction; and the letter B means belted-bias

ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a tire. The

load index can range from 1 to 279. Speed ratings

range from A to Z.

Tire Terminology and De�nitions

Air Pressure:The amount of air inside the tire pressing

outward on each square inch of the tire. Air pressure

is expressed in pounds per square inch (psi) or

kilopascal (kPa).

Accessory Weight:This means the combined weight

of optional accessories. Some examples of optional

accessories are, automatic transmission, power steering,

power brakes, power windows, power seats, and air

conditioning.

Aspect Ratio:The relationship of a tire’s height to

its width.

5-54

Page 315 of 390

If a Tire Goes Flat

Your vehicle has no spare tire, no tire changing

equipment and no place to store a tire.

It is unusual for a tire to blow out while you are driving,

especially if you maintain your tires properly. See

Tires on page 5-51. If air goes out of a tire, it’s much

more likely to leak out slowly. But if you should

ever have a blow out here are a few tips about what to

expect and what to do:

If a front tire fails, the flat tire will create a drag that

pulls the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blow out, particularly on a curve, acts much like

a skid and may require the same correction you

would use in a skid. In any rear blow out, remove your

foot from the accelerator pedal. Get the vehicle

under control by steering the way you want the vehicle

to go. It may be very bumpy and noisy, but you can

still steer. Gently brake to a stop, well off the road

if possible.If a tire goes flat, avoid further tire and wheel damage by

driving slowly to a level place and stopping. Then do this:

1. Turn on the hazard warning flashers.

2. Park your vehicle. If your vehicle has an automatic

transmission, set the parking brake firmly and put the

shift lever in PARK (P). SeeShifting Into Park (P) on

page 2-23for additional information. If your vehicle

has a manual transmission, move the shift lever to

REVERSE (R) and set the parking brake firmly. See

Parking Your Vehicle (Manual Transmission) on

page 2-25for additional information.

3. Turn off the engine.

4. Inspect the flat tire.

If the tire has been separated from the wheel or has

damaged sidewalls or large tears that allow rapid

air loss, call a tire repair facility. SeeRoadside

Assistance Program on page 7-6.

5-67

Page 318 of 390

3. Remove the valve stem cap from the flat tire by

turning it counterclockwise.

If an object, such as a nail, has penetrated the tire,

do not remove it.

4. Attach the sealant filling hose (A) onto the tire valve

stem. Turn it clockwise until it is tight.

Make sure the inflator kit on/off switch (B) is in the

O (off) position.5. Plug the air compressor accessory plug (C) into

an accessory power outlet in the vehicle. See

Accessory Power Outlet(s) on page 3-19for

more information.

{CAUTION:

Idling the engine in a closed-in place or with

the climate control system off can cause

deadly carbon monoxide (CO). SeeEngine

Exhaust on page 2-26.

6. Start the vehicle. SeeStarting the Engine on

page 2-17for more information. The vehicle must be

running while using the air compressor.

{CAUTION:

In�ating something too much can make it

explode, and you or others could be injured.

Be sure to read the in�ator instructions, and

in�ate the tire to its recommended pressure.

Do not exceed 36 psi (248 kPa).

5-70

Page 319 of 390

7. Move the inflator kit switch to the I (on) position.

The inflator kit will force sealant and air into the

tire. Sealant may leak from the puncture hole until

the vehicle is driven and the hole has sealed.

8. Make sure there is a proper connection between

the tire valve stem and the sealant filling hose by

looking at the air pressure gage. If there is not

a pressure reading while the compressor is running,

the connection between the inflator kit and the

tire is bad.

Check the attachment between the sealant filling

hose and the tire valve stem.

9. Inflate the tire up to the recommended inflation

pressure, found on the Tire and Loading

Information label located on the vehicle’s center

pillar (B-pillar) below the vehicle’s door latch,

using the air pressure gage on the top of the unit

as a guide.

The pressure gage reading is slightly high while the

compressor is on. Turn the compressor off to get

an accurate pressure reading.Notice:If the recommended pressure cannot be

reached after 15 minutes, the vehicle should not be

driven farther. Damage to the tire is severe and

the sealant will not be effective. Remove the

air compressor plug from the accessory power

outlet and unscrew the in�ating hose from the tire

valve. SeeRoadside Assistance Program on

page 7-6.

10. Move the inflator kit switch to the O (off) position

once the correct tire pressure is obtained.

11. Turn off the engine.

12. Unplug the air compressor accessory plug from the

accessory power outlet in the vehicle.

13. Disconnect the sealant filling hose from the tire

valve stem, by turning it counterclockwise, and

replace the tire valve stem cap.

Be careful when handling the tire inflator

components as they may be hot after usage.

14. Wrap the sealant filling hose around the air

compressor channel to stow it in its original location.

15. Stow the air compressor accessory plug back in the

air compressor. To do this, wrap the air compressor

accessory plug, snap in the plug, and then push

in the bottom and then the top of the wrapped

air compressor accessory plug.

5-71

Page 322 of 390

4. Push the air compressor inflator hose onto the

tire valve stem and push the lever down to

secure in place.

5. Plug the air compressor accessory plug into an

accessory power outlet in the vehicle. See

Accessory Power Outlet(s) on page 3-19for

more information.

{CAUTION:

Idling the engine in a closed-in place or with

the climate control system off can cause

deadly carbon monoxide (CO). SeeEngine

Exhaust on page 2-26.

6. Start the vehicle. SeeStarting the Engine on

page 2-17for more information. The vehicle must be

running while using the air compressor.

{CAUTION:

In�ating something too much can make it

explode, and you or others could be injured.

Be sure to read the in�ator instructions, and

in�ate the tire to its recommended pressure.

Do not exceed 36 psi (248 kPa).

7. Move the inflator kit switch to the I (on) position.

8. Make sure there is a proper connection between the

tire valve stem and the air compressor hose by

looking at the air pressure gage. If there is not a

pressure reading while the compressor is running,

the connection between the inflator kit and the

tire is bad.

Check the attachment between the air compressor

hose and the tire valve stem.

5-74