service CHEVROLET TRACKER 2004 2.G Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 2004, Model line: TRACKER, Model: CHEVROLET TRACKER 2004 2.GPages: 374, PDF Size: 2.57 MB

Page 236 of 374

How to Add Fluid

Here's how to add ¯uid. Refer to the Maintenance

Schedule to determine what kind of ¯uid to use. See

Part D: Recommended Fluids and Lubricants on

page 6-30.

1. Remove the ®ller plug.

2. Remove the drain plug, drain the ¯uid and reinstall

the drain plug.

3. Add ¯uid at the ®ller plug hole. Add only enough

¯uid to bring the ¯uid level up to the bottom of the

®ller plug hole.

4. Reinstall the ®ller plug. Be sure the plug is fully

seated.

Hydraulic Clutch

It is not necessary to regularly check clutch ¯uid unless

you suspect there is a leak in the system. Adding

¯uid won't correct a leak.

A ¯uid loss in this system could indicate a problem.

Have the system inspected and repaired.

When to Check and What to Use

Refer to the Maintenance Schedule to determine how

often you should check the ¯uid level in your clutch

master cylinder reservoir and for the proper ¯uid. See

Part B: Owner Checks and Services on page 6-24andPart D: Recommended Fluids and Lubricants on

page 6-30.

5-24

Page 242 of 374

If No Steam Is Coming From Your

Engine

If you get an engine overheat warning but see or hear

no steam, the problem may not be too serious.

Sometimes the engine can get a little too hot when you:

·Climb a long hill on a hot day.

·Stop after high-speed driving.

·Idle for long periods in traffic.

·Tow a trailer.

If you get the overheat warning with no sign of steam,

try this for a minute or so:

1. In heavy traffic, let the engine idle in NEUTRAL (N)

while stopped. If it is safe to do so, pull off the road,

shift to PARK (P) or NEUTRAL (N) and let the

engine idle.

2. Turn on your heater to full hot at the highest fan

speed and open the window as necessary.If you no longer have the overheat warning, you can

drive. Just to be safe, drive slower for about 10 minutes.

If the warning doesn't come back on, you can drive

normally.

If the warning continues, pull over, stop, and park your

vehicle right away.

If there's still no sign of steam, push down the

accelerator until the engine speed is about twice as fast

as normal idle speed for at least three minutes while

you're parked. If you still have the warning,

turn off the

engine and get everyone out of the vehicleuntil it

cools down.

You may decide not to lift the hood but to get service

help right away.

5-30

Page 244 of 374

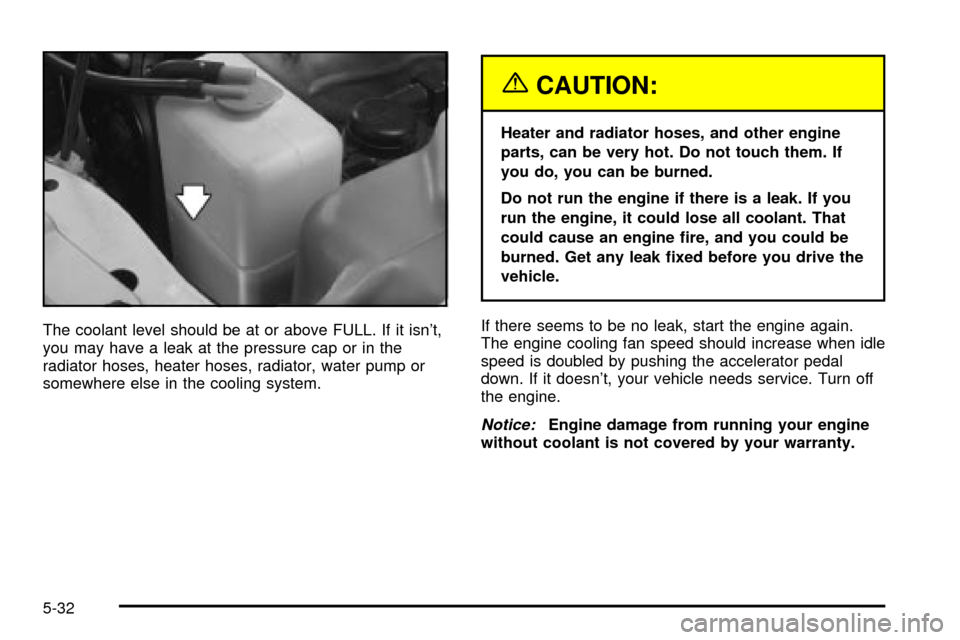

The coolant level should be at or above FULL. If it isn't,

you may have a leak at the pressure cap or in the

radiator hoses, heater hoses, radiator, water pump or

somewhere else in the cooling system.

{CAUTION:

Heater and radiator hoses, and other engine

parts, can be very hot. Do not touch them. If

you do, you can be burned.

Do not run the engine if there is a leak. If you

run the engine, it could lose all coolant. That

could cause an engine ®re, and you could be

burned. Get any leak ®xed before you drive the

vehicle.

If there seems to be no leak, start the engine again.

The engine cooling fan speed should increase when idle

speed is doubled by pushing the accelerator pedal

down. If it doesn't, your vehicle needs service. Turn off

the engine.

Notice:Engine damage from running your engine

without coolant is not covered by your warranty.

5-32

Page 253 of 374

Brake Wear

Your vehicle has front disc brakes and rear drum

brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads

are worn and new pads are needed. The sound

may come and go or be heard all the time your vehicle

is moving (except when you are pushing on the

brake pedal ®rmly).

{CAUTION:

The brake wear warning sound means that

soon your brakes will not work well. That

could lead to an accident. When you hear the

brake wear warning sound, have your vehicle

serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are ®rst applied or lightly

applied. This does not mean something is wrong with

your brakes.Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque speci®cations.

Your rear drum brakes do not have wear indicators, but

if you ever hear a rear brake rubbing noise, have the

rear brake linings inspected immediately. Also, the rear

brake drums should be removed and inspected each

time the tires are removed for rotation or changing.

When you have the front brake pads replaced, have the

rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

See

Brake System Inspection on page 6-29.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

5-41

Page 258 of 374

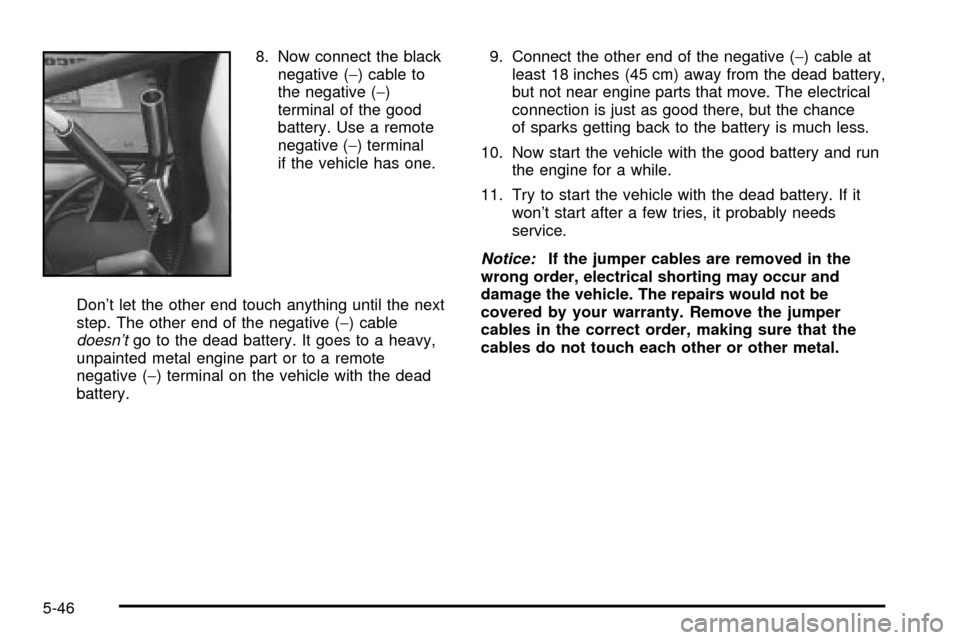

8. Now connect the black

negative (-) cable to

the negative (-)

terminal of the good

battery. Use a remote

negative (-) terminal

if the vehicle has one.

Don't let the other end touch anything until the next

step. The other end of the negative (-) cable

doesn'tgo to the dead battery. It goes to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal on the vehicle with the dead

battery.9. Connect the other end of the negative (-) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, but the chance

of sparks getting back to the battery is much less.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle with the dead battery. If it

won't start after a few tries, it probably needs

service.

Notice:If the jumper cables are removed in the

wrong order, electrical shorting may occur and

damage the vehicle. The repairs would not be

covered by your warranty. Remove the jumper

cables in the correct order, making sure that the

cables do not touch each other or other metal.

5-46

Page 260 of 374

Rear Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine

how often to check the lubricant and when to change it.

See

Part C: Periodic Maintenance Inspections on

page 6-28andPart A: Scheduled Maintenance Services

on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you'll need to add some lubricant.

1. Remove the ®ller plug.

2. Remove the drain plug, drain the lubricant and

reinstall the drain plug.

3. Add enough lubricant to raise the level to the

bottom of the ®ller plug hole.

4. Reinstall the ®ller plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-30.

5-48

Page 261 of 374

Four-Wheel Drive

Most lubricant checks in this section also apply to

four-wheel-drive vehicles. However, they have

two additional systems that need lubrication.

Transfer Case

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Part A: Scheduled Maintenance Services on page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you'll need to add some lubricant. Add enough lubricant

to raise the level to the bottom of the ®ller plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-30.

5-49

Page 262 of 374

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it. See

Part C: Periodic Maintenance Inspections on page 6-28andPart A: Scheduled Maintenance Services on

page 6-4.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you may need to add some lubricant.

1. Remove the ®ller plug.

2. Remove the drain plug, drain the lubricant and

reinstall the drain plug.

3. When the differential is cold, add enough lubricant

to raise the level to 1/2 inch (12 mm) below the ®ller

plug hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level

to the bottom of the ®ller plug hole.

4. Reinstall the ®ller plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant to use. SeePart D: Recommended

Fluids and Lubricants on page 6-30.

5-50

Page 267 of 374

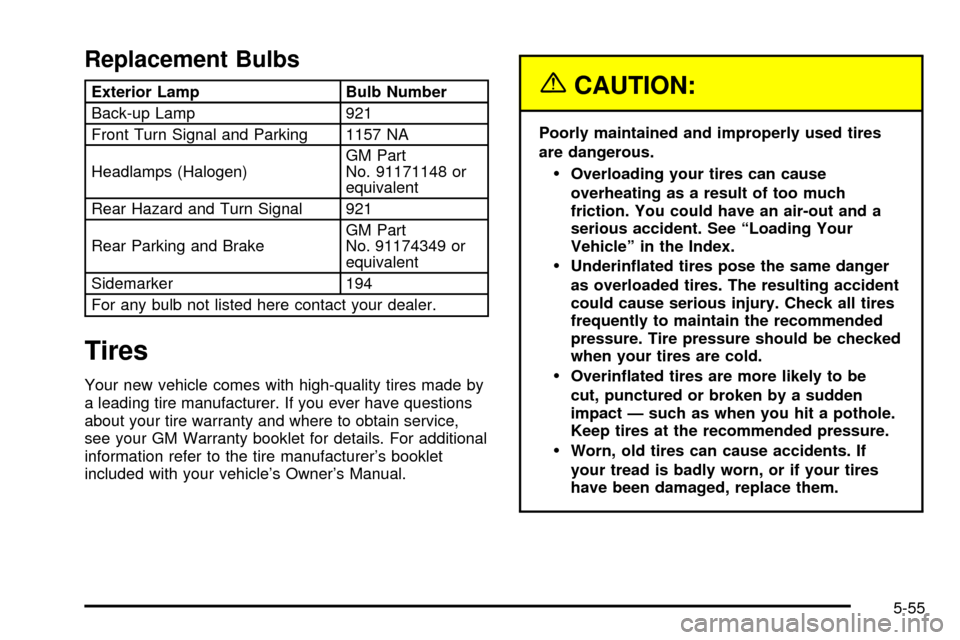

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up Lamp 921

Front Turn Signal and Parking 1157 NA

Headlamps (Halogen)GM Part

No. 91171148 or

equivalent

Rear Hazard and Turn Signal 921

Rear Parking and BrakeGM Part

No. 91174349 or

equivalent

Sidemarker 194

For any bulb not listed here contact your dealer.

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer. If you ever have questions

about your tire warranty and where to obtain service,

see your GM Warranty booklet for details. For additional

information refer to the tire manufacturer's booklet

included with your vehicle's Owner's Manual.

{CAUTION:

Poorly maintained and improperly used tires

are dangerous.

·Overloading your tires can cause

overheating as a result of too much

friction. You could have an air-out and a

serious accident. See ªLoading Your

Vehicleº in the Index.

·Underin¯ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

·Overin¯ated tires are more likely to be

cut, punctured or broken by a sudden

impact Ð such as when you hit a pothole.

Keep tires at the recommended pressure.

·Worn, old tires can cause accidents. If

your tread is badly worn, or if your tires

have been damaged, replace them.

5-55

Page 269 of 374

(A) Tire Size Code:The tire size code is a combination

of letters and numbers used to de®ne a particular

tire's width, height, aspect ratio, construction type and

service description. See the ªTire Size Codeº illustration

later in this section for more detail.

(B) Tire Performance Criteria Speci®cation (TPC

Spec):Original equipment tires designed to GM's

speci®c tire performance criteria have a TPC

speci®cation code molded onto the sidewall. GM's TPC

speci®cations meet or exceed all federal safety

guidelines.

(C) Department of Transportation (DOT):The

Department of Transportation (DOT) code indicates that

the tire is in compliance with the U.S. Department of

Transportation Motor Vehicle Safety Standards.(D) Tire Identi®cation Number (TIN):The letters and

numbers following DOT code are the Tire Identi®cation

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides of the

tire, although only one side may have the date of

manufacture.

(E) Tire Ply Material:The type of cord and number of

plies in the sidewall and under the tread.

(F) Uniform Tire Quality Grading (UTQG):Tire

manufacturers are required to grade tires based on three

performance factors: treadwear, traction and

temperature resistance. For more information, see

Uniform Tire Quality Grading on page 5-68.

(G) Maximum Cold In¯ation Load Limit:Maximum

load that can be carried and the maximum pressure

needed to support that load. For information on

recommended tire pressure see

In¯ation - Tire Pressure

on page 5-63andLoading Your Vehicle on page 4-51.

5-57