CHEVROLET UPLANDER 2009 1.G Owners Manual

Manufacturer: CHEVROLET, Model Year: 2009, Model line: UPLANDER, Model: CHEVROLET UPLANDER 2009 1.GPages: 464, PDF Size: 2.59 MB

Page 351 of 464

To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (−) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (−) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

5. Return the remote positive (+) terminal cover or

underhood fuse block cover to its original position.

Headlamp Aiming

Headlamp aim has been preset at the factory and

should need no further adjustment.

However, if your vehicle is damaged in a crash, the

headlamp aim may be affected. Aim adjustment to the

low-beam headlamps may be necessary if oncoming

drivers �ash their high-beam headlamps at you

(for vertical aim).

If the headlamps need to be re-aimed, it is

recommended that you take the vehicle to your

dealer/retailer for service.

Bulb Replacement

For the proper type of replacement bulbs, see

Replacement Bulbs on page 5-45.

For any bulb changing procedure not listed in this

section, contact your dealer/retailer.

Halogen Bulbs

{CAUTION:

Halogen bulbs have pressurized gas inside and

can burst if you drop or scratch the bulb. You or

others could be injured. Be sure to read and follow

the instructions on the bulb package.

5-41

Page 352 of 464

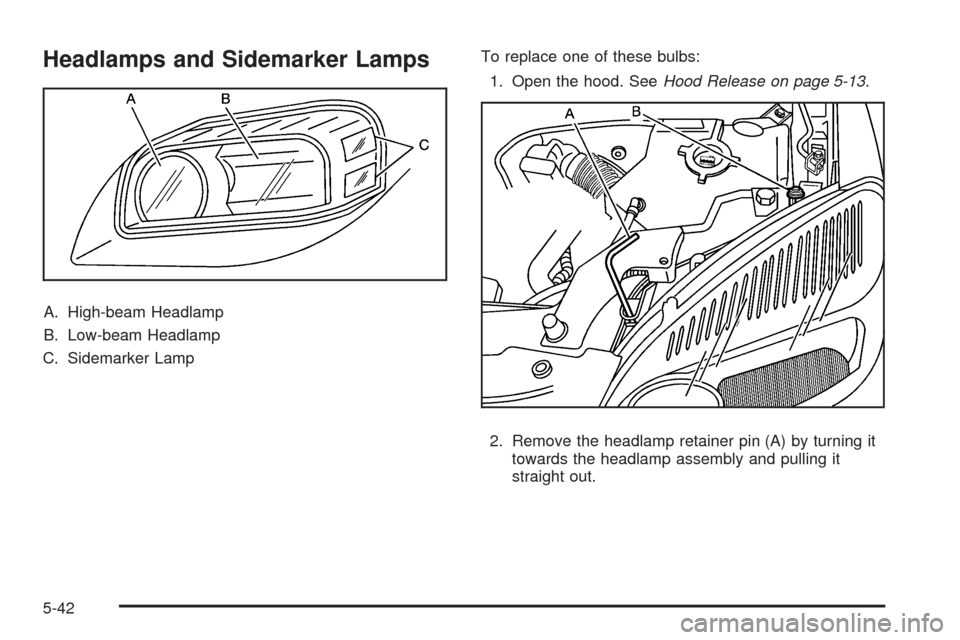

Headlamps and Sidemarker Lamps

A. High-beam Headlamp

B. Low-beam Headlamp

C. Sidemarker LampTo replace one of these bulbs:

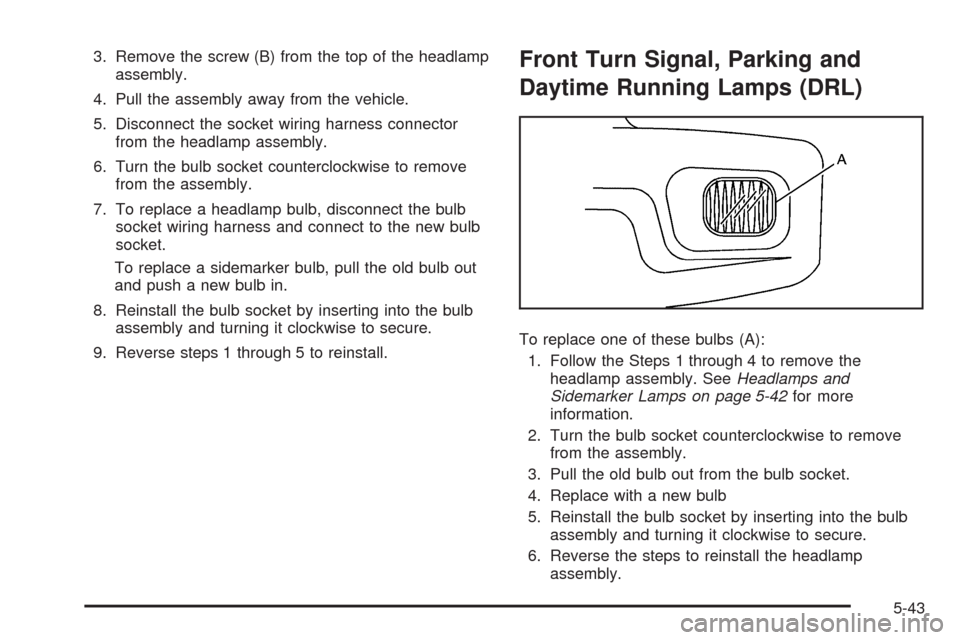

1. Open the hood. SeeHood Release on page 5-13.

2. Remove the headlamp retainer pin (A) by turning it

towards the headlamp assembly and pulling it

straight out.

5-42

Page 353 of 464

3. Remove the screw (B) from the top of the headlamp

assembly.

4. Pull the assembly away from the vehicle.

5. Disconnect the socket wiring harness connector

from the headlamp assembly.

6. Turn the bulb socket counterclockwise to remove

from the assembly.

7. To replace a headlamp bulb, disconnect the bulb

socket wiring harness and connect to the new bulb

socket.

To replace a sidemarker bulb, pull the old bulb out

and push a new bulb in.

8. Reinstall the bulb socket by inserting into the bulb

assembly and turning it clockwise to secure.

9. Reverse steps 1 through 5 to reinstall.Front Turn Signal, Parking and

Daytime Running Lamps (DRL)

To replace one of these bulbs (A):

1. Follow the Steps 1 through 4 to remove the

headlamp assembly. SeeHeadlamps and

Sidemarker Lamps on page 5-42for more

information.

2. Turn the bulb socket counterclockwise to remove

from the assembly.

3. Pull the old bulb out from the bulb socket.

4. Replace with a new bulb

5. Reinstall the bulb socket by inserting into the bulb

assembly and turning it clockwise to secure.

6. Reverse the steps to reinstall the headlamp

assembly.

5-43

Page 354 of 464

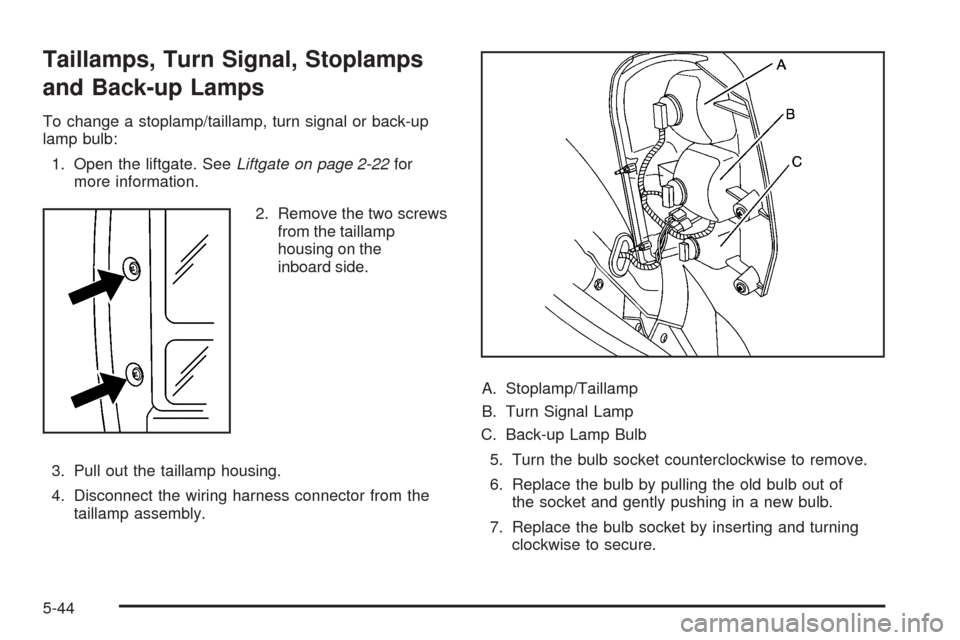

Taillamps, Turn Signal, Stoplamps

and Back-up Lamps

To change a stoplamp/taillamp, turn signal or back-up

lamp bulb:

1. Open the liftgate. SeeLiftgate on page 2-22for

more information.

2. Remove the two screws

from the taillamp

housing on the

inboard side.

3. Pull out the taillamp housing.

4. Disconnect the wiring harness connector from the

taillamp assembly.A. Stoplamp/Taillamp

B. Turn Signal Lamp

C. Back-up Lamp Bulb

5. Turn the bulb socket counterclockwise to remove.

6. Replace the bulb by pulling the old bulb out of

the socket and gently pushing in a new bulb.

7. Replace the bulb socket by inserting and turning

clockwise to secure.

5-44

Page 355 of 464

8. Reinstall the taillamp assembly by inserting the

outboard locating/retaining pins until the lamp is

seated.

9. Secure with the inboard screws.

License Plate Lamp

To replace one of these bulbs:

1. Remove the two screws holding each of the license

plate lamps to the fascia.

2. Turn and pull the license plate lamp forward

through the fascia opening.3. Turn the bulb socket counterclockwise and pull the

bulb straight out of the socket.

4. Push the new bulb into the bulb socket and turn it

clockwise to lock it into place.

5. Push and turn the license plate back through the

fascia opening.

6. Reinstall the two screws holding the license plate

lamps to the fascia.

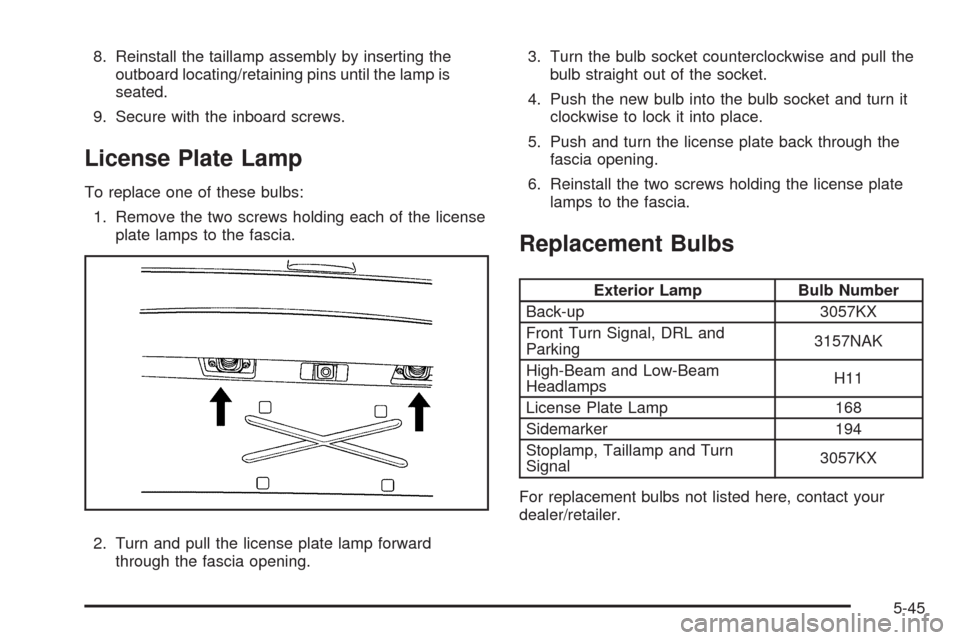

Replacement Bulbs

Exterior Lamp Bulb Number

Back-up 3057KX

Front Turn Signal, DRL and

Parking3157NAK

High-Beam and Low-Beam

HeadlampsH11

License Plate Lamp 168

Sidemarker 194

Stoplamp, Taillamp and Turn

Signal3057KX

For replacement bulbs not listed here, contact your

dealer/retailer.

5-45

Page 356 of 464

Windshield Wiper Blade

Replacement

Windshield wiper blades should be inspected for wear

and cracking. SeeScheduled Maintenance on page 6-4

for more information.

Replacement blades come in different types and are

removed in different ways. For proper type and length,

seeMaintenance Replacement Parts on page 6-13.

To replace the windshield wiper blade assembly do the

following:

1. Lift the wiper arm and turn the blade until it is

facing away from the windshield.

2. Squeeze the tabs (B) on each side of the wiper

blade assembly to remove the wiper arm (A)

from the blade (C).

Allowing the wiper blade arm to touch the windshield

when no wiper blade is installed could damage

the windshield. Any damage that occurs would not

be covered by your warranty. Do not allow the

wiper blade arm to touch the windshield.

3. Push the new wiper blade securely on the wiper

arm until you hear the tabs on each side of the

wiper blade assembly click into place.

To replace the rear wiper blade, follow the steps listed

above.

5-46

Page 357 of 464

Tires

Your new vehicle comes with high-quality tires

made by a leading tire manufacturer. If you ever

have questions about your tire warranty and where

to obtain service, see your vehicle Warranty

booklet for details.

{CAUTION:

Poorly maintained and improperly used

tires are dangerous.

Overloading your tires can cause

overheating as a result of too much

�exing. You could have an air-out and

a serious accident. SeeLoading the

Vehicle on page 4-19.

CAUTION: (Continued)

CAUTION: (Continued)

Underin�ated tires pose the same danger

as overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be

checked when your tires are cold. See

Inflation - Tire Pressure on page 5-54.

Overin�ated tires are more likely to be

cut, punctured, or broken by a sudden

impact — such as when you hit a pothole.

Keep tires at the recommended pressure.

Worn, old tires can cause accidents.

If your tread is badly worn, or if your tires

have been damaged, replace them.

SeeHigh-Speed Operation on page 5-56for

in�ation pressure adjustment for high speed

driving.

5-47

Page 358 of 464

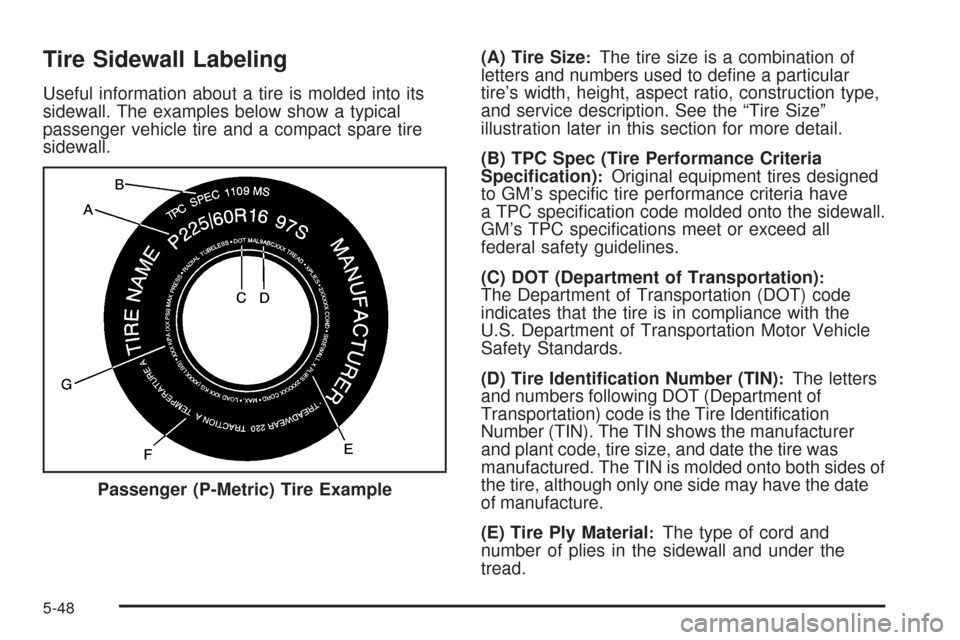

Tire Sidewall Labeling

Useful information about a tire is molded into its

sidewall. The examples below show a typical

passenger vehicle tire and a compact spare tire

sidewall.(A) Tire Size

:The tire size is a combination of

letters and numbers used to de�ne a particular

tire’s width, height, aspect ratio, construction type,

and service description. See the “Tire Size”

illustration later in this section for more detail.

(B) TPC Spec (Tire Performance Criteria

Speci�cation)

:Original equipment tires designed

to GM’s speci�c tire performance criteria have

a TPC speci�cation code molded onto the sidewall.

GM’s TPC speci�cations meet or exceed all

federal safety guidelines.

(C) DOT (Department of Transportation)

:The Department of Transportation (DOT) code

indicates that the tire is in compliance with the

U.S. Department of Transportation Motor Vehicle

Safety Standards.

(D) Tire Identi�cation Number (TIN)

:The letters

and numbers following DOT (Department of

Transportation) code is the Tire Identi�cation

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides of

the tire, although only one side may have the date

of manufacture.

(E) Tire Ply Material

:The type of cord and

number of plies in the sidewall and under the

tread. Passenger (P-Metric) Tire Example

5-48

Page 359 of 464

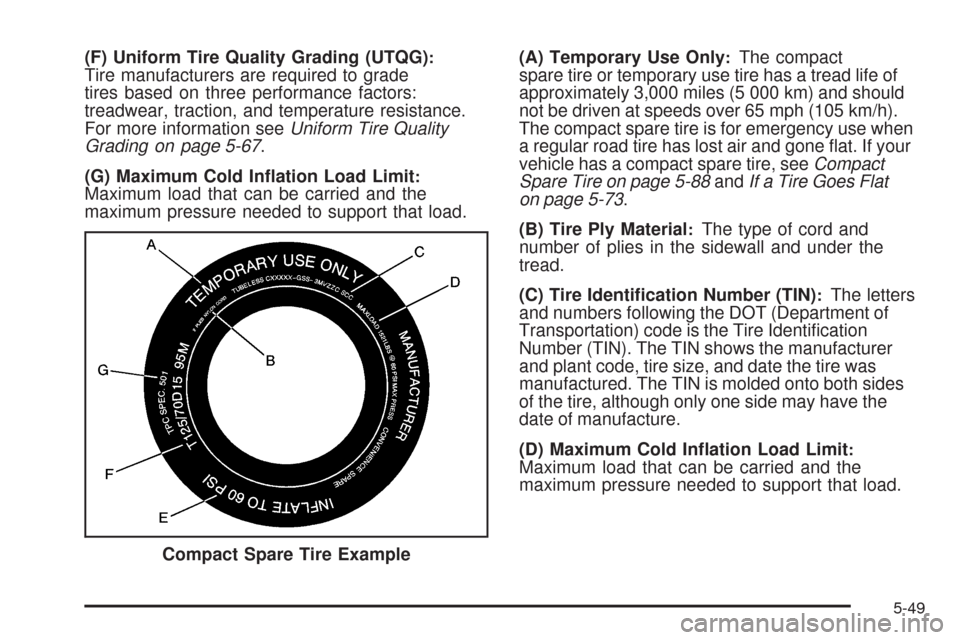

(F) Uniform Tire Quality Grading (UTQG):Tire manufacturers are required to grade

tires based on three performance factors:

treadwear, traction, and temperature resistance.

For more information seeUniform Tire Quality

Grading on page 5-67.

(G) Maximum Cold In�ation Load Limit

:Maximum load that can be carried and the

maximum pressure needed to support that load.(A) Temporary Use Only

:The compact

spare tire or temporary use tire has a tread life of

approximately 3,000 miles (5 000 km) and should

not be driven at speeds over 65 mph (105 km/h).

The compact spare tire is for emergency use when

a regular road tire has lost air and gone �at. If your

vehicle has a compact spare tire, seeCompact

Spare Tire on page 5-88andIf a Tire Goes Flat

on page 5-73.

(B) Tire Ply Material

:The type of cord and

number of plies in the sidewall and under the

tread.

(C) Tire Identi�cation Number (TIN)

:The letters

and numbers following the DOT (Department of

Transportation) code is the Tire Identi�cation

Number (TIN). The TIN shows the manufacturer

and plant code, tire size, and date the tire was

manufactured. The TIN is molded onto both sides

of the tire, although only one side may have the

date of manufacture.

(D) Maximum Cold In�ation Load Limit

:Maximum load that can be carried and the

maximum pressure needed to support that load.

Compact Spare Tire Example

5-49

Page 360 of 464

(E) Tire In�ation:The temporary use tire or

compact spare tire should be in�ated to 60 psi

(420 kPa). For more information on tire pressure

and in�ation seeInflation - Tire Pressure on

page 5-54.

(F) Tire Size

:A combination of letters and

numbers de�ne a tire’s width, height, aspect

ratio, construction type, and service description.

The letter T as the �rst character in the tire

size means the tire is for temporary use only.

(G) TPC Spec (Tire Performance Criteria

Speci�cation)

:Original equipment tires designed

to GM’s speci�c tire performance criteria have

a TPC speci�cation code molded onto the sidewall.

GM’s TPC speci�cations meet or exceed all

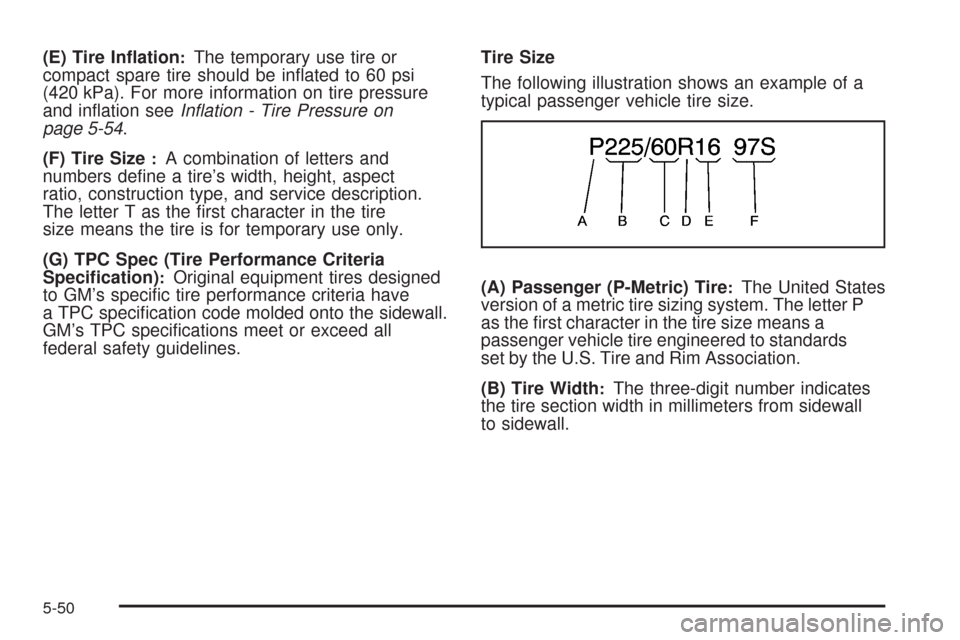

federal safety guidelines.Tire Size

The following illustration shows an example of a

typical passenger vehicle tire size.

(A) Passenger (P-Metric) Tire:The United States

version of a metric tire sizing system. The letter P

as the �rst character in the tire size means a

passenger vehicle tire engineered to standards

set by the U.S. Tire and Rim Association.

(B) Tire Width

:The three-digit number indicates

the tire section width in millimeters from sidewall

to sidewall.

5-50