lock CHRYSLER 200 2015 2.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2015, Model line: 200, Model: CHRYSLER 200 2015 2.GPages: 698, PDF Size: 5.12 MB

Page 567 of 698

5. Remove the spare tire.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

Preparations For Jacking

1. Park the vehicle on a firm level surface as far from theedge of the roadway as possible. Avoid icy or slippery

areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off

the road to avoid being hit when operating the jack

or changing the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn the ignition off to the LOCK position.

6. Chock both the front and rear of the wheel diagonally opposite of the jacking position. For

example, if changing the right front

tire, chock the left rear wheel. Place

both chocks under the tire.

NOTE: Passengers should not remain in the vehicle

when the vehicle is being jacked.

6

WHAT TO DO IN EMERGENCIES 565

Page 570 of 698

2. If equipped with aluminum wheels where the centercap covers the wheel bolts, use the wheel bolt wrench

to pry the center cap off carefully before raising the

vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove, the wheel bolts on the wheel with the flat tire. Turn the wheel bolts counter-

clockwise one turn while the wheel is still on the

ground.

4. Place the jack underneath the notched lift area that is closest to the flat tire.

Removing Jack Handle From Jack

Front Body Flange

568 WHAT TO DO IN EMERGENCIES

Page 572 of 698

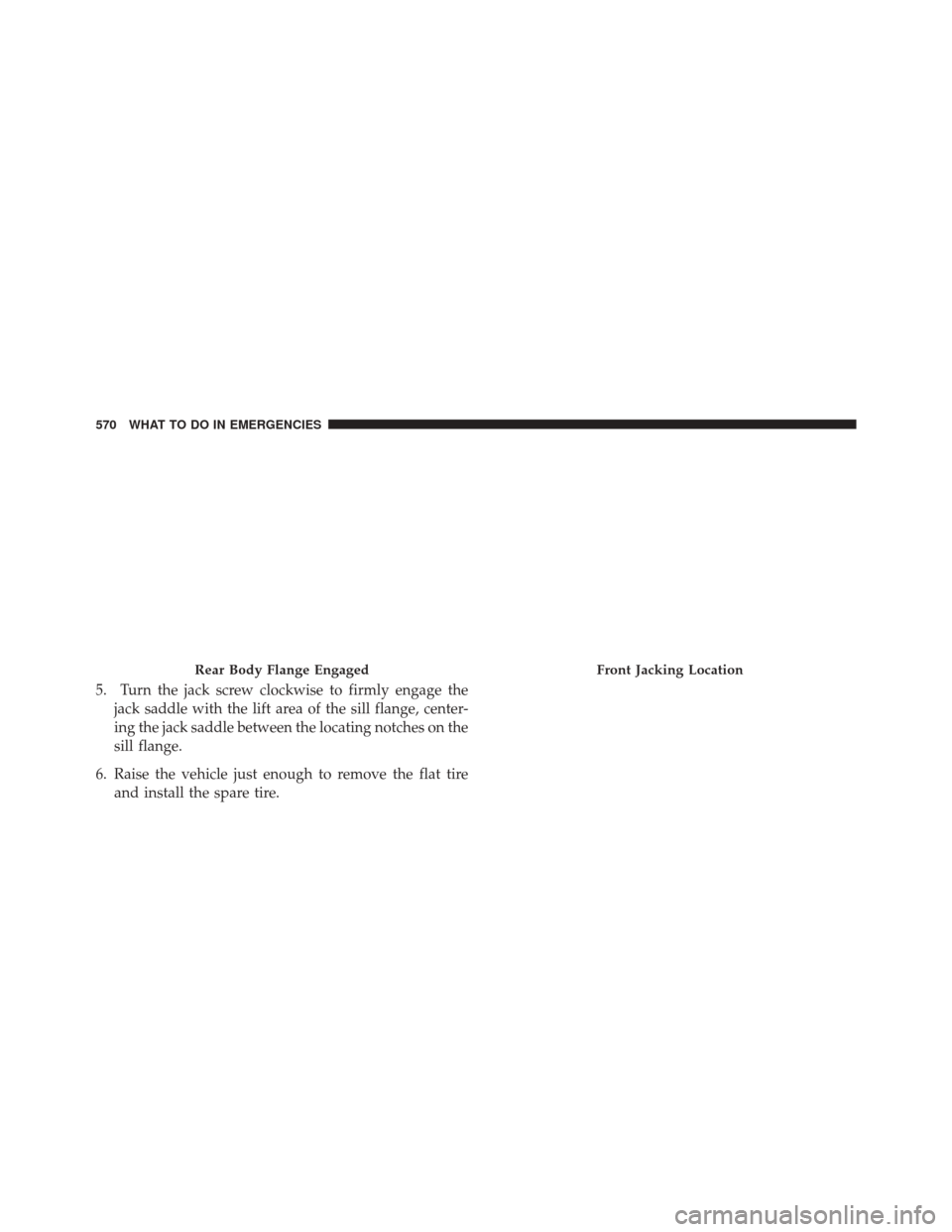

5. Turn the jack screw clockwise to firmly engage thejack saddle with the lift area of the sill flange, center-

ing the jack saddle between the locating notches on the

sill flange.

6. Raise the vehicle just enough to remove the flat tire and install the spare tire.

Rear Body Flange EngagedFront Jacking Location

570 WHAT TO DO IN EMERGENCIES

Page 575 of 698

10. Lower the vehicle to the ground by turning the jackhandle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. Refer

to “Torque Specifications” in this section for proper

lug bolt torque. If in doubt about the correct tight-

ness, have them checked with a torque wrench by

your authorized dealer or at a service station.

12. Lower the jack until it is free. Remove the wheel chocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Securely stow

the jack, tools, chocks and flat tire. Release the

parking brake before driving the vehicle.WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. Have the deflated (flat) tire

repaired or replaced immediately.

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels withwheel covers, install two wheel bolts on the wheel

which are on each side of the valve stem. Install the

wheel bolts with the threaded end of the bolt toward

the wheel. Lightly tighten the wheel bolts.6

WHAT TO DO IN EMERGENCIES 573

Page 576 of 698

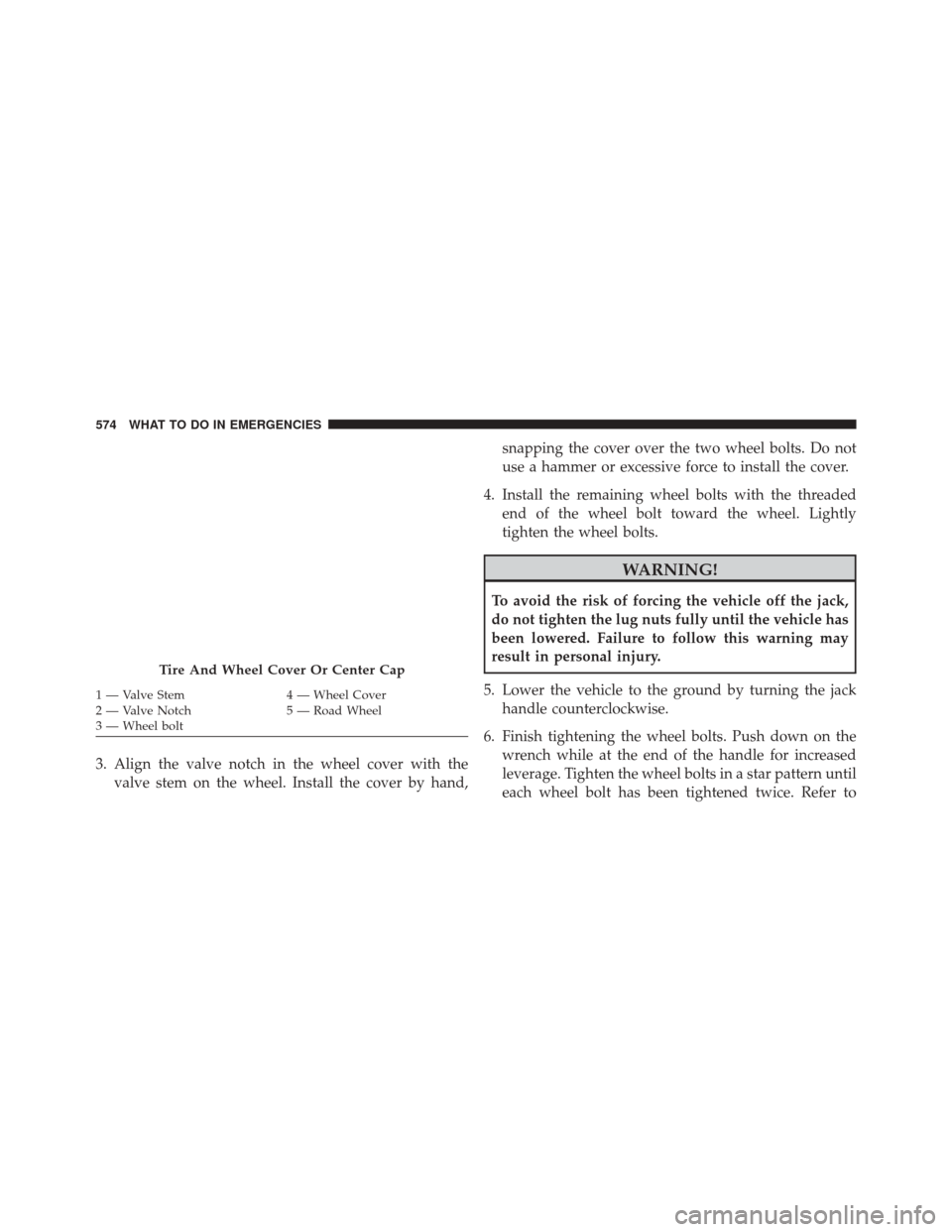

3. Align the valve notch in the wheel cover with thevalve stem on the wheel. Install the cover by hand, snapping the cover over the two wheel bolts. Do not

use a hammer or excessive force to install the cover.

4. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly

tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel bolt 574 WHAT TO DO IN EMERGENCIES

Page 577 of 698

“Torque Specifications” in this section for proper lug

bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

7. Lower the jack until it is free. Remove the wheel chocks. Reassemble the lug wrench to the jack assem-

bly and stow it in the spare tire area. Secure the

assembly using the means provided. Release the park-

ing brake before driving the vehicle.

8. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threadedend of the wheel bolt toward the wheel. Lightly

tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in personal injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern until

each wheel bolt has been tightened twice. Refer to

“Torque Specifications” in this section for the proper

lug bolt torque. If in doubt about the correct tightness,

have them checked with a torque wrench by your

authorized dealer or service station.

6

WHAT TO DO IN EMERGENCIES 575

Page 579 of 698

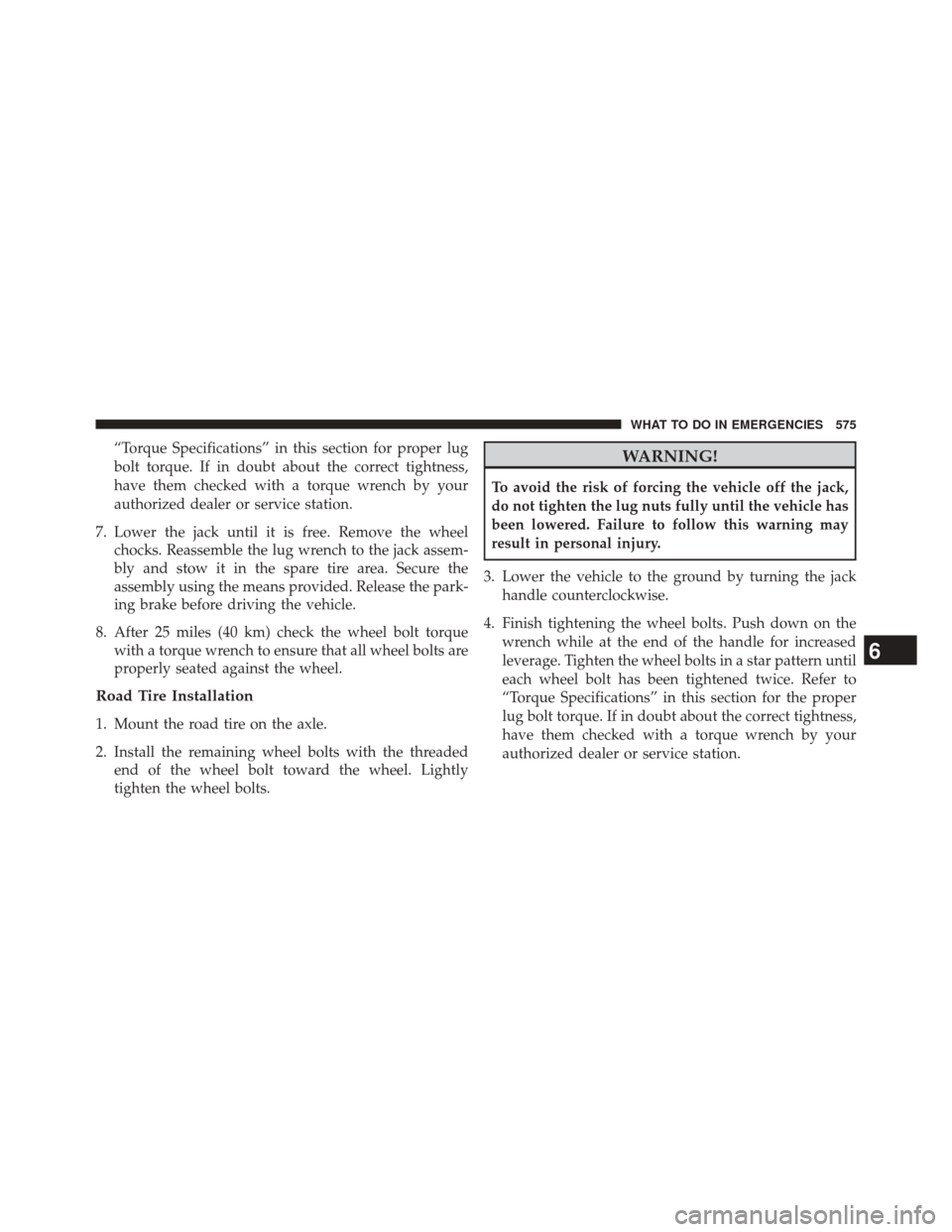

WARNING!

•Take care to avoid the radiator cooling fan when-

ever the hood is raised. It can start anytime the

ignition switch is ON. You can be injured by

moving fan blades.

• Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

• Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

1. Set the parking brake, shift the automatic transmission into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electri- cal accessories.

1 — Positive Battery Post

2 — Negative Battery Post

6

WHAT TO DO IN EMERGENCIES 577

Page 585 of 698

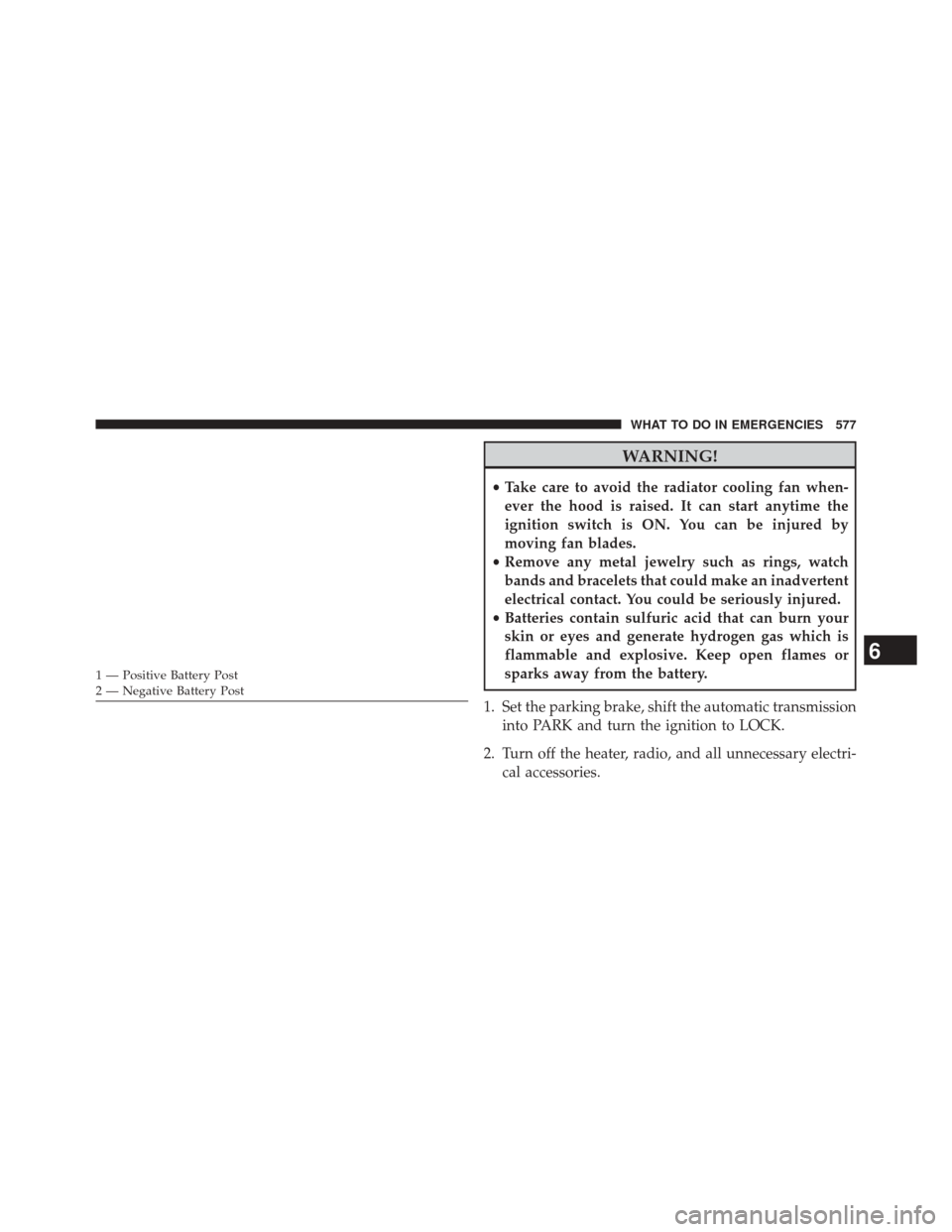

4. Pull the tether to rotate the lever up and rearward,until it locks vertically in place. Verify that the Manual

Park Release lever is locked in the released position. 5. The vehicle is now out of PARK and can be towed.

Release the parking brake only when the vehicle is

securely connected to a tow vehicle.

Manual Park Release TetherLocked Position6

WHAT TO DO IN EMERGENCIES 583

Page 586 of 698

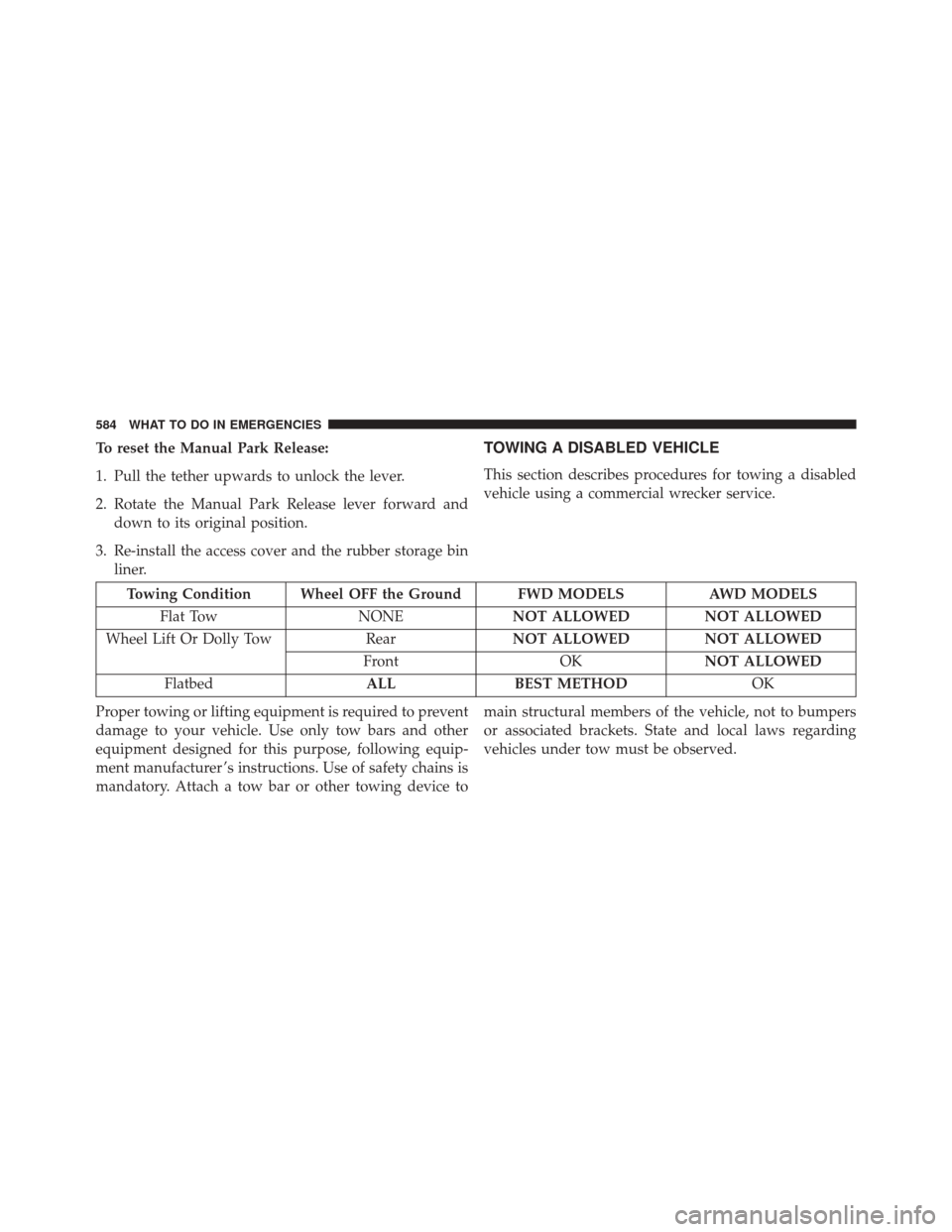

To reset the Manual Park Release:

1. Pull the tether upwards to unlock the lever.

2. Rotate the Manual Park Release lever forward anddown to its original position.

3. Re-install the access cover and the rubber storage bin liner.TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled

vehicle using a commercial wrecker service.

Towing Condition Wheel OFF the Ground FWD MODELS AWD MODELS

Flat Tow NONENOT ALLOWED NOT ALLOWED

Wheel Lift Or Dolly Tow RearNOT ALLOWED NOT ALLOWED

Front OKNOT ALLOWED

Flatbed ALLBEST METHOD OK

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equip-

ment manufacturer ’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to main structural members of the vehicle, not to bumpers

or associated brackets. State and local laws regarding

vehicles under tow must be observed.

584 WHAT TO DO IN EMERGENCIES

Page 607 of 698

CAUTION!

The A/C air filter is identified with an arrow to

indicate airflow direction through the filter. Failure

to properly install the filter will result in the need to

replace it more often.

7. Install the passenger side hush panel under the dash panel and console closeout.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as MOPAR® Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit; after

lubricating excess oil and grease should be removed.

Particular attention should also be given to hood latching

components to ensure proper function. When performing

other underhood services, the hood latch, release mecha-

nism and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR®

Lock Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumula-

tions of salt or road film.7

MAINTAINING YOUR VEHICLE 605