power steering fluid CHRYSLER 300 C 2008 1.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: 300 C, Model: CHRYSLER 300 C 2008 1.GPages: 520, PDF Size: 5.43 MB

Page 81 of 520

Door Latches

Check for positive closing, latching, and locking.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

engine coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel, power steering fluid, or

brake fluid leaks are suspected, the cause should be

located and corrected immediately.

80 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 84 of 520

\3Lights-On Reminder...................134

\3Fog Lights — If Equipped...............134

\3Multi-Function Lever...................134

\3Overhead Console Map/Reading Lights.....136

\3Interior Lights.......................136

\1Windshield Wipers And Washers............138

\3Intermittent Wiper System...............138

\3Mist Feature.........................139

\3Windshield Washers...................139

\3Headlights On With Wipers

(Available With Auto Headlights Only)......139

\3Rain Sensing Wipers — If Equipped........140

\3Adding Washer Fluid..................141\1Headlight Washers — If Equipped...........142

\3Adding Washer Fluid..................143

\1Tilt/Telescoping Steering Column...........144

\1Power Tilt/Telescoping Steering Column —

If Equipped...........................145

\1Adjustable Pedals — If Equipped...........147

\1Electronic Speed Control..................148

\3Electronic Speed Control Operation........149

\3To Activate..........................149

\3To Set At A Desired Speed...............150

\3To Deactivate........................150

\3To Resume Speed.....................150

\3To Vary The Speed Setting...............150

UNDERSTANDING THE FEATURES OF YOUR VEHICLE 83

3

Page 328 of 520

If both the Brake Warning Light and the ABS Light

remain on, the Anti-Lock brakes (ABS) and Electronic

Brake Force Distribution (EBD) systems are not function-

ing. Immediate repair to the ABS system is required.

POWER STEERING

The standard power steering system will give you good

vehicle response and increased ease of maneuverability

in tight spaces. The system will provide mechanical

steering capability if power assist is lost.

If for some reason the power assist is interrupted, it will

still be possible to steer your vehicle. Under these condi-

tions, you will observe a substantial increase in steering

effort, especially at very low vehicle speeds and during

parking maneuvers.NOTE:Increased noise levels at the end of the steering

wheel travel are considered normal and do not indicate

that there is a problem with the power steering system.

Upon initial start-up in cold weather, the power steering

pump may make noise for a short amount of time. This is

due to the cold, thick fluid in the steering system. This

noise should be considered normal, and it does not in any

way damage the steering system.

WARNING!

Continued operation with reduced power steering

assist could pose a safety risk to yourself and others.

Service should be obtained as soon as possible.

STARTING AND OPERATING 327

5

Page 329 of 520

CAUTION!

Prolonged operation of the steering system at the end

of the steering wheel travel will increase the steering

fluid temperature and it should be avoided when

possible. Damage to the power steering pump may

occur.

MULTI DISPLACEMENT SYSTEM (MDS) — 5.7L

Engine Only

This feature offers improved fuel economy by shutting

off four of the engine’s eight cylinders during light load

and cruise conditions. The system is automatic with no

driver inputs or additional driving skills required.

NOTE:The MDS system may take some time to return

to full functionality after a battery disconnect.

TRACTION CONTROL SYSTEM (TCS) — IF

EQUIPPED

WARNING!

The Traction Control System (TCS) cannot prevent

the natural laws of physics from acting on the ve-

hicle, nor can it increase the traction afforded. The

TCS cannot prevent accidents, including those result-

ing from excessive speed in turns, or hydroplaning.

Only a safe, attentive, and skillful driver can prevent

accidents. The capabilities of a TCS-equipped ve-

hicle must never be exploited in a reckless or dan-

gerous manner, which could jeopardize the user’s

safety or the safety of others.

The Traction Control System (TCS) is standard on ve-

hicles equipped with Electronic Stability Program (ESP).

328 STARTING AND OPERATING

Page 413 of 520

\3Air Conditioner Maintenance.............430

\3A/C Air Filter — If Equipped............431

\3Power Steering — Fluid Check............432

\3Front & Rear Suspension Ball Joints........432

\3Steering Linkage......................433

\3Body Lubrication.....................433

\3Windshield Wiper Blades................433

\3Windshield Washers/Headlight Washers —

If Equipped.........................434

\3Exhaust System......................434

\3Cooling System.......................435

\3Hoses And Vacuum/Vapor Harnesses.......440

\3Fuel System.........................441\3Brake System........................441

\3Automatic Transmission................444

\3All Wheel Drive (AWD) — If Equipped.....445

\3Front And Rear Wheel Bearings...........446

\3Appearance Care And Protection From

Corrosion...........................446

\3Cleaning The Center Console Cup Holders . . . 450

\1Fuses (Power Distribution Centers)..........451

\3Fuses (Front Power Distribution Center).....451

\3Fuses (Rear Power Distribution Center)......453

\1Vehicle Storage........................458

\1Replacement Bulbs......................459

\1Bulb Replacement......................460

412 MAINTAINING YOUR VEHICLE

Page 415 of 520

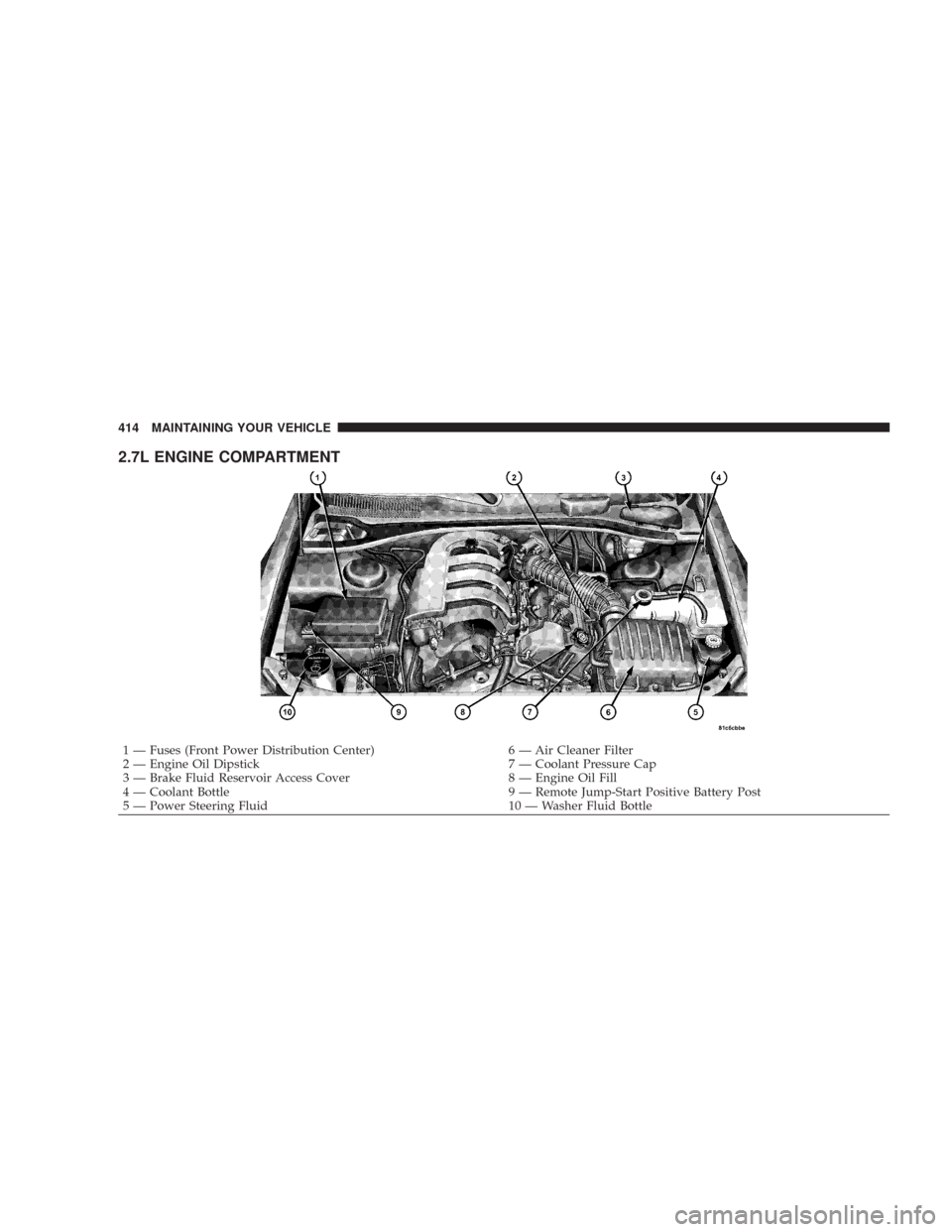

2.7L ENGINE COMPARTMENT

1 — Fuses (Front Power Distribution Center) 6 — Air Cleaner Filter

2 — Engine Oil Dipstick 7 — Coolant Pressure Cap

3 — Brake Fluid Reservoir Access Cover 8 — Engine Oil Fill

4 — Coolant Bottle 9 — Remote Jump-Start Positive Battery Post

5 — Power Steering Fluid 10 — Washer Fluid Bottle 414 MAINTAINING YOUR VEHICLE

Page 416 of 520

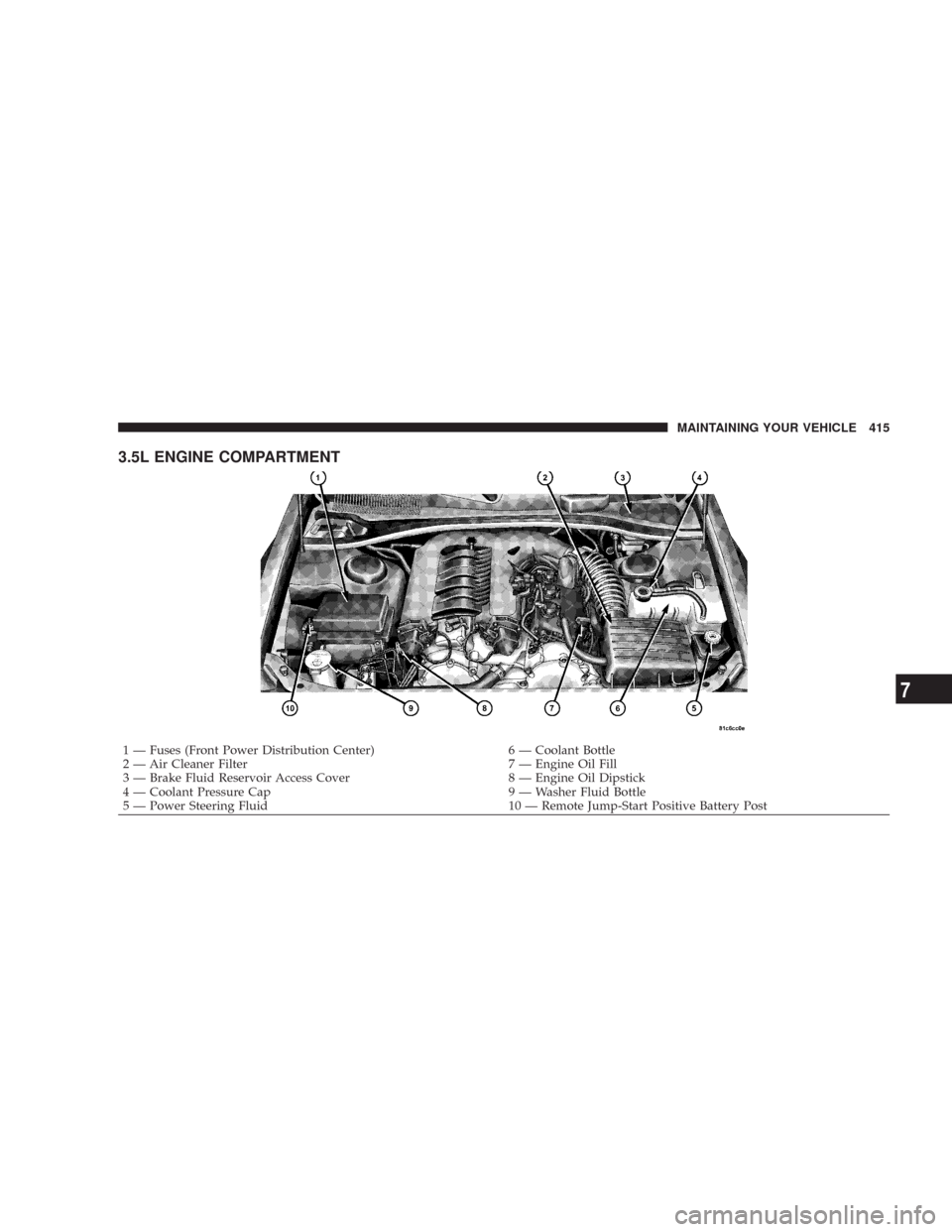

3.5L ENGINE COMPARTMENT

1 — Fuses (Front Power Distribution Center) 6 — Coolant Bottle

2 — Air Cleaner Filter 7 — Engine Oil Fill

3 — Brake Fluid Reservoir Access Cover 8 — Engine Oil Dipstick

4 — Coolant Pressure Cap 9 — Washer Fluid Bottle

5 — Power Steering Fluid 10 — Remote Jump-Start Positive Battery PostMAINTAINING YOUR VEHICLE 415

7

Page 417 of 520

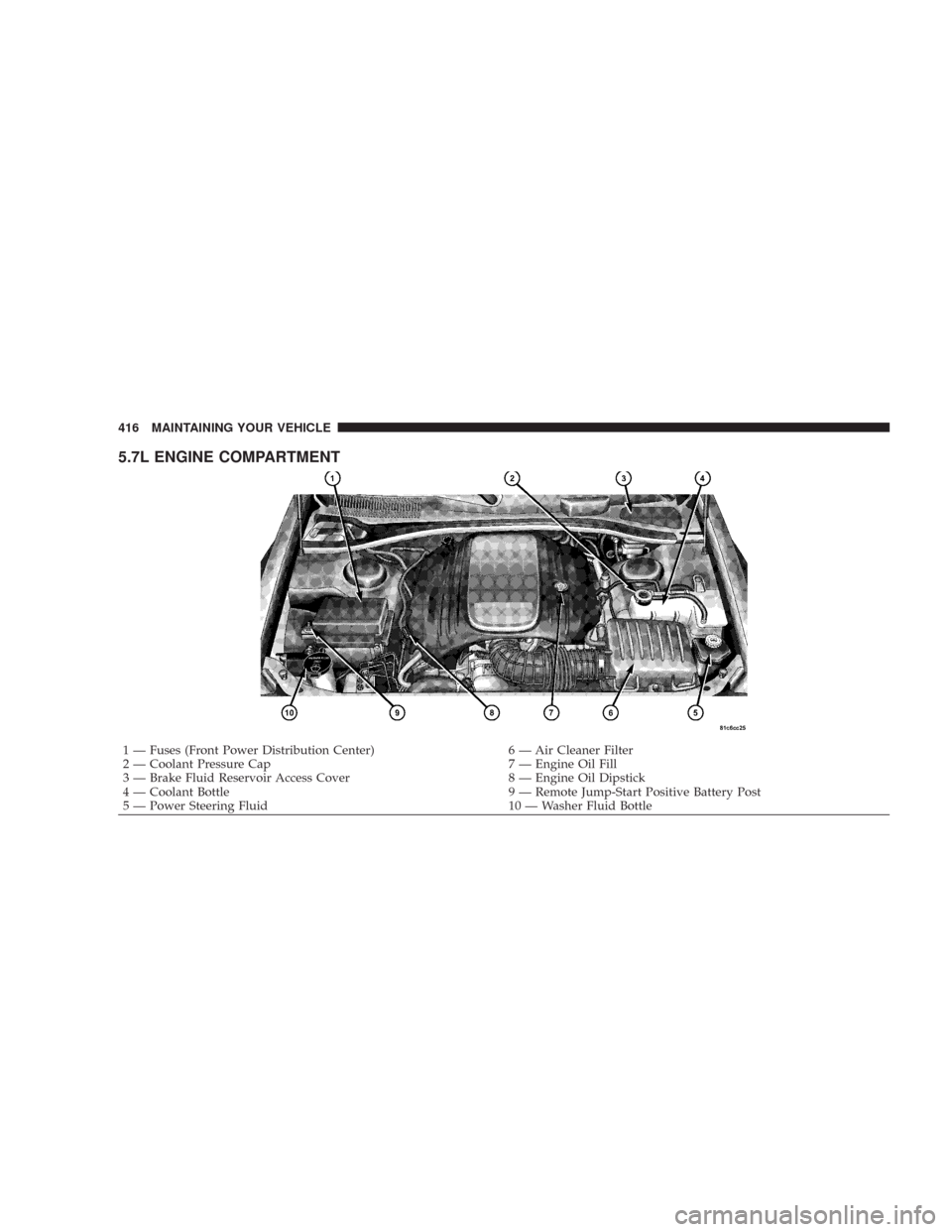

5.7L ENGINE COMPARTMENT

1 — Fuses (Front Power Distribution Center) 6 — Air Cleaner Filter

2 — Coolant Pressure Cap 7 — Engine Oil Fill

3 — Brake Fluid Reservoir Access Cover 8 — Engine Oil Dipstick

4 — Coolant Bottle 9 — Remote Jump-Start Positive Battery Post

5 — Power Steering Fluid 10 — Washer Fluid Bottle 416 MAINTAINING YOUR VEHICLE

Page 433 of 520

Install new filter with arrows pointing in the direction of

airflow, which is toward the rear of the vehicle (text and

arrows on the filter indicate this).

Refer to the “Maintenance Schedule” in Section 8 of

this manual for the recommended air conditioning

filter replacement intervals.

Power Steering — Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturer’s recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to “Fluids, Lubricants, and Genuine

Parts” in this section for the correct fluid type.

Front & Rear Suspension Ball Joints

The suspension ball joints should be inspected for exter-

nal leakage or damage when other maintenance is per-

formed.

432 MAINTAINING YOUR VEHICLE

Page 443 of 520

Brake and Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, tears, cuts, abrasion, and excessive swelling

indicate deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:

•Often, fluid such as oil, power steering fluid, and

brake fluid are used during assembly plant operations

to facilitate the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is notnecessarily an indication of leakage. Actual dripping

of hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

•Inspect the brake hoses whenever the brake system is

serviced and at every engine oil change. Inspect hy-

draulic brake hoses for surface cracking, scuffing, or

worn spots. If there is any evidence of cracking,

scuffing, or worn spots, the hose should be replaced

immediately! Eventual deterioration of the hose can

take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

442 MAINTAINING YOUR VEHICLE