ignition CHRYSLER CARAVAN 2000 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2000Pages: 436, PDF Size: 3.4 MB

Page 5 of 436

TABLE OF CONTENTS - Continued

VERIFICATION TEST

VER-1ANO START VERIFICATION................................422

VER-2AROAD TEST VERIFICATION...............................423

VER-3ASPEED CONTROL VERIFICATION..........................424

8.0 MAINTENANCE AND SERVICE INFORMATION.............................425

8.1PROGRAMMING THE ENGINE CONTROL MODULE...................425

8.2PROGRAMMING THE BODY CONTROL MODULE.....................425

8.3PROGRAMMING THE SENTRY KEY IMMOBILIZER MODULE...........426

8.4PROGRAMMING IGNITION KEYS TO THE SENTRY KEY IMMOBILIZER

MODULE.......................................................426

10.0 SCHEMATIC DIAGRAM.................................................427

11.0 REQUIRED TOOLS AND EQUIPMENT....................................428

12.0 GLOSSARY OF TERMS.................................................428

v

ProCarManuals.com

Page 8 of 436

3.2 Functional Operation

3.2.1 ECM On-Board Diagnostics

The ECM has been programmed to monitor many different circuits of the diesel fuel injection

system. This monitoring is called ``on-board diagnosis''.

Certain criteria must be met for a diagnostic trouble code to be entered into the ECM memory. The

criteria may be a range of: engine rpm, engine temperature, and/or input voltage to the ECM. If

all of the criteria for monitoring a system or circuit are met and a problem is sensed, then a trouble

code will be stored in the ECM.

It is possible that a trouble code for a monitored circuit may not be entered into the ECM memory

even though a malfunction has occurred. This may happen when the monitoring criteria have not

been met.

The ECM compares input signal voltages from each input device with specifications (the

established high and low limits of the range) that are programmed into it for that device. If the input

voltage is not within specifications and other trouble code criteria are met, a trouble code will be

stored in the ECM memory.

3.2.2 ECM Operating Modes

As input signals to the engine control module (ECM) change, the ECM adjusts its response to

output devices. For example, the ECM must calculate a different fuel quantity and fuel timing for

idle than it does for wide open throttle. There are several different modes of operation that

determine how the ECM responds to the various input signals.

Ignition Switch On (Engine Off Mode)

When the ignition switch activates the fuel injection system, the following actions occur:

1. The ECM determines atmospheric air pressure from the atmospheric pressure sensor

located in the ECM.

2. The ECM energizes the fuel quantity actuator and the fuel shudown solenoid if no faults

are present.

If the engine is not started within 5 seconds of ignition on, the ECM deactivates the fuel quantity

actuator and the fuel shutdown solenoid to prevent overheating.

Engine Start-Up Mode-The ECM uses the engine temperature sensor, fuel temperature sensor,

atmospheric pressure sensor, boost pressure sensor and the engine speed sensor to determine

fuel delivery during this mode.

Normal Driving Modes- Engine idle, warm-up, acceleration, deceleration and wide open throttle

modes are all controlled based on the sensor inputs to the ECM and are modified based on

engine temperature, boost pressure and engine speed.

Overheat Protection Mode- If engine temperature becomes too hot, the ECM activates high

speed radiator fan operation and limits fuel quantity for engine protection.

Limp-In Modes- The ECM operates in limp-in mode when certain system faults are detected.

The ECM operates in one of the following modes based on the severity of the fault:

1. 10% torque reduction.

2. 50% torque reduction.

3. Engine speed limited to 1100 rpm.

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

2

ProCarManuals.com

Page 9 of 436

After-Run- When fused ignition switch output is removed from the ECM cavity 47, the ECM

performs a self-diagnostic check in the following order:

1. Electrical shut-off test

2. Fuel quantity actuator test

3. Monitoring module test

4. Voltage regulator test

5. Main relay test (if tests 1-4 pass)

If any of tests 1-4 fail, the fault is stored in memory, and can be retrieved during the next ignition

cycle using the DRB.

3.2.3 Monitored Circuits

The ECM is able to monitor and identify most driveability related trouble conditions. Some circuits

are directly monitored through ECM feedback circuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those states with expected values. Other systems are

monitored indirectly when the ECM conducts a rationality test to identify problems.

Although most subsystems of the powertrain control module are either directly or indirectly

monitored, there may be occasions when diagnostic trouble codes are not immediately identified.

For a trouble code to set, specific conditions must be met and unless these conditions are

encountered, a code will not set.

3.2.4 SKIS On-Board Diagnostics

The SKIS module has been programmed to transmit and monitor many different coded messages

as well as CCD Bus messages. This monitoring is called ``On-Board Diagnosis''.

Certain criteria must be met for a diagnostic trouble code to be entered into the Sentry Key

Immobilizer Module (SKIM) memory. The criteria may be a range of: input voltage, CCD Bus

messages, or coded messages to the SKIM. If all of the criteria for monitoring a circuit or function

are met and a fault is sensed, a diagnostic trouble code will be stored in the SKIM memory.

3.2.5 SKIS Overview

The Sentry Key Immobilizer System (SKIS) is an immobilizer system designed to prevent

unauthorized vehicle operation. The system consists of a Sentry Key Immobilizer Module (SKIM),

ignition key(s) equipped with a transponder chip, engine controller and body controller. When the

ignition switch is turned on, the SKIM interrogates the ignition key. If the ignition key is ªValidº the

SKIM sends a CCD Bus message to the body controller indicating the presence of a valid ignition

key. The BCM then supplies the ECM with a valid immobilizer signal allowing the engine to

continue to operate.

3.2.6 SKIS Operation

When ignition power is supplied to the SKIM, the SKIM performs an internal self-test. After the

self-test is completed, the SKIM energizes the antenna (this activates the transponder chip) and

sends a challenge to the transponder chip. The transponder chip responds to the challenge by

generating an encrypted response message using the following:

Secret Key þ This is an electronically stored value (identification number) that is unique to each

SKIS. The secret key is stored in the SKIM, BCM and all ignition key transponders.

Challenge þ This is a random number that is generated by the SKIM at each ignition key cycle.

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

3

ProCarManuals.com

Page 10 of 436

The secret key and challenge are plugged into an algorithm that produces the encrypted response

message. The transponder uses the crypto algorithm to receive, decode and respond to the

message sent by SKIM. After responding to the coded message, the transponder sends a

transponder I.D. message to the SKIM. The SKIM compares the transponder I.D. to the available

valid key codes in SKIM memory (8 key maximum). After validating the key the SKIM sends a

CCD Bus message called a ªSeed Requestº to the body controller then waits for a body controller

response. If the body controller does not respond, the SKIM will send the seed request again.

After three failed attempts the SKIM will stop sending the seed request and store a trouble code.

If the body controller sends a seed response, the SKIM sends a valid/invalid key message to the

body controller. This is an encrypted message that is generated using the following:

VIN þ Vehicle Identification Number

Seed þ This is a random number that is generated by the BCM at each ignition key cycle.

The VIN and seed are plugged into a rolling code algorithm that encrypts the ªvalid/invalid keyº

message. The body controller uses the rolling code algorithm to receive, decode and respond to

the valid/invalid key message sent by SKIM. After sending the valid/invalid key message the SKIM

waits 3.5 seconds for a PCM status message from the body controller. If the BCM does not

respond with a valid key message to the SKIM, a fault is detected and a trouble code stored.

The SKIS incorporates a warning (``ALARM SET'') lamp located in the message center. The lamp

receives switched ignition voltage and is hardwired to the body controller. The lamp is actuated

when the SKIM sends a CCD Bus message to the body controller requesting the lamp on. The

body controller then provides the ground for the lamp. The SKIM will request lamp operation for

the following:

± ± bulb check at ignition on

± to alert the vehicle operator to a SKIS malfunction

For all faults except transponder faults and VIN mismatch, the lamp remains on steady. In the

event of a transponder fault the light flashes at the rate of 1Hz (once per second). If a fault is

present the lamp will remain on or flashing for the complete ignition cycle. If a fault is stored in

SKIM memory which prevents the system from operating properly, the ECM will allow the engine

to start and run (for 2 seconds) up to six times. After the sixth attempt, the ECM disables the

starter relay until the fault is corrected..

3.3 Diagnostic Trouble Codes

Each diagnostic trouble code is diagnosed by following a specific testing procedure. The

diagnostic test procedures contain step-by-step instructions for determining the cause of trouble

codes as well as no trouble code problems. It is not necessary to perform all of the tests in this

book to diagnose an individual code.

Always begin by reading the diagnostic trouble codes using the DRB. This procedure begins in

the DTC TEST - Checking the System for Diagnostic Trouble Codes. This will direct you to the

specific test(s) that must be performed.

3.3.1 Hard Code

A diagnostic trouble code that comes back within one cycle of the ignition key is a ªhardº code.

This means that the defect is there every time the engine control module/SKIM checks that circuit

or function. Procedures in this manual verify if the trouble code is a hard code at the beginning

of each test. When it is not a hard code, an ªintermittentº test must be performed.

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

4

ProCarManuals.com

Page 11 of 436

3.3.2 Intermittent Code

A diagnostic trouble code that is not there every time the engine control module/SKIM checks the

circuit is an ªintermittentº code. Most intermittent codes are caused by wiring or connector

problems. Defects that come and go like this are the most difficult to diagnose; they must be

looked for under specific conditions that cause them. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect related wire harness connectors. Look for broken, bent, pushed out, or

corroded terminals.

²Visually inspect the related harnesses. Look for chafed, pierced, or partially broken wire.

²Refer to any hotlines or technical service bulletins that may apply.

NOTE: Electromagnetic (radio) interference can cause an intermittent system malfunction. This

interference can interrupt communication between the ignition key transponder and the SKIM.

3.3.3 Reset Counter

The reset counter counts the number of times the vehicle has been started since codes were last

set, erased, or the battery was disconnected. The reset counter will count up to 255 start counts.

The number of starts helps determine when the trouble code actually happened. This is recorded

by the ECM and can be viewed on the DRB as the RESET COUNTER.

When there are no trouble codes stored in memory, the DRB will display ªNO TROUBLE CODES

FOUNDº and the reset counter will show ªRESET COUNT = XXX.º

3.3.4 ECM Diagnostic Trouble Codes

A/C CONTROL SHORT CIRCUIT

A/C CONTROL OPEN CIRCUIT

A/C SYSTEM PRESSURE SIGNAL HIGH EXCEEDED

A/C SYSTEM PRESSURE SIGNAL LOW EXCEEDED

A/C SYSTEM PRESSURE SUPPLY HIGH EXCEEDED

A/C SYSTEM PRESSURE SUPPLY LOW EXCEEDED

ACCELERATOR PEDAL SENSOR SIGNAL HIGH EXCEEDED

ACCELERATOR PEDAL SENSOR PLAUSIBILITY

ACCELERATOR PEDAL SENSOR PWG PLAUS WITH LOW IDLE SWITCH

ACCELERATOR PEDAL SENSOR PWG PLAUS WITH POTENTIOMETER

ATMOSPHERIC PRESSURE SENSOR SRC HIGH EXCEEDED

ATMOSPHERIC PRESSURE SENSOR SRC LOW EXCEEDED

BATTERY VOLTAGE SRC HIGH EXCEEDED

BRAKE SIGNAL PLAUS WITH REDUNDANT CONTACT

CLUTCH SIGNAL PLAUSIBILITY

CONTROL SLEEVE SENSOR SIGNAL HIGH EXCEEDED

CONTROL SLEEVE SENSOR START END POS. NOT ATTAINED

CONTROL SLEEVE SENSOR STOP END POS. NOT ATTAINED

CRUISE STATUS INDICATOR LAMP SHORT CIRCUIT

DIAGNOSTIC LAMP OPEN CIRCUIT

DIAGNOSTIC LAMP SHORT CIRCUIT

DIESEL POWER RELAY SHUTS OFF TOO EARLY

DIESEL POWER RELAY SHUTS OFF TOO LATE

EEPROM PLAUSIBILITY CHECKSUM ERROR FOR ADJ. (EGR)

EEPROM PLAUSIBILITY CHECKSUM ERROR IN CC212

EEPROM PLAUSIBILITY COMMUNICATION WITH EEPROM

EEPROM PLAUSIBILITY FUNC. SWITCH WRONG OR MISSING

EEPROM PLAUSIBILITY VER. NUMBER NOT CORRESPONDING

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

5

ProCarManuals.com

Page 15 of 436

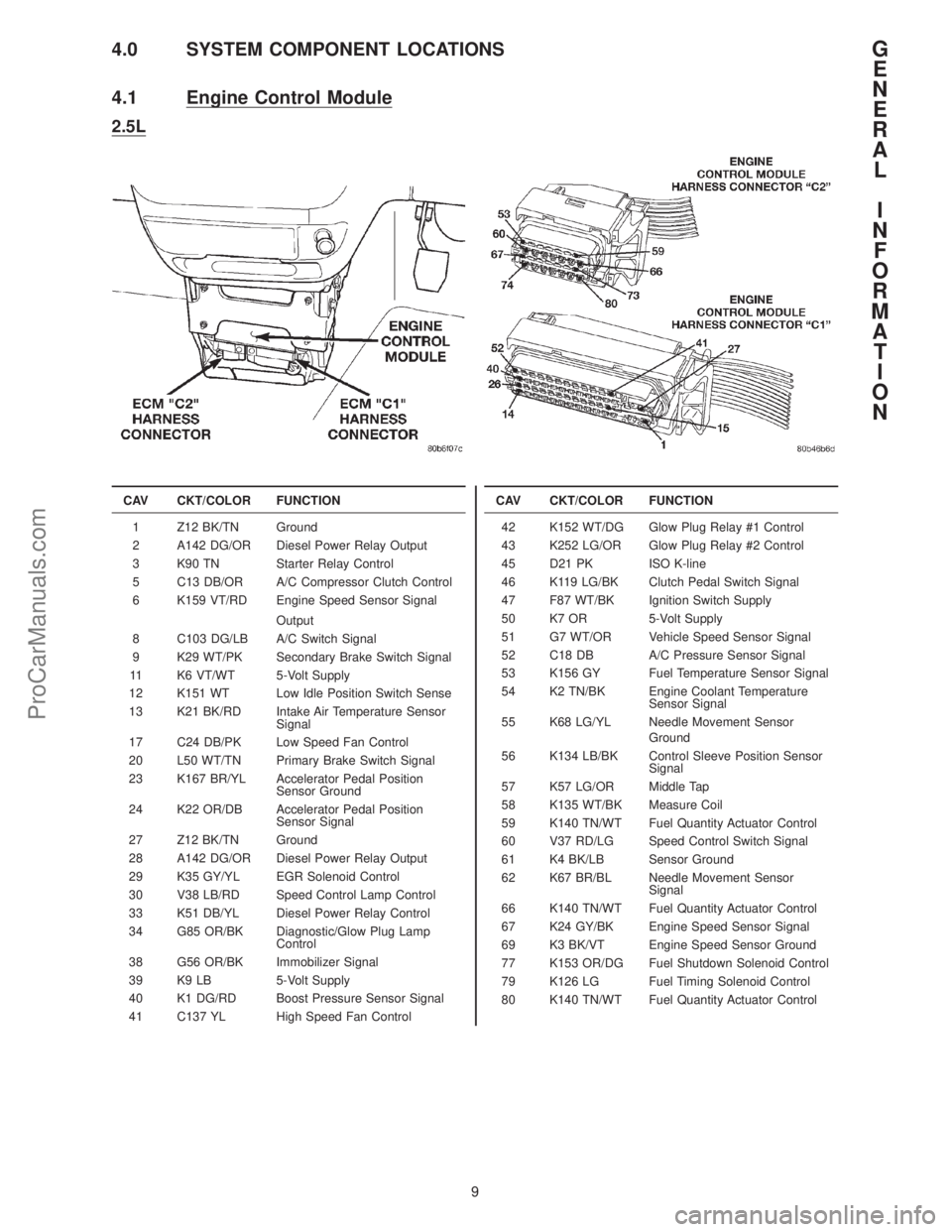

4.0 SYSTEM COMPONENT LOCATIONS

4.1 Engine Control Module

2.5L

CAV CKT/COLOR FUNCTION

1 Z12 BK/TN Ground

2 A142 DG/OR Diesel Power Relay Output

3 K90 TN Starter Relay Control

5 C13 DB/OR A/C Compressor Clutch Control

6 K159 VT/RD Engine Speed Sensor Signal

Output

8 C103 DG/LB A/C Switch Signal

9 K29 WT/PK Secondary Brake Switch Signal

11 K6 VT/WT 5-Volt Supply

12 K151 WT Low Idle Position Switch Sense

13 K21 BK/RD Intake Air Temperature Sensor

Signal

17 C24 DB/PK Low Speed Fan Control

20 L50 WT/TN Primary Brake Switch Signal

23 K167 BR/YL Accelerator Pedal Position

Sensor Ground

24 K22 OR/DB Accelerator Pedal Position

Sensor Signal

27 Z12 BK/TN Ground

28 A142 DG/OR Diesel Power Relay Output

29 K35 GY/YL EGR Solenoid Control

30 V38 LB/RD Speed Control Lamp Control

33 K51 DB/YL Diesel Power Relay Control

34 G85 OR/BK Diagnostic/Glow Plug Lamp

Control

38 G56 OR/BK Immobilizer Signal

39 K9 LB 5-Volt Supply

40 K1 DG/RD Boost Pressure Sensor Signal

41 C137 YL High Speed Fan ControlCAV CKT/COLOR FUNCTION

42 K152 WT/DG Glow Plug Relay #1 Control

43 K252 LG/OR Glow Plug Relay #2 Control

45 D21 PK ISO K-line

46 K119 LG/BK Clutch Pedal Switch Signal

47 F87 WT/BK Ignition Switch Supply

50 K7 OR 5-Volt Supply

51 G7 WT/OR Vehicle Speed Sensor Signal

52 C18 DB A/C Pressure Sensor Signal

53 K156 GY Fuel Temperature Sensor Signal

54 K2 TN/BK Engine Coolant Temperature

Sensor Signal

55 K68 LG/YL Needle Movement Sensor

Ground

56 K134 LB/BK Control Sleeve Position Sensor

Signal

57 K57 LG/OR Middle Tap

58 K135 WT/BK Measure Coil

59 K140 TN/WT Fuel Quantity Actuator Control

60 V37 RD/LG Speed Control Switch Signal

61 K4 BK/LB Sensor Ground

62 K67 BR/BL Needle Movement Sensor

Signal

66 K140 TN/WT Fuel Quantity Actuator Control

67 K24 GY/BK Engine Speed Sensor Signal

69 K3 BK/VT Engine Speed Sensor Ground

77 K153 OR/DG Fuel Shutdown Solenoid Control

79 K126 LG Fuel Timing Solenoid Control

80 K140 TN/WT Fuel Quantity Actuator Control

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

9

ProCarManuals.com

Page 24 of 436

²Choose the proper range and function for the measurement. Do not try voltage or current

measurements that may exceed the rated capacity.

²Do not exceed the limits shown in the table below:

FUNCTION INPUT LIMIT

Volts 0 - 500 peak volts AC

0 - 500 volts DC

Ohms (resistance)* 0 - 1.12 megohms

Frequency Measured

Frequency Generated0-10kHz

Temperature -58 - 1100É F

-50 - 600É C

* Ohms cannot be measured if voltage is

present. Ohms can be measured only in a

non-powered circuit.

²Voltage between any terminal and ground must not exceed 500v DC or 500v peak AC.

²Use caution when measuring voltage above 25v DC or 25v AC.

²The circuit being tested must be protected by a 10A fuse or circuit breaker.

²Use the low current shunt to measure circuits up to 10A. Use the high current clamp to

measure circuits exceeding 10A.

²When testing for the presence of voltage or current, make sure the meter is functioning

correctly. Take a reading of a known voltage or current before accepting a zero reading.

²When measuring current, connect the meter in series with the load.

²Disconnect the live test lead before disconnecting the common test lead.

5.3 Warnings

5.3.1 Vehicle Damage Warnings

Before disconnecting any control module, make sure the ignition is ``off''. Failure to do so could

damage the module.

When testing voltage or continuity at any control module, use the terminal side (not the wire end)

of the connector. Do not probe a wire through the insulation; this will damage it and eventually

cause it to fail because of corrosion.

Be careful when performing electrical tests so as to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, other codes could be set, making diagnosis of

the original problem more difficult.

5.3.2 Road Testing a Complaint Vehicle

Some complaints will require a test drive as part of the repair verification procedure. The purpose

of the test drive is to try to duplicate the diagnostic code or symptom condition.

CAUTION: Before road testing a vehicle, be sure that all components are reassembled.

During the test drive, do not try to read the DRB screen while in motion. Do not hang the

DRB from the rear view mirror or operate it yourself. Have an assistant available to operate

the DRB.

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

18

ProCarManuals.com

Page 27 of 436

TEST DTCCHECKING FOR DIAGNOSTIC TROUBLE CODES

DRBIIITDIAGNOSTIC TROUBLE CODE (DTC) DISPLAYEDDIAGNOSTIC

TESTSCAN

TOOL

Engine Speed Sensor Over Speed Recognition TC-36 P0725

Engine Speed Sensor Static Plausibility TC-38 P0725

Fan Control Open Circuit Fan #1TC-39 P1690

Fan Control Open Circuit Fan #2TC-40 P1690

Fan Control Short Circuit Fan #1TC-41 P1690

Fan Control Short Circuit Fan #2TC-42 P1690

Fuel Quantity Actuator Neg. Gov. Deviation Cold TC-43 P1220

Fuel Quantity Actuator Neg. Gov. Deviation Warm TC-44 P1220

Fuel Quantity Actuator Pos. Gov. Deviation Cold TC-45 P1220

Fuel Quantity Actuator Pos. Gov. Deviation Warm TC-46 P1220

Fuel Temperature Sensor SRC High Exceeded TC-47 P0180

Fuel Temperature Sensor SRC Low Exceeded TC-48 P0180

Glow Relay #1 Controller Open Circuit TC-51 P1635

Glow Relay #2 Controller Open Circuit TC-52 P1635

Glow Relay #1 Controller Short Circuit TC-53 P1635

Glow Relay #2 Controller Short Circuit TC-54 P1635

Inductive Aux. Speed Sensor Dynamic Plausibility TC-56 P1725

Inductive Aux. Speed Sensor Overspeed Recognition TC-57 P1725

Inductive Aux. Speed Sensor Plausibility TC-58 P1725

Inductive Aux. Speed Sensor Static Plausibility TC-59 P1725

Intake Air Temperature Sensor Signal High Exceeded TC-62 P0110

Intake Air Temperature Sensor Signal Low Exceeded TC-63 P0110

Microcontroller Gate-array Monitoring** P1615

Microcontroller Gate-array Watchdog** P1615

Microcontroller Prepare Fuel Quantity Stop ** P1615

Microcontroller Recovery Has Occurred ** P1615

Microcontroller Redundant Overrun Monitoring ** P1615

Needle Movement Sensor High Exceeded TC-72 P1201

Needle Movement Sensor Low Exceeded TC-73 P1201

Redundant Emer. Stop Plausibility in After-run TC-74 P1660

Redundant Emer. Stop Powerstate Defective TC-75 P1660

Regulator Lower Regulator Limit** P1610

Regulator Upper Regulator Limit** P1610

Smart Start Relay Short CircuitTC-76 P1675

Solenoid Valve Controller Open Circuit TC-79 P1630

Solenoid Valve Controller Short Circuit TC-80 P1630

Temperature of Engine Coolant SRC High Exceeded TC-81 P0115

Temperature of Engine Coolant SRC Low Exceeded TC-82 P0115

Terminal #15 Plausibility After Start-up TC-84 P1605

Timing Governing Negative Governor Deviation TC-85 P1230

Timing Governing Positive Governor Deviation TC-86 P1230

UþREF (2.5V)** P1620

Vehicle Speed Sensor Pec Frequency Too High TC-91 P0500

Vehicle Speed Sensor Signal High Exceeded TC-91 P0500

Vehicle Speed Sensor PlausibilityTC-91 P0500

Immobilizer Signal LostTC-94 P1685

Invalid SKIM MessageTC-94 P1685

** These trouble codes indicate an internal ECM fault. Using the DRB, clear ECM trouble code(s).

Perform several engine run cycles turning the ignition off for at least 10 seconds between cycles.

Using the DRB, read ECM trouble codes. If the code is present, replace the Engine Control Module.

NOTE: If trouble code TERMINAL 15 PLAUSIBILITY AFTER START-UP is present with other trouble

codes, perform TC-84 diagnosis first.

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

21

ProCarManuals.com

Page 31 of 436

TEST TC-1ACONTINUED - REPAIRING - A/C CONTROL SHORT CIRCUIT

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

TEST TC-1A TURN IGNITION ON.

CONTINUED FROM IS THE A/C CLUTCH NO CONTINUE TEST

THE PREVIOUS WITH THE DRB, RELAY CLICKING? TC-1A ON THE

PAGE. ACTUATE THE A/C NEXT PAGE.

CLUTCH RELAY.

YES

THE CONDITION TO SET USING THE SCHEMATIC

THE TROUBLE CODE IS AS A GUIDE, INSPECT WERE ANY PROBLEMS YES REPAIR AS

NOT PRESENT. THE WIRING AND FOUND? NECESSARY.*

CONNECTORS.

FIG.1 FIG.2

NO

WIGGLE THE WIRING NOTE: THE DRB MUST REPAIR AS

HARNESS FROM THE STILL BE ACTUATING DID THE WIGGLING YES NECESSARY WHERE

RELAY TO THE THE A/C CLUTCH INTERRUPT THE WIGGLING CAUSED

ENGINE CONTROL RELAY. CLICKING? CLICKING TO BE

MODULE.INTERRUPTED.*

NO

REFER TO GENERAL

INFORMATION 3.3.2 YES

FOR ADDITIONAL TEST COMPLETED.*

INFORMATION ON

INTERMITTENT CODES.

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

25

ProCarManuals.com

Page 33 of 436

TEST TC-1ACONTINUED - REPAIRING - A/C CONTROL SHORT CIRCUIT

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

TEST TC-1A

CONTINUED FROM TURN IGNITION OFF.

THE PREVIOUS REMOVE THE A/C

PAGE. CLUTCH RELAY.**

USING AN OHMMETER, 85 AND 86 IS THE RESISTANCE

MEASURE RESISTANCE 85 AND 87 BELOW 30.0 OHMS YES REPLACE THE A/C

BETWEEN A/C CLUTCH 85 AND 30 FOR ANY OF THE CLUTCH RELAY.*

RELAY TERMINALS... 85 AND 87A MEASUREMENTS?

FIG.2

NO

DISCONNECT THE ECM REMOVE THE DIESEL

HARNESS POWER RELAY.**

CONNECTORS.**

WITH A JUMPER WIRE, TURN IGNITION ON.

CONNECT DIESEL POWER

RELAY CONN. CAVITIES USE A VOLTMETER IN

30 AND 87 (IN PDC). THE FOLLOWING

FIG.3 STEP.

MEASURE THE RELAYREPAIR A/C CLUTCH

CONTROL CIRCUIT AT IS THE VOLTAGE YES RELAY CONTROL

RELAY CONNECTOR ABOVE 1.0 VOLT? CIRCUIT FOR SHORT

(IN PDC).TO VOLTAGE.*

FIG.1

NO

REPLACE THE ENGINE

CONTROL MODULE.*

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

27

ProCarManuals.com