height CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 78 of 2399

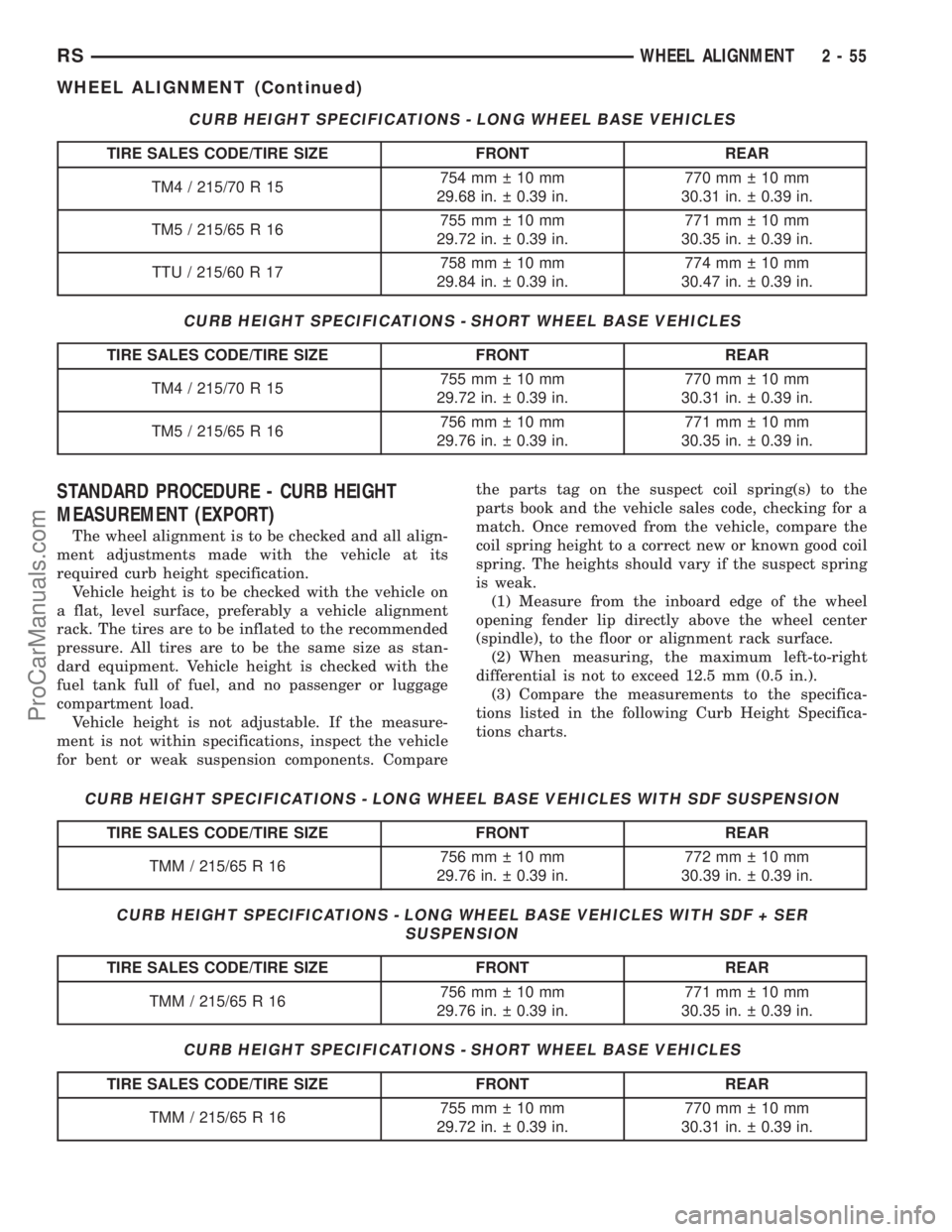

CURB HEIGHT SPECIFICATIONS - LONG WHEEL BASE VEHICLES

TIRE SALES CODE/TIRE SIZE FRONT REAR

TM4 / 215/70 R 15754mm 10mm

29.68 in. 0.39 in.770mm 10mm

30.31 in. 0.39 in.

TM5 / 215/65 R 16755mm 10mm

29.72 in. 0.39 in.771mm 10mm

30.35 in. 0.39 in.

TTU / 215/60 R 17758mm 10mm

29.84 in. 0.39 in.774mm 10mm

30.47 in. 0.39 in.

CURB HEIGHT SPECIFICATIONS - SHORT WHEEL BASE VEHICLES

TIRE SALES CODE/TIRE SIZE FRONT REAR

TM4 / 215/70 R 15755mm 10mm

29.72 in. 0.39 in.770mm 10mm

30.31 in. 0.39 in.

TM5 / 215/65 R 16756mm 10mm

29.76 in. 0.39 in.771mm 10mm

30.35 in. 0.39 in.

STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT (EXPORT)

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Comparethe parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare the

coil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, the maximum left-to-right

differential is not to exceed 12.5 mm (0.5 in.).

(3) Compare the measurements to the specifica-

tions listed in the following Curb Height Specifica-

tions charts.

CURB HEIGHT SPECIFICATIONS - LONG WHEEL BASE VEHICLES WITH SDF SUSPENSION

TIRE SALES CODE/TIRE SIZE FRONT REAR

TMM / 215/65 R 16756mm 10mm

29.76 in. 0.39 in.772mm 10mm

30.39 in. 0.39 in.

CURB HEIGHT SPECIFICATIONS - LONG WHEEL BASE VEHICLES WITH SDF + SER

SUSPENSION

TIRE SALES CODE/TIRE SIZE FRONT REAR

TMM / 215/65 R 16756mm 10mm

29.76 in. 0.39 in.771mm 10mm

30.35 in. 0.39 in.

CURB HEIGHT SPECIFICATIONS - SHORT WHEEL BASE VEHICLES

TIRE SALES CODE/TIRE SIZE FRONT REAR

TMM / 215/65 R 16755mm 10mm

29.72 in. 0.39 in.770mm 10mm

30.31 in. 0.39 in.

RSWHEEL ALIGNMENT2-55

WHEEL ALIGNMENT (Continued)

ProCarManuals.com

Page 79 of 2399

SPECIFICATIONS

WHEEL ALIGNMENT

NOTE: All specifications are given in degrees.

NOTE: All wheel alignments are to be set at curb

height. (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE)

FRONT WHEEL ALIGNMENT PREFERRED SETTING ACCEPTABLE RANGE

CAMBER +0.10É -0.30É to +0.50É

Cross-Camber (Maximum side-to-side

difference)0.0É 0.50É

CASTER* +2.31É +1.31É to +3.31É

Cross-Caster (Maximum side-to-side difference) 0.0É 1.00É

TOTAL TOE** +0.10É20.10É to +0.30É

Maximum side-to-side difference 0.0É 0.06É

REAR WHEEL ALIGNMENT PREFERRED SETTING ACCEPTABLE RANGE

CAMBER* 0.0É -0.25É to +0.25É

TOTAL TOE* ** 0.0É20.20É to +0.20É

THRUST ANGLE* 0.0É -0.30É to +0.30É

Notes:

* For reference only. These are non-adjustable angles.

** TOTAL TOE is the sum of both left and right wheel toe settings. TOTAL TOE must be equally split between

each front wheel to ensure the steering wheel is centered after setting toe. Positive toe is toe-in and negative toe

is toe-out

2 - 56 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

ProCarManuals.com

Page 131 of 2399

DISC BRAKE CALIPER - FRONT

REMOVAL

REMOVAL - FRONT DISC BRAKE CALIPER

(DISC/DISC BRAKES)..................26

REMOVAL - FRONT DISC BRAKE CALIPER

(DISC/DRUM BRAKES).................26

DISASSEMBLY

DISASSEMBLY - CALIPER GUIDE PIN

BUSHINGS (DISC/DISC BRAKES).........27

DISASSEMBLY - CALIPER PISTON AND

SEAL...............................27

CLEANING - CALIPER...................28

INSPECTION - CALIPER..................28

ASSEMBLY

ASSEMBLY - CALIPER GUIDE PIN

BUSHINGS (DISC/DISC BRAKES).........28

ASSEMBLY - CALIPER PISTON AND SEAL . . 28

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

CALIPER (DISC/DISC BRAKES)...........29

INSTALLATION - FRONT DISC BRAKE

CALIPER (DISC/DRUM BRAKES)..........30

DISC BRAKE CALIPER - REAR

REMOVAL - REAR DISC BRAKE CALIPER....30

DISASSEMBLY - CALIPER PISTON AND SEAL . 31

CLEANING - CALIPER...................32

INSPECTION - CALIPER..................32

ASSEMBLY - CALIPER PISTON AND SEAL . . . 32

INSTALLATION - REAR DISC BRAKE CALIPER . 33

DISC BRAKE CALIPER ADAPTER

REMOVAL - FRONT DISC BRAKE CALIPER

ADAPTER...........................34

INSTALLATION - FRONT DISC BRAKE

CALIPER ADAPTER....................34

DISC BRAKE CALIPER GUIDE PINS

REMOVAL - DISC BRAKE CALIPER GUIDE

PINS (DISC/DRUM BRAKES).............34

INSTALLATION - DISC BRAKE CALIPER

GUIDE PINS (DISC/DRUM BRAKES).......34

DRUM

REMOVAL.............................35

INSTALLATION.........................35

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................35

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING.....................35

SPECIFICATIONS

BRAKE FLUID........................35

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK . 36

OPERATION - NON-ABS JUNCTION BLOCK . . 36

REMOVAL - NON-ABS JUNCTION BLOCK....36

INSTALLATION - NON-ABS JUNCTION BLOCK . 36

MASTER CYLINDER

DESCRIPTION

DESCRIPTION........................37DESCRIPTION - RHD..................38

OPERATION...........................38

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING..................38

REMOVAL

REMOVAL - LHD......................39

REMOVAL - RHD......................40

DISASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR).........................40

ASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR).........................41

INSTALLATION

INSTALLATION - LHD..................41

INSTALLATION - RHD..................42

PEDAL - ADJUSTABLE

DESCRIPTION.........................42

OPERATION...........................42

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL SYSTEM......................43

REMOVAL.............................43

INSTALLATION.........................45

PEDAL TORQUE SHAFT - RHD

REMOVAL.............................47

INSTALLATION.........................47

POWER BRAKE BOOSTER

DESCRIPTION.........................48

OPERATION...........................49

DIAGNOSIS AND TESTING - POWER BRAKE

BOOSTER...........................49

REMOVAL

REMOVAL - LHD......................50

REMOVAL - RHD......................52

INSTALLATION

INSTALLATION - LHD..................53

INSTALLATION - RHD..................55

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)....................56

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)....................57

DIAGNOSIS AND TESTING -

PROPORTIONING VALVE (HEIGHT

SENSING)...........................57

REMOVAL - PROPORTIONING VALVE

(HEIGHT SENSING)....................58

INSTALLATION - PROPORTIONING VALVE

(HEIGHT SENSING)....................59

ROTOR

DIAGNOSIS AND TESTING - BRAKE ROTOR . . 59

STANDARD PROCEDURE - BRAKE ROTOR

MACHINING..........................61

REMOVAL - FRONT BRAKE ROTOR........62

INSTALLATION - FRONT BRAKE ROTOR.....62

SPECIFICATIONS

BRAKE ROTOR.......................63

BRAKE ROTOR - EXPORT..............63

5 - 2 BRAKES - BASERS

ProCarManuals.com

Page 185 of 2399

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(14) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(15) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(16) Install the battery, clamp and mounting nut.

(17) Install the positive battery cable on the bat-

tery.

(18) Install the negative battery cable on the bat-

tery.

(19) Install the battery thermal guard shield.

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(20) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(21) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(22) Road test vehicle to ensure proper operation

of the brakes.

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)

NOTE: Only vehicles without antilock brakes (ABS)

have a proportioning valve. Vehicles with ABS uti-

lize electronic brake distribution which is controlled

through the ABS integrated control unit.

Vehicles not equipped with ABS use a height sens-

ing proportioning valve. It is mounted to the body of

the vehicle above the rear axle (Fig. 91). It has an

actuator lever that attaches to the rear axle and

moves with the axle to help the valve sense the vehi-

cle height.

CAUTION: The height sensing proportioning valve

is not adjustable. No attempt should be made to

adjust it. It is replaced as a complete assembly.

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

Fig. 90 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

Fig. 91 HEIGHT SENSING PROPORTIONING VALVE

1 - PROPORTIONING VALVE

2 - ACTUATOR LEVER

3 - AXLE BRACKET

4 - REAR AXLE

5 - 56 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

ProCarManuals.com

Page 186 of 2399

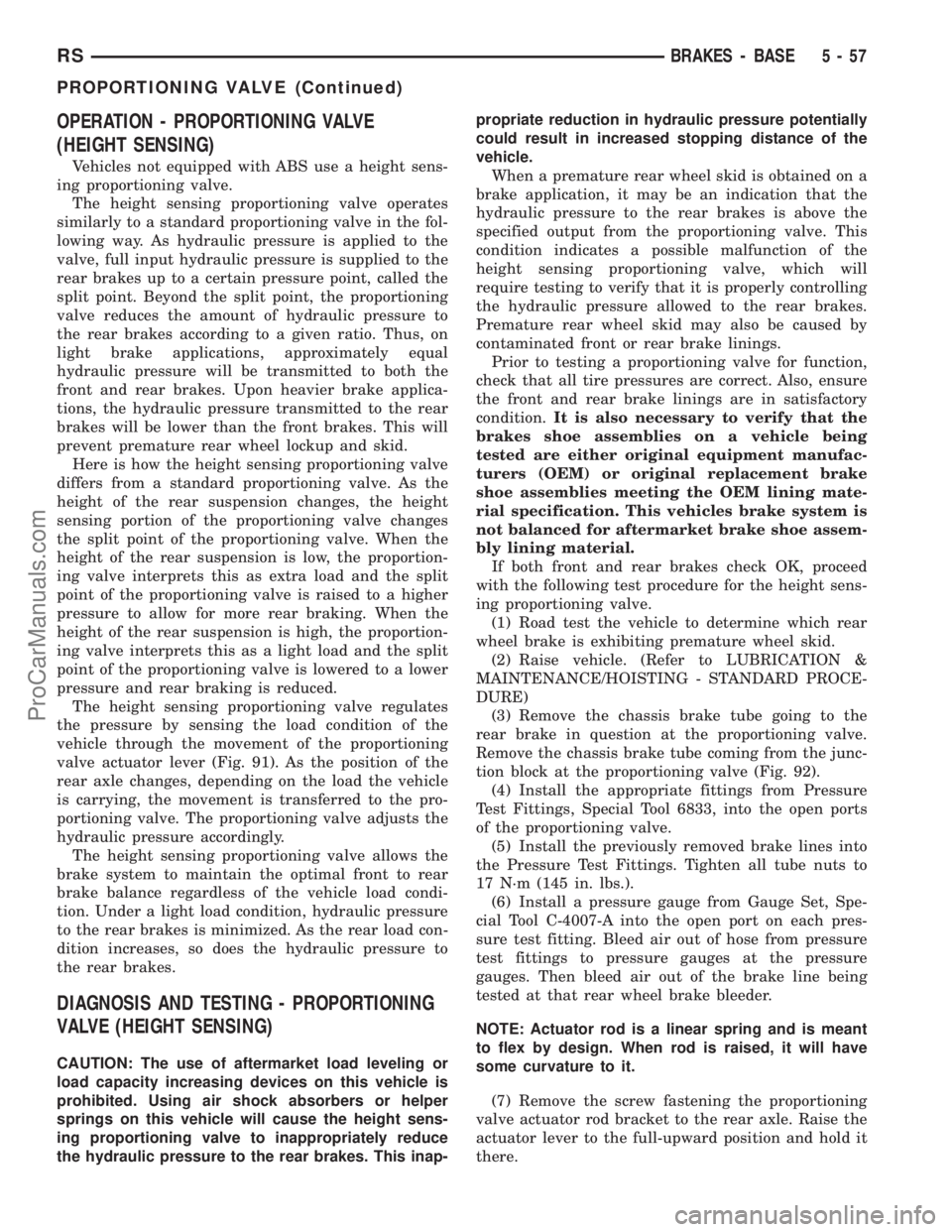

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)

Vehicles not equipped with ABS use a height sens-

ing proportioning valve.

The height sensing proportioning valve operates

similarly to a standard proportioning valve in the fol-

lowing way. As hydraulic pressure is applied to the

valve, full input hydraulic pressure is supplied to the

rear brakes up to a certain pressure point, called the

split point. Beyond the split point, the proportioning

valve reduces the amount of hydraulic pressure to

the rear brakes according to a given ratio. Thus, on

light brake applications, approximately equal

hydraulic pressure will be transmitted to both the

front and rear brakes. Upon heavier brake applica-

tions, the hydraulic pressure transmitted to the rear

brakes will be lower than the front brakes. This will

prevent premature rear wheel lockup and skid.

Here is how the height sensing proportioning valve

differs from a standard proportioning valve. As the

height of the rear suspension changes, the height

sensing portion of the proportioning valve changes

the split point of the proportioning valve. When the

height of the rear suspension is low, the proportion-

ing valve interprets this as extra load and the split

point of the proportioning valve is raised to a higher

pressure to allow for more rear braking. When the

height of the rear suspension is high, the proportion-

ing valve interprets this as a light load and the split

point of the proportioning valve is lowered to a lower

pressure and rear braking is reduced.

The height sensing proportioning valve regulates

the pressure by sensing the load condition of the

vehicle through the movement of the proportioning

valve actuator lever (Fig. 91). As the position of the

rear axle changes, depending on the load the vehicle

is carrying, the movement is transferred to the pro-

portioning valve. The proportioning valve adjusts the

hydraulic pressure accordingly.

The height sensing proportioning valve allows the

brake system to maintain the optimal front to rear

brake balance regardless of the vehicle load condi-

tion. Under a light load condition, hydraulic pressure

to the rear brakes is minimized. As the rear load con-

dition increases, so does the hydraulic pressure to

the rear brakes.

DIAGNOSIS AND TESTING - PROPORTIONING

VALVE (HEIGHT SENSING)

CAUTION: The use of aftermarket load leveling or

load capacity increasing devices on this vehicle is

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

When a premature rear wheel skid is obtained on a

brake application, it may be an indication that the

hydraulic pressure to the rear brakes is above the

specified output from the proportioning valve. This

condition indicates a possible malfunction of the

height sensing proportioning valve, which will

require testing to verify that it is properly controlling

the hydraulic pressure allowed to the rear brakes.

Premature rear wheel skid may also be caused by

contaminated front or rear brake linings.

Prior to testing a proportioning valve for function,

check that all tire pressures are correct. Also, ensure

the front and rear brake linings are in satisfactory

condition.It is also necessary to verify that the

brakes shoe assemblies on a vehicle being

tested are either original equipment manufac-

turers (OEM) or original replacement brake

shoe assemblies meeting the OEM lining mate-

rial specification. This vehicles brake system is

not balanced for aftermarket brake shoe assem-

bly lining material.

If both front and rear brakes check OK, proceed

with the following test procedure for the height sens-

ing proportioning valve.

(1) Road test the vehicle to determine which rear

wheel brake is exhibiting premature wheel skid.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove the chassis brake tube going to the

rear brake in question at the proportioning valve.

Remove the chassis brake tube coming from the junc-

tion block at the proportioning valve (Fig. 92).

(4) Install the appropriate fittings from Pressure

Test Fittings, Special Tool 6833, into the open ports

of the proportioning valve.

(5) Install the previously removed brake lines into

the Pressure Test Fittings. Tighten all tube nuts to

17 N´m (145 in. lbs.).

(6) Install a pressure gauge from Gauge Set, Spe-

cial Tool C-4007-A into the open port on each pres-

sure test fitting. Bleed air out of hose from pressure

test fittings to pressure gauges at the pressure

gauges. Then bleed air out of the brake line being

tested at that rear wheel brake bleeder.

NOTE: Actuator rod is a linear spring and is meant

to flex by design. When rod is raised, it will have

some curvature to it.

(7) Remove the screw fastening the proportioning

valve actuator rod bracket to the rear axle. Raise the

actuator lever to the full-upward position and hold it

there.

RSBRAKES - BASE5-57

PROPORTIONING VALVE (Continued)

ProCarManuals.com

Page 187 of 2399

(8) With the aid of a helper, apply pressure to the

brake pedal until a pressure of 6895 kPa (1000 psi) is

obtained on the proportioning valve inlet gauge.

Then, based on the type of brake system the vehicle

is equipped with and the pressure specification

shown on the following table, compare the pressure

reading on the outlet gauge to the specification. If

outlet pressure at the proportioning valve is not

within specification when required inlet pressure is

obtained, replace the proportioning valve. (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/PROPOR-

TIONING VALVE - REMOVAL)

CAUTION: Do not attempt to adjust the height sens-

ing proportioning valve. If found to be defective,

replace the valve.(9) Remove the pressure test fittings and pressure

gauges from the proportioning valve.

(10) Install the chassis brake lines in the correct

ports of the proportioning valve. Tighten all tube

nuts to 17 N´m (145 in. lbs.).

(11) If necessary, repeat the above steps on the

remaining side of the proportioning valve which con-

trol the other rear wheel brake.

(12) Attach the actuator lever and bracket to the

rear axle.

(13) Bleed rear brakes. (Refer to 5 - BRAKES -

STANDARD PROCEDURE)

(14) Road test vehicle.

PROPORTIONING VALVE SPECIFICATIONS

WHEEL

BASEDRIVE

TRAINSALES CODE BRAKE SYSTEMSPLIT

POINTSLOPEINLET

PRESSURE

PSIOUTLET

PRESSURE

PSI

SWB FWD BRB-BGF159DISC/DRUM

W/O ANTILOCKVAR. .59 1000 PSI 675-875 PSI

REMOVAL - PROPORTIONING VALVE (HEIGHT

SENSING)

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the proportioning valve.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

CAUTION: Before removing the brake tubes from

the proportioning valve, the proportioning valve and

the brake tubes must be thoroughly cleaned. This is

required to prevent contamination from entering the

proportioning valve or the brake tubes.

(3) Remove the four brake tubes from the inlet and

outlet ports of the proportioning valve (Fig. 92).

(4) Remove the two bolts attaching the proportion-

ing valve and bracket to the vehicle (Fig. 92).

(5) Slide the bracket out from under rear track bar

bracket. Lower the valve down enough to pull its

actuator rod out of the axle bracket and remove the

proportioning valve from the vehicle.

Fig. 92 PROPORTIONING VALVE MOUNTING

1 - LEFT REAR OUTLET TUBE

2 - RIGHT REAR OUTLET TUBE

3 - RIGHT REAR INLET TUBE

4 - MOUNTING BOLTS

5 - LEFT REAR INLET TUBE

5 - 58 BRAKES - BASERS

PROPORTIONING VALVE (Continued)

ProCarManuals.com

Page 188 of 2399

INSTALLATION - PROPORTIONING VALVE

(HEIGHT SENSING)

(1) Install the end of the actuator rod through the

axle bracket grommet and slide the proportioning

valve bracket under the rear track bar body bracket

(Fig. 92).

(2) Install the proportioning valve attaching bolts

(Fig. 92). Tighten the attaching bolts to a torque of

54 N´m (40 ft. lbs.).

(3) Install the four chassis brake lines into the

inlet and outlet ports of the proportioning valve (Fig.

92). Tighten all tube nuts to a torque of 17 N´m (145

in. lbs.).

CAUTION: The height sensing proportioning valve

is not adjustable. No attempt should be made to

adjust it.

(4) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. (Refer to 5 - BRAKES - BASE - STANDARD

PROCEDURE).

(5) Lower the vehicle to the ground.

(6) Road test the vehicle to verify proper operation

of the brake system.

ROTOR

DIAGNOSIS AND TESTING - BRAKE ROTOR

Any servicing of the rotor requires extreme care to

maintain the rotor within service tolerances to

ensure proper brake action.

Excessive runout or wobble in a rotor can increase

pedal travel due to piston knock-back. This increases

guide pin sleeve wear due to the tendency of the cal-

iper to follow the rotor wobble.

When diagnosing a brake noise or pulsation, the

machined disc braking surface should be checked and

inspected.

BRAKING SURFACE INSPECTION

Light braking surface scoring and wear is accept-

able. If heavy scoring or warping is evident, the rotor

must be refaced or replaced. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - STAN-

DARD PROCEDURE).

Excessive wear and scoring of the rotor can cause

improper lining contact on the rotor's braking sur-

face. If the ridges on the rotor are not removed before

new brake shoes are installed, improper wear of the

shoes will result.

If a vehicle has not been driven for a period of time,

the rotor's braking surface will rust in the areas not

covered by the brake shoes at that time. Once the

vehicle is driven, noise and chatter from the disc

brakes can result when the brakes are applied.

Some discoloration or wear of the rotor surface is

normal and does not require resurfacing when lin-

ings are replaced. If cracks or burned spots are evi-

dent, the rotor must be replaced.

ROTOR MINIMUM THICKNESS

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if it is worn

below minimum thickness or if machining the rotor

will cause its thickness to fall below specifications.

CAUTION: Do not machine the rotor if it will cause

the rotor to fall below minimum thickness.

Minimum thickness specifications are cast on the

rotor's unmachined surface (Fig. 93). Limits can also

be found in this section's specification table. (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/ROTOR -

SPECIFICATIONS)

ROTOR THICKNESS VARIATION

Thickness variation in a rotor's braking surface

can result in pedal pulsation, chatter and surge. This

can also be caused by excessive runout in the rotor or

the hub.

Rotor thickness variation measurements should be

made in conjunction with measuring runout. Mea-

sure thickness of the brake rotor at 12 equal points

around the rotor braking surface with a micrometer

at a radius approximately 25 mm (1 inch) from edge

of rotor (Fig. 94). If thickness measurements vary

beyond the specification listed in the specifaction

table (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTOR - SPECIFICATIONS), the rotor should

be refaced or replaced. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - STANDARD

PROCEDURE).

Fig. 93 Minimum Brake Rotor Thickness Markings

(Typical)

1 - ROTOR MINIMUM THICKNESS MARKING

2 - ROTOR

RSBRAKES - BASE5-59

PROPORTIONING VALVE (Continued)

ProCarManuals.com

Page 610 of 2399

RESTRAINTS

TABLE OF CONTENTS

page page

RESTRAINTS

DESCRIPTION..........................2

OPERATION............................2

WARNING.............................2

DIAGNOSIS AND TESTING - AIRBAG SYSTEM . 2

CLOCK SPRING

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE - CLOCK SPRING

CENTERING..........................3

REMOVAL.............................3

INSTALLATION..........................3

DRIVER AIRBAG

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE - CLEAN UP.......4

REMOVAL.............................4

INSTALLATION..........................4

DRIVER AIRBAG TRIM COVER

REMOVAL.............................4

INSTALLATION..........................5

OCCUPANT RESTRAINT CONTROLLER

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................5

PASSENGER AIRBAG

DESCRIPTION..........................6

OPERATION............................6

STANDARD PROCEDURE - CLEAN UP.......6

REMOVAL.............................6

INSTALLATION..........................6

SEAT AIRBAG

DESCRIPTION..........................7

OPERATION............................7

SEAT BELT OUTBOARD FRONT

REMOVAL.............................7

INSTALLATION..........................7

SEAT BELT FIRST ROW ANCHOR BRACKET -

LW B

REMOVAL.............................8

INSTALLATION..........................8

SEAT BELT LEFT FIRST ROW OUTBOARD -

SWB THREE DOOR

REMOVAL.............................8

INSTALLATION..........................8SEAT BELT FIRST ROW OUTBOARD - SWB

FOUR DOOR

REMOVAL.............................9

INSTALLATION..........................9

SEAT BELT FIRST ROW OUTBOARD - LWB

FOUR DOOR

REMOVAL.............................10

INSTALLATION.........................10

SEAT BELT SECOND RIGHT ROW OUTBOARD

-LWB

REMOVAL.............................10

INSTALLATION.........................10

SEAT BELT SECOND RIGHT ROW OUTBOARD

- LBW WITH REAR HVAC

REMOVAL.............................11

INSTALLATION.........................11

SEAT BELT SECOND ROW OUTBOARD - SWB

REMOVAL.............................12

INSTALLATION.........................12

SEAT BELT BUCKLE - FRONT INBOARD

REMOVAL.............................13

INSTALLATION.........................13

SEAT BELT BUCKLE FIRST ROW QUAD

BUCKET

REMOVAL.............................13

INSTALLATION.........................13

SEAT BELT BUCKLE FIRST ROW - TWO

PASSENGER BENCH

REMOVAL.............................14

INSTALLATION.........................14

SEAT BELT BUCKLE SECOND ROW - THREE

PASSENGER BENCH

REMOVAL.............................14

INSTALLATION.........................14

SEAT BELT TENSIONER

DESCRIPTION.........................14

OPERATION...........................14

SHOULDER BELT HEIGHT ADJUSTER

REMOVAL.............................15

INSTALLATION.........................15

SHOULDER BELT HEIGHT ADJUSTER KNOB

REMOVAL.............................15

INSTALLATION.........................15

SIDE IMPACT AIRBAG CONTROL MODULE

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

RSRESTRAINTS8O-1

ProCarManuals.com

Page 616 of 2399

(2) Install airbag attaching bolts to the instrument

panel.

(3) Connect yellow wire connector from passenger

airbag.

(4) Install Instrument panel. Refer to Body, Instru-

ment Panel, Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

UNDEPLOYED AIRBAG

(1) Install Passenger Airbag into instrument panel.

(2) Install airbag attaching bolts to the instrument

panel.

(3) Connect yellow wire connector from passenger

airbag.

(4) Install Instrument panel. Refer to Body, Instru-

ment Panel, Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

SEAT AIRBAG

DESCRIPTION

The side impact airbag system Seat Airbags are

located in the outboard side of the front seat backs.One in each front seat. The seat airbag inflator

assembly is within the airbag housing (Fig. 1). Each

airbag is mounted to the seat back frame. If deployed

or defective, the entire seat back assembly must be

replaced.

OPERATION

Only the Side Impact Airbag Control Module

(SIACM) can deploy the side airbags. When supplied

with the proper electrical signal, the seat airbag

inflator will produce a gas and discharge the bag

directly between the occupant and the side of the

vehicle, protecting the occupant. Upon deployment,

the seat back trim cover will tear open and allow the

side airbag to fully inflate and quickly deflate.

SEAT BELT OUTBOARD

FRONT

REMOVAL

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(2) Remove cover from seat belt turning loop.

(3) Remove bolt attaching turning loop to shoulder

belt height adjuster (Fig. 2).

(4) Remove turning loop from B-pillar.

(5) Remove lower B-pillar trim cover or quarter

trim panel.

(6) Remove bolt attaching seat belt retractor to

B-pillar (Fig. 2).

(7) Lift retractor upward and disengage arrow

head retainer attaching retractor to B-pillar.

(8) Remove seat belt from vehicle.

INSTALLATION

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Place seat belt into position.

(2) Lower retractor into position B-pillar.

(3) Install bolt attaching seat belt retractor to

B-pillar. Tighten all seat belt anchor bolts to 39 N´m

(29 ft. lbs.) torque.

(4) Install turning loop onto B-pillar.

(5) Install lower B-pillar trim cover or quarter

trim panel.

(6) Install bolt attaching turning loop to shoulder

belt height adjuster. Tighten all seat belt anchor

bolts to 39 N´m (29 ft. lbs.) torque.

(7) Press cover onto the seat belt turning loop.

Fig. 1 SEAT AIRBAG - TYPICAL

RSRESTRAINTS8O-7

PASSENGER AIRBAG (Continued)

ProCarManuals.com

Page 617 of 2399

(8) Install shoulder harness height adjuster knob

by pushing onto the adjuster.

SEAT BELT FIRST ROW

ANCHOR BRACKET - LWB

REMOVAL

(1) Remove lower quarter trim panel.

(2) Remove bolt attaching first row seat belt

anchor bracket to floor.

(3) Remove bracket from vehicle.

INSTALLATION

(1) Position bracket to vehicle.

(2) Install bolt attaching first row seat belt anchor

bracket to floor.

(3) Install lower quarter trim panel.

NOTE: The tightening specification for all seat belt

anchor bolts is 39 N´m (29 ft. lbs.) torque.

SEAT BELT LEFT FIRST ROW

OUTBOARD - SWB THREE

DOOR

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 3).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove B-pillar upper trim cover.

(10) Remove C-pillar upper trim cover.

(11) Remove lower quarter trim panel.

(12) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(13) Remove bolt attaching seat belt retractor to

quarter panel.

(14) Lift retractor upward and disengage arrow

head retainer attaching retractor to quarter panel

(Fig. 3).

(15) Remove seat belt from vehicle.

INSTALLATION

(1) Install seat belt into position.

(2) Lower retractor into position to quarter panel.

(3) Install bolt attaching seat belt retractor to

quarter panel. Tighten all seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(4) Install lower quarter trim panel.

(5) Install C-pillar upper trim cover.

(6) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(7) Install B-pillar upper trim cover.

(8) Install turning loop onto C-pillar. Tighten all

seat belt anchor bolts to 39 N´m (29 ft. lbs.) torque.

(9) Press clam shell cover over seat belt turning

loop.

(10) Install anchor to floor.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing it onto adjuster.

Fig. 2 SEAT BELT - OUTBOARD FRONT

1 - B-PILLAR TRIM LOWER

2 - BELT

3 - B-PILLAR TRIM UPPER

4 - HEIGHT ADJUSTER

5 - KNOB

6 - B-PILLAR TRIM LOWER

7 - FLOOR ANCHOR

8 - FLOOR ANCHOR

9 - 30É OUTBOARD

10 - RETRACTOR

8O - 8 RESTRAINTSRS

SEAT BELT OUTBOARD FRONT (Continued)

ProCarManuals.com