shaft CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1584 of 2399

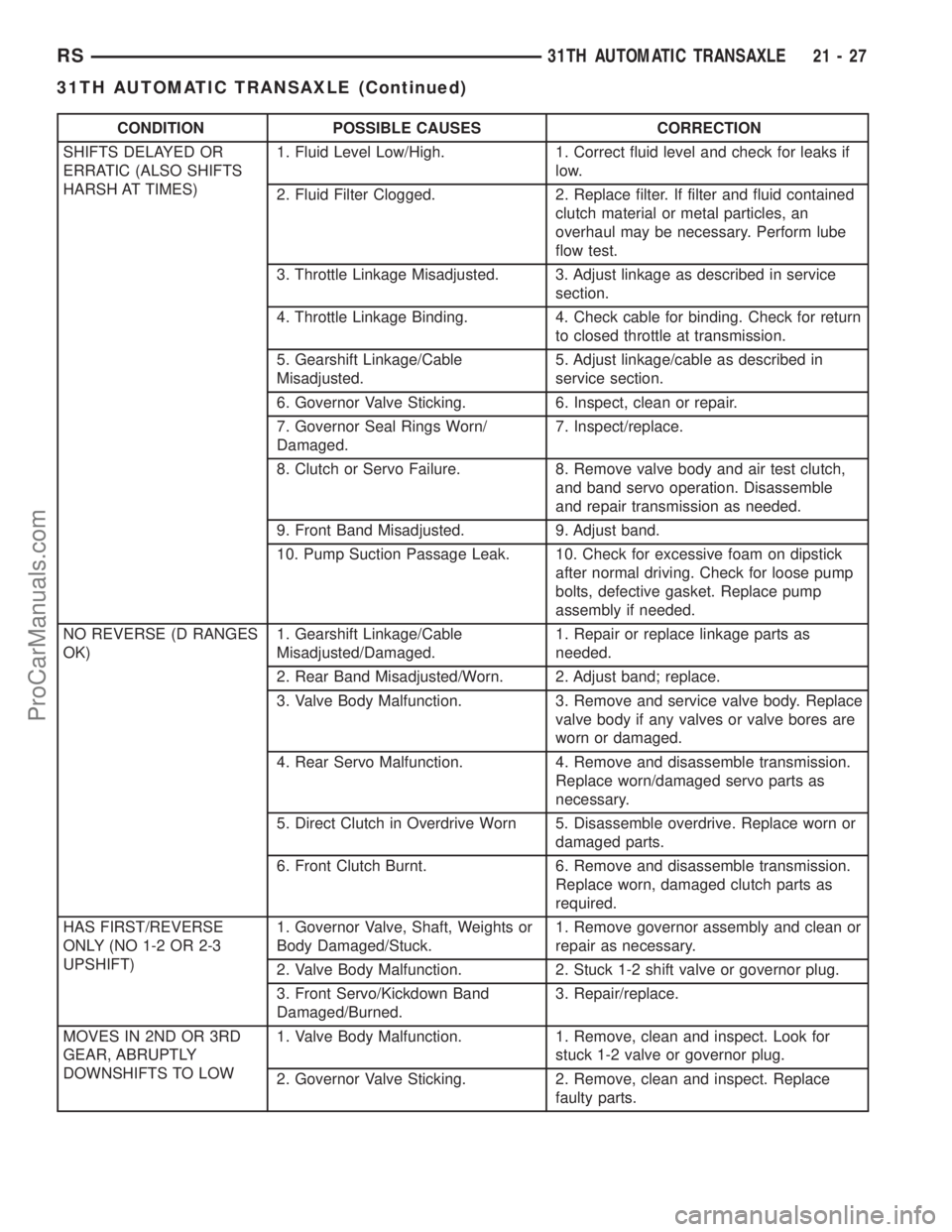

CONDITION POSSIBLE CAUSES CORRECTION

SHIFTS DELAYED OR

ERRATIC (ALSO SHIFTS

HARSH AT TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

clutch material or metal particles, an

overhaul may be necessary. Perform lube

flow test.

3. Throttle Linkage Misadjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

to closed throttle at transmission.

5. Gearshift Linkage/Cable

Misadjusted.5. Adjust linkage/cable as described in

service section.

6. Governor Valve Sticking. 6. Inspect, clean or repair.

7. Governor Seal Rings Worn/

Damaged.7. Inspect/replace.

8. Clutch or Servo Failure. 8. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

9. Front Band Misadjusted. 9. Adjust band.

10. Pump Suction Passage Leak. 10. Check for excessive foam on dipstick

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

NO REVERSE (D RANGES

OK)1. Gearshift Linkage/Cable

Misadjusted/Damaged.1. Repair or replace linkage parts as

needed.

2. Rear Band Misadjusted/Worn. 2. Adjust band; replace.

3. Valve Body Malfunction. 3. Remove and service valve body. Replace

valve body if any valves or valve bores are

worn or damaged.

4. Rear Servo Malfunction. 4. Remove and disassemble transmission.

Replace worn/damaged servo parts as

necessary.

5. Direct Clutch in Overdrive Worn 5. Disassemble overdrive. Replace worn or

damaged parts.

6. Front Clutch Burnt. 6. Remove and disassemble transmission.

Replace worn, damaged clutch parts as

required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Valve, Shaft, Weights or

Body Damaged/Stuck.1. Remove governor assembly and clean or

repair as necessary.

2. Valve Body Malfunction. 2. Stuck 1-2 shift valve or governor plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

stuck 1-2 valve or governor plug.

2. Governor Valve Sticking. 2. Remove, clean and inspect. Replace

faulty parts.

RS31TH AUTOMATIC TRANSAXLE21-27

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1585 of 2399

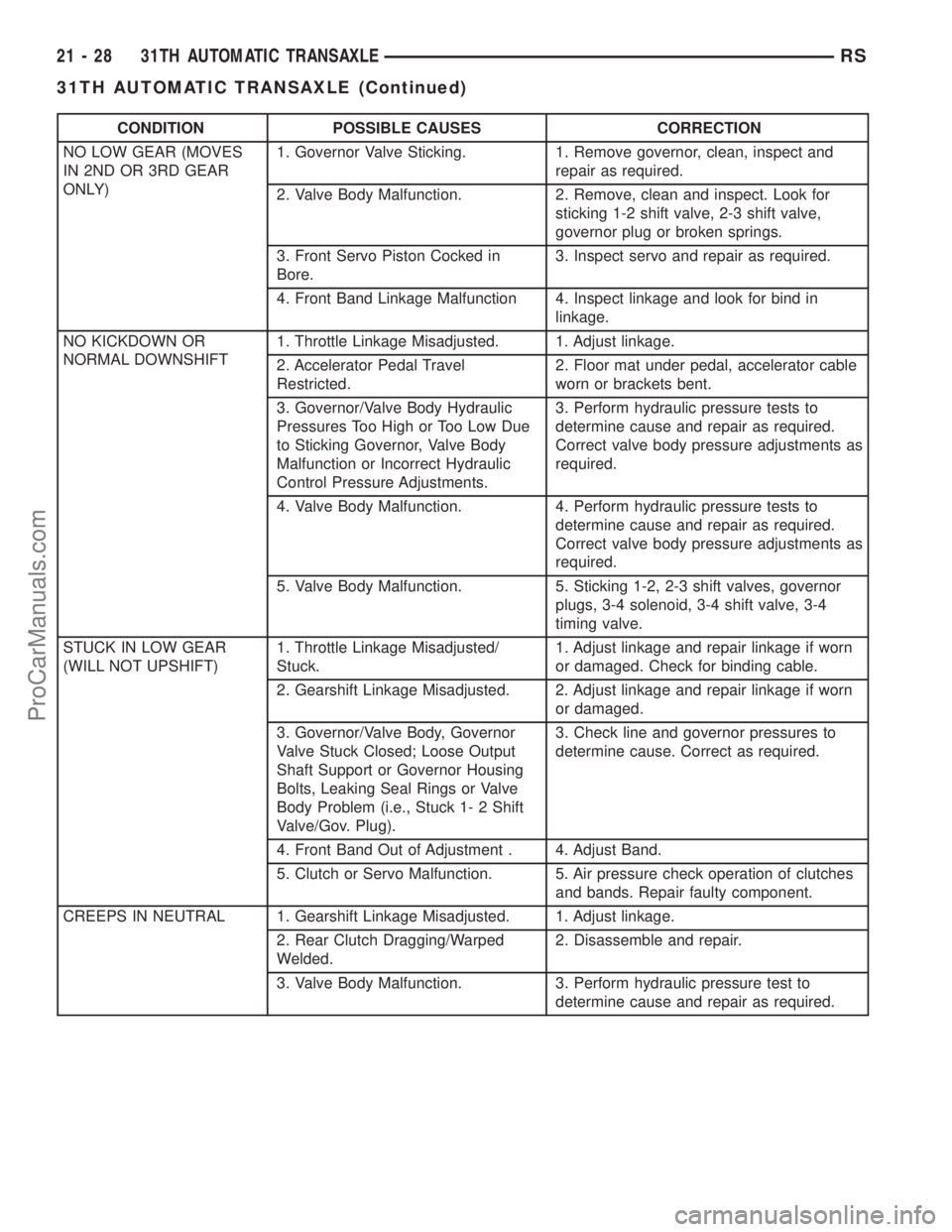

CONDITION POSSIBLE CAUSES CORRECTION

NO LOW GEAR (MOVES

IN 2ND OR 3RD GEAR

ONLY)1. Governor Valve Sticking. 1. Remove governor, clean, inspect and

repair as required.

2. Valve Body Malfunction. 2. Remove, clean and inspect. Look for

sticking 1-2 shift valve, 2-3 shift valve,

governor plug or broken springs.

3. Front Servo Piston Cocked in

Bore.3. Inspect servo and repair as required.

4. Front Band Linkage Malfunction 4. Inspect linkage and look for bind in

linkage.

NO KICKDOWN OR

NORMAL DOWNSHIFT1. Throttle Linkage Misadjusted. 1. Adjust linkage.

2. Accelerator Pedal Travel

Restricted.2. Floor mat under pedal, accelerator cable

worn or brackets bent.

3. Governor/Valve Body Hydraulic

Pressures Too High or Too Low Due

to Sticking Governor, Valve Body

Malfunction or Incorrect Hydraulic

Control Pressure Adjustments.3. Perform hydraulic pressure tests to

determine cause and repair as required.

Correct valve body pressure adjustments as

required.

4. Valve Body Malfunction. 4. Perform hydraulic pressure tests to

determine cause and repair as required.

Correct valve body pressure adjustments as

required.

5. Valve Body Malfunction. 5. Sticking 1-2, 2-3 shift valves, governor

plugs, 3-4 solenoid, 3-4 shift valve, 3-4

timing valve.

STUCK IN LOW GEAR

(WILL NOT UPSHIFT)1. Throttle Linkage Misadjusted/

Stuck.1. Adjust linkage and repair linkage if worn

or damaged. Check for binding cable.

2. Gearshift Linkage Misadjusted. 2. Adjust linkage and repair linkage if worn

or damaged.

3. Governor/Valve Body, Governor

Valve Stuck Closed; Loose Output

Shaft Support or Governor Housing

Bolts, Leaking Seal Rings or Valve

Body Problem (i.e., Stuck 1- 2 Shift

Valve/Gov. Plug).3. Check line and governor pressures to

determine cause. Correct as required.

4. Front Band Out of Adjustment . 4. Adjust Band.

5. Clutch or Servo Malfunction. 5. Air pressure check operation of clutches

and bands. Repair faulty component.

CREEPS IN NEUTRAL 1. Gearshift Linkage Misadjusted. 1. Adjust linkage.

2. Rear Clutch Dragging/Warped

Welded.2. Disassemble and repair.

3. Valve Body Malfunction. 3. Perform hydraulic pressure test to

determine cause and repair as required.

21 - 28 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1587 of 2399

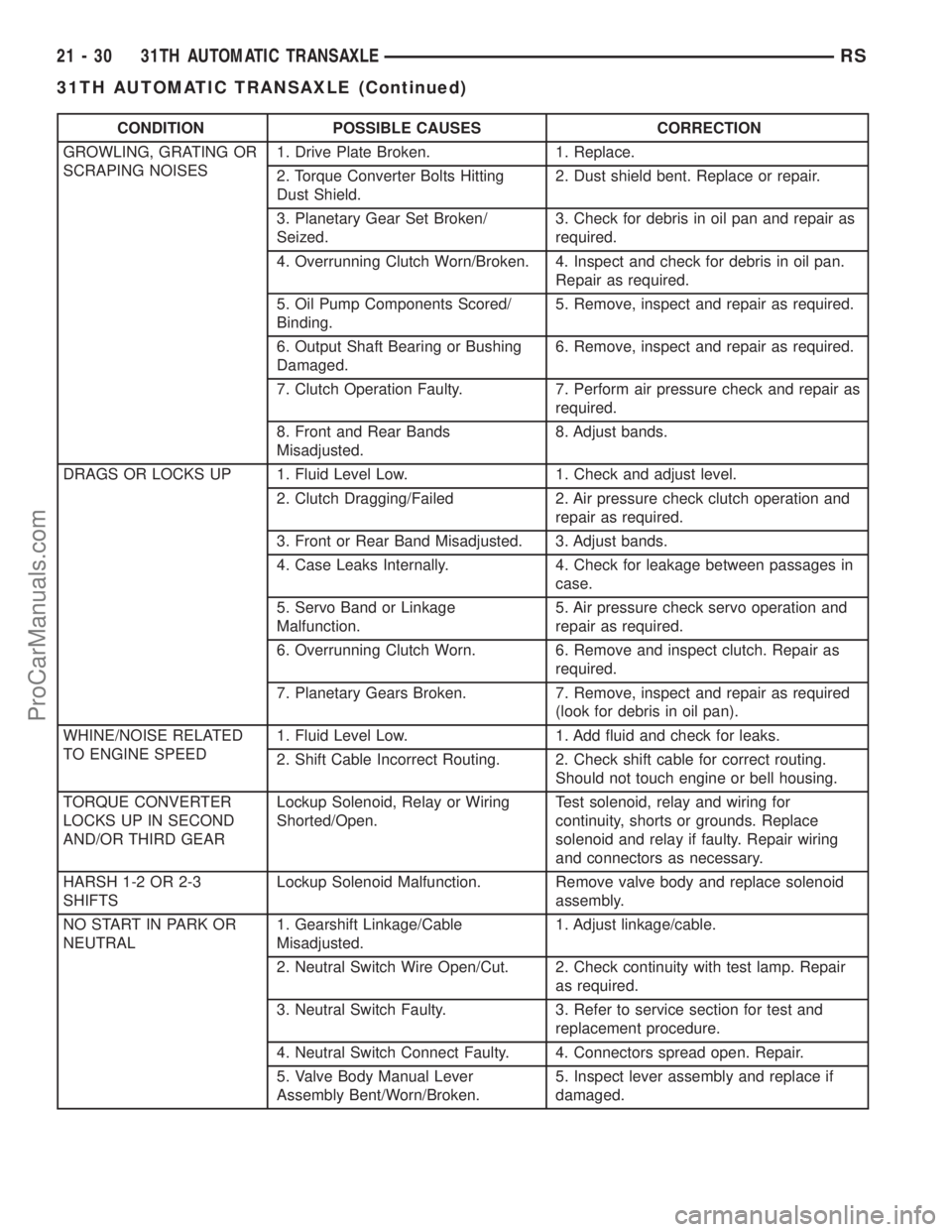

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

Repair as required.

5. Oil Pump Components Scored/

Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Misadjusted.8. Adjust bands.

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

repair as required.

3. Front or Rear Band Misadjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and

repair as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

(look for debris in oil pan).

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK OR

NEUTRAL1. Gearshift Linkage/Cable

Misadjusted.1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

21 - 30 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1588 of 2399

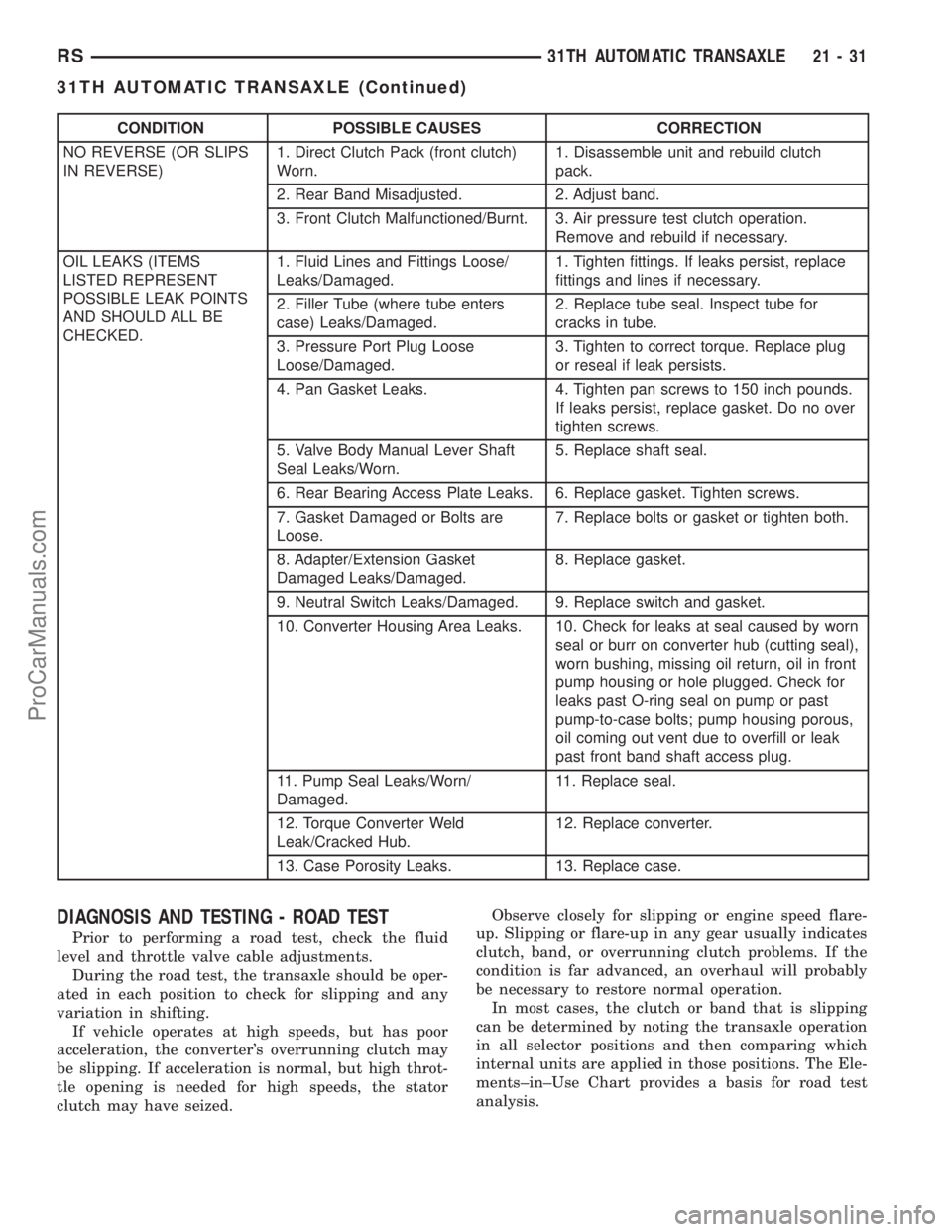

CONDITION POSSIBLE CAUSES CORRECTION

NO REVERSE (OR SLIPS

IN REVERSE)1. Direct Clutch Pack (front clutch)

Worn.1. Disassemble unit and rebuild clutch

pack.

2. Rear Band Misadjusted. 2. Adjust band.

3. Front Clutch Malfunctioned/Burnt. 3. Air pressure test clutch operation.

Remove and rebuild if necessary.

OIL LEAKS (ITEMS

LISTED REPRESENT

POSSIBLE LEAK POINTS

AND SHOULD ALL BE

CHECKED.1. Fluid Lines and Fittings Loose/

Leaks/Damaged.1. Tighten fittings. If leaks persist, replace

fittings and lines if necessary.

2. Filler Tube (where tube enters

case) Leaks/Damaged.2. Replace tube seal. Inspect tube for

cracks in tube.

3. Pressure Port Plug Loose

Loose/Damaged.3. Tighten to correct torque. Replace plug

or reseal if leak persists.

4. Pan Gasket Leaks. 4. Tighten pan screws to 150 inch pounds.

If leaks persist, replace gasket. Do no over

tighten screws.

5. Valve Body Manual Lever Shaft

Seal Leaks/Worn.5. Replace shaft seal.

6. Rear Bearing Access Plate Leaks. 6. Replace gasket. Tighten screws.

7. Gasket Damaged or Bolts are

Loose.7. Replace bolts or gasket or tighten both.

8. Adapter/Extension Gasket

Damaged Leaks/Damaged.8. Replace gasket.

9. Neutral Switch Leaks/Damaged. 9. Replace switch and gasket.

10. Converter Housing Area Leaks. 10. Check for leaks at seal caused by worn

seal or burr on converter hub (cutting seal),

worn bushing, missing oil return, oil in front

pump housing or hole plugged. Check for

leaks past O-ring seal on pump or past

pump-to-case bolts; pump housing porous,

oil coming out vent due to overfill or leak

past front band shaft access plug.

11. Pump Seal Leaks/Worn/

Damaged.11. Replace seal.

12. Torque Converter Weld

Leak/Cracked Hub.12. Replace converter.

13. Case Porosity Leaks. 13. Replace case.

DIAGNOSIS AND TESTING - ROAD TEST

Prior to performing a road test, check the fluid

level and throttle valve cable adjustments.

During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

If vehicle operates at high speeds, but has poor

acceleration, the converter's overrunning clutch may

be slipping. If acceleration is normal, but high throt-

tle opening is needed for high speeds, the stator

clutch may have seized.Observe closely for slipping or engine speed flare-

up. Slipping or flare-up in any gear usually indicates

clutch, band, or overrunning clutch problems. If the

condition is far advanced, an overhaul will probably

be necessary to restore normal operation.

In most cases, the clutch or band that is slipping

can be determined by noting the transaxle operation

in all selector positions and then comparing which

internal units are applied in those positions. The Ele-

ments±in±Use Chart provides a basis for road test

analysis.

RS31TH AUTOMATIC TRANSAXLE21-31

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1590 of 2399

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi.as lever is moved counter-

clockwise.

(6) Low/reverse pressure should read the same as

line pressure, within 3 psi.

(7) This tests pump output, pressure regulation,

and condition of rear clutch and rear servo hydraulic

circuits.

TEST TWO (SELECTOR IN 2)

(1) Attach one gauge to line pressure port, and tee

another gauge into lower cooler line fitting. This will

allow lubrication pressure readings to be taken.

(2) Operate engine at 1000 rpm for test.

(3) Move selector lever on transaxle one detent for-

ward from full rearward position. This is selector 2

position.

Fig. 1 Test Port Locations

1 - ACCUMULATOR VENT 8 - TO COOLER

2 - MANUAL THROTTLE LEVER SHAFT 9 - KICKDOWN RELEASE (FRONT CLUTCH)

3 - MANUAL SHIFT LEVER SHAFT 10 - KICKDOWN APPLY

4 - LOW-REVERSE PRESSURE 11 - CONVERTER CLUTCH SOLENOID CONNECTOR

5 - GOVERNER PRESSURE (BELOW DIFFERENTIAL COVER ON

RIGHT SIDE)12 - FROM COOLER

6 - LINE PRESSURE 13 - KICKDOWN BAND ADJUSTING SCREW

7 - KICKDOWN APPLY AT ACCUMULATOR

Fig. 2 Governor Pressure Tap

1 - GOVERNOR PRESSURE PLUG

RS31TH AUTOMATIC TRANSAXLE21-33

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1595 of 2399

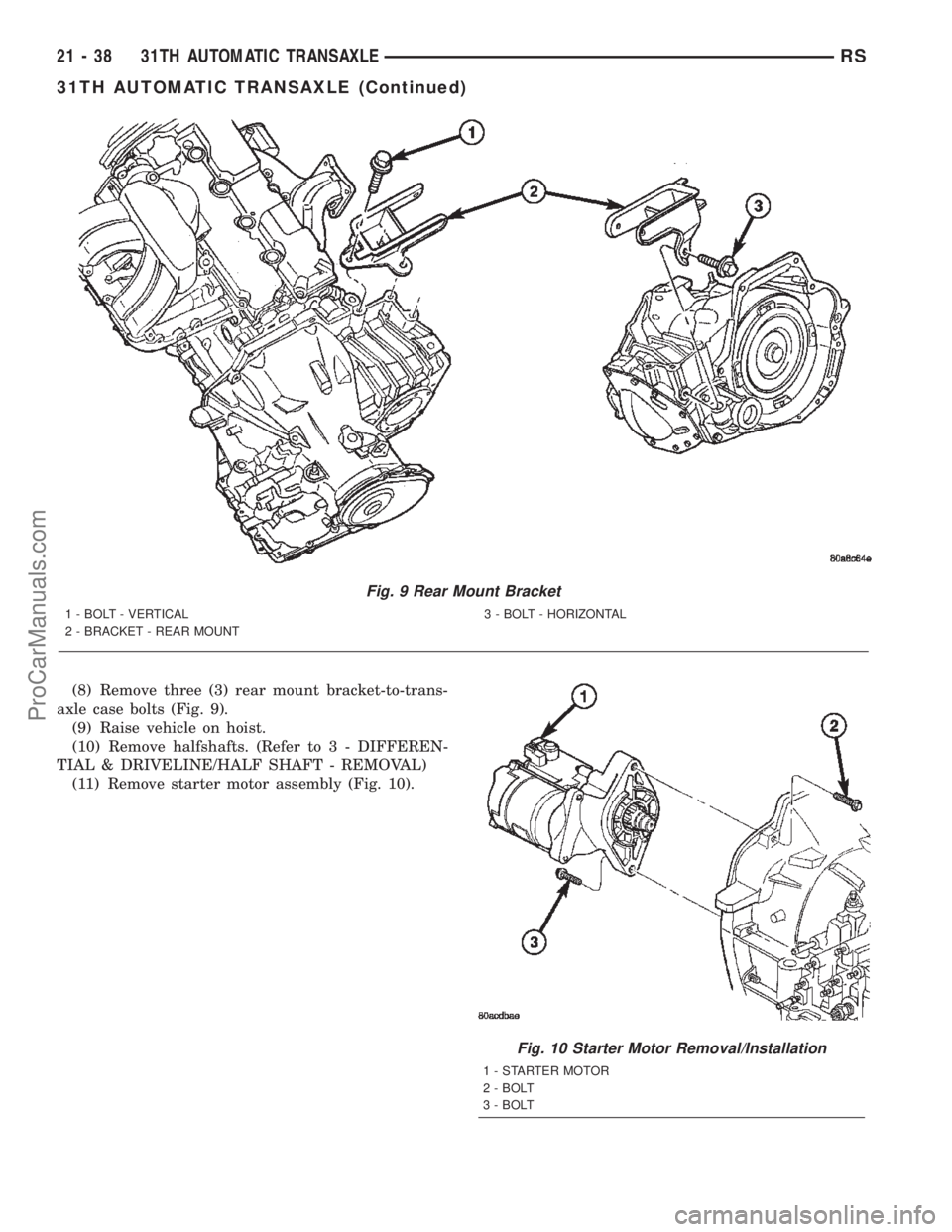

(8) Remove three (3) rear mount bracket-to-trans-

axle case bolts (Fig. 9).

(9) Raise vehicle on hoist.

(10) Remove halfshafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)

(11) Remove starter motor assembly (Fig. 10).

Fig. 9 Rear Mount Bracket

1 - BOLT - VERTICAL

2 - BRACKET - REAR MOUNT3 - BOLT - HORIZONTAL

Fig. 10 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT

3 - BOLT

21 - 38 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1597 of 2399

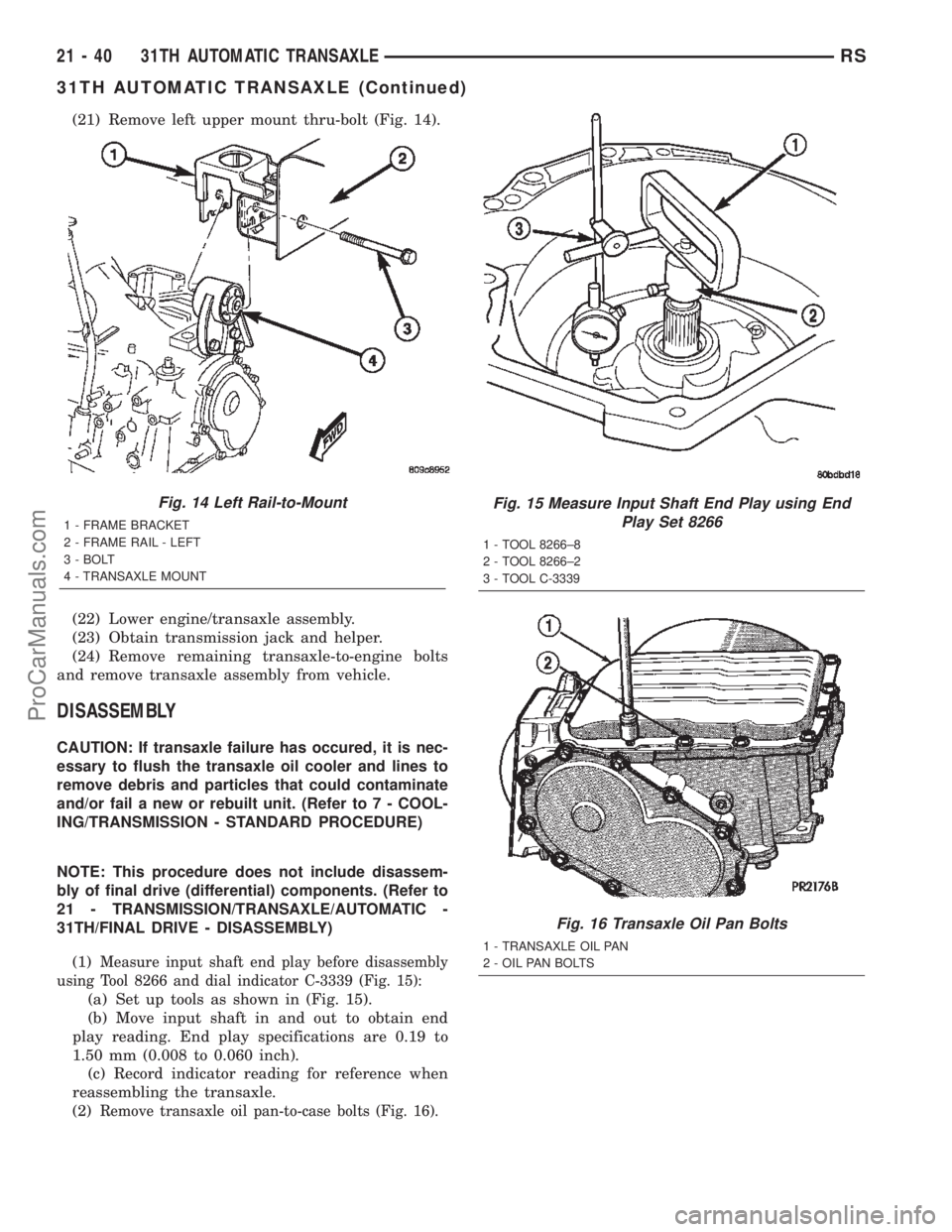

(21) Remove left upper mount thru-bolt (Fig. 14).

(22) Lower engine/transaxle assembly.

(23) Obtain transmission jack and helper.

(24) Remove remaining transaxle-to-engine bolts

and remove transaxle assembly from vehicle.

DISASSEMBLY

CAUTION: If transaxle failure has occured, it is nec-

essary to flush the transaxle oil cooler and lines to

remove debris and particles that could contaminate

and/or fail a new or rebuilt unit. (Refer to 7 - COOL-

ING/TRANSMISSION - STANDARD PROCEDURE)

NOTE: This procedure does not include disassem-

bly of final drive (differential) components. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/FINAL DRIVE - DISASSEMBLY)

(1)

Measure input shaft end play before disassembly

using Tool 8266 and dial indicator C-3339 (Fig. 15):

(a) Set up tools as shown in (Fig. 15).

(b) Move input shaft in and out to obtain end

play reading. End play specifications are 0.19 to

1.50 mm (0.008 to 0.060 inch).

(c) Record indicator reading for reference when

reassembling the transaxle.

(2)

Remove transaxle oil pan-to-case bolts (Fig. 16).

Fig. 14 Left Rail-to-Mount

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

Fig. 15 Measure Input Shaft End Play using End

Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

Fig. 16 Transaxle Oil Pan Bolts

1 - TRANSAXLE OIL PAN

2 - OIL PAN BOLTS

21 - 40 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1603 of 2399

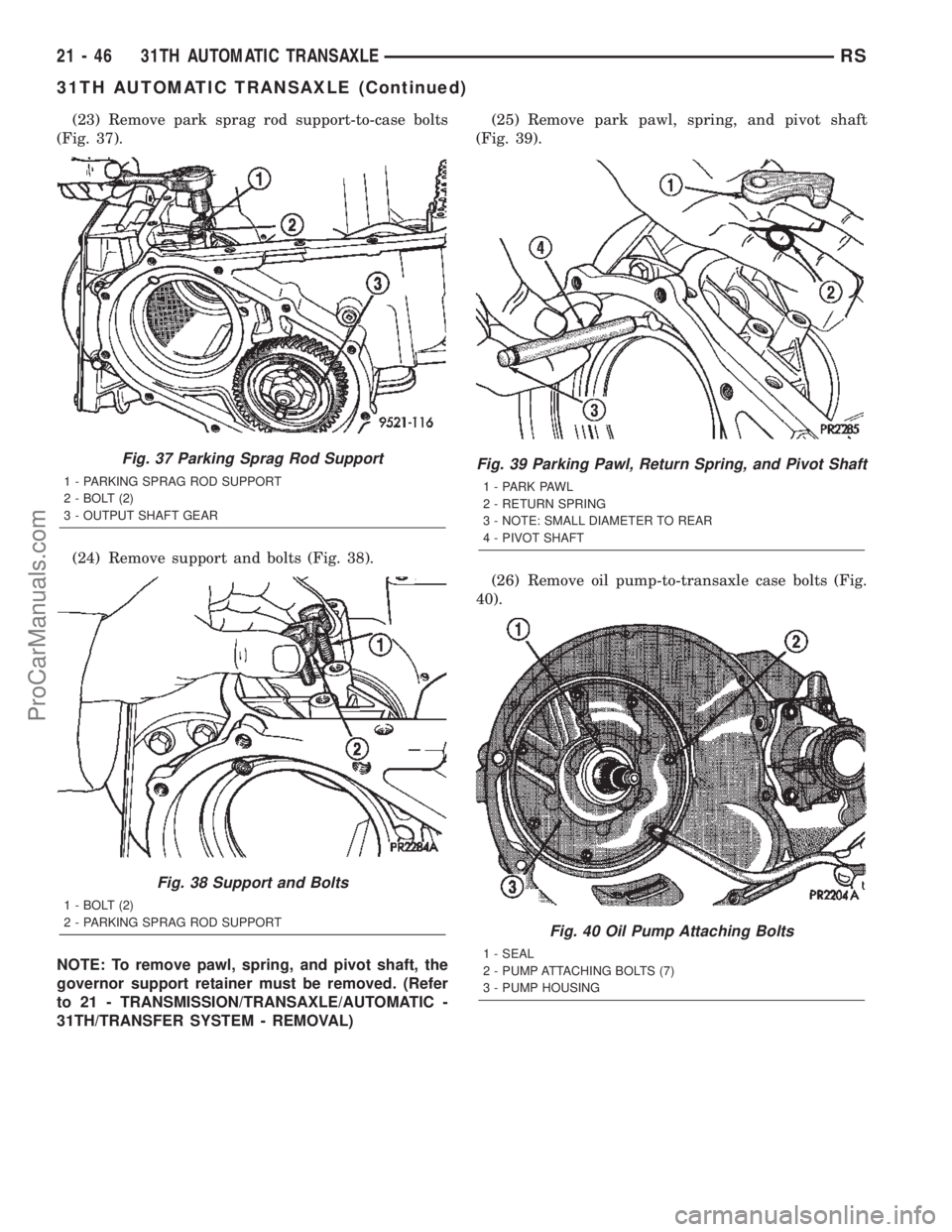

(23) Remove park sprag rod support-to-case bolts

(Fig. 37).

(24) Remove support and bolts (Fig. 38).

NOTE: To remove pawl, spring, and pivot shaft, the

governor support retainer must be removed. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/TRANSFER SYSTEM - REMOVAL)(25) Remove park pawl, spring, and pivot shaft

(Fig. 39).

(26) Remove oil pump-to-transaxle case bolts (Fig.

40).

Fig. 37 Parking Sprag Rod Support

1 - PARKING SPRAG ROD SUPPORT

2 - BOLT (2)

3 - OUTPUT SHAFT GEAR

Fig. 38 Support and Bolts

1 - BOLT (2)

2 - PARKING SPRAG ROD SUPPORT

Fig. 39 Parking Pawl, Return Spring, and Pivot Shaft

1 - PARK PAWL

2 - RETURN SPRING

3 - NOTE: SMALL DIAMETER TO REAR

4 - PIVOT SHAFT

Fig. 40 Oil Pump Attaching Bolts

1 - SEAL

2 - PUMP ATTACHING BOLTS (7)

3 - PUMP HOUSING

21 - 46 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1605 of 2399

(31) Remove front clutch assembly (Fig. 45).

(32) Remove rear clutch assembly (Fig. 46).

Inspect #2 thrust washer.(33) Remove #3 thrust washer (Fig. 47).

(34) Remove front planetary gear-to-output shaft

snap ring (Fig. 48).

Fig. 45 Front Clutch Assembly

1 - REAR CLUTCH ASSEMBLY

2 - FRONT CLUTCH ASSEMBLY

Fig. 46 No. 2 Thrust Washer and Rear Clutch

1 - REAR CLUTCH ASSEMBLY

2 - #2 THRUST WASHER

Fig. 47 No. 3 Thrust Washer

1 - OUTPUT SHAFT

2 - SUN GEAR DRIVING SHELL

3 - #3 THRUST WASHER (SELECT FIT)

Fig. 48 Front Planetary Gear Snap Ring

1 - FRONT PLANETARY GEAR SNAP RING

2 - SNAP RING PLIERS

3 - FRONT PLANETARY GEAR ASSEMBLY

21 - 48 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1606 of 2399

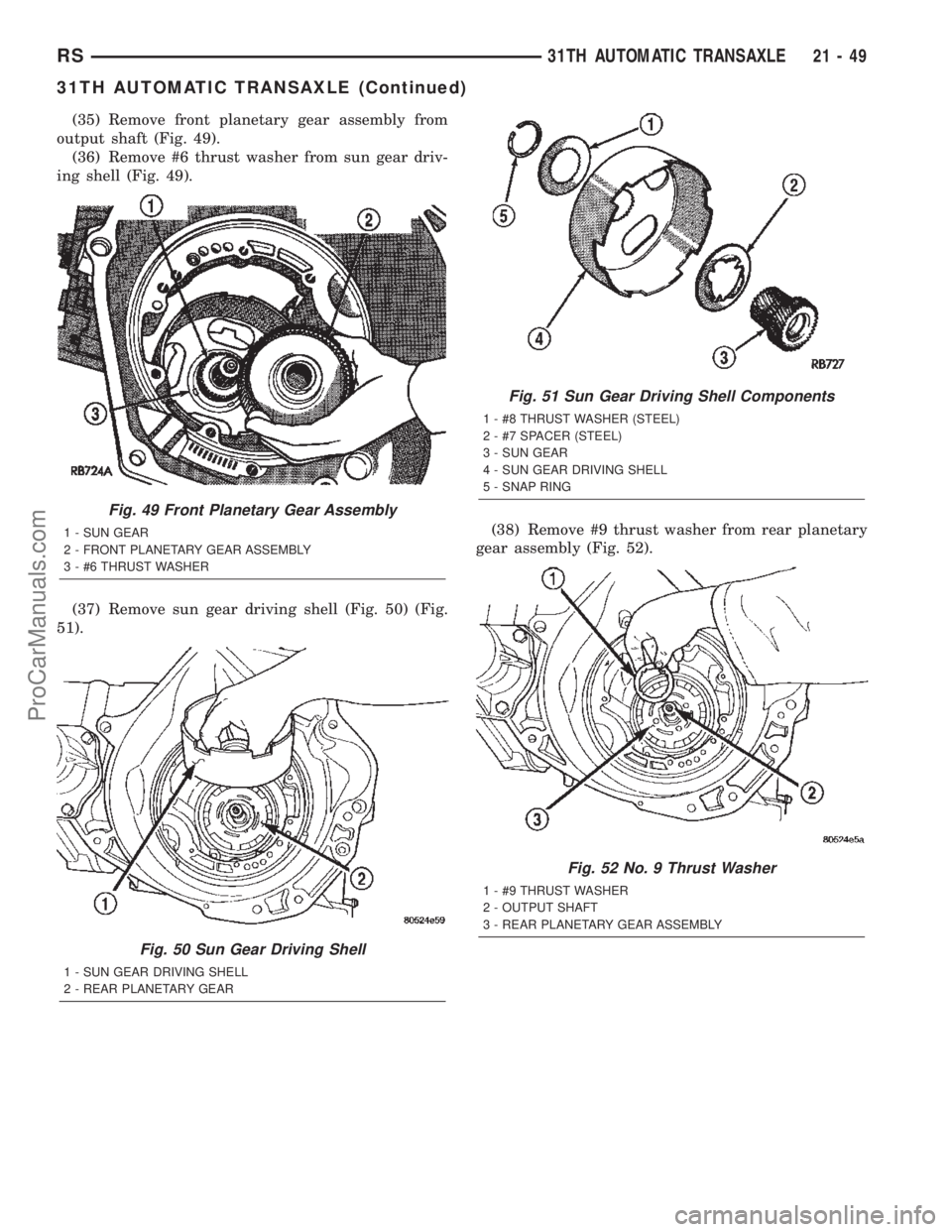

(35) Remove front planetary gear assembly from

output shaft (Fig. 49).

(36) Remove #6 thrust washer from sun gear driv-

ing shell (Fig. 49).

(37) Remove sun gear driving shell (Fig. 50) (Fig.

51).(38) Remove #9 thrust washer from rear planetary

gear assembly (Fig. 52).

Fig. 49 Front Planetary Gear Assembly

1 - SUN GEAR

2 - FRONT PLANETARY GEAR ASSEMBLY

3 - #6 THRUST WASHER

Fig. 50 Sun Gear Driving Shell

1 - SUN GEAR DRIVING SHELL

2 - REAR PLANETARY GEAR

Fig. 51 Sun Gear Driving Shell Components

1 - #8 THRUST WASHER (STEEL)

2 - #7 SPACER (STEEL)

3 - SUN GEAR

4 - SUN GEAR DRIVING SHELL

5 - SNAP RING

Fig. 52 No. 9 Thrust Washer

1 - #9 THRUST WASHER

2 - OUTPUT SHAFT

3 - REAR PLANETARY GEAR ASSEMBLY

RS31TH AUTOMATIC TRANSAXLE21-49

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com