seat memory CHRYSLER CARAVAN 2002 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1114 of 2399

MASS AIR FLOW SENSOR (DIESEL) - ORANGE 5 WAY

CAV CIRCUIT FUNCTION

1- -

2 K342 16BR/WT ECM/PCM RELAY OUTPUT

3 K957 20BK/OR MASS AIR FLOW SENSOR GROUND

4 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

5 K55 20DB/OR MASS AIR FLOW SENSOR SIGNAL

MEMORY SEAT/MIRROR MODULE C1 - GRAY 26 WAY

CAV CIRCUIT FUNCTION

1 P69 20TN/WT LEFT MIRROR SENSOR GROUND

2 P25 20LG/VT SEAT HORIZONTAL POSITION SIGNAL

3 P27 20LG/LB REAR RISER POSITION SIGNAL

4- -

5- -

6 P67 20OR RIGHT MIRROR VERTICAL POSITION SIGNAL

7 P64 20TN/OR LEFT MIRROR VERTICAL POSITION SIGNAL

8 P21 20LG/TN SEAT FRONT DOWN SWITCH SENSE

9 P13 20LG/OR SEAT REAR DOWN SWITCH SENSE

10 P15 20LG/WT SEAT HORIZONTAL FORWARD SWITCH SENSE

11 P43 14LG/VT RECLINER UP SWITCH SENSE

12 - -

13 - -

14 P66 20WT RIGHT MIRROR SENSOR GROUND

15 P26 20LG FRONT RISER POSITION SIGNAL

16 P47 20LG/LB RECLINER POSITION SIGNAL

17 - -

18 - -

19 P68 20YL RIGHT MIRROR HORIZONTAL POSITION SIGNAL

20 P65 20TN/YL LEFT MIRROR HORIZONTAL POSITION SIGNAL

21 P19 20LG/LB SEAT FRONT UP SWITCH SENSE

22 P11 20LG/YL SEAT REAR UP SWITCH SENSE

23 P17 20LG/DG SEAT HORIZONTAL REARWARD SWITCH SENSE

24 P41 14LG/GY RECLINER DOWN SWITCH SENSE

25 - -

26 D25 20WT/VT PCI BUS

RS8W-80 CONNECTOR PIN-OUTS8W-80-83

ProCarManuals.com

Page 1115 of 2399

MEMORY SEAT/MIRROR MODULE C2 - GRAY 16 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3 P73 18TN/LB LEFT MIRROR COMMON DRIVER (RIGHT/DOWN)

4 P75 18DB LEFT MIRROR LEFT DRIVER

5 P71 18TN/GY LEFT MIRROR UP DRIVER

6 P29 20LG/WT SEAT SENSOR 5 VOLT SUPPLY

7- -

8- -

9- -

10 - -

11 P70 18LB RIGHT MIRROR COMMON DRIVER (RIGHT/DOWN)

12 P74 18TN/DB RIGHT MIRROR LEFT DRIVER

13 P72 18GY RIGHT MIRROR UP DRIVER

14 - -

15 - -

16 P28 20LG/BR SEAT POSITION SENSOR GROUND

MEMORY SEAT/MIRROR MODULE C3 - WHITE 12 WAY

CAV CIRCUIT FUNCTION

1 P111 14LG/YL SEAT REAR UP DRIVER

2 P115 14LG SEAT HORIZONTAL FORWARD DRIVER

3 P119 14LG/DG SEAT FRONT UP DRIVER

4 P113 14LG/WT SEAT REAR DOWN DRIVER

5 P121 14LG/DB SEAT FRONT DOWN DRIVER

6- -

7 P143 14LG/GY SEAT RECLINER UP DRIVER

8 P9 20LG/OR SEAT SWITCH B(+) SUPPLY

9- -

10 P141 14LG/BR SEAT RECLINER DOWN DRIVER

11 P117 14LG/LB SEAT HORIZONTAL REARWARD DRIVER

12 - -

MEMORY SEAT/MIRROR MODULE C4 - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 Z849 14BK/OR GROUND

2 A210 14OR/RD FUSED B(+)

MEMORY SET SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 G200 20VT/BR MEMORY SELECT SWITCH MUX

2 G920 20VT/YL MEMORY SELECT SWITCH RETURN

8W - 80 - 84 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1124 of 2399

POWER MIRROR SWITCH - BLACK 13 WAY

CAV CIRCUIT FUNCTION

1 P70 18TN/LB (MEMORY) RIGHT MIRROR COMMON DRIVER (RIGHT/DOWN)

1 P70 20TN/LB RIGHT MIRROR COMMON DRIVER (RIGHT/DOWN)

2- -

3- -

4- -

5 E18 20OR/LB PANEL LAMPS DRIVER

6 P73 20TN/VT LEFT MIRROR COMMON DRIVER (RIGHT/DOWN)

6 P73 18TN/VT (MEMORY) LEFT MIRROR COMMON DRIVER (RIGHT/DOWN)

7 P75 18TN/LG (MEMORY) LEFT MIRROR LEFT DRIVER

7 P75 20TN/LG LEFT MIRROR LEFT DRIVER

8 P74 18TN/DB (MEMORY) RIGHT MIRROR LEFT DRIVER

8 P74 20TN/DB RIGHT MIRROR LEFT DRIVER

9 A108 18LG/RD FUSED B(+)

10 - -

11 Z408 18BK/LG GROUND

12 P71 20TN/DG LEFT MIRROR UP DRIVER

12 P71 18TN/DG (MEMORY) LEFT MIRROR UP DRIVER

13 P72 18TN/GY (MEMORY) RIGHT MIRROR UP DRIVER

13 P72 20TN/GY RIGHT MIRROR UP DRIVER

POWER OUTLET - NATURAL 3 WAY

CAV CIRCUIT FUNCTION

1 A105 16DB/RD FUSED B(+)

2- -

3 Z738 16BK/WT GROUND

POWER SEAT CIRCUIT BREAKER (30A) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 A110 12OR/RD FUSED B(+)

2 A210 14OR/RD FUSED SEAT SWITCH DRIVER

2 A210 14OR/RD FUSED SEAT SWITCH DRIVER

POWER WINDOW CIRCUIT BREAKER (25A) - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 F30 12PK/YL FUSED ACCESSORY RELAY OUTPUT

2 F304 12WT/PK FUSED WINDOW CIRCUIT BREAKER OUTPUT

RS8W-80 CONNECTOR PIN-OUTS8W-80-93

ProCarManuals.com

Page 1154 of 2399

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Liftgate Ajar Switch (Manual

Release)BK At Latch 42

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 42

Liftgate Cinch/Release Motor BL Liftgate N/S

Liftgate Cylinder Lock Switch BK At Switch 42

Liftgate Left Pinch Sensor BK Left Side of Liftgate N/S

Liftgate Right Pinch Sensor BK Right Side of Liftgate N/S

Low Note Horn BK Left Frame Rail 5

Manifold Absolute Pressure Sensor BK On Intake 10

Mass Air Flow Sensor (Diesel) OR Top of Engine 11, 12

Memory Seat/Mirror Module C1 GY Under Driver Seat N/S

Memory Seat/Mirror Module C2 GY Under Driver Seat N/S

Memory Seat/Mirror Module C3 WT Under Driver Seat N/S

Memory Seat/Mirror Module C4 GY Under Driver Seat N/S

Memory Seat Front Vertical Motor RD Under Seat N/S

Memory Seat Front Vertical

Position SensorBK Under Seat N/S

Memory Seat Horizontal Motor BK Under Seat N/S

Memory Seat Horizontal Position

SensorBK Under Seat N/S

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical Position

SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Seat Switch BK At Switch Driver Door N/S

Message Center WT Rear of Message Center 15, 16, 23

Mode Door Actuator GY Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 15, 16, 17, 18, 26

Output Speed Sensor GY Front of Transmission 14

Overhead Console BK Front of Console N/S

Oxygen Sensor 1/1 Upstream BK Rear of Engine 9, 10, 14

Oxygen Sensor 1/2 Downstream BK Rear of Engine 9, 10, 14

Park/Neutral Positon Switch BK Front of Transmission 10

Passenger Airbag YL Passenger Side of Instrument Panel 15, 18, 19 24

Passenger Blend Door Actuator On HVAC N/S

Passenger Door Courtesy Lamp BK At Lamp 37

Passenger Door Lock Switch BK At Switch 37

Passenger Folding Mirror Relay BL Right Kick Panel N/S

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module C1 GY At Heated Seat N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1160 of 2399

SPLICE NUMBER LOCATION FIG.

S177 In Right Headlamp Wiring Assembly N/S

S179 In Left Headlamp Wiring Assembly N/S

S187 (2.5L) Near T/O for Engine Control Module C1 11

S188 (2.5L) Near T/O for Radiator Fan Relay No.1 2

S201 In T/O to Instrument Panel Speaker 15, 21

S202 Near T/O for Instrument Panel Switch Bank 15, 21

S203 Near T/O for Instrument Panel Switch Bank 15, 21

S204 Near T/O to Instrument Panel Speaker 15, 21

S205 Near T/O for C201 15

S206 Near T/O for Instrument Cluster 15

S207 In A/C Unit Assembly N/S

S208 (RHD) Between T/O for Antenna Connector and T/O for Front

Cigar Lighter21

S209 (RHD) Between T/O for Front Cigar Lighter and T/O for Brake

Transmission Shift Interlock Solenoid21

S210 (RHD) Near T/O for C203 21

S211 In Steering Column Wiring Assembly N/S

S212 In Steering Column Wiring Assembly N/S

S302 In Floor Pan Track Wiring 31

S303 In T/O to Data Link Connector 31

S304 Near T/O for C307 32

S305 Near T/O for Memory Seat/Mirror Module - C2 N/S

S306 In Floor Pan Track Wiring 32

S307 Near T/O for Memory Power Seat Switch N/S

S308 In Floor Pan Track Wiring 31

S309 In Floor Pan Track Wiring 31

S310 Near T/O for C301 30

S311 In Floor Pan Track Wiring 29

S312 Near T/O for C320 N/S

S313 Near T/O for Power Liftgate Module 40

S314 In Floor Pan Track Wiring 29

S315 In Floor Pan Track Wiring 29

S316 In Floor Pan Track Wiring 29

S317 Near T/O for C101 30

S318 Near T/O for Power Seat Circuit Breaker N/S

S319 In Floor Pan Track Wiring 32

S320 Near T/O for C200 31

S321 In T/O to Data Link Connector 31

S322 Near T/O for C301 30

S323 In Floor Pan Track Wiring 31

S324 In Floor Pan Track Wiring 29

S325 In Floor Pan Track Wiring 29

S326 Near T/O for C101 30

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-13

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1200 of 2399

tion. The IOD fuse is a 15 ampere blade-type car-

tridge fuse and, when removed, it is stored in a fuse

cavity adjacent to the washer fuse within the IPM.

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

removed is to reduce the normal IOD of the vehicle

electrical system during new vehicle transportation

and pre-delivery storage to reduce battery depletion,

while still allowing vehicle operation so that the

vehicle can be loaded, unloaded and moved as needed

by both vehicle transportation company and dealer

personnel.

The IOD fuse is removed from the IPM fuse cavity

when the vehicle is shipped from the assembly plant.

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation. Once the

vehicle is prepared for delivery, the IOD function of

this fuse becomes transparent and the fuse that has

been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

Battery Systemfor additional service information.

REMOVAL

(1) Turn the ignition switch to the Off position.

(2) Unlatch and open the cover of the intelligent

power module.

(3) Remove the IOD fuse from fuse location

markedIODof the Integrated Power Module (IPM).

(4) Store the removed IOD fuse by installing it in

the unused fuse storage markedSPAREof the IPM.

(5) Close and latch the IPM.

INSTALLATION

(1) Be certain the ignition switch is in the Off posi-

tion.

(2) Unlatch and open the cover of the Integrated

Power Module (IPM).

(3) Remove the stored 15 amp IOD fuse from fuse

storage markedSPAREof the IPM.

(4) Use a thumb to press the IOD fuse firmly down

into IPM fuse cavity markedIOD.

(5) Close and latch the IPM cover.

POWER OUTLET

DESCRIPTION

Accessory power outlets are standard equipment on

this model. Two power outlets are installed in the

instrument panel center lower bezel, which is located

near the bottom of the instrument panel center stack

area. Two additional power outlets are also incorpo-

rated into the vehicle, one on the left rear C-pillar

trim and the other in the center console, if equipped.

The power outlets bases are secured by a snap fit in

the appropriate bezels. A hinged plug flips closed to

conceal and protect the power outlet base when the

power outlet is not being used.

The power outlet receptacle unit and the power

outlet plugs are each available for service replace-

ment.

OPERATION

The power outlet base or receptacle shell is con-

nected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The power outlet on the instrument panel marked

with a battery receives battery voltage from a fuse in

the Integrated Power Module (IPM) at all times. The

other power outlet on the instrument panel marked

with a key receives battery voltage only when the

key is in the on position.

The power outlet located in the center console

receives battery voltage all the time when positioned

between thefront seatsand key-on voltage when

positioned between therear seats. The power outlet

located on the C-pillar receives battery voltage only

when the key is in the on position.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

For complete circuit diagrams, refer toCigar

Lighter/Power Outletin Wiring Diagrams.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-5

IOD FUSE (Continued)

ProCarManuals.com

Page 2004 of 2399

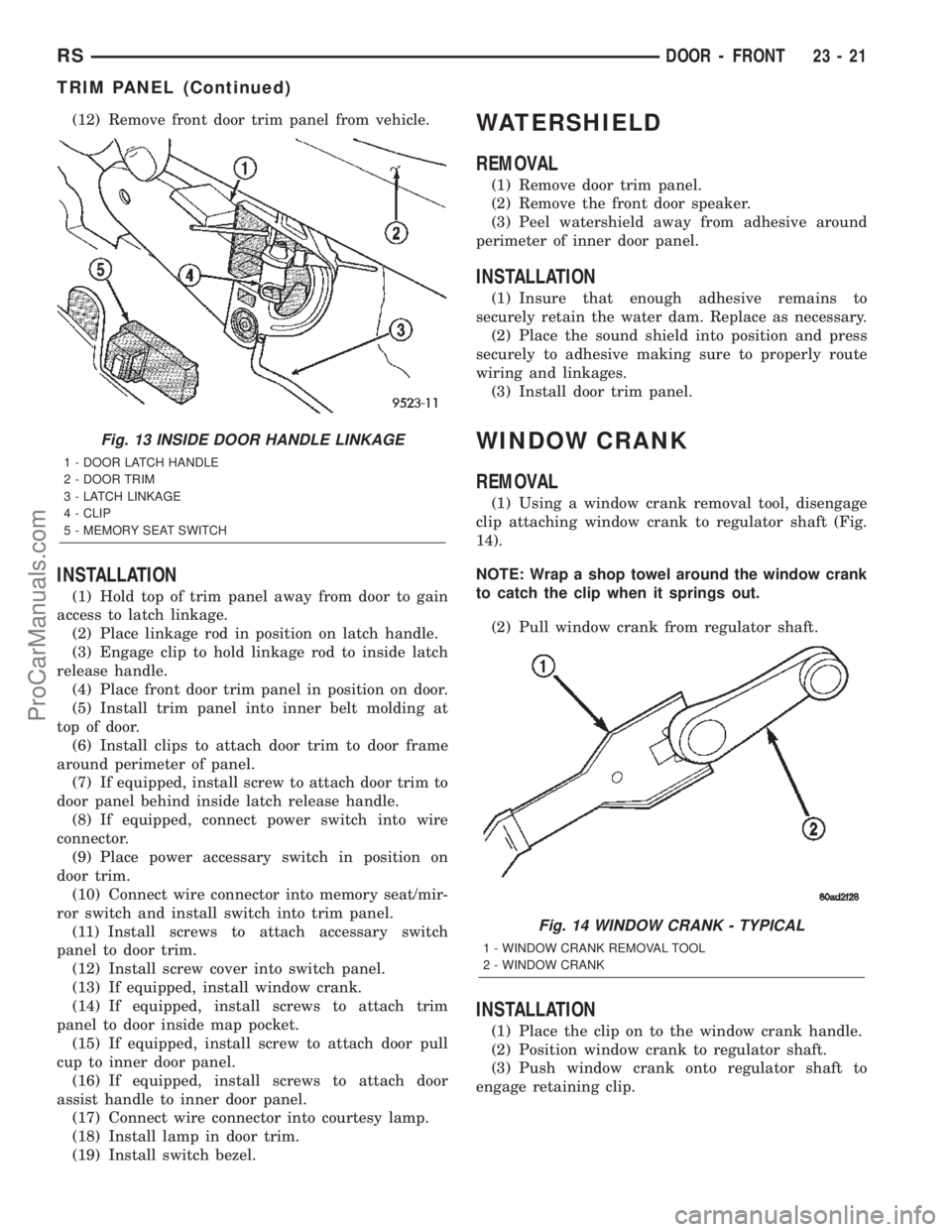

(12) Remove front door trim panel from vehicle.

INSTALLATION

(1) Hold top of trim panel away from door to gain

access to latch linkage.

(2) Place linkage rod in position on latch handle.

(3) Engage clip to hold linkage rod to inside latch

release handle.

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel.

(2) Remove the front door speaker.

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the sound shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install door trim panel.

WINDOW CRANK

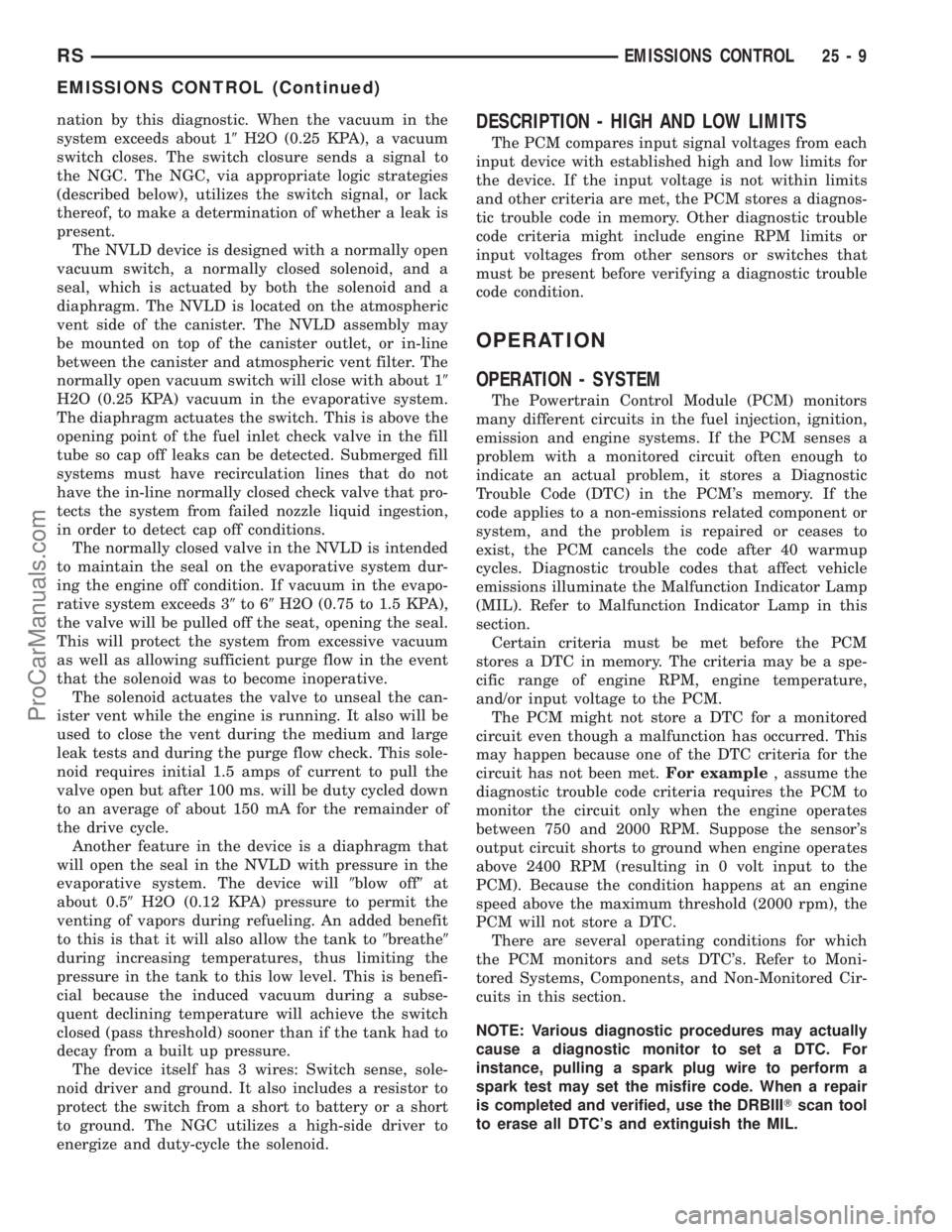

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

14).

NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

Fig. 13 INSIDE DOOR HANDLE LINKAGE

1 - DOOR LATCH HANDLE

2 - DOOR TRIM

3 - LATCH LINKAGE

4 - CLIP

5 - MEMORY SEAT SWITCH

Fig. 14 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)

ProCarManuals.com

Page 2368 of 2399

nation by this diagnostic. When the vacuum in the

system exceeds about 19H2O (0.25 KPA), a vacuum

switch closes. The switch closure sends a signal to

the NGC. The NGC, via appropriate logic strategies

(described below), utilizes the switch signal, or lack

thereof, to make a determination of whether a leak is

present.

The NVLD device is designed with a normally open

vacuum switch, a normally closed solenoid, and a

seal, which is actuated by both the solenoid and a

diaphragm. The NVLD is located on the atmospheric

vent side of the canister. The NVLD assembly may

be mounted on top of the canister outlet, or in-line

between the canister and atmospheric vent filter. The

normally open vacuum switch will close with about 19

H2O (0.25 KPA) vacuum in the evaporative system.

The diaphragm actuates the switch. This is above the

opening point of the fuel inlet check valve in the fill

tube so cap off leaks can be detected. Submerged fill

systems must have recirculation lines that do not

have the in-line normally closed check valve that pro-

tects the system from failed nozzle liquid ingestion,

in order to detect cap off conditions.

The normally closed valve in the NVLD is intended

to maintain the seal on the evaporative system dur-

ing the engine off condition. If vacuum in the evapo-

rative system exceeds 39to 69H2O (0.75 to 1.5 KPA),

the valve will be pulled off the seat, opening the seal.

This will protect the system from excessive vacuum

as well as allowing sufficient purge flow in the event

that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the can-

ister vent while the engine is running. It also will be

used to close the vent during the medium and large

leak tests and during the purge flow check. This sole-

noid requires initial 1.5 amps of current to pull the

valve open but after 100 ms. will be duty cycled down

to an average of about 150 mA for the remainder of

the drive cycle.

Another feature in the device is a diaphragm that

will open the seal in the NVLD with pressure in the

evaporative system. The device will9blow off9at

about 0.59H2O (0.12 KPA) pressure to permit the

venting of vapors during refueling. An added benefit

to this is that it will also allow the tank to9breathe9

during increasing temperatures, thus limiting the

pressure in the tank to this low level. This is benefi-

cial because the induced vacuum during a subse-

quent declining temperature will achieve the switch

closed (pass threshold) sooner than if the tank had to

decay from a built up pressure.

The device itself has 3 wires: Switch sense, sole-

noid driver and ground. It also includes a resistor to

protect the switch from a short to battery or a short

to ground. The NGC utilizes a high-side driver to

energize and duty-cycle the solenoid.DESCRIPTION - HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

OPERATION

OPERATION - SYSTEM

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRBIIITscan tool

to erase all DTC's and extinguish the MIL.

RSEMISSIONS CONTROL25-9

EMISSIONS CONTROL (Continued)

ProCarManuals.com