steering wheel CHRYSLER CARAVAN 2002 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 163 of 2399

DISC BRAKE CALIPER

ADAPTER

REMOVAL - FRONT DISC BRAKE CALIPER

ADAPTER

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove front wheel and tire assembly, disc

brake caliper and brake shoes. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/BRAKE PADS/SHOES

- REMOVAL)

(3) Remove two bolts fastening adapter to steering

knuckle, then remove disc brake caliper adapter.

INSTALLATION - FRONT DISC BRAKE CALIPER

ADAPTER

(1) Place adapter over brake rotor and align

adapter mounting holes to knuckle.

CAUTION: Adapter mounting bolts have a special

DacrometTcoating applied to resist corrosion. If

mounting bolts need to be replaced, use only

MoparTreplacement parts.

(2) Install adapter mounting bolts and tighten to

169 N´m (125 ft. lbs.) torque.

(3) Install brake shoes, disc brake caliper and

wheel and tire assembly. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/BRAKE PADS/SHOES -

INSTALLATION)

(4) Lower vehicle.

(5) Pump the brake pedal several times to set the

pads to the brake rotor.

(6) Check and adjust brake fluid level as neces-

sary.

DISC BRAKE CALIPER GUIDE

PINS

REMOVAL - DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES)

(1) Raise the vehicle. Refer to HOISTING in

LUBRICATION AND MAINTENANCE.

(2) Remove the front tire and wheel assembly.

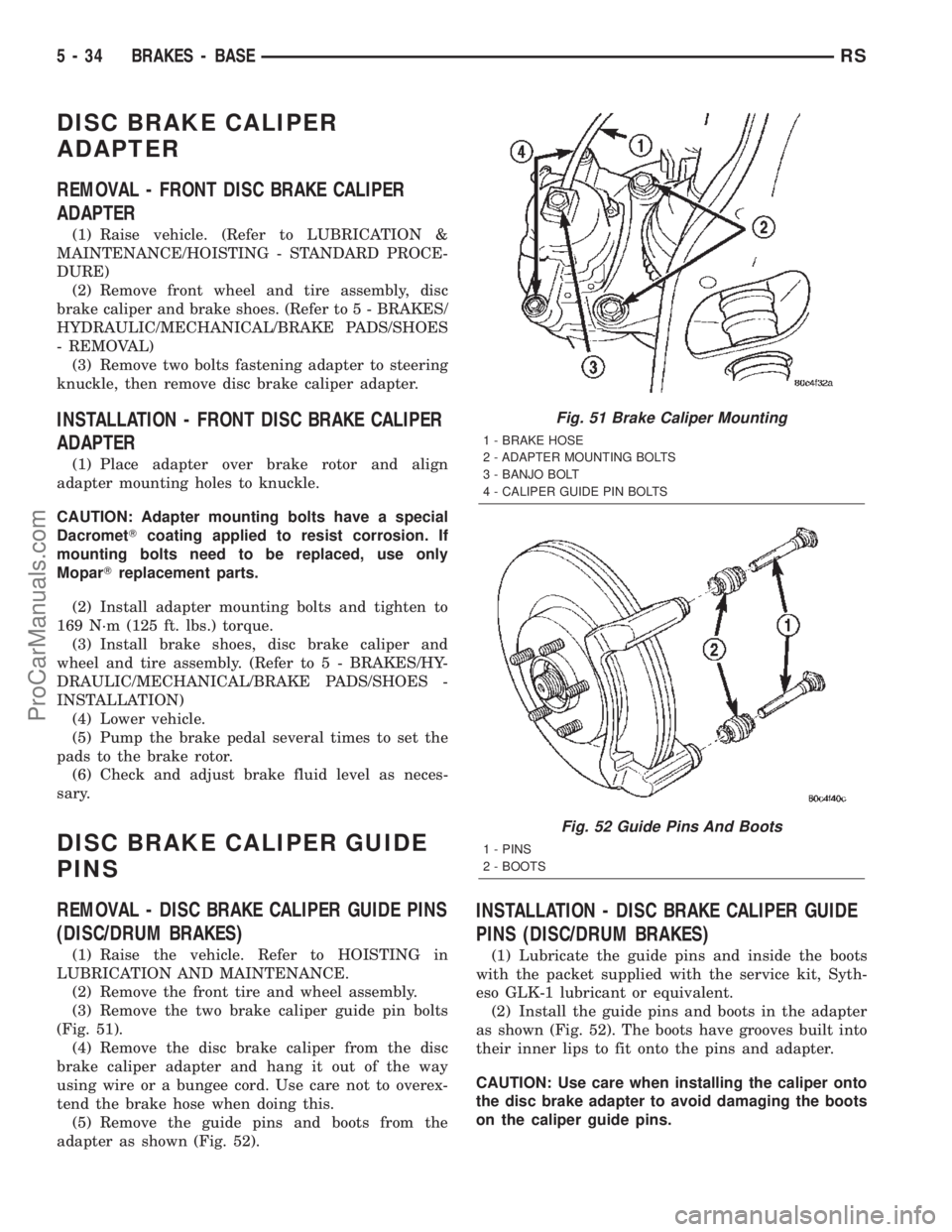

(3) Remove the two brake caliper guide pin bolts

(Fig. 51).

(4) Remove the disc brake caliper from the disc

brake caliper adapter and hang it out of the way

using wire or a bungee cord. Use care not to overex-

tend the brake hose when doing this.

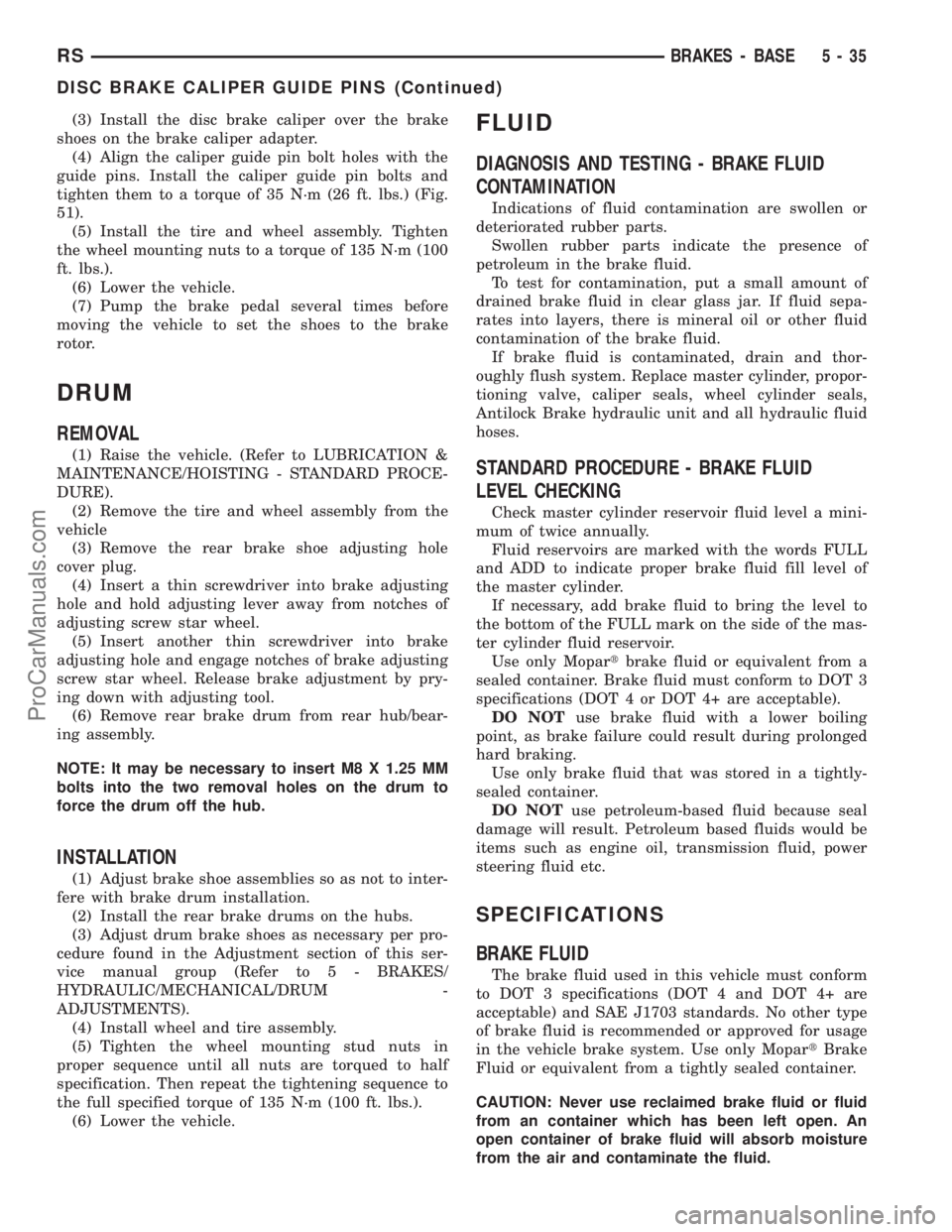

(5) Remove the guide pins and boots from the

adapter as shown (Fig. 52).

INSTALLATION - DISC BRAKE CALIPER GUIDE

PINS (DISC/DRUM BRAKES)

(1) Lubricate the guide pins and inside the boots

with the packet supplied with the service kit, Syth-

eso GLK-1 lubricant or equivalent.

(2) Install the guide pins and boots in the adapter

as shown (Fig. 52). The boots have grooves built into

their inner lips to fit onto the pins and adapter.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

Fig. 51 Brake Caliper Mounting

1 - BRAKE HOSE

2 - ADAPTER MOUNTING BOLTS

3 - BANJO BOLT

4 - CALIPER GUIDE PIN BOLTS

Fig. 52 Guide Pins And Boots

1 - PINS

2 - BOOTS

5 - 34 BRAKES - BASERS

ProCarManuals.com

Page 164 of 2399

(3) Install the disc brake caliper over the brake

shoes on the brake caliper adapter.

(4) Align the caliper guide pin bolt holes with the

guide pins. Install the caliper guide pin bolts and

tighten them to a torque of 35 N´m (26 ft. lbs.) (Fig.

51).

(5) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(6) Lower the vehicle.

(7) Pump the brake pedal several times before

moving the vehicle to set the shoes to the brake

rotor.

DRUM

REMOVAL

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove the tire and wheel assembly from the

vehicle

(3) Remove the rear brake shoe adjusting hole

cover plug.

(4) Insert a thin screwdriver into brake adjusting

hole and hold adjusting lever away from notches of

adjusting screw star wheel.

(5) Insert another thin screwdriver into brake

adjusting hole and engage notches of brake adjusting

screw star wheel. Release brake adjustment by pry-

ing down with adjusting tool.

(6) Remove rear brake drum from rear hub/bear-

ing assembly.

NOTE: It may be necessary to insert M8 X 1.25 MM

bolts into the two removal holes on the drum to

force the drum off the hub.

INSTALLATION

(1) Adjust brake shoe assemblies so as not to inter-

fere with brake drum installation.

(2) Install the rear brake drums on the hubs.

(3) Adjust drum brake shoes as necessary per pro-

cedure found in the Adjustment section of this ser-

vice manual group (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/DRUM -

ADJUSTMENTS).

(4) Install wheel and tire assembly.

(5) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brake hydraulic unit and all hydraulic fluid

hoses.

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Fluid reservoirs are marked with the words FULL

and ADD to indicate proper brake fluid fill level of

the master cylinder.

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.

Use only Mopartbrake fluid or equivalent from a

sealed container. Brake fluid must conform to DOT 3

specifications (DOT 4 or DOT 4+ are acceptable).

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only MopartBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

RSBRAKES - BASE5-35

DISC BRAKE CALIPER GUIDE PINS (Continued)

ProCarManuals.com

Page 165 of 2399

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

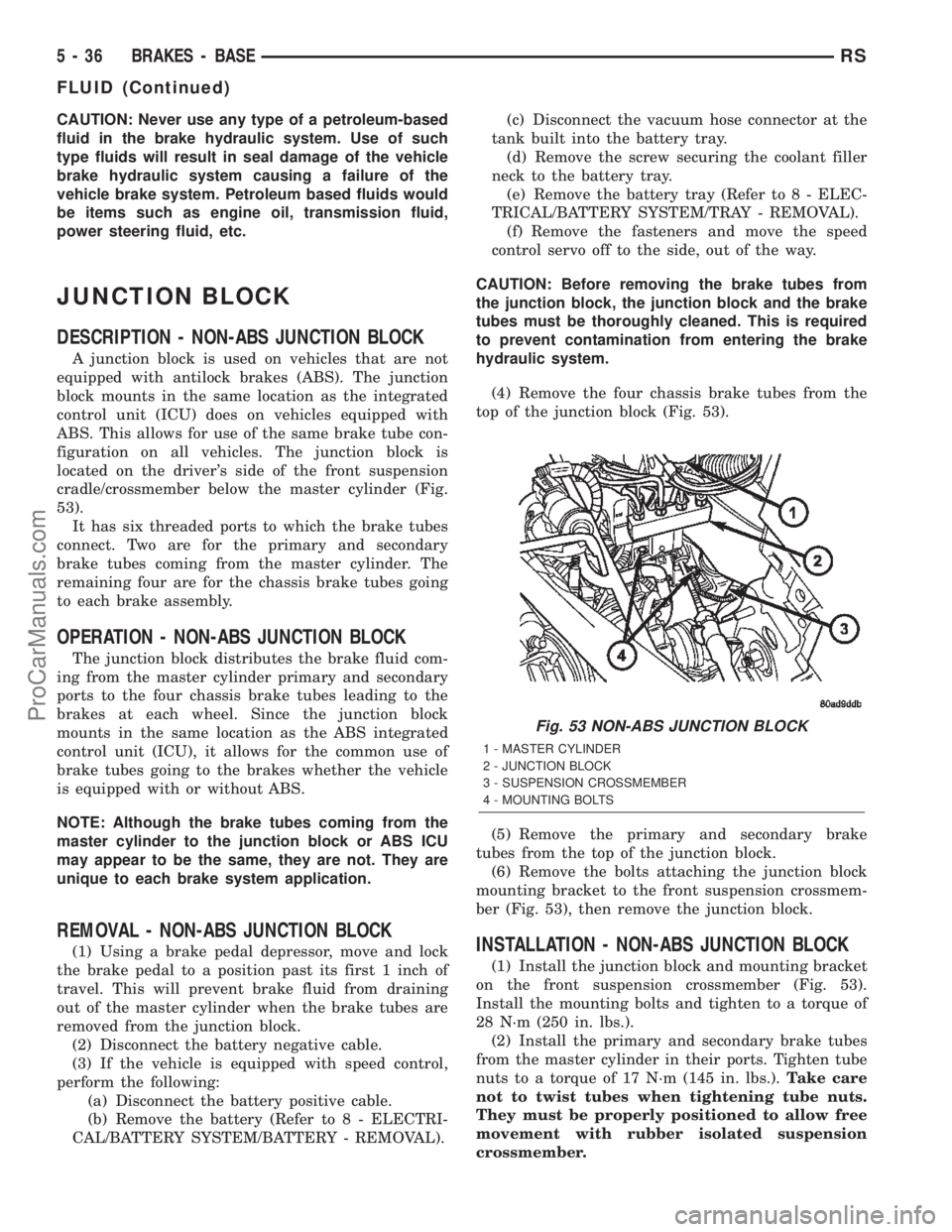

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped with

ABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is

located on the driver's side of the front suspension

cradle/crossmember below the master cylinder (Fig.

53).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated

control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

(4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 53).

(5) Remove the primary and secondary brake

tubes from the top of the junction block.

(6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 53), then remove the junction block.INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 53).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.).

(2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.).Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

movement with rubber isolated suspension

crossmember.

Fig. 53 NON-ABS JUNCTION BLOCK

1 - MASTER CYLINDER

2 - JUNCTION BLOCK

3 - SUSPENSION CROSSMEMBER

4 - MOUNTING BOLTS

5 - 36 BRAKES - BASERS

FLUID (Continued)

ProCarManuals.com

Page 171 of 2399

(5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

57).

(6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopart

Brake Fluid or equivalent.

(11) Road test vehicle to ensure proper operation of

brakes.

INSTALLATION - RHD

CAUTION: Different types of master cylinders are

used on this vehicle depending on brake options. If

a new master cylinder is being installed, be sure it

is the correct master cylinder for the type of brake

system the vehicle is equipped with.

CAUTION: When replacing the master cylinder on a

vehicle, a NEW vacuum seal MUST be installed on

the master cylinder.

(1) Install a NEW vacuum seal on master cylinder

making sure seal fits squarely in groove of master

cylinder casting.

(2) Position master cylinder on studs of power

brake booster, aligning booster push rod with master

cylinder piston.

(3) Install the two master cylinder mounting nuts

(Fig. 59). Tighten both mounting nuts to a torque of

25 N´m (225 in. lbs.).

CAUTION: When tightening the primary and sec-

ondary brake tube nuts at master cylinder, be sure

brake tubes do not contact any other components

within the vehicle and that there is slack in the flex-

ible sections of the tubes. This is required due to

the movement between the ABS ICU and the master

cylinder while the vehicle is in motion.

(4) Connect primary and secondary brake tubes to

master cylinder primary and secondary ports (Fig.

59). Brake tubes must be held securely when tight-

ened to control orientation of flex section. Tighten

tube nuts to a torque of 17 N´m (145 in. lbs.).

(5) Install wiring harness connector to brake fluid

level switch mounted in brake fluid reservoir (Fig.

55).

(6) Install battery, clamp and nut.

(7) Install battery shield.

(8) Connect positive battery terminal.

(9) Connect negative battery terminal.

(10) Fill master cylinder with clean, fresh Mopart

Brake Fluid or equivalent.(11) Road test vehicle to ensure proper operation of

brakes.

PEDAL - ADJUSTABLE

DESCRIPTION

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The effort required for pedal application will not

change regardless of pedal position.

The adjustable pedal system allows the pedals to

adjust up to 3 inches (75 mm) at a rate of approxi-

mately 0.4 in./sec. (9 mm/sec.). An adjustment switch

is located on the left side of the steering column

lower shroud.

If the vehicle is equipped with Remote Keyless

Entry (RKE), an optional memory feature is avail-

able.

The serviceable components of the APS are:

²Adjustable pedal assembly (includes motor,

cables, pedals, gear box, sensor and module)

²Adjustable pedal module (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/

ADJUSTABLE PEDAL MODULE)

²Adjustable pedal switch

²Pedal position sensor

OPERATION

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor. The

pedal drive motor turns a screw that changes the

position of the accelerator pedal. The motor also

drives a cable connected to a gear box that changes

the brake pedal position the same distance as the

accelerator pedal. The pedals can be moved rearward

(closer to the driver) or forward (away from driver).

Each pedal is moved on its activating lever to a posi-

tion where the driver feels most comfortable. The

position and operation of the activating levers are not

changed.

Pedal adjustment is inhibited when the vehicle is

in reverse or when cruise control is engaged. The

Electronic Vehicle Information Center (EVIC) will

display a message when the Adjustable Pedal Module

(APM) is disabled. i.e.:9Adjustable Pedal Disabled -

Cruise Control Engaged9or9Adjustable Pedal Dis-

abled - Vehicle in Reverse9.

Foot pressure or debris can stall pedal adjustment.

In order to avoid damage to system components dur-

5 - 42 BRAKES - BASERS

MASTER CYLINDER (Continued)

ProCarManuals.com

Page 172 of 2399

ing pedal adjustment, the APM will monitor pedal

position sensor voltage. If the APM does not detect

expected voltage change within 3 seconds, it will cut

power to the adjustable pedal motor.

An optional memory feature is available. This

allows storing of one or two preferred pedal positions

in the APS. A preferred position can be stored and

recalled using the door-mounted switches. A stored

pedal position can be recalled (but not stored) using

the Remote Keyless Entry (RKE) if equipped with

the memory feature.

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL SYSTEM

Refer to Appropriate Diagnostic Information.

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

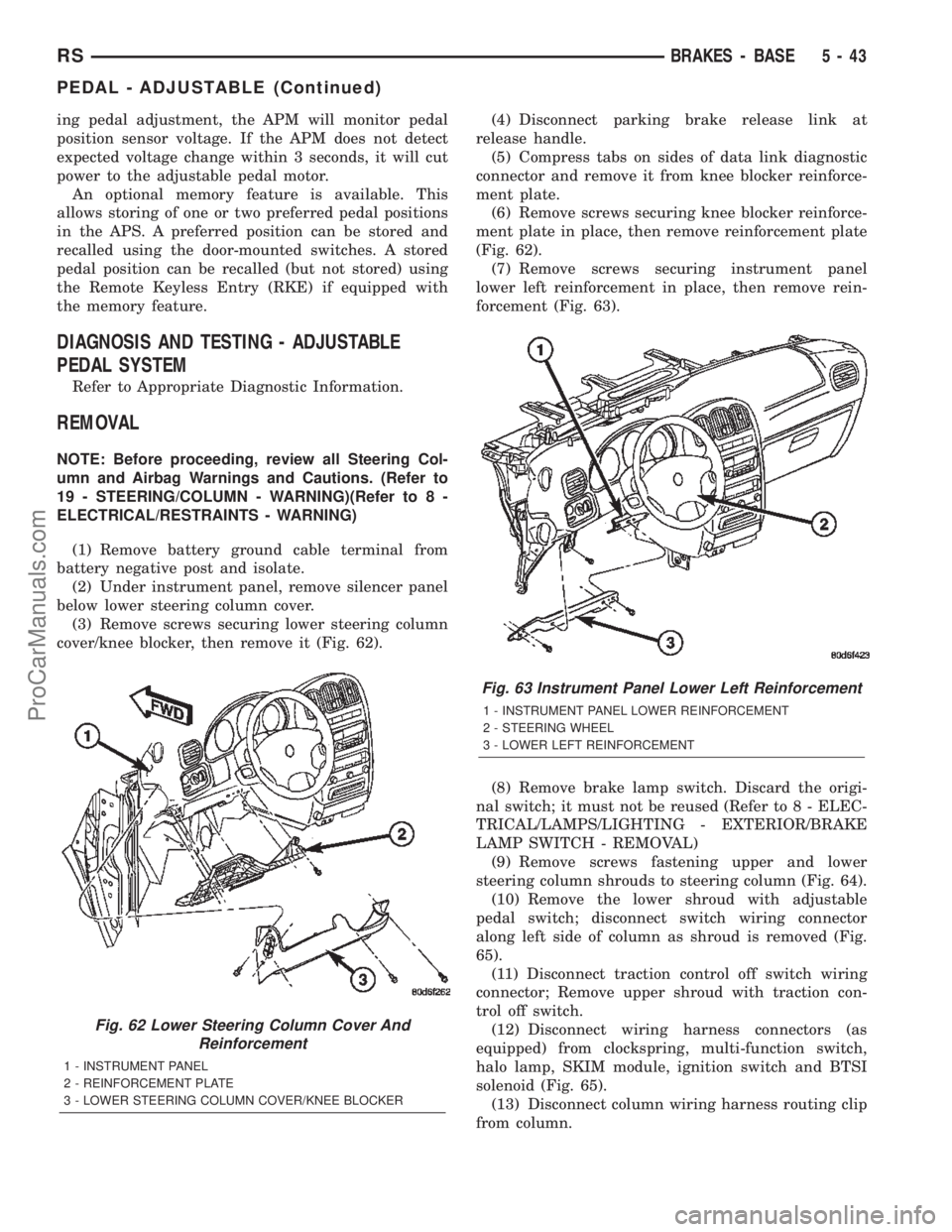

(3) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 62).(4) Disconnect parking brake release link at

release handle.

(5) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.

(6) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 62).

(7) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 63).

(8) Remove brake lamp switch. Discard the origi-

nal switch; it must not be reused (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL)

(9) Remove screws fastening upper and lower

steering column shrouds to steering column (Fig. 64).

(10) Remove the lower shroud with adjustable

pedal switch; disconnect switch wiring connector

along left side of column as shroud is removed (Fig.

65).

(11) Disconnect traction control off switch wiring

connector; Remove upper shroud with traction con-

trol off switch.

(12) Disconnect wiring harness connectors (as

equipped) from clockspring, multi-function switch,

halo lamp, SKIM module, ignition switch and BTSI

solenoid (Fig. 65).

(13) Disconnect column wiring harness routing clip

from column.

Fig. 62 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 63 Instrument Panel Lower Left Reinforcement

1 - INSTRUMENT PANEL LOWER REINFORCEMENT

2 - STEERING WHEEL

3 - LOWER LEFT REINFORCEMENT

RSBRAKES - BASE5-43

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 173 of 2399

(14) Disconnect PRNDL cable from shift lever and

column bracket (Fig. 66).

(15) Disconnect shift cable at shift lever mecha-

nism pin (Fig. 66).(16) Remove pinch side clip, then remove shift

cable from bracket on column.

(17) Turn the steering wheel from the STRAIGHT-

AHEAD position 180É to the right (upside-down posi-

tion), then remove the key and lock the column in

place.

(18) Remove the pinch bolt securing column cou-

pling to intermediate shaft (Fig. 67).

Fig. 64 Steering Column Shrouds

1 - FIXED SHROUD

2 - UPPER SHROUD

3 - CLOCKSPRING

4 - LOWER SHROUD

5 - STEERING COLUMN

Fig. 65 Pedal Switch Wiring Connector

1 - STEERING COLUMN FIXED SHROUD

2 - BRAKE TRANSMISSION SHIFT INTERLOCK

3 - B.T.S.I. WIRING CONNECTOR

4 - PEDAL SWITCH WIRING CONNECTOR

Fig. 66 Shift Cable At Steering Column

1 - SHIFT LEVER MECHANISM

2 - SHIFT CABLE

3 - BRACKET

4 - PRNDL CABLE

5 - STEERING COLUMN

Fig. 67 Pinch Bolt

1 - PINCH BOLT

2 - STEERING COLUMN

5 - 44 BRAKES - BASERS

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 176 of 2399

(27) Install lower steering column cover/knee

blocker (Fig. 62).

(28) Install silencer panel below lower steering col-

umn cover/knee blocker.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery in following manor:

(a) Connect scan tool (DRBIIIt) to data link

diagnostic connector located below steering column.

(b) Turn ignition key to ON position. Exit vehi-

cle with scan tool leaving scan tool harness

plugged in.

(c) Ensuring that there are no occupants in vehi-

cle, connect ground (-) cable to the negative post of

the battery.

(d) Using scan tool, read and record any airbag

fault codes. Refer to Appropriate Diagnostic Infor-

mation if any faults are found.

(e) Through drivers open window, Reach around

back of steering wheel (between steering wheel and

instrument cluster) and turn ignition key to OFF,

then back ON while observing instrument cluster

airbag indicator lamp. It should go on for six to

eight seconds, then go out. This action indicates

that airbag system is functioning normally. If air-

bag indicator lamp fails to light, blinks on and off,

or goes on and stays on, there is an airbag system

malfunction. Refer to Appropriate Diagnostic Infor-

mation to diagnose the system malfunction.

(30) Using scan tool (DRBIIIt), check for and clear

any existing adjustable pedal fault codes. The adjust-

able pedal system is now activated.

(31) Turn key to OFF and remove scan tool from

vehicle.

(32) Test operation of adjustable pedals, memory

seats (if equipped), RKE (if equipped), and all func-

tions that are steering column operated. If applica-

ble, reset the radio and the clock.

(33) Road test the vehicle to ensure proper opera-

tion of the steering and brake systems.

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL)

(3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Removethe link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled.

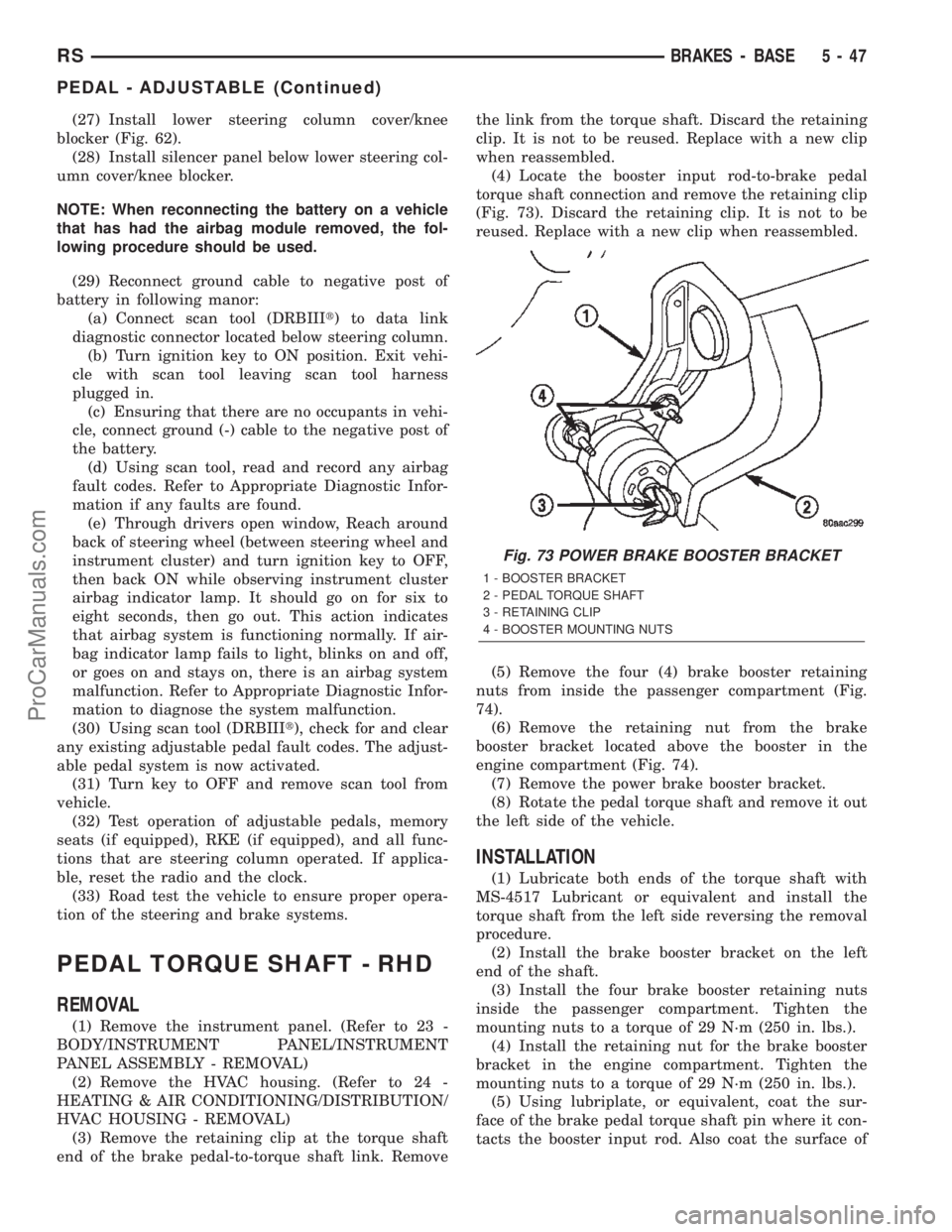

(4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 73). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled.

(5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

74).

(6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 74).

(7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.

(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(4) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

Fig. 73 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

RSBRAKES - BASE5-47

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 189 of 2399

ROTOR RUNOUT

On-vehicle rotor runout is the combination of the

individual runout of the hub face and the runout of

the rotor. (The hub and rotor runouts are separable).

To measure rotor runout on the vehicle, first remove

the tire and wheel assembly. Reinstall the wheel

mounting nuts on the studs, tightening the rotor to

the hub. Mount the Dial Indicator, Special Tool

C-3339, with Mounting Adaptor, Special Tool SP-

1910 on steering arm. The dial indicator plunger

should contact braking surface of rotor approximately

ten millimeters from edge of rotor (Fig. 95). Check

lateral runout on both sides of the rotor, marking the

low and high spots on both. Runout limits can be

found in the specification table in this section. (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/RO-

TOR - SPECIFICATIONS)

If runout is in excess of the specification, check the

lateral runout of the hub face. Before removing the

rotor from the hub, place a chalk mark across both

the rotor and the one wheel stud closest to where the

high runout measurement was taken. This way, the

original mounting spot of the rotor on the hub is

indexed (Fig. 96).

Remove the rotor from the hub.

NOTE: Clean the hub face surface before checking

runout. This provides a clean surface to get an

accurate indicator reading.Mount Dial Indicator, Special Tool C-3339, and

Mounting Adaptor, Special Tool SP-1910, to the steer-

ing knuckle. Position the indicator stem so it contacts

the hub face near the outer diameter. Care must be

taken to position stem outside of the stud circle, but

inside of the chamfer on the hub rim (Fig. 97).

Hub runout should not exceed 0.03 mm (0.0012

inch). If runout exceeds this specification, the hub

must be replaced. (Refer to 2 - SUSPENSION/

FRONT/HUB / BEARING - REMOVAL)(Refer to 2 -

SUSPENSION/REAR/HUB / BEARING - REMOVAL)

Fig. 94 Checking Rotor For Thickness

1 - CALIPER

Fig. 95 Checking Rotor Runout

1 - SPECIAL TOOL SP-1910

2 - 10 MILLIMETERS FROM EDGE

3 - DISC SURFACE

4 - SPECIAL TOOL C-3339

Fig. 96 Marking Rotor and Wheel Stud

1 - CHALK MARK

5 - 60 BRAKES - BASERS

ROTOR (Continued)

ProCarManuals.com

Page 191 of 2399

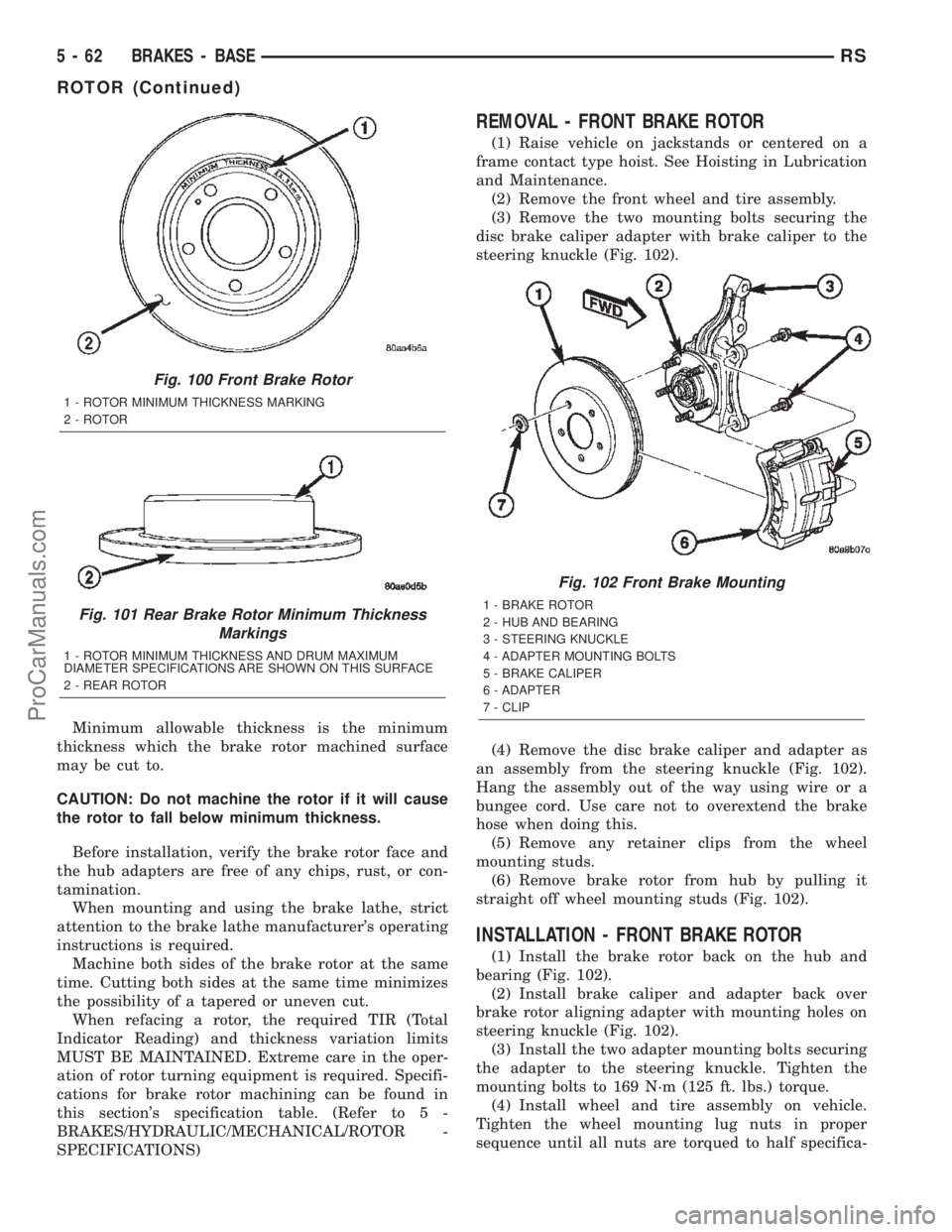

Minimum allowable thickness is the minimum

thickness which the brake rotor machined surface

may be cut to.

CAUTION: Do not machine the rotor if it will cause

the rotor to fall below minimum thickness.

Before installation, verify the brake rotor face and

the hub adapters are free of any chips, rust, or con-

tamination.

When mounting and using the brake lathe, strict

attention to the brake lathe manufacturer's operating

instructions is required.

Machine both sides of the brake rotor at the same

time. Cutting both sides at the same time minimizes

the possibility of a tapered or uneven cut.

When refacing a rotor, the required TIR (Total

Indicator Reading) and thickness variation limits

MUST BE MAINTAINED. Extreme care in the oper-

ation of rotor turning equipment is required. Specifi-

cations for brake rotor machining can be found in

this section's specification table. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTOR -

SPECIFICATIONS)

REMOVAL - FRONT BRAKE ROTOR

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the front wheel and tire assembly.

(3) Remove the two mounting bolts securing the

disc brake caliper adapter with brake caliper to the

steering knuckle (Fig. 102).

(4) Remove the disc brake caliper and adapter as

an assembly from the steering knuckle (Fig. 102).

Hang the assembly out of the way using wire or a

bungee cord. Use care not to overextend the brake

hose when doing this.

(5) Remove any retainer clips from the wheel

mounting studs.

(6) Remove brake rotor from hub by pulling it

straight off wheel mounting studs (Fig. 102).

INSTALLATION - FRONT BRAKE ROTOR

(1) Install the brake rotor back on the hub and

bearing (Fig. 102).

(2) Install brake caliper and adapter back over

brake rotor aligning adapter with mounting holes on

steering knuckle (Fig. 102).

(3) Install the two adapter mounting bolts securing

the adapter to the steering knuckle. Tighten the

mounting bolts to 169 N´m (125 ft. lbs.) torque.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting lug nuts in proper

sequence until all nuts are torqued to half specifica-

Fig. 100 Front Brake Rotor

1 - ROTOR MINIMUM THICKNESS MARKING

2 - ROTOR

Fig. 101 Rear Brake Rotor Minimum Thickness

Markings

1 - ROTOR MINIMUM THICKNESS AND DRUM MAXIMUM

DIAMETER SPECIFICATIONS ARE SHOWN ON THIS SURFACE

2 - REAR ROTOR

Fig. 102 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

5 - 62 BRAKES - BASERS

ROTOR (Continued)

ProCarManuals.com

Page 214 of 2399

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE

SYSTEM............................85

DESCRIPTION - ANTILOCK BRAKE

SYSTEM (EXPORT)....................85

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............86

DESCRIPTION - TRACTION CONTROL

SYSTEM............................86

OPERATION

OPERATION - ANTILOCK BRAKE SYSTEM . . 86

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............87

OPERATION - TRACTION CONTROL

SYSTEM............................87

CAUTION

CAUTIONS..........................88

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING...................88

SPECIFICATIONS

ABS FASTENER TORQUE...............89

TONE WHEEL RUNOUT................89

WHEEL SPEED SENSOR AIR GAP........89

FRONT WHEEL SPEED SENSOR

REMOVAL.............................89

INSTALLATION.........................89

REAR WHEEL SPEED SENSOR - AWD

REMOVAL.............................90INSTALLATION.........................90

REAR WHEEL SPEED SENSOR - FWD

REMOVAL.............................91

INSTALLATION.........................91

TONE WHEEL

INSPECTION - TONE WHEEL..............92

TRACTION CONTROL SWITCH

DIAGNOSIS AND TESTING - TRACTION

CONTROL SWITCH....................92

HYDRAULIC/MECHANICAL

OPERATION - HYDRAULIC CIRCUITS AND

VALVES .............................93

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................99

OPERATION...........................99

ICU (INTEGRATED CONTROL UNIT)

DESCRIPTION........................100

OPERATION..........................100

REMOVAL

REMOVAL - LHD.....................100

REMOVAL - RHD.....................101

DISASSEMBLY - ICU...................103

ASSEMBLY - ICU......................103

INSTALLATION

INSTALLATION - LHD.................104

INSTALLATION - RHD.................105

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE SYSTEM

This section covers the physical and operational

descriptions and the on-car service procedures for the

Mark 20e Antilock Brake System and the Mark 20e

Antilock Brake System with traction control.

The purpose of the antilock brake system (ABS) is

to prevent wheel lockup under braking conditions on

virtually any type of road surface. Antilock braking is

desirable because a vehicle that is stopped without

locking the wheels retains directional stability and

some steering capability. This allows the driver to

retain greater control of the vehicle during braking.

DESCRIPTION - ANTILOCK BRAKE SYSTEM

(EXPORT)

Four-wheel disc antilock brakes are standard on all

models. The Mark 20e antilock brake system is used

on all models. Depending on whether the vehicle is a

left-hand drive (LHD) or right-hand drive (RHD)

model, the integrated control unit (ICU) is located in

one of two locations. On LHD models, the ICU is

mounted above the front suspension cradle/cross-

member below the master cylinder. On RHD models,

the ICU is located behind the front suspension cra-

dle/crossmember on the left side of the vehicle.

RSBRAKES - ABS5-85

ProCarManuals.com