shaft CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1696 of 2399

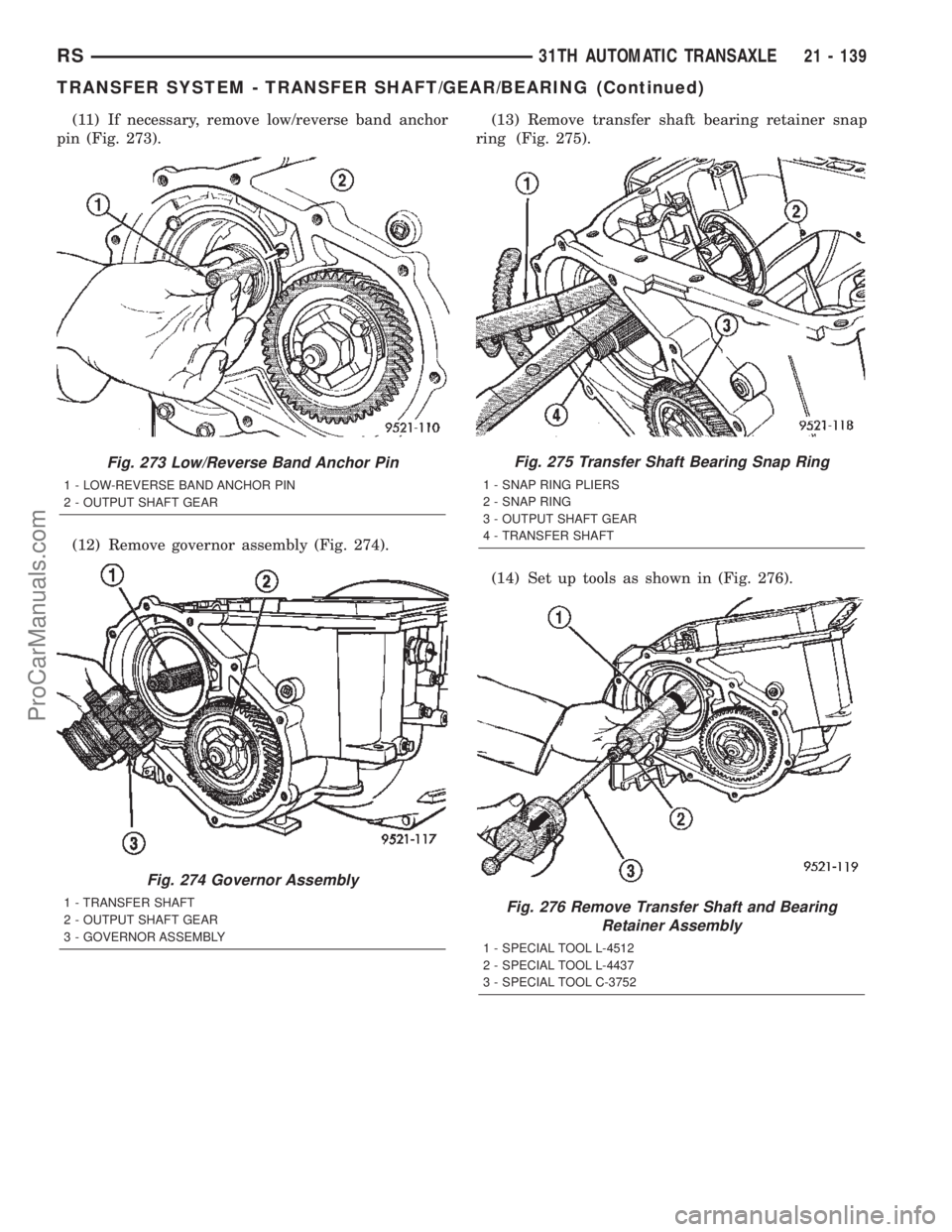

(11) If necessary, remove low/reverse band anchor

pin (Fig. 273).

(12) Remove governor assembly (Fig. 274).(13) Remove transfer shaft bearing retainer snap

ring (Fig. 275).

(14) Set up tools as shown in (Fig. 276).

Fig. 273 Low/Reverse Band Anchor Pin

1 - LOW-REVERSE BAND ANCHOR PIN

2 - OUTPUT SHAFT GEAR

Fig. 274 Governor Assembly

1 - TRANSFER SHAFT

2 - OUTPUT SHAFT GEAR

3 - GOVERNOR ASSEMBLY

Fig. 275 Transfer Shaft Bearing Snap Ring

1 - SNAP RING PLIERS

2 - SNAP RING

3 - OUTPUT SHAFT GEAR

4 - TRANSFER SHAFT

Fig. 276 Remove Transfer Shaft and Bearing

Retainer Assembly

1 - SPECIAL TOOL L-4512

2 - SPECIAL TOOL L-4437

3 - SPECIAL TOOL C-3752

RS31TH AUTOMATIC TRANSAXLE21 - 139

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1697 of 2399

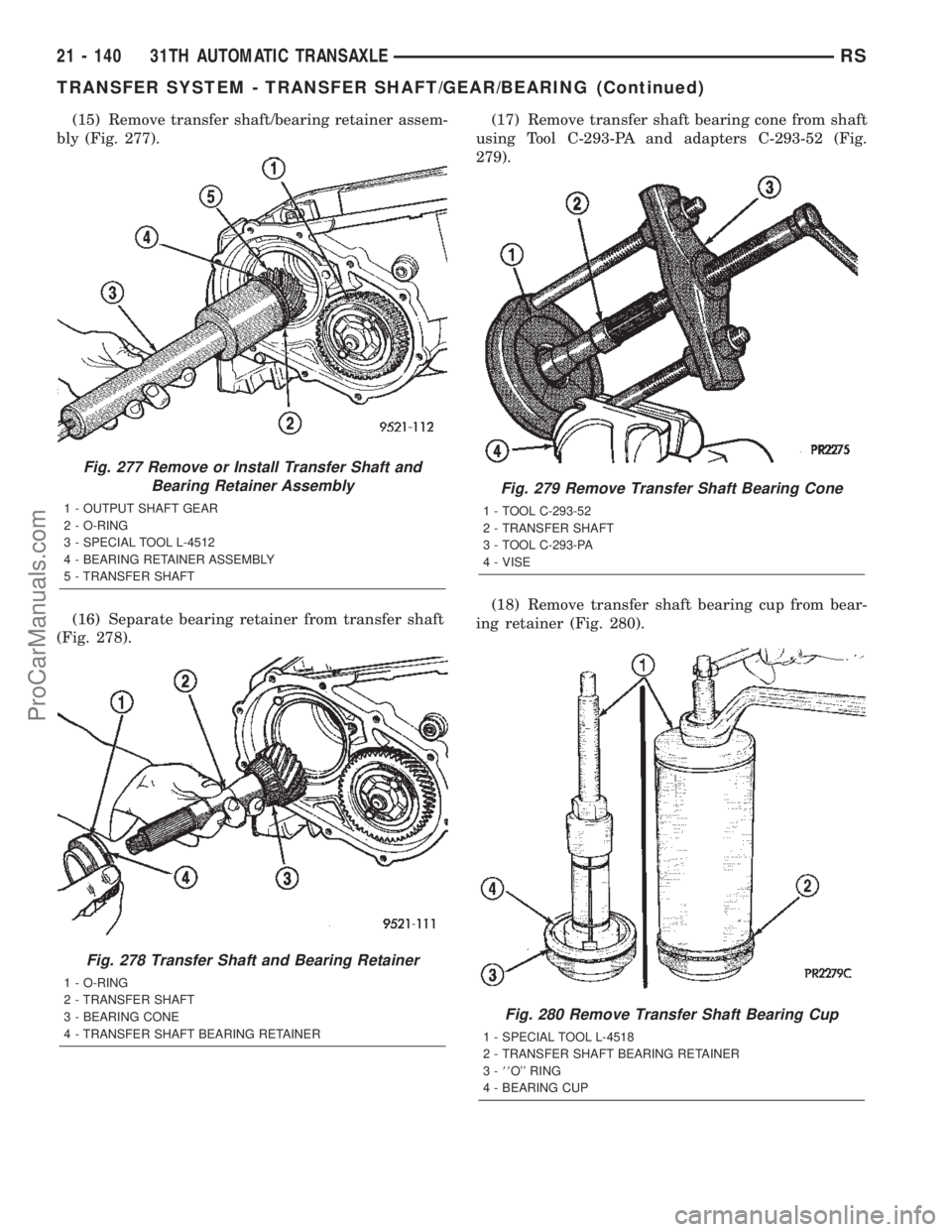

(15) Remove transfer shaft/bearing retainer assem-

bly (Fig. 277).

(16) Separate bearing retainer from transfer shaft

(Fig. 278).(17) Remove transfer shaft bearing cone from shaft

using Tool C-293-PA and adapters C-293-52 (Fig.

279).

(18) Remove transfer shaft bearing cup from bear-

ing retainer (Fig. 280).

Fig. 277 Remove or Install Transfer Shaft and

Bearing Retainer Assembly

1 - OUTPUT SHAFT GEAR

2 - O-RING

3 - SPECIAL TOOL L-4512

4 - BEARING RETAINER ASSEMBLY

5 - TRANSFER SHAFT

Fig. 278 Transfer Shaft and Bearing Retainer

1 - O-RING

2 - TRANSFER SHAFT

3 - BEARING CONE

4 - TRANSFER SHAFT BEARING RETAINER

Fig. 279 Remove Transfer Shaft Bearing Cone

1 - TOOL C-293-52

2 - TRANSFER SHAFT

3 - TOOL C-293-PA

4 - VISE

Fig. 280 Remove Transfer Shaft Bearing Cup

1 - SPECIAL TOOL L-4518

2 - TRANSFER SHAFT BEARING RETAINER

3-88O'' RING

4 - BEARING CUP

21 - 140 31TH AUTOMATIC TRANSAXLERS

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1698 of 2399

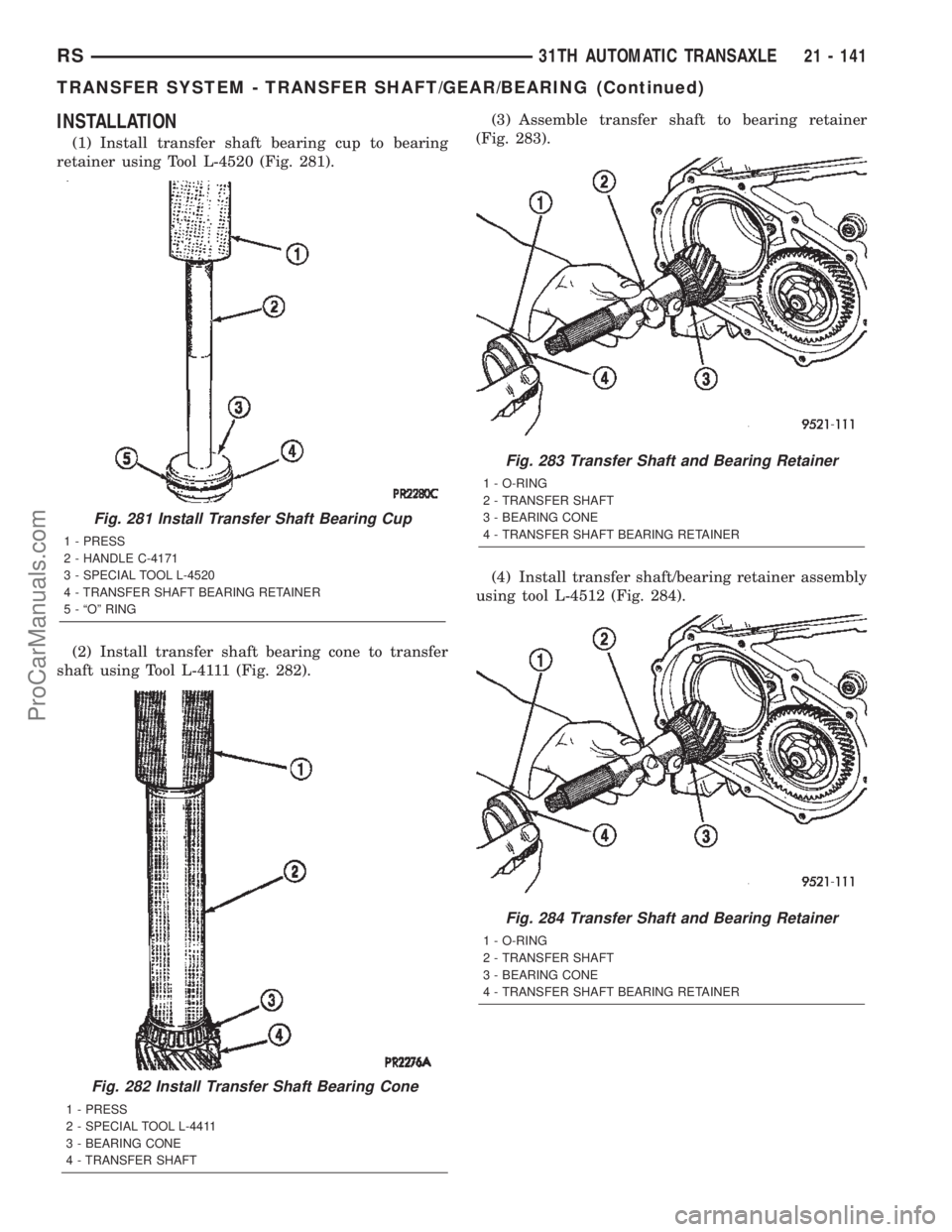

INSTALLATION

(1) Install transfer shaft bearing cup to bearing

retainer using Tool L-4520 (Fig. 281).

(2) Install transfer shaft bearing cone to transfer

shaft using Tool L-4111 (Fig. 282).(3) Assemble transfer shaft to bearing retainer

(Fig. 283).

(4) Install transfer shaft/bearing retainer assembly

using tool L-4512 (Fig. 284).

Fig. 282 Install Transfer Shaft Bearing Cone

1 - PRESS

2 - SPECIAL TOOL L-4411

3 - BEARING CONE

4 - TRANSFER SHAFT

Fig. 281 Install Transfer Shaft Bearing Cup

1 - PRESS

2 - HANDLE C-4171

3 - SPECIAL TOOL L-4520

4 - TRANSFER SHAFT BEARING RETAINER

5 - ªOº RING

Fig. 283 Transfer Shaft and Bearing Retainer

1 - O-RING

2 - TRANSFER SHAFT

3 - BEARING CONE

4 - TRANSFER SHAFT BEARING RETAINER

Fig. 284 Transfer Shaft and Bearing Retainer

1 - O-RING

2 - TRANSFER SHAFT

3 - BEARING CONE

4 - TRANSFER SHAFT BEARING RETAINER

RS31TH AUTOMATIC TRANSAXLE21 - 141

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1699 of 2399

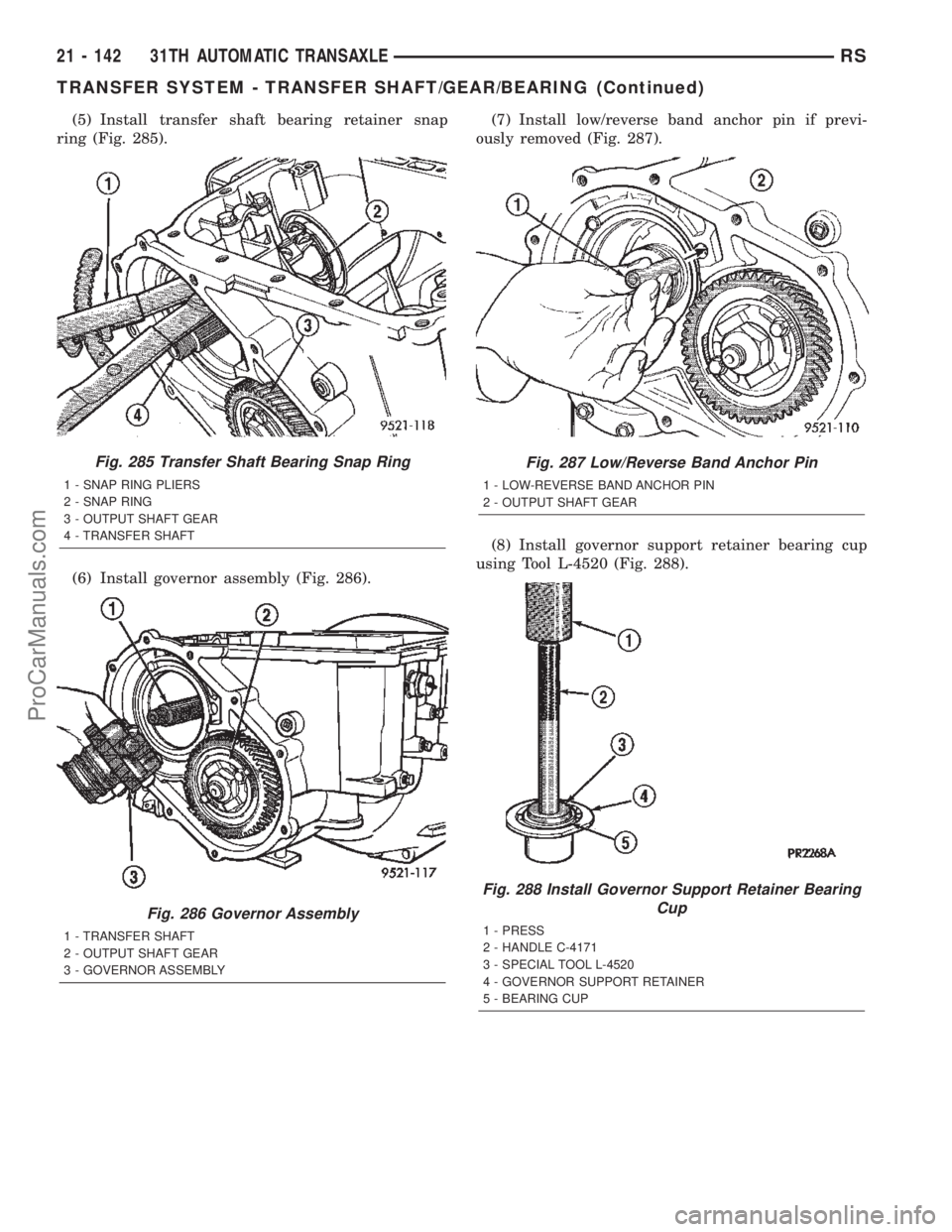

(5) Install transfer shaft bearing retainer snap

ring (Fig. 285).

(6) Install governor assembly (Fig. 286).(7) Install low/reverse band anchor pin if previ-

ously removed (Fig. 287).

(8) Install governor support retainer bearing cup

using Tool L-4520 (Fig. 288).

Fig. 285 Transfer Shaft Bearing Snap Ring

1 - SNAP RING PLIERS

2 - SNAP RING

3 - OUTPUT SHAFT GEAR

4 - TRANSFER SHAFT

Fig. 286 Governor Assembly

1 - TRANSFER SHAFT

2 - OUTPUT SHAFT GEAR

3 - GOVERNOR ASSEMBLY

Fig. 287 Low/Reverse Band Anchor Pin

1 - LOW-REVERSE BAND ANCHOR PIN

2 - OUTPUT SHAFT GEAR

Fig. 288 Install Governor Support Retainer Bearing

Cup

1 - PRESS

2 - HANDLE C-4171

3 - SPECIAL TOOL L-4520

4 - GOVERNOR SUPPORT RETAINER

5 - BEARING CUP

21 - 142 31TH AUTOMATIC TRANSAXLERS

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1700 of 2399

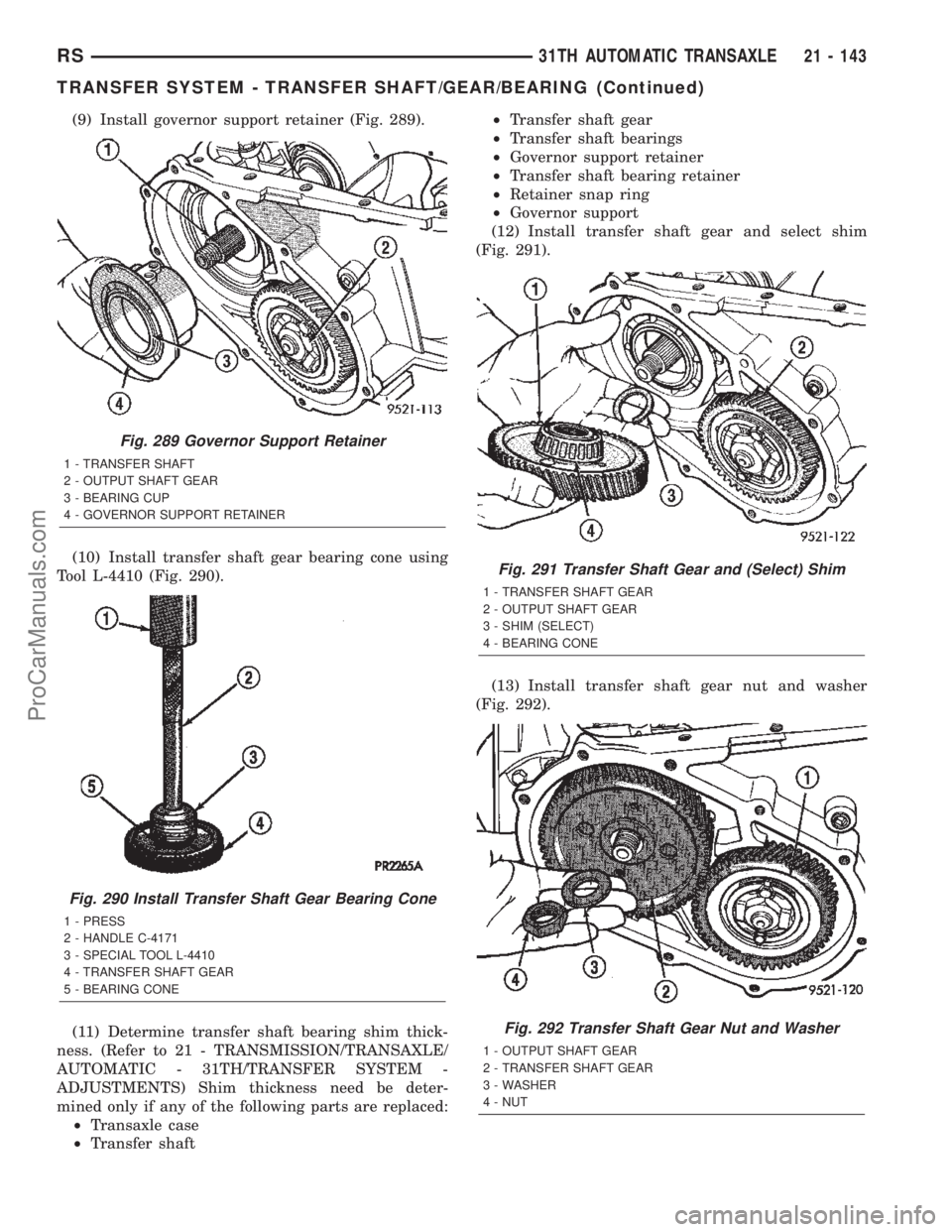

(9) Install governor support retainer (Fig. 289).

(10) Install transfer shaft gear bearing cone using

Tool L-4410 (Fig. 290).

(11) Determine transfer shaft bearing shim thick-

ness. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 31TH/TRANSFER SYSTEM -

ADJUSTMENTS) Shim thickness need be deter-

mined only if any of the following parts are replaced:

²Transaxle case

²Transfer shaft²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

(12) Install transfer shaft gear and select shim

(Fig. 291).

(13) Install transfer shaft gear nut and washer

(Fig. 292).

Fig. 289 Governor Support Retainer

1 - TRANSFER SHAFT

2 - OUTPUT SHAFT GEAR

3 - BEARING CUP

4 - GOVERNOR SUPPORT RETAINER

Fig. 290 Install Transfer Shaft Gear Bearing Cone

1 - PRESS

2 - HANDLE C-4171

3 - SPECIAL TOOL L-4410

4 - TRANSFER SHAFT GEAR

5 - BEARING CONE

Fig. 291 Transfer Shaft Gear and (Select) Shim

1 - TRANSFER SHAFT GEAR

2 - OUTPUT SHAFT GEAR

3 - SHIM (SELECT)

4 - BEARING CONE

Fig. 292 Transfer Shaft Gear Nut and Washer

1 - OUTPUT SHAFT GEAR

2 - TRANSFER SHAFT GEAR

3 - WASHER

4 - NUT

RS31TH AUTOMATIC TRANSAXLE21 - 143

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1701 of 2399

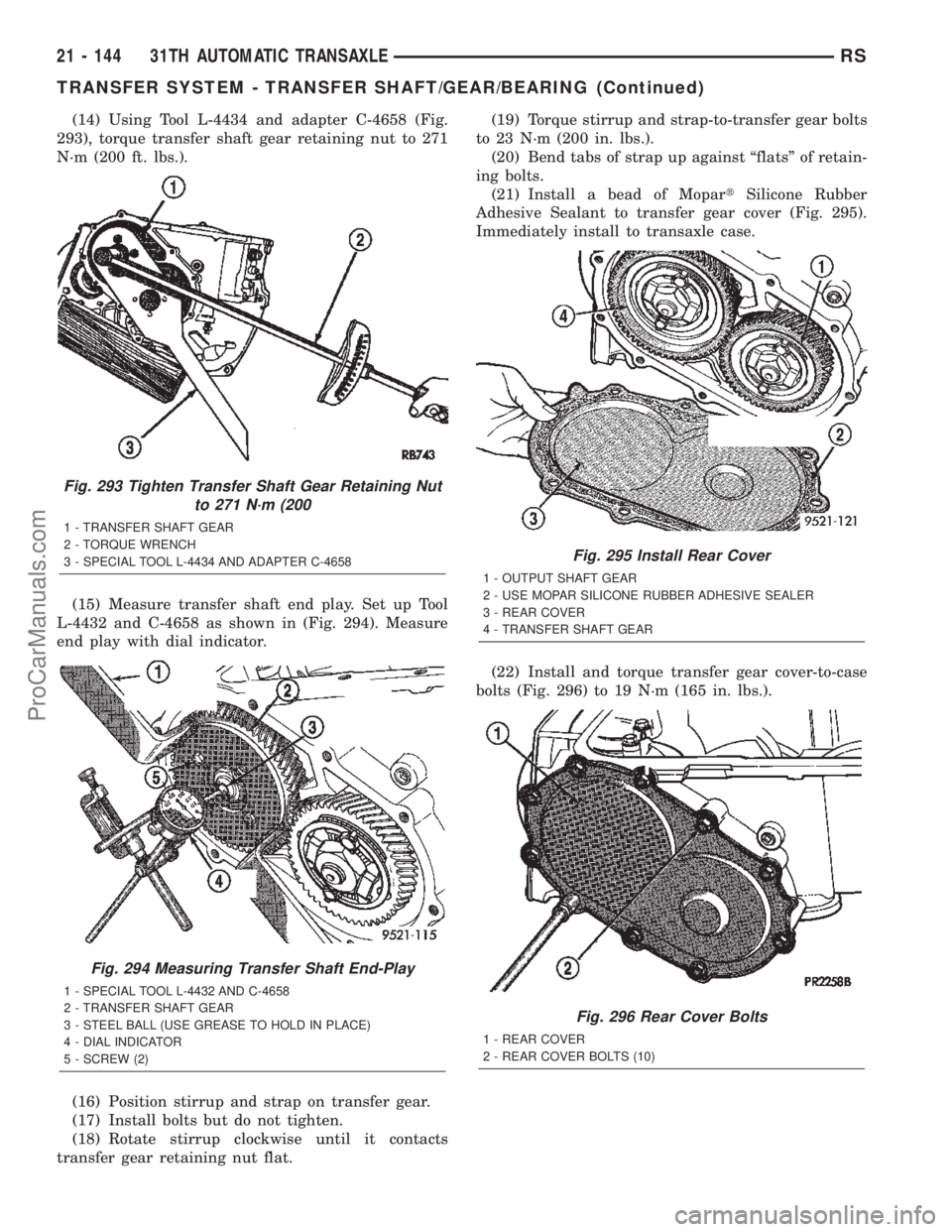

(14) Using Tool L-4434 and adapter C-4658 (Fig.

293), torque transfer shaft gear retaining nut to 271

N´m (200 ft. lbs.).

(15) Measure transfer shaft end play. Set up Tool

L-4432 and C-4658 as shown in (Fig. 294). Measure

end play with dial indicator.

(16) Position stirrup and strap on transfer gear.

(17) Install bolts but do not tighten.

(18) Rotate stirrup clockwise until it contacts

transfer gear retaining nut flat.(19) Torque stirrup and strap-to-transfer gear bolts

to 23 N´m (200 in. lbs.).

(20) Bend tabs of strap up against ªflatsº of retain-

ing bolts.

(21) Install a bead of MopartSilicone Rubber

Adhesive Sealant to transfer gear cover (Fig. 295).

Immediately install to transaxle case.

(22) Install and torque transfer gear cover-to-case

bolts (Fig. 296) to 19 N´m (165 in. lbs.).

Fig. 293 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200

1 - TRANSFER SHAFT GEAR

2 - TORQUE WRENCH

3 - SPECIAL TOOL L-4434 AND ADAPTER C-4658

Fig. 294 Measuring Transfer Shaft End-Play

1 - SPECIAL TOOL L-4432 AND C-4658

2 - TRANSFER SHAFT GEAR

3 - STEEL BALL (USE GREASE TO HOLD IN PLACE)

4 - DIAL INDICATOR

5 - SCREW (2)

Fig. 295 Install Rear Cover

1 - OUTPUT SHAFT GEAR

2 - USE MOPAR SILICONE RUBBER ADHESIVE SEALER

3 - REAR COVER

4 - TRANSFER SHAFT GEAR

Fig. 296 Rear Cover Bolts

1 - REAR COVER

2 - REAR COVER BOLTS (10)

21 - 144 31TH AUTOMATIC TRANSAXLERS

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1702 of 2399

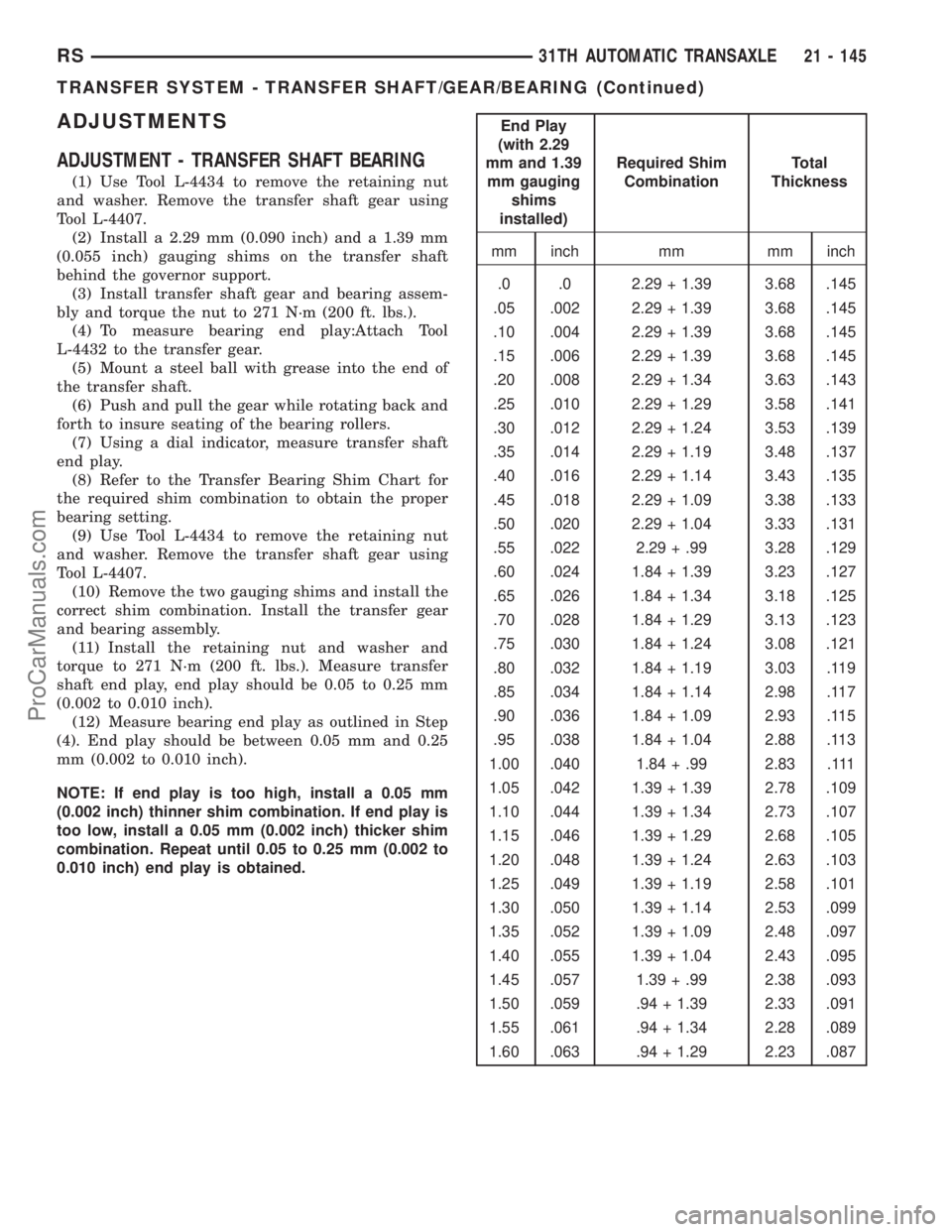

ADJUSTMENTS

ADJUSTMENT - TRANSFER SHAFT BEARING

(1) Use Tool L-4434 to remove the retaining nut

and washer. Remove the transfer shaft gear using

Tool L-4407.

(2) Install a 2.29 mm (0.090 inch) and a 1.39 mm

(0.055 inch) gauging shims on the transfer shaft

behind the governor support.

(3) Install transfer shaft gear and bearing assem-

bly and torque the nut to 271 N´m (200 ft. lbs.).

(4) To measure bearing end play:Attach Tool

L-4432 to the transfer gear.

(5) Mount a steel ball with grease into the end of

the transfer shaft.

(6) Push and pull the gear while rotating back and

forth to insure seating of the bearing rollers.

(7) Using a dial indicator, measure transfer shaft

end play.

(8) Refer to the Transfer Bearing Shim Chart for

the required shim combination to obtain the proper

bearing setting.

(9) Use Tool L-4434 to remove the retaining nut

and washer. Remove the transfer shaft gear using

Tool L-4407.

(10) Remove the two gauging shims and install the

correct shim combination. Install the transfer gear

and bearing assembly.

(11) Install the retaining nut and washer and

torque to 271 N´m (200 ft. lbs.). Measure transfer

shaft end play, end play should be 0.05 to 0.25 mm

(0.002 to 0.010 inch).

(12) Measure bearing end play as outlined in Step

(4). End play should be between 0.05 mm and 0.25

mm (0.002 to 0.010 inch).

NOTE: If end play is too high, install a 0.05 mm

(0.002 inch) thinner shim combination. If end play is

too low, install a 0.05 mm (0.002 inch) thicker shim

combination. Repeat until 0.05 to 0.25 mm (0.002 to

0.010 inch) end play is obtained.

End Play

(with 2.29

mm and 1.39

mm gauging

shims

installed)Required Shim

CombinationTotal

Thickness

mm inch mm mm inch

.0 .0 2.29 + 1.39 3.68 .145

.05 .002 2.29 + 1.39 3.68 .145

.10 .004 2.29 + 1.39 3.68 .145

.15 .006 2.29 + 1.39 3.68 .145

.20 .008 2.29 + 1.34 3.63 .143

.25 .010 2.29 + 1.29 3.58 .141

.30 .012 2.29 + 1.24 3.53 .139

.35 .014 2.29 + 1.19 3.48 .137

.40 .016 2.29 + 1.14 3.43 .135

.45 .018 2.29 + 1.09 3.38 .133

.50 .020 2.29 + 1.04 3.33 .131

.55 .022 2.29 + .99 3.28 .129

.60 .024 1.84 + 1.39 3.23 .127

.65 .026 1.84 + 1.34 3.18 .125

.70 .028 1.84 + 1.29 3.13 .123

.75 .030 1.84 + 1.24 3.08 .121

.80 .032 1.84 + 1.19 3.03 .119

.85 .034 1.84 + 1.14 2.98 .117

.90 .036 1.84 + 1.09 2.93 .115

.95 .038 1.84 + 1.04 2.88 .113

1.00 .040 1.84 + .99 2.83 .111

1.05 .042 1.39 + 1.39 2.78 .109

1.10 .044 1.39 + 1.34 2.73 .107

1.15 .046 1.39 + 1.29 2.68 .105

1.20 .048 1.39 + 1.24 2.63 .103

1.25 .049 1.39 + 1.19 2.58 .101

1.30 .050 1.39 + 1.14 2.53 .099

1.35 .052 1.39 + 1.09 2.48 .097

1.40 .055 1.39 + 1.04 2.43 .095

1.45 .057 1.39 + .99 2.38 .093

1.50 .059 .94 + 1.39 2.33 .091

1.55 .061 .94 + 1.34 2.28 .089

1.60 .063 .94 + 1.29 2.23 .087

RS31TH AUTOMATIC TRANSAXLE21 - 145

TRANSFER SYSTEM - TRANSFER SHAFT/GEAR/BEARING (Continued)

ProCarManuals.com

Page 1706 of 2399

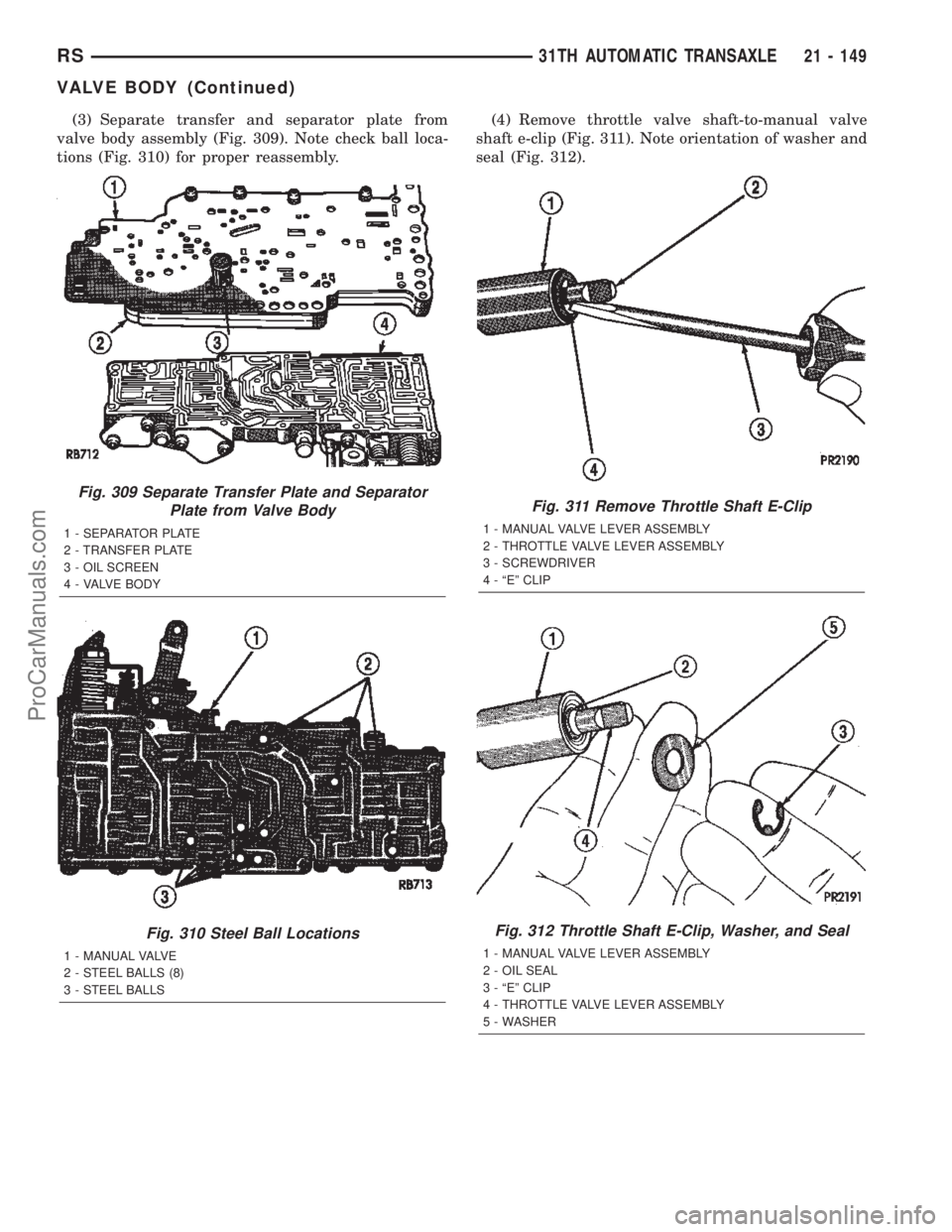

(3) Separate transfer and separator plate from

valve body assembly (Fig. 309). Note check ball loca-

tions (Fig. 310) for proper reassembly.(4) Remove throttle valve shaft-to-manual valve

shaft e-clip (Fig. 311). Note orientation of washer and

seal (Fig. 312).

Fig. 309 Separate Transfer Plate and Separator

Plate from Valve Body

1 - SEPARATOR PLATE

2 - TRANSFER PLATE

3 - OIL SCREEN

4 - VALVE BODY

Fig. 310 Steel Ball Locations

1 - MANUAL VALVE

2 - STEEL BALLS (8)

3 - STEEL BALLS

Fig. 311 Remove Throttle Shaft E-Clip

1 - MANUAL VALVE LEVER ASSEMBLY

2 - THROTTLE VALVE LEVER ASSEMBLY

3 - SCREWDRIVER

4 - ªEº CLIP

Fig. 312 Throttle Shaft E-Clip, Washer, and Seal

1 - MANUAL VALVE LEVER ASSEMBLY

2 - OIL SEAL

3 - ªEº CLIP

4 - THROTTLE VALVE LEVER ASSEMBLY

5 - WASHER

RS31TH AUTOMATIC TRANSAXLE21 - 149

VALVE BODY (Continued)

ProCarManuals.com

Page 1707 of 2399

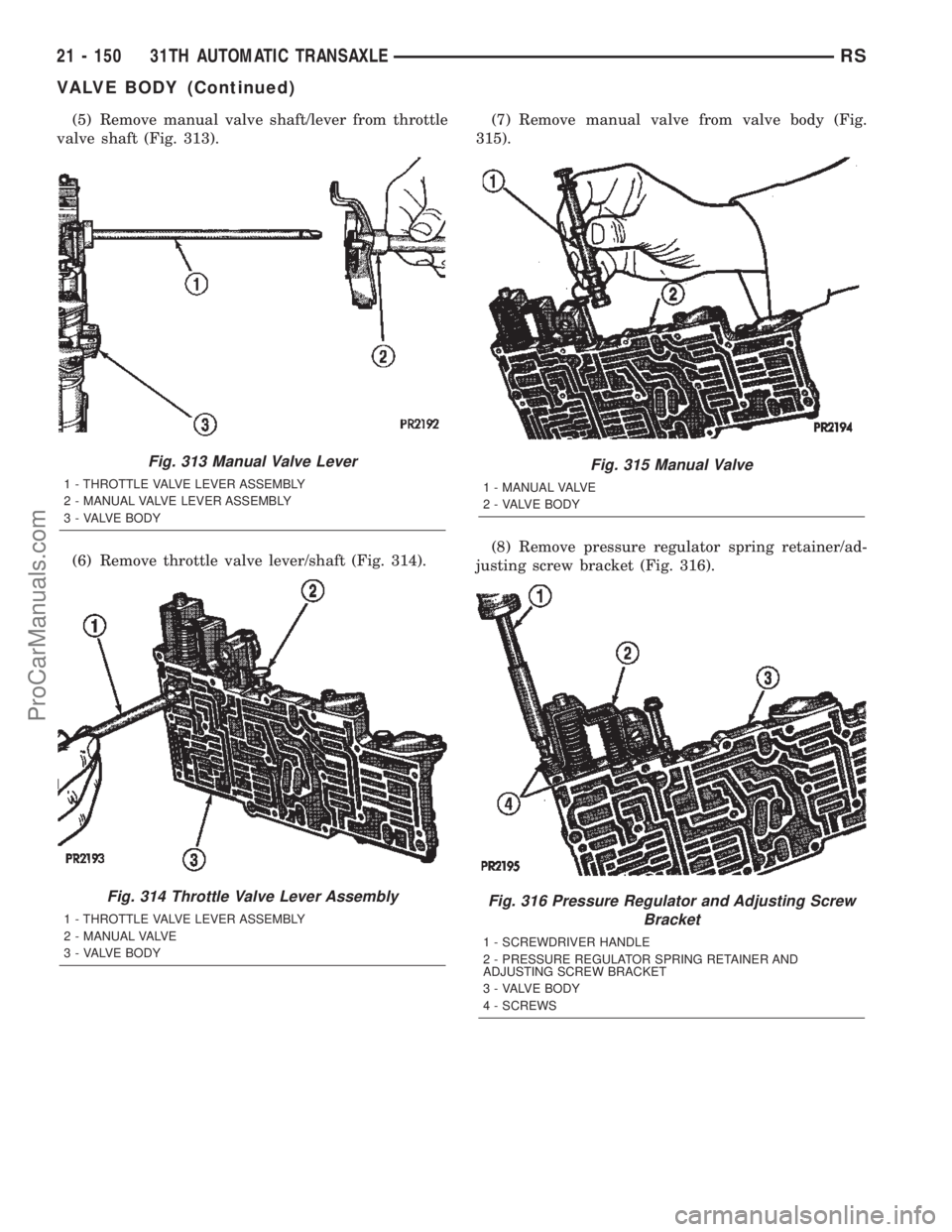

(5) Remove manual valve shaft/lever from throttle

valve shaft (Fig. 313).

(6) Remove throttle valve lever/shaft (Fig. 314).(7) Remove manual valve from valve body (Fig.

315).

(8) Remove pressure regulator spring retainer/ad-

justing screw bracket (Fig. 316).

Fig. 313 Manual Valve Lever

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE LEVER ASSEMBLY

3 - VALVE BODY

Fig. 314 Throttle Valve Lever Assembly

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE

3 - VALVE BODY

Fig. 315 Manual Valve

1 - MANUAL VALVE

2 - VALVE BODY

Fig. 316 Pressure Regulator and Adjusting Screw

Bracket

1 - SCREWDRIVER HANDLE

2 - PRESSURE REGULATOR SPRING RETAINER AND

ADJUSTING SCREW BRACKET

3 - VALVE BODY

4 - SCREWS

21 - 150 31TH AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1712 of 2399

valve or plug edges. Squareness of these edges is

vitally important. These edges prevent foreign matter

from lodging between the valves, plugs and bore.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Also inspect the coating on the alu-

minum valves and plugs. If the coating is damaged

or worn through, the valve (or valve body) should be

replaced.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores. Valve

body bores do not change dimensionally with use. If

the valve body functioned correctly when new, it will

continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

ASSEMBLY

(1) Install shift/shuttle valves and springs as

shown in (Fig. 320).

(2) Install torque converter clutch solenoid, spring,

and plug as shown in (Fig. 319).

(3) Install governor plugs as shown in (Fig. 318).

(4) Install pressure regulator and manual control

springs and valves as shown in (Fig. 317).

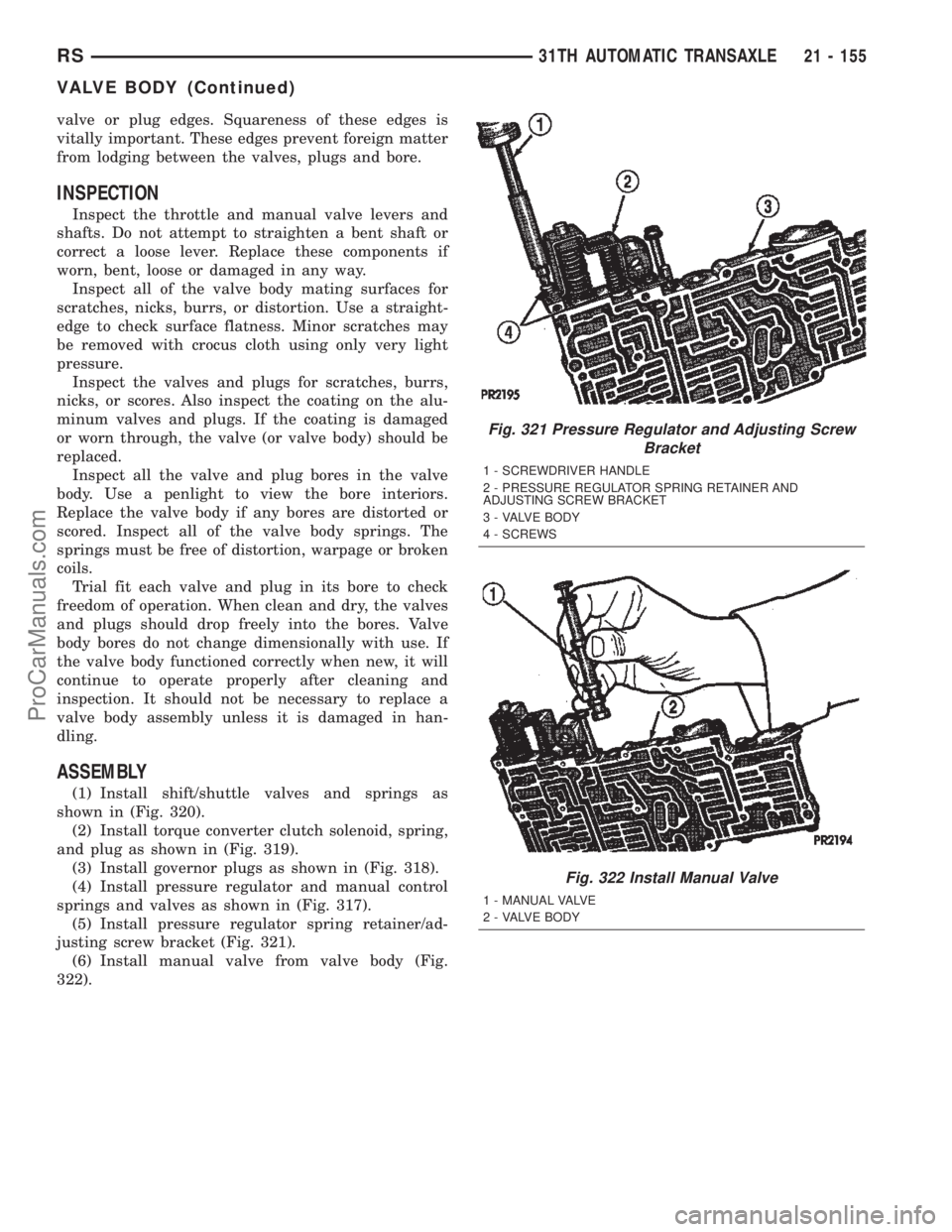

(5) Install pressure regulator spring retainer/ad-

justing screw bracket (Fig. 321).

(6) Install manual valve from valve body (Fig.

322).

Fig. 321 Pressure Regulator and Adjusting Screw

Bracket

1 - SCREWDRIVER HANDLE

2 - PRESSURE REGULATOR SPRING RETAINER AND

ADJUSTING SCREW BRACKET

3 - VALVE BODY

4 - SCREWS

Fig. 322 Install Manual Valve

1 - MANUAL VALVE

2 - VALVE BODY

RS31TH AUTOMATIC TRANSAXLE21 - 155

VALVE BODY (Continued)

ProCarManuals.com