shaft CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1713 of 2399

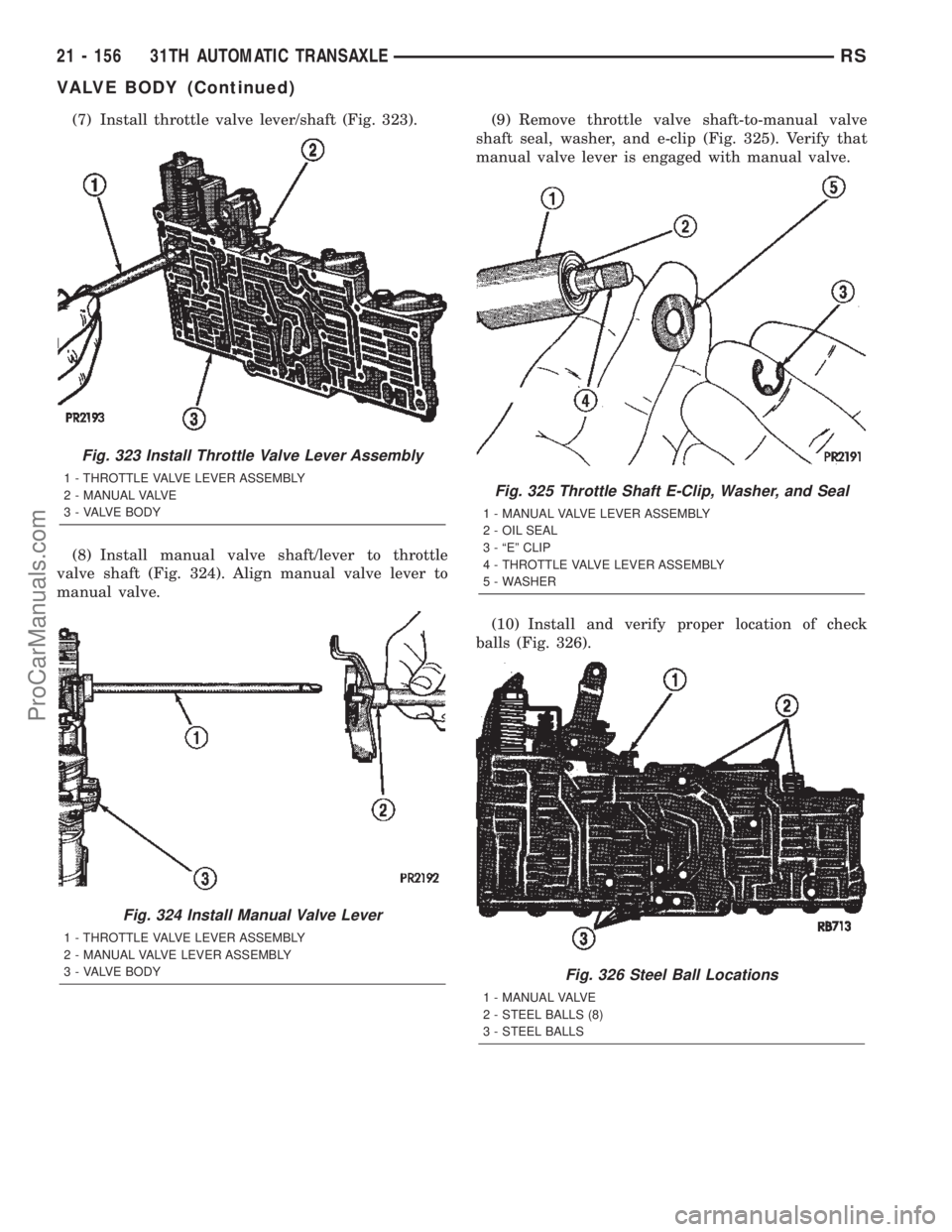

(7) Install throttle valve lever/shaft (Fig. 323).

(8) Install manual valve shaft/lever to throttle

valve shaft (Fig. 324). Align manual valve lever to

manual valve.(9) Remove throttle valve shaft-to-manual valve

shaft seal, washer, and e-clip (Fig. 325). Verify that

manual valve lever is engaged with manual valve.

(10) Install and verify proper location of check

balls (Fig. 326).

Fig. 323 Install Throttle Valve Lever Assembly

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE

3 - VALVE BODY

Fig. 324 Install Manual Valve Lever

1 - THROTTLE VALVE LEVER ASSEMBLY

2 - MANUAL VALVE LEVER ASSEMBLY

3 - VALVE BODY

Fig. 325 Throttle Shaft E-Clip, Washer, and Seal

1 - MANUAL VALVE LEVER ASSEMBLY

2 - OIL SEAL

3 - ªEº CLIP

4 - THROTTLE VALVE LEVER ASSEMBLY

5 - WASHER

Fig. 326 Steel Ball Locations

1 - MANUAL VALVE

2 - STEEL BALLS (8)

3 - STEEL BALLS

21 - 156 31TH AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

ProCarManuals.com

Page 1720 of 2399

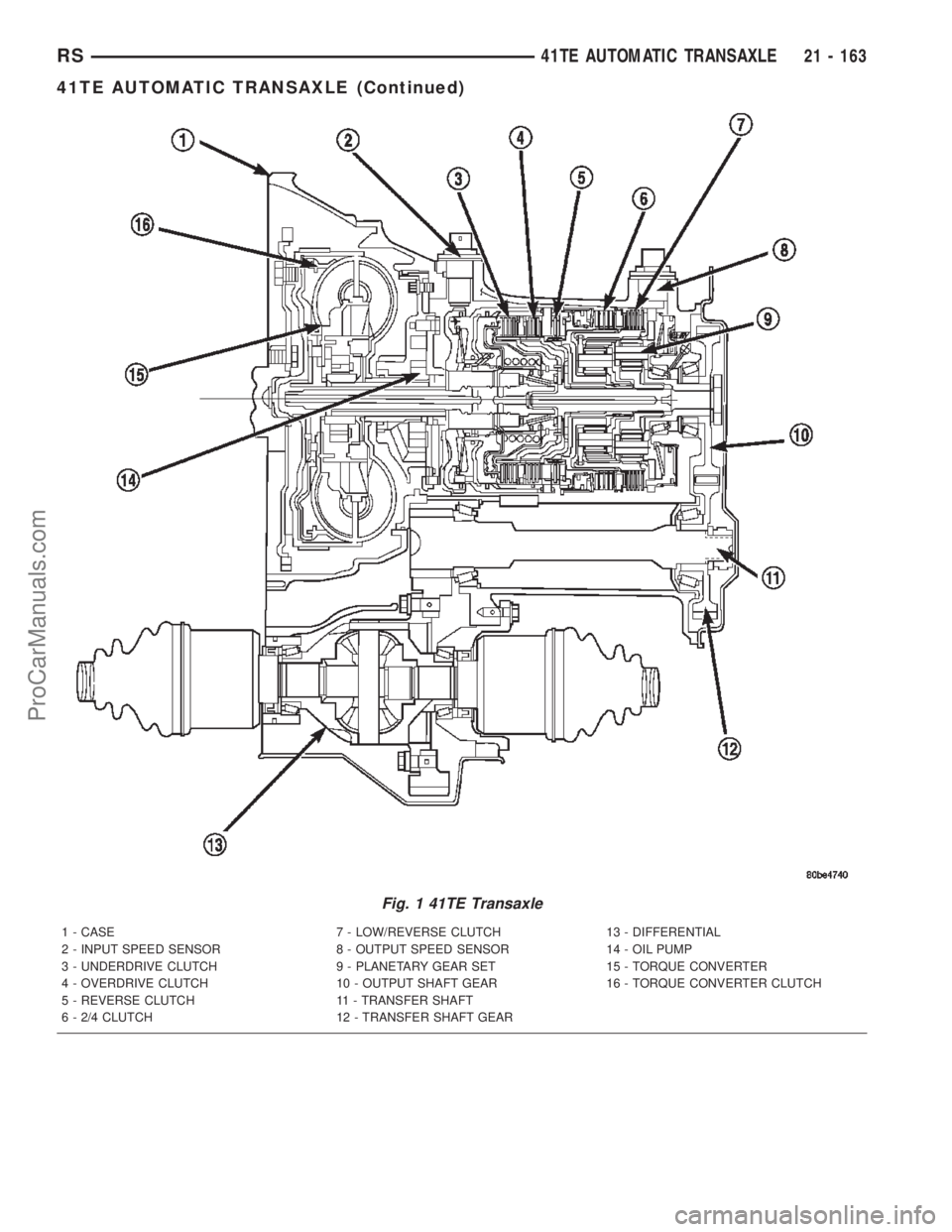

Fig. 1 41TE Transaxle

1 - CASE 7 - LOW/REVERSE CLUTCH 13 - DIFFERENTIAL

2 - INPUT SPEED SENSOR 8 - OUTPUT SPEED SENSOR 14 - OIL PUMP

3 - UNDERDRIVE CLUTCH 9 - PLANETARY GEAR SET 15 - TORQUE CONVERTER

4 - OVERDRIVE CLUTCH 10 - OUTPUT SHAFT GEAR 16 - TORQUE CONVERTER CLUTCH

5 - REVERSE CLUTCH 11 - TRANSFER SHAFT

6 - 2/4 CLUTCH 12 - TRANSFER SHAFT GEAR

RS41TE AUTOMATIC TRANSAXLE21 - 163

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1724 of 2399

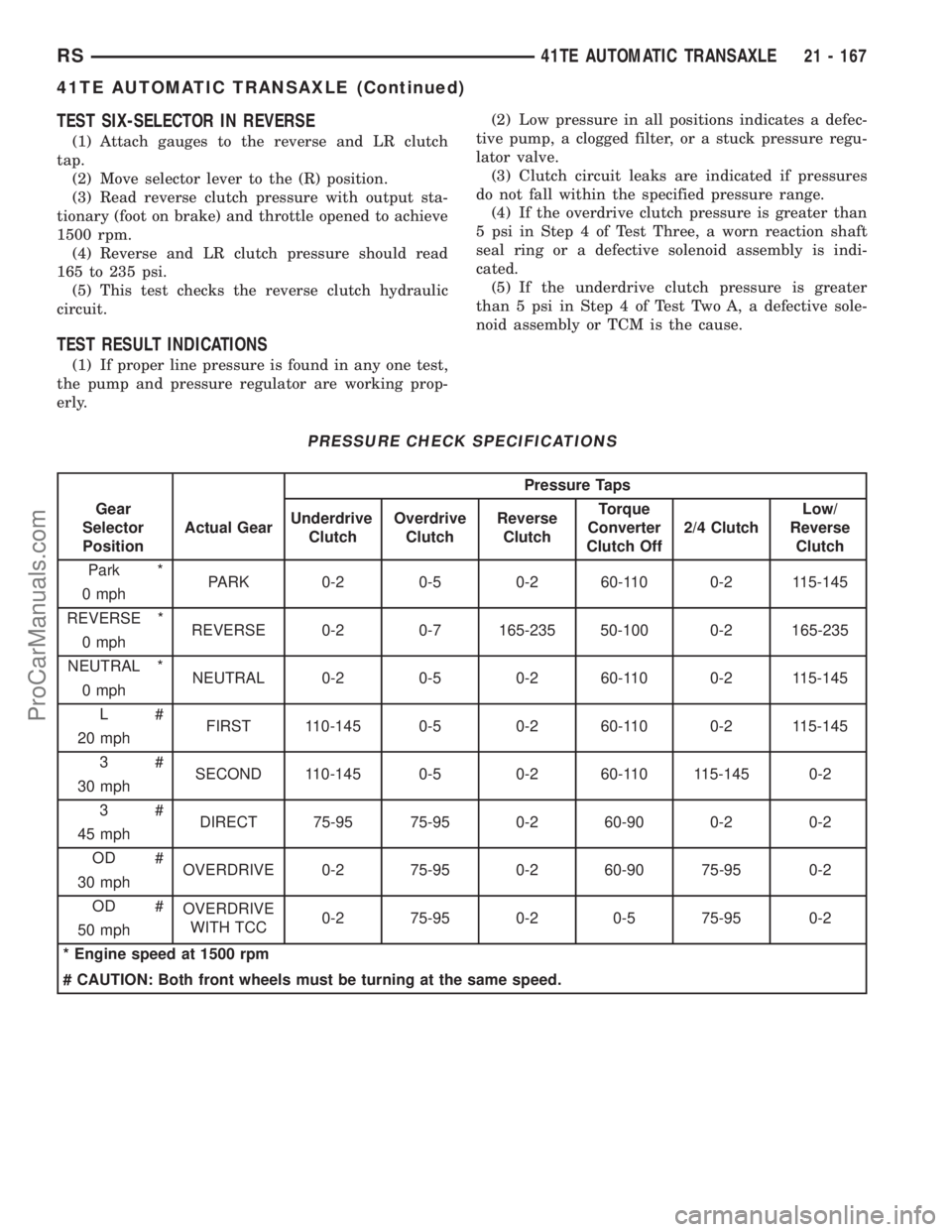

TEST SIX-SELECTOR IN REVERSE

(1) Attach gauges to the reverse and LR clutch

tap.

(2) Move selector lever to the (R) position.

(3) Read reverse clutch pressure with output sta-

tionary (foot on brake) and throttle opened to achieve

1500 rpm.

(4) Reverse and LR clutch pressure should read

165 to 235 psi.

(5) This test checks the reverse clutch hydraulic

circuit.

TEST RESULT INDICATIONS

(1) If proper line pressure is found in any one test,

the pump and pressure regulator are working prop-

erly.(2) Low pressure in all positions indicates a defec-

tive pump, a clogged filter, or a stuck pressure regu-

lator valve.

(3) Clutch circuit leaks are indicated if pressures

do not fall within the specified pressure range.

(4) If the overdrive clutch pressure is greater than

5 psi in Step 4 of Test Three, a worn reaction shaft

seal ring or a defective solenoid assembly is indi-

cated.

(5) If the underdrive clutch pressure is greater

than 5 psi in Step 4 of Test Two A, a defective sole-

noid assembly or TCM is the cause.

PRESSURE CHECK SPECIFICATIONS

Pressure Taps

Gear

Selector

PositionActual GearUnderdrive

ClutchOverdrive

ClutchReverse

ClutchTorque

Converter

Clutch Off2/4 ClutchLow/

Reverse

Clutch

Park *

PARK 0-2 0-5 0-2 60-110 0-2 115-145

0 mph

REVERSE *

REVERSE 0-2 0-7 165-235 50-100 0-2 165-235

0 mph

NEUTRAL *

NEUTRAL 0-2 0-5 0-2 60-110 0-2 115-145

0 mph

L#

FIRST 110-145 0-5 0-2 60-110 0-2 115-145

20 mph

3#

SECOND 110-145 0-5 0-2 60-110 115-145 0-2

30 mph

3#

DIRECT 75-95 75-95 0-2 60-90 0-2 0-2

45 mph

OD #

OVERDRIVE 0-2 75-95 0-2 60-90 75-95 0-2

30 mph

OD #

OVERDRIVE

WITH TCC0-2 75-95 0-2 0-5 75-95 0-2

50 mph

* Engine speed at 1500 rpm

# CAUTION: Both front wheels must be turning at the same speed.

RS41TE AUTOMATIC TRANSAXLE21 - 167

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1725 of 2399

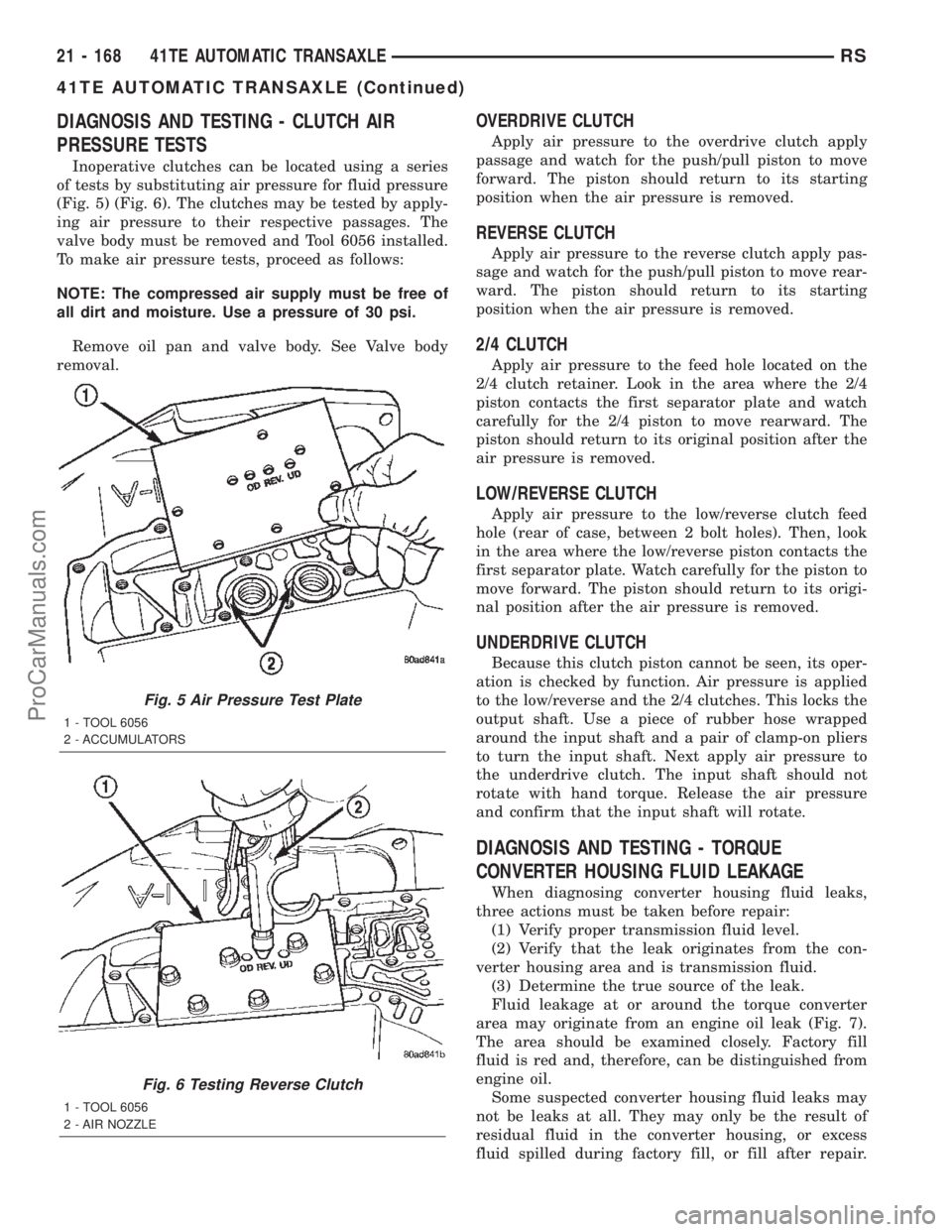

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS

Inoperative clutches can be located using a series

of tests by substituting air pressure for fluid pressure

(Fig. 5) (Fig. 6). The clutches may be tested by apply-

ing air pressure to their respective passages. The

valve body must be removed and Tool 6056 installed.

To make air pressure tests, proceed as follows:

NOTE: The compressed air supply must be free of

all dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. See Valve body

removal.

OVERDRIVE CLUTCH

Apply air pressure to the overdrive clutch apply

passage and watch for the push/pull piston to move

forward. The piston should return to its starting

position when the air pressure is removed.

REVERSE CLUTCH

Apply air pressure to the reverse clutch apply pas-

sage and watch for the push/pull piston to move rear-

ward. The piston should return to its starting

position when the air pressure is removed.

2/4 CLUTCH

Apply air pressure to the feed hole located on the

2/4 clutch retainer. Look in the area where the 2/4

piston contacts the first separator plate and watch

carefully for the 2/4 piston to move rearward. The

piston should return to its original position after the

air pressure is removed.

LOW/REVERSE CLUTCH

Apply air pressure to the low/reverse clutch feed

hole (rear of case, between 2 bolt holes). Then, look

in the area where the low/reverse piston contacts the

first separator plate. Watch carefully for the piston to

move forward. The piston should return to its origi-

nal position after the air pressure is removed.

UNDERDRIVE CLUTCH

Because this clutch piston cannot be seen, its oper-

ation is checked by function. Air pressure is applied

to the low/reverse and the 2/4 clutches. This locks the

output shaft. Use a piece of rubber hose wrapped

around the input shaft and a pair of clamp-on pliers

to turn the input shaft. Next apply air pressure to

the underdrive clutch. The input shaft should not

rotate with hand torque. Release the air pressure

and confirm that the input shaft will rotate.

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE

When diagnosing converter housing fluid leaks,

three actions must be taken before repair:

(1) Verify proper transmission fluid level.

(2) Verify that the leak originates from the con-

verter housing area and is transmission fluid.

(3) Determine the true source of the leak.

Fluid leakage at or around the torque converter

area may originate from an engine oil leak (Fig. 7).

The area should be examined closely. Factory fill

fluid is red and, therefore, can be distinguished from

engine oil.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill, or fill after repair.

Fig. 5 Air Pressure Test Plate

1 - TOOL 6056

2 - ACCUMULATORS

Fig. 6 Testing Reverse Clutch

1 - TOOL 6056

2 - AIR NOZZLE

21 - 168 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1727 of 2399

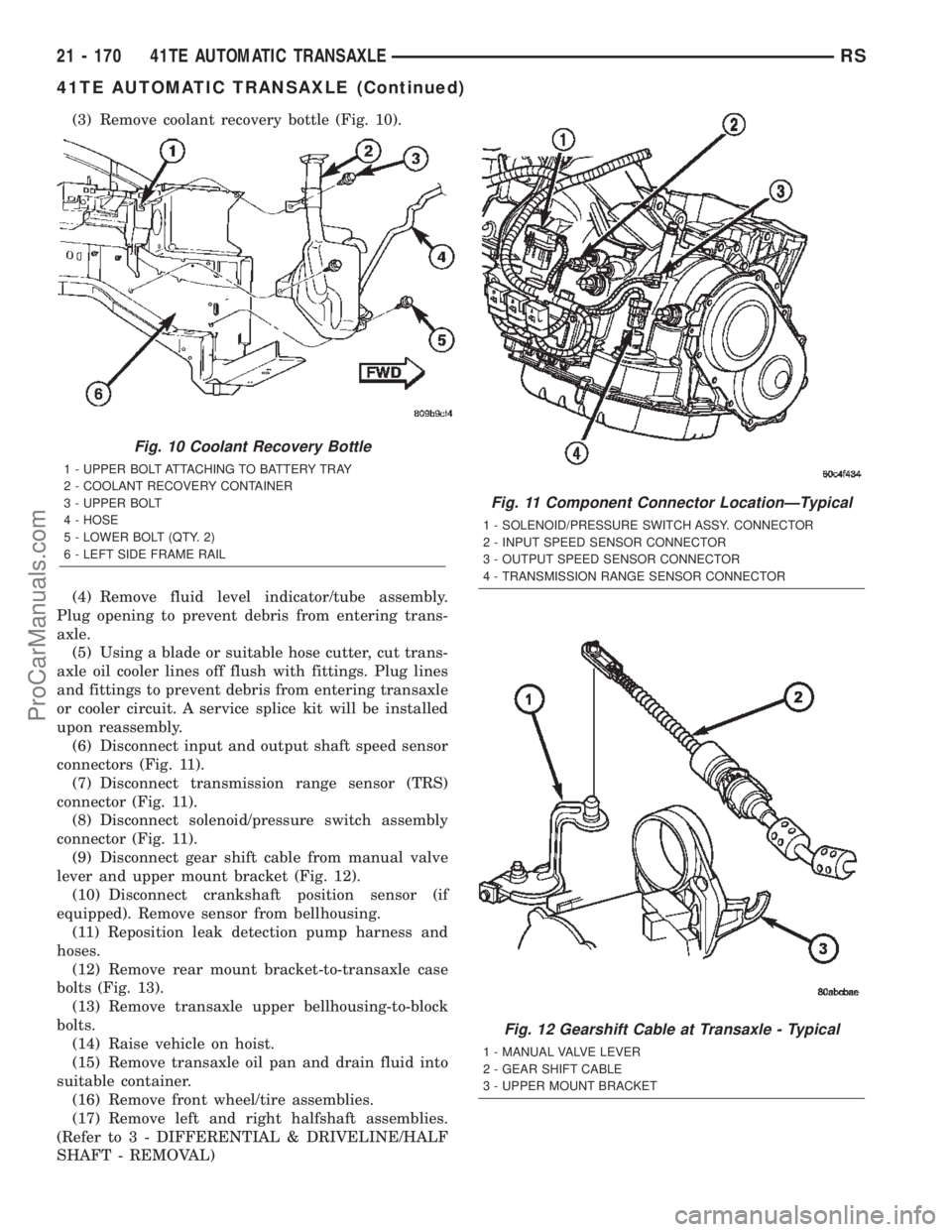

(3) Remove coolant recovery bottle (Fig. 10).

(4) Remove fluid level indicator/tube assembly.

Plug opening to prevent debris from entering trans-

axle.

(5) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug lines

and fittings to prevent debris from entering transaxle

or cooler circuit. A service splice kit will be installed

upon reassembly.

(6) Disconnect input and output shaft speed sensor

connectors (Fig. 11).

(7) Disconnect transmission range sensor (TRS)

connector (Fig. 11).

(8) Disconnect solenoid/pressure switch assembly

connector (Fig. 11).

(9) Disconnect gear shift cable from manual valve

lever and upper mount bracket (Fig. 12).

(10) Disconnect crankshaft position sensor (if

equipped). Remove sensor from bellhousing.

(11) Reposition leak detection pump harness and

hoses.

(12) Remove rear mount bracket-to-transaxle case

bolts (Fig. 13).

(13) Remove transaxle upper bellhousing-to-block

bolts.

(14) Raise vehicle on hoist.

(15) Remove transaxle oil pan and drain fluid into

suitable container.

(16) Remove front wheel/tire assemblies.

(17) Remove left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL)

Fig. 10 Coolant Recovery Bottle

1 - UPPER BOLT ATTACHING TO BATTERY TRAY

2 - COOLANT RECOVERY CONTAINER

3 - UPPER BOLT

4 - HOSE

5 - LOWER BOLT (QTY. 2)

6 - LEFT SIDE FRAME RAIL

Fig. 11 Component Connector LocationÐTypical

1 - SOLENOID/PRESSURE SWITCH ASSY. CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 12 Gearshift Cable at Transaxle - Typical

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

21 - 170 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1732 of 2399

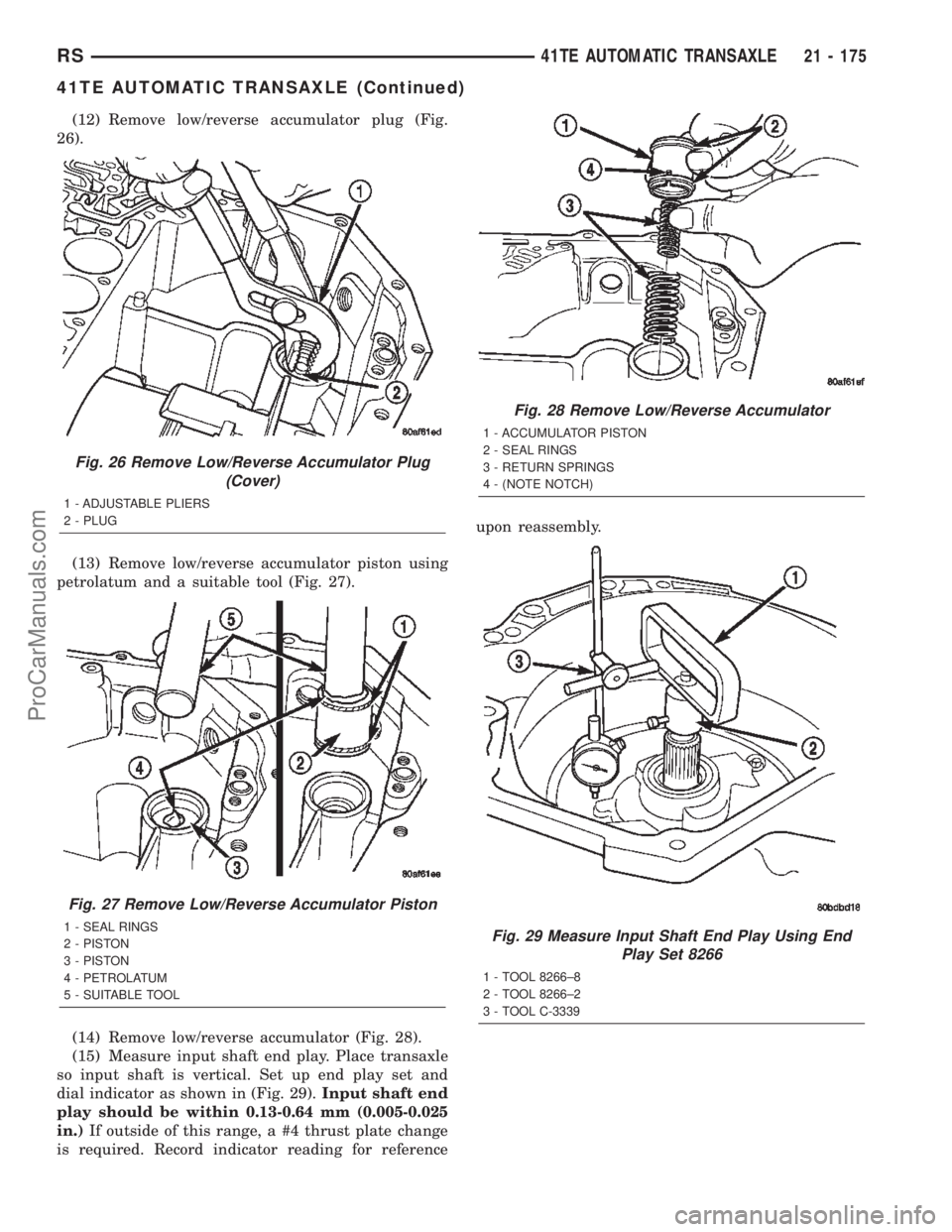

(12) Remove low/reverse accumulator plug (Fig.

26).

(13) Remove low/reverse accumulator piston using

petrolatum and a suitable tool (Fig. 27).

(14) Remove low/reverse accumulator (Fig. 28).

(15) Measure input shaft end play. Place transaxle

so input shaft is vertical. Set up end play set and

dial indicator as shown in (Fig. 29).Input shaft end

play should be within 0.13-0.64 mm (0.005-0.025

in.)If outside of this range, a #4 thrust plate change

is required. Record indicator reading for referenceupon reassembly.

Fig. 26 Remove Low/Reverse Accumulator Plug

(Cover)

1 - ADJUSTABLE PLIERS

2 - PLUG

Fig. 27 Remove Low/Reverse Accumulator Piston

1 - SEAL RINGS

2 - PISTON

3 - PISTON

4 - PETROLATUM

5 - SUITABLE TOOL

Fig. 28 Remove Low/Reverse Accumulator

1 - ACCUMULATOR PISTON

2 - SEAL RINGS

3 - RETURN SPRINGS

4 - (NOTE NOTCH)

Fig. 29 Measure Input Shaft End Play Using End

Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

RS41TE AUTOMATIC TRANSAXLE21 - 175

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1733 of 2399

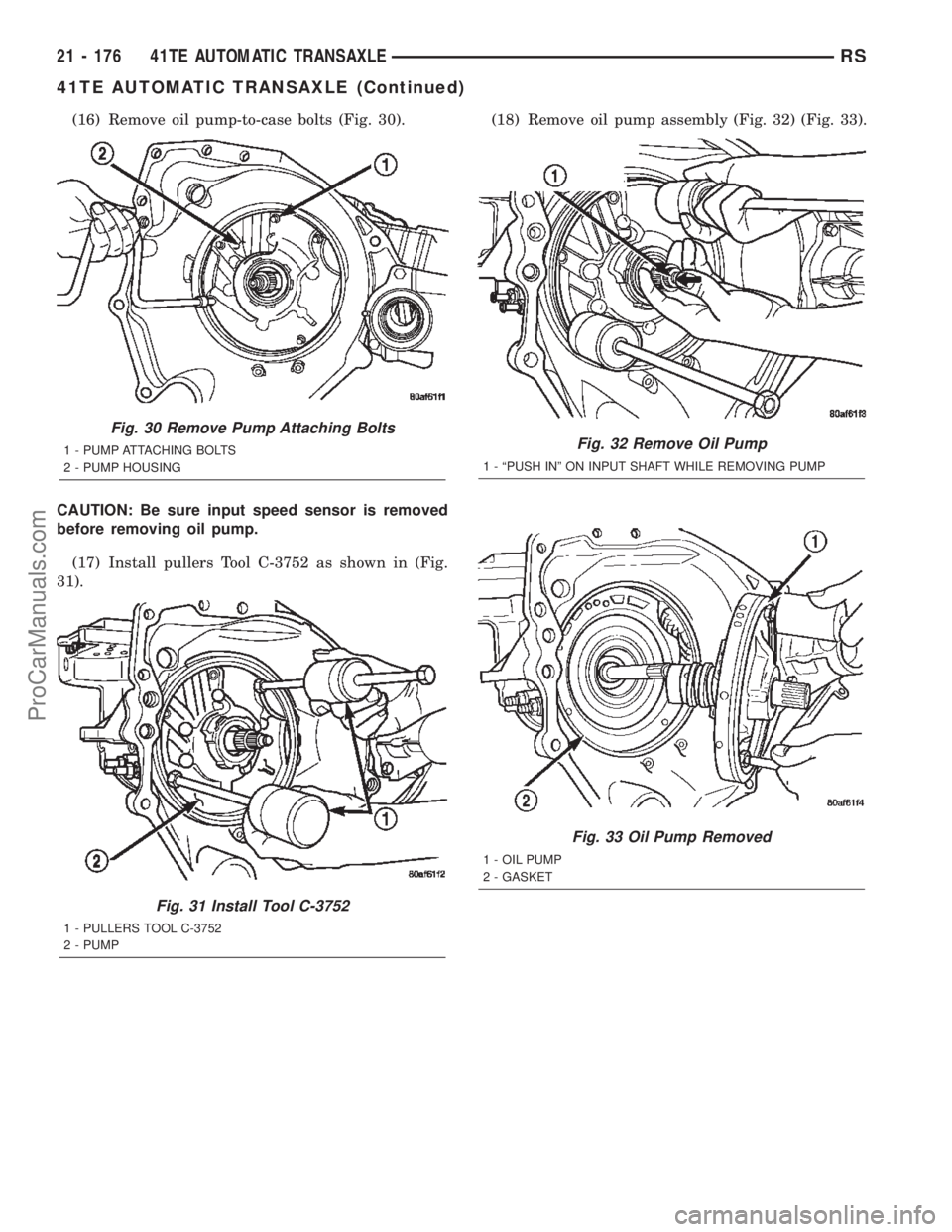

(16) Remove oil pump-to-case bolts (Fig. 30).

CAUTION: Be sure input speed sensor is removed

before removing oil pump.

(17) Install pullers Tool C-3752 as shown in (Fig.

31).(18) Remove oil pump assembly (Fig. 32) (Fig. 33).

Fig. 33 Oil Pump Removed

1 - OIL PUMP

2 - GASKET

Fig. 30 Remove Pump Attaching Bolts

1 - PUMP ATTACHING BOLTS

2 - PUMP HOUSING

Fig. 31 Install Tool C-3752

1 - PULLERS TOOL C-3752

2 - PUMP

Fig. 32 Remove Oil Pump

1 - ªPUSH INº ON INPUT SHAFT WHILE REMOVING PUMP

21 - 176 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1735 of 2399

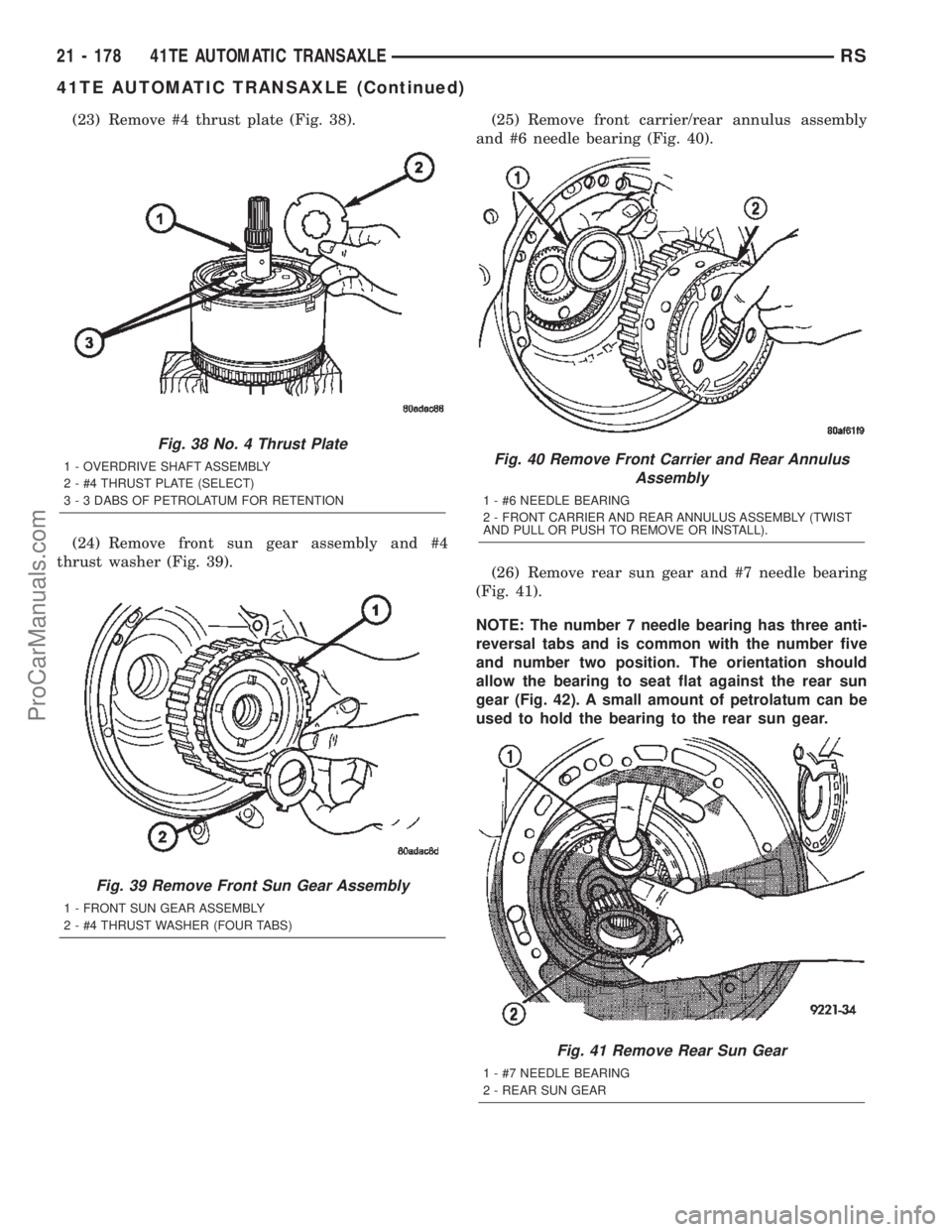

(23) Remove #4 thrust plate (Fig. 38).

(24) Remove front sun gear assembly and #4

thrust washer (Fig. 39).(25) Remove front carrier/rear annulus assembly

and #6 needle bearing (Fig. 40).

(26) Remove rear sun gear and #7 needle bearing

(Fig. 41).

NOTE: The number 7 needle bearing has three anti-

reversal tabs and is common with the number five

and number two position. The orientation should

allow the bearing to seat flat against the rear sun

gear (Fig. 42). A small amount of petrolatum can be

used to hold the bearing to the rear sun gear.

Fig. 38 No. 4 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #4 THRUST PLATE (SELECT)

3 - 3 DABS OF PETROLATUM FOR RETENTION

Fig. 39 Remove Front Sun Gear Assembly

1 - FRONT SUN GEAR ASSEMBLY

2 - #4 THRUST WASHER (FOUR TABS)

Fig. 40 Remove Front Carrier and Rear Annulus

Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 41 Remove Rear Sun Gear

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

21 - 178 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1739 of 2399

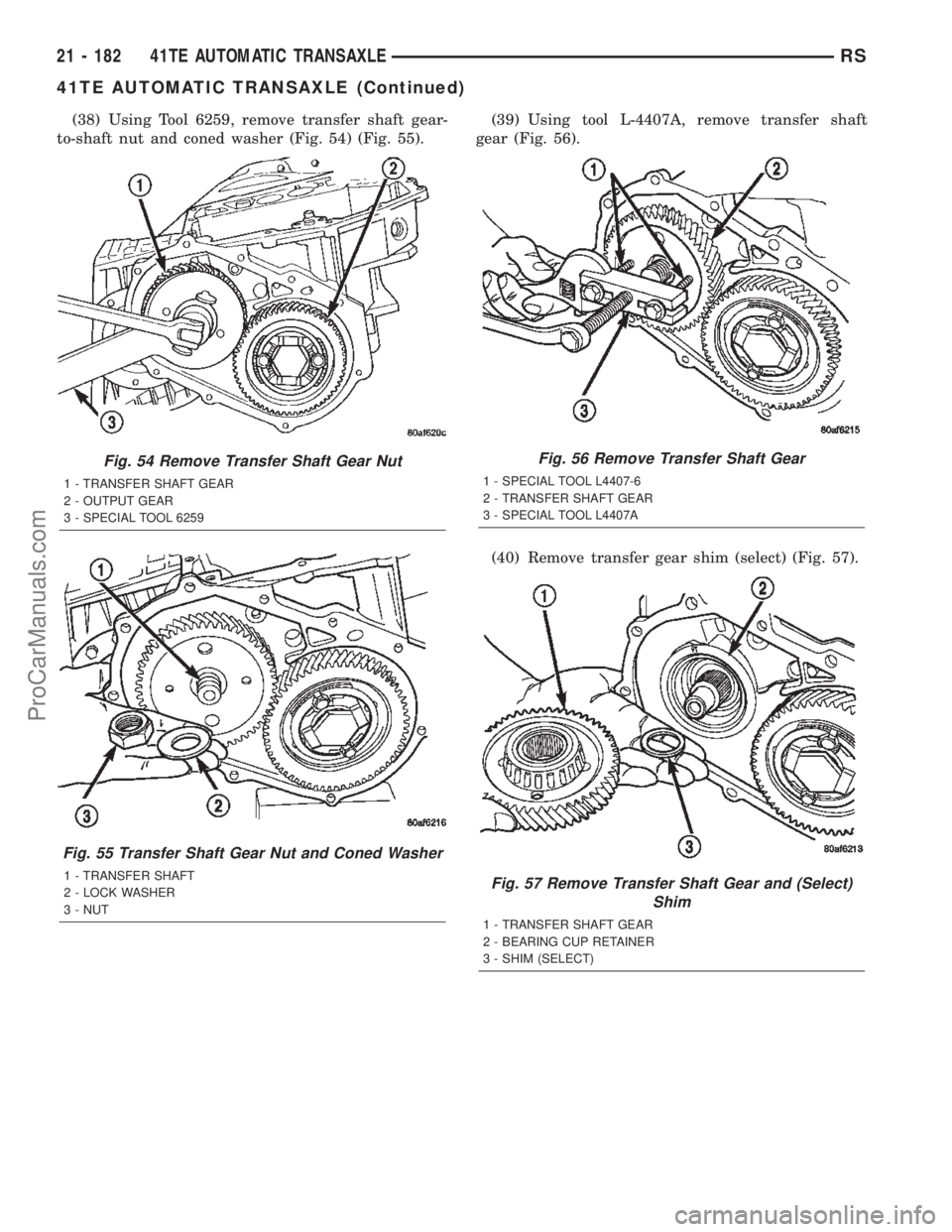

(38) Using Tool 6259, remove transfer shaft gear-

to-shaft nut and coned washer (Fig. 54) (Fig. 55).(39) Using tool L-4407A, remove transfer shaft

gear (Fig. 56).

(40) Remove transfer gear shim (select) (Fig. 57).

Fig. 54 Remove Transfer Shaft Gear Nut

1 - TRANSFER SHAFT GEAR

2 - OUTPUT GEAR

3 - SPECIAL TOOL 6259

Fig. 55 Transfer Shaft Gear Nut and Coned Washer

1 - TRANSFER SHAFT

2 - LOCK WASHER

3 - NUT

Fig. 56 Remove Transfer Shaft Gear

1 - SPECIAL TOOL L4407-6

2 - TRANSFER SHAFT GEAR

3 - SPECIAL TOOL L4407A

Fig. 57 Remove Transfer Shaft Gear and (Select)

Shim

1 - TRANSFER SHAFT GEAR

2 - BEARING CUP RETAINER

3 - SHIM (SELECT)

21 - 182 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1740 of 2399

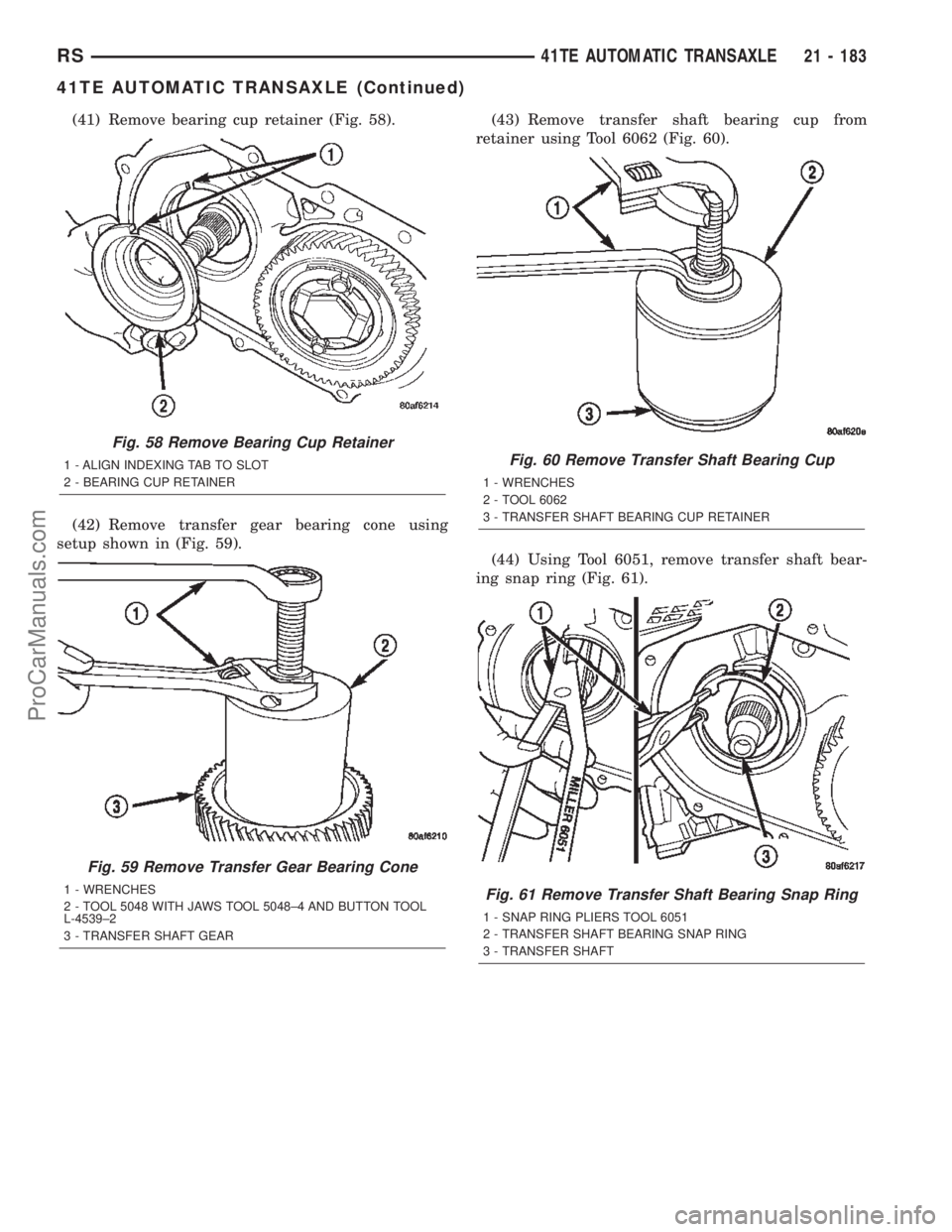

(41) Remove bearing cup retainer (Fig. 58).

(42) Remove transfer gear bearing cone using

setup shown in (Fig. 59).(43) Remove transfer shaft bearing cup from

retainer using Tool 6062 (Fig. 60).

(44) Using Tool 6051, remove transfer shaft bear-

ing snap ring (Fig. 61).

Fig. 58 Remove Bearing Cup Retainer

1 - ALIGN INDEXING TAB TO SLOT

2 - BEARING CUP RETAINER

Fig. 59 Remove Transfer Gear Bearing Cone

1 - WRENCHES

2 - TOOL 5048 WITH JAWS TOOL 5048±4 AND BUTTON TOOL

L-4539±2

3 - TRANSFER SHAFT GEAR

Fig. 60 Remove Transfer Shaft Bearing Cup

1 - WRENCHES

2 - TOOL 6062

3 - TRANSFER SHAFT BEARING CUP RETAINER

Fig. 61 Remove Transfer Shaft Bearing Snap Ring

1 - SNAP RING PLIERS TOOL 6051

2 - TRANSFER SHAFT BEARING SNAP RING

3 - TRANSFER SHAFT

RS41TE AUTOMATIC TRANSAXLE21 - 183

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com