instrument panel CHRYSLER CARAVAN 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 432 of 2399

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) section for more DTC information.

The Check Gauges Lamp (if equipped) or Battery

Lamp monitors:charging system voltage,engine

coolant temperature and engine oil pressure. If an

extreme condition is indicated, the lamp will be illu-

minated. The signal to activate the lamp is sent via

the PCI bus circuits. The lamp is located on the

instrument panel. Refer to the Instrument Cluster

section for additional information.

The PCM uses the inlet air temperature sensor to

control the charge system voltage. This temperature,

along with data from monitored line voltage, is used

by the PCM to vary the battery charging rate. The

system voltage is higher at cold temperatures and is

gradually reduced as the calculated battery tempera-

ture increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture.

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 50 engine starts if the

problem does not occur again.

DIAGNOSTIC TROUBLE CODES

A DTC description can be read using the DRBIIIt

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for information.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTC

to be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.ERASING DIAGNOSTIC TROUBLE CODES

The DRBIIItScan Tool must be used to erase a

DTC.

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp or battery lamp is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE)

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBIIItscan tool.

Perform the following inspections before attaching

the scan tool.

(1) Inspect the battery condition. Refer to the Bat-

tery section (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING) for proce-

dures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications (Refer to 8 - ELECTRICAL/

CHARGING - SPECIFICATIONS).

RGCHARGING8Fa-21

CHARGING (Continued)

ProCarManuals.com

Page 442 of 2399

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................31

OPERATION...........................31

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................31

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................34

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................36

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................36

SPECIFICATIONS

STARTER ...........................37Torques.............................37

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................38

REMOVAL - 3.3/3.8L...................39

REMOVAL - 3.5L......................39

REMOVAL - 2.5L......................40

INSTALLATION

INSTALLATION - 2.4L..................41

INSTALLATION - 3.3/3.8L................41

INSTALLATION - 3.5L..................41

INSTALLATION - 2.5L..................41

STARTING

DESCRIPTION

The starting system has (Fig. 1):

²Ignition switch

²Starter relay

²Transmission Range Sensor or Park/Neutral

Switch

²Wiring harness

²Battery

²Starter motor with an integral solenoid

²Powertrain Control Module (PCM)

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

RGSTARTING8Fa-31

ProCarManuals.com

Page 455 of 2399

The electrically heated Rear Window Defogger (Fig.

1), Heated Power Side View Mirrors, and Heated

Windshield Wiper De-icer (Fig. 2)is available on

select models.

OPERATION

The Rear Window Defogger(Refer to 8 - ELECTRI-

CAL/HEATED GLASS - DESCRIPTION) system con-

sists of two vertical bus bars linked by a series of

grid lines on the inside surface of the rear window.

The electrical circuit consists of the rear defogger

switch in the HVAC control assembly and a relay

with timer switch to turn OFF the system after ten

minutes. The main feed circuit is protected by fuse

13 (40 amp) in the Power Distribution Center (PDC)

which is connected directly to the front control mod-

ule (FCM) to form an integrated unit called an Inte-

grated Power Module (IPM). The rear defogger

switch and relay also activates the heated power side

view mirrors. The rear defogger switch also activates

the heated windshield wiper de-icer which is powered

by the RUN/ACC relay in the IPM and feed thru fuse

#11 (20 amp) in the PDC. The heated mirror circuit

is protected by a non-servicable Positive Temperature

Coefficient (PTC) located inside the PDC. The heated

windshield wiper de-icer circuit is protected by fuse

11 (20 amp) in the PDC.

The Heated Windshield Wiper Deicer is also acti-

vated when the DEFROST mode is selected on the

HVAC. In the DEFROST mode the rear defogger

timout is bypassed, the heated windshield wiper de-

icer will stay ON until the another mode is selected.

For circuit information and component location refer

to appropriate section for Wiring Diagrams.

CAUTION:

Since grid lines can be damaged or scraped off

with sharp instruments, care should be taken in

cleaning the glass or removing foreign materials,

decals or stickers. Normal glass cleaning solvents

or hot water used with rags or toweling is recom-

mended.

DEFOGGER RELAY

DESCRIPTION

There is no heated windshield wiper de-icer relay.

The grid is powered directly from fuse #11 in the

PDC and is controlled directly from the HVAC con-

trol assembly.

REAR WINDOW DEFOGGER

GRID

STANDARD PROCEDURE - GRID LINE REPAIR

REAR

For Grid repair procedure for the rear window

defogger (Refer to 8 - ELECTRICAL/HEATED

GLASS/WINDSHIELD GRID - STANDARD PROCE-

DURE).

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The rear window defogger switch is integrated into

the HVAC control panel assembly (Fig. 3)

OPERATION

A LED indicator will illuminate when the switch is

activated. The switch energizes the HVAC control

assembly when it requests the Front Control Module

(FCM) to activate the rear window defogger relay.

The relay controls the current to flow to the grids of

the rear window defogger, heated power side view

mirrors and the heated windshield wiper de-icer. The

defogger relay will be on for approximately 10 min-

utes or until the control switch or ignition is turned

off.

Fig. 3 HVAC CONTROL PANEL

1 - TRIM BEZEL

2 - ACT SENSOR

3 - A/C REQUEST SWITCH

4 - REAR WINDOW DEFOGGER/HEATED MIRRORS SWITCH

COMBO

5 - FRONT WINDOW DEFROSTER MODE SELECTOR

8G - 2 HEATED GLASSRS

HEATED GLASS (Continued)

ProCarManuals.com

Page 460 of 2399

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM.............................8

DRIVER HEATED SEAT SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH.........................9

REMOVAL.............................10

INSTALLATION.........................10

HEATED SEAT ELEMENT

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS..........................11REMOVAL.............................12

INSTALLATION.........................12

HEATED SEAT SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR............................12

PASSENGER HEATED SEAT SWITCH

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH.................13

REMOVAL.............................14

INSTALLATION.........................15

HEATED SEAT SYSTEM

DESCRIPTION

Vehicles with the heated seat option can be visu-

ally identified by the two separate heated seat

switches located in the instrument panel center

stack, just above the radio (Fig. 1). The heated seat

system allows the front seat driver and passenger to

select from two different levels of supplemental elec-

trical seat heating (HI/LO), or no seat heating to suit

their individual comfort requirements. The heated

seat system for this vehicle includes the following

major components, which are described in further

detail later in this section:

²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle, two for each front seat.

One heated seat element is integral to each front

seat trim cover, one in the seat back and one in the

seat bottom (cushion). Service replacement heating

elements are available, refer to heated seat elements

later in this section for additional information.

²Heated Seat Modules- Two heated seat mod-

ules are used per vehicle. One module is mounted to

each of the seat cushion pans, located under the for-

ward edge of each front seat. Refer to heated seat

module in the electronic control modules section of

the service manual for additional information.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle, one for each front seat. The

heated seat sensors are integral to each of the heated

seat bottoms (cushions).

Fig. 1 HEATED SEAT SWITCH LOCATIONS

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-7

ProCarManuals.com

Page 461 of 2399

²Heated Seat Switch- Two heated seat

switches are used per vehicle, one for the driver and

one for the passenger side front seats. The switches

are mounted to in the instrument panel center stack.

Refer to the description of the heated seat switch

later in this section for additional information.

Hard wired circuitry connects the heated seat sys-

tem components to each other through the electrical

system of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

heated seat system components through the use of a

combination of soldered splices and splice block con-

nectors. Refer to Wiring for complete system wiring

schematics. The wiring information also includes the

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

The heated seat system components operate on

battery current received through a fuse in the Inte-

grated Power Module (IPM) on a fused ignition

switch output (run-acc) circuit so that the system willonly operate when the ignition switch is in the On or

Accessory positions. The heated seat system will be

turned Off automatically whenever the ignition

switch is turned to any position except On or Acces-

sory. Also, the heated seat system will not operate

when the surface temperature of the seat cushion

cover at either heated seat sensor is above the

designed temperature set points of the system. The

heated seat system has a self-diagnostic capability.

When certain failures are detected within the heated

seat system, the system will provide a visual indica-

tion of the failure by flashing the Light Emitting

Diode (LED) indicator lamps located in the heated

seat switches. See the owner's manual in the vehicle

glove box for more information on the features, use

and operation of the heated seat system.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

Refer toWiring Diagramsfor complete wiring

schematics. The wiring information also includes the

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

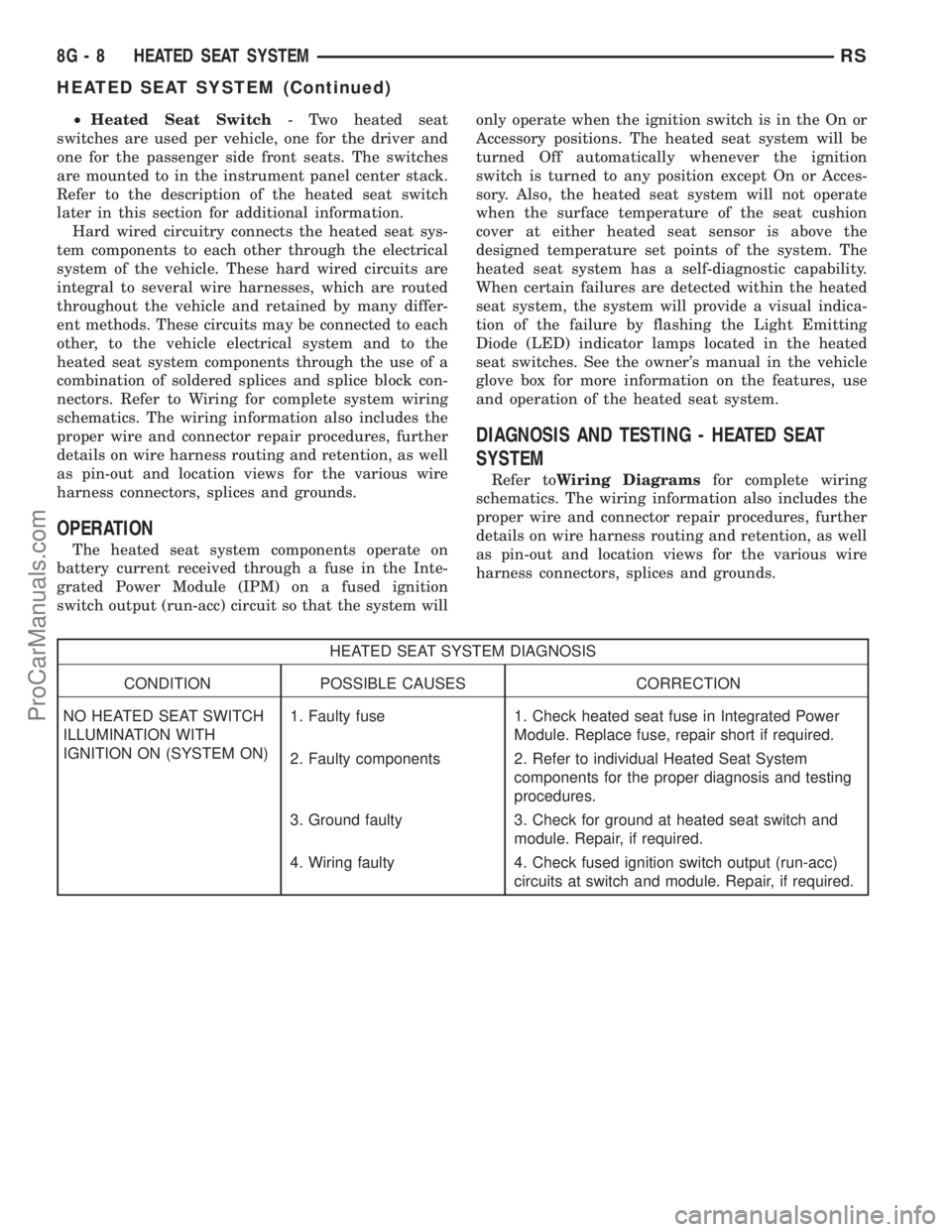

HEATED SEAT SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO HEATED SEAT SWITCH

ILLUMINATION WITH

IGNITION ON (SYSTEM ON)1. Faulty fuse 1. Check heated seat fuse in Integrated Power

Module. Replace fuse, repair short if required.

2. Faulty components 2. Refer to individual Heated Seat System

components for the proper diagnosis and testing

procedures.

3. Ground faulty 3. Check for ground at heated seat switch and

module. Repair, if required.

4. Wiring faulty 4. Check fused ignition switch output (run-acc)

circuits at switch and module. Repair, if required.

8G - 8 HEATED SEAT SYSTEMRS

HEATED SEAT SYSTEM (Continued)

ProCarManuals.com

Page 462 of 2399

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

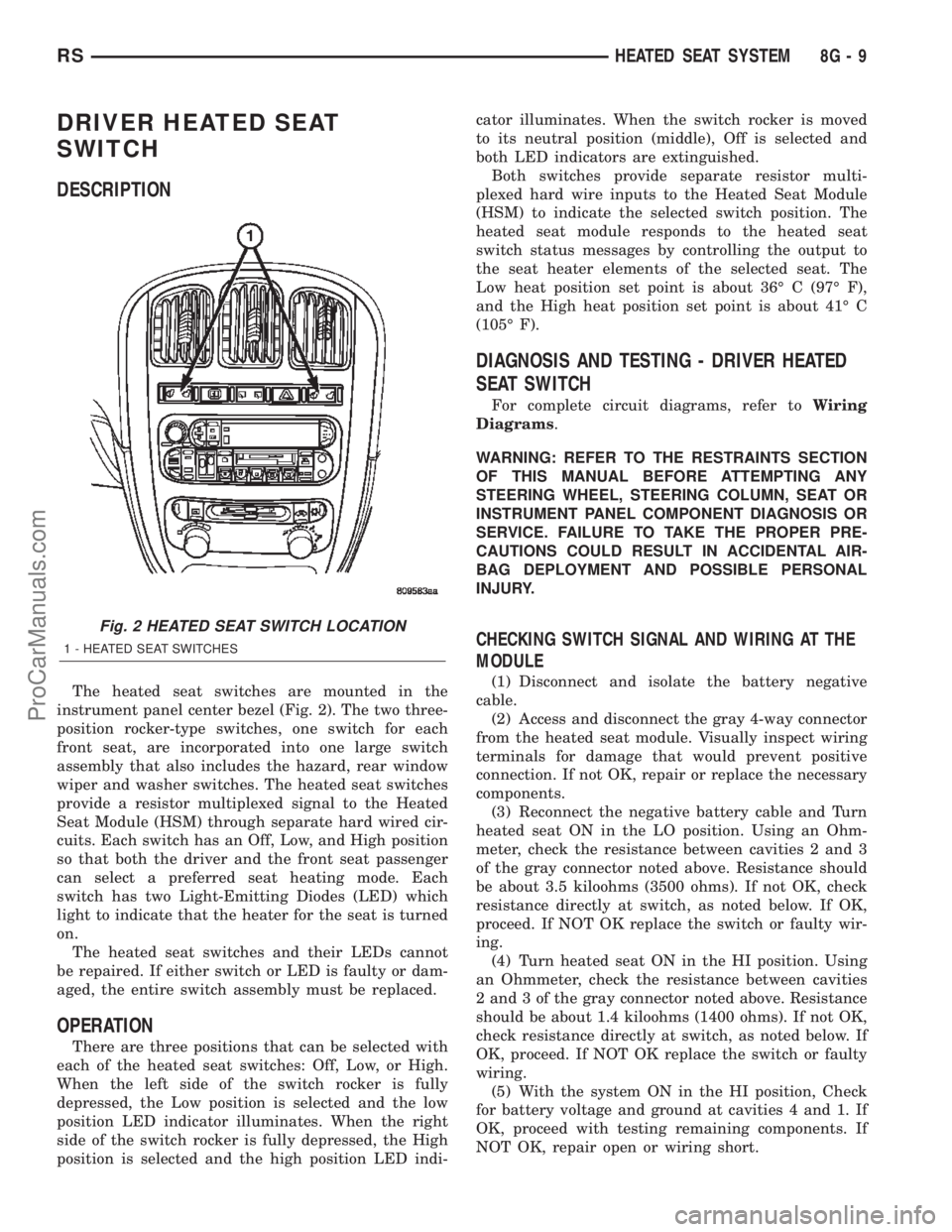

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 2). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

provide a resistor multiplexed signal to the Heated

Seat Module (HSM) through separate hard wired cir-

cuits. Each switch has an Off, Low, and High position

so that both the driver and the front seat passenger

can select a preferred seat heating mode. Each

switch has two Light-Emitting Diodes (LED) which

light to indicate that the heater for the seat is turned

on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the Heated Seat Module

(HSM) to indicate the selected switch position. The

heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

Fig. 2 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-9

ProCarManuals.com

Page 463 of 2399

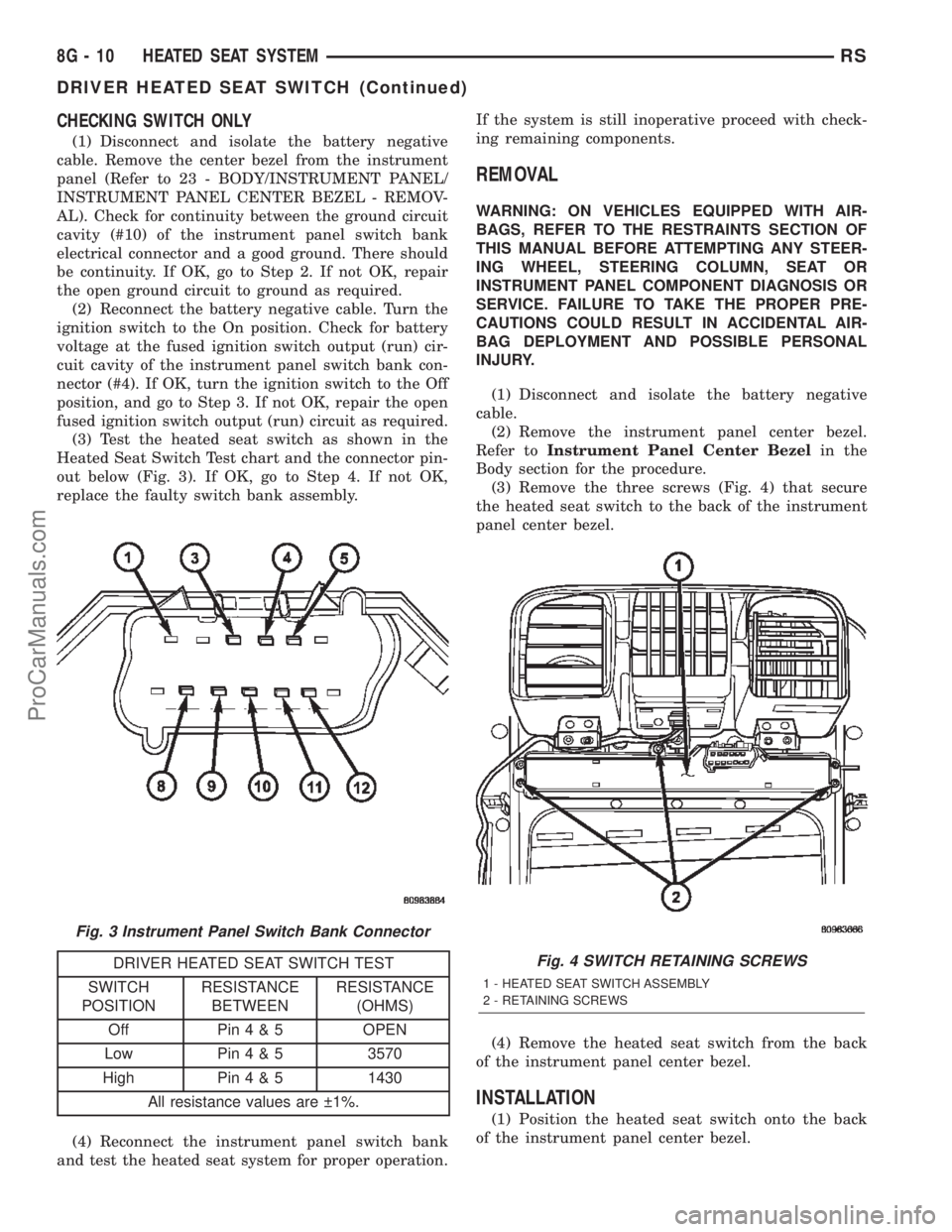

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL). Check for continuity between the ground circuit

cavity (#10) of the instrument panel switch bank

electrical connector and a good ground. There should

be continuity. If OK, go to Step 2. If not OK, repair

the open ground circuit to ground as required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

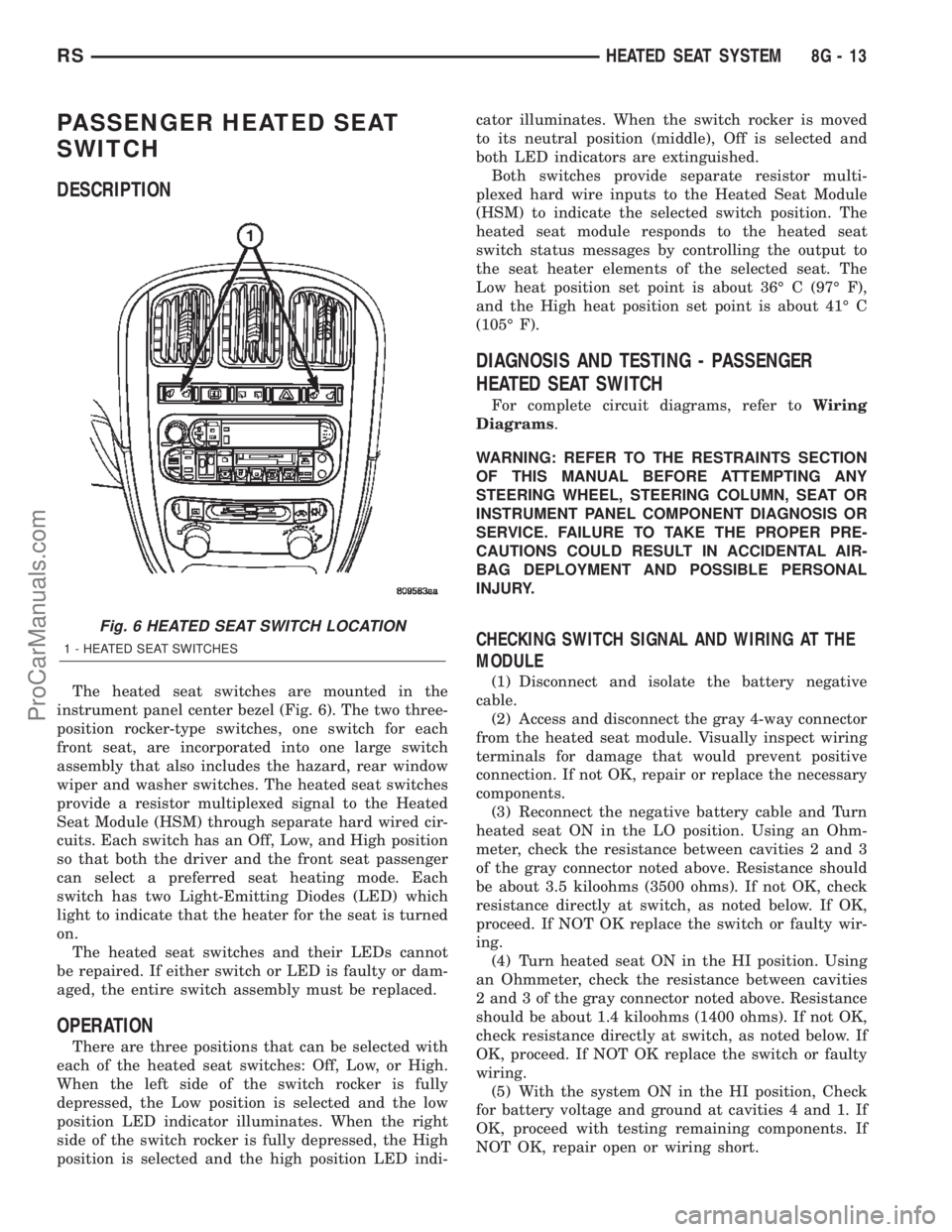

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 3). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

DRIVER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin4&5OPEN

Low Pin4&53570

High Pin4&51430

All resistance values are 1%.

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.If the system is still inoperative proceed with check-

ing remaining components.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

(3) Remove the three screws (Fig. 4) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

Fig. 3 Instrument Panel Switch Bank Connector

Fig. 4 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 10 HEATED SEAT SYSTEMRS

DRIVER HEATED SEAT SWITCH (Continued)

ProCarManuals.com

Page 464 of 2399

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel. Tighten the screws to 1.5 N´m (13

in. lbs.) (Fig. 4).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

HEATED SEAT ELEMENT

DESCRIPTION

The heated seat system includes two seat heating ele-

ments in each front seat, one for the seat cushion and

the other for the seat back. The two elements for each

seat that are connected in series with the Heated Seat

Module (HSM). The temperature sensor is a Negative

Temperature Coefficient (NTC) thermistor. One temper-

ature sensor is used for each seat, and it is located on

the seat cushion heating element for all models.

The seat heating elements are sewn into the seat

cushion cover trim and seat back cover trim units.

The heated seat elements and the temperature sen-

sor cannot be adjusted or repaired and, if faulty or

damaged, the seat element assembly must be

replaced. Refer to the procedure in this section.

OPERATION

The heated seat elements resist the flow of electrical

current. When battery current is passed through the

elements, the energy lost by the resistance of the ele-

ments to the current flow is released in the form of

heat. The temperature sensor is a NTC thermistor.

When the temperature of the seat cushion cover rises,

the resistance of the sensor decreases. The heated seat

module supplies a five-volt current to one side of each

sensor, and monitors the voltage drop through the

sensor on a return circuit. The heated seat module

uses this temperature sensor input to monitor the

temperature of the seat, and regulates the current

flow to the seat heating elements accordingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS

The wire harness connectors for the seat cushion and

seat back heating elements are located under the seat,

at the heated seat module. For circuit descriptions and

diagrams, refer to section 8W, Wiring Diagrams.

In order to access and test the heated seat ele-

ments it will be necessary to remove the appropriate

front seat retaining bolts and lay the seat rearward,

up against one of the rear seats. It is not necessary

to disconnect the seat electrical connectors, just use

care not to damage the attached wire harnesses

while testing.NOTE: WHEN CHECKING HEATED SEAT ELE-

MENTS FOR CONTINUITY, BE CERTAIN TO MOVE

THE HEATING ELEMENT BEING CHECKED. MOV-

ING THE ELEMENT, SUCH AS SITTING IN THE SEAT

WILL ELIMINATE THE POSSIBILITY OF AN INTER-

MITTENT OPEN IN THE ELEMENT WHICH WOULD

ONLY BE EVIDENT IF THE ELEMENT WAS MOVED

IN A CERTAIN DIRECTION. FAILURE TO CHECK

THE ELEMENT IN VARIOUS POSITIONS COULD

RESULT IN AN INCOMPLETE TEST.

SEAT CUSHION ELEMENT

(1) From under the vehicle, remove the appropri-

ate seats four retaining nuts.

(2) From inside the vehicle, pull the seat up, off

the mounting studs and lay it back, up against one of

the rear seats.

(3) Locate the heated seat module, attached to the

bottom of the seat cushion pan. Remove the heated

seat module from the seat cushion pan. Do not dis-

connect the electrical connectors at this time.

(4) Locate the green 4-way electrical connector,

connected to the heated seat module. Disconnect the

green 4-way connector from the heated seat module.

(5) Check for continuity between the two outboard

circuit cavities of the wire harness connector (Pins

1&4). There should be continuity. If OK, refer to

Heated Seat Module Diagnosis and Testing in the

Electronic Control Modules section of the service

manual for complete system testing procedures. If

not OK, install a replacement heated seat cushion

element. Refer to the procedure in this section.

SEAT BACK ELEMENT

(1) From under the vehicle, remove the appropri-

ate seats four retaining nuts.

(2) From inside the vehicle, pull the seat up and

off the mounting studs and lay it back, up against

one of the rear seats.

(3) Locate the heated seat module, attached to the

bottom of the seat cushion pan. Remove the heated

seat module from the seat cushion pan. Do not dis-

connect the electrical connectors at this time.

(4) Locate the gray 2-way electrical connector, con-

nected to the heated seat module. Disconnect the

2-way connector from the heated seat module.

(5) Check for continuity between the two circuit

cavities of the 2-way wire harness connector. There

should be continuity. If OK, refer to Heated Seat

Module Diagnosis and Testing in the Electronic Con-

trol Modules section of the service manual for com-

plete system testing procedures. If not OK, install a

replacement heated seat back element. Refer to the

procedure in this section.

RSHEATED SEAT SYSTEM8G-11

DRIVER HEATED SEAT SWITCH (Continued)

ProCarManuals.com

Page 466 of 2399

PASSENGER HEATED SEAT

SWITCH

DESCRIPTION

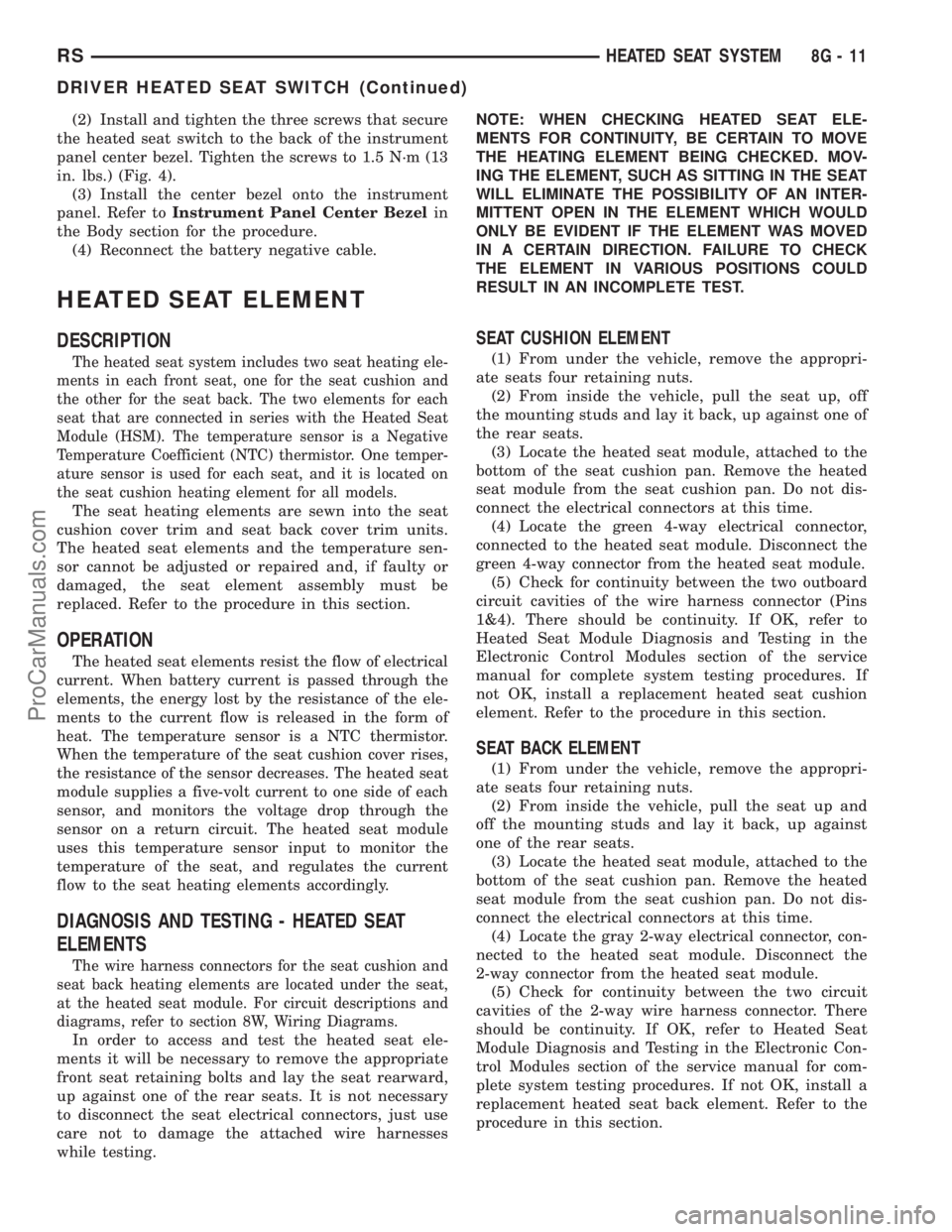

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 6). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

provide a resistor multiplexed signal to the Heated

Seat Module (HSM) through separate hard wired cir-

cuits. Each switch has an Off, Low, and High position

so that both the driver and the front seat passenger

can select a preferred seat heating mode. Each

switch has two Light-Emitting Diodes (LED) which

light to indicate that the heater for the seat is turned

on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the Heated Seat Module

(HSM) to indicate the selected switch position. The

heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

Fig. 6 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-13

ProCarManuals.com

Page 467 of 2399

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL). Check for continuity between the ground circuit

cavity (#10) of the instrument panel switch bank

electrical connector and a good ground. There should

be continuity. If OK, go to Step 2. If not OK, repair

the open ground circuit to ground as required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 7). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are 1%.(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

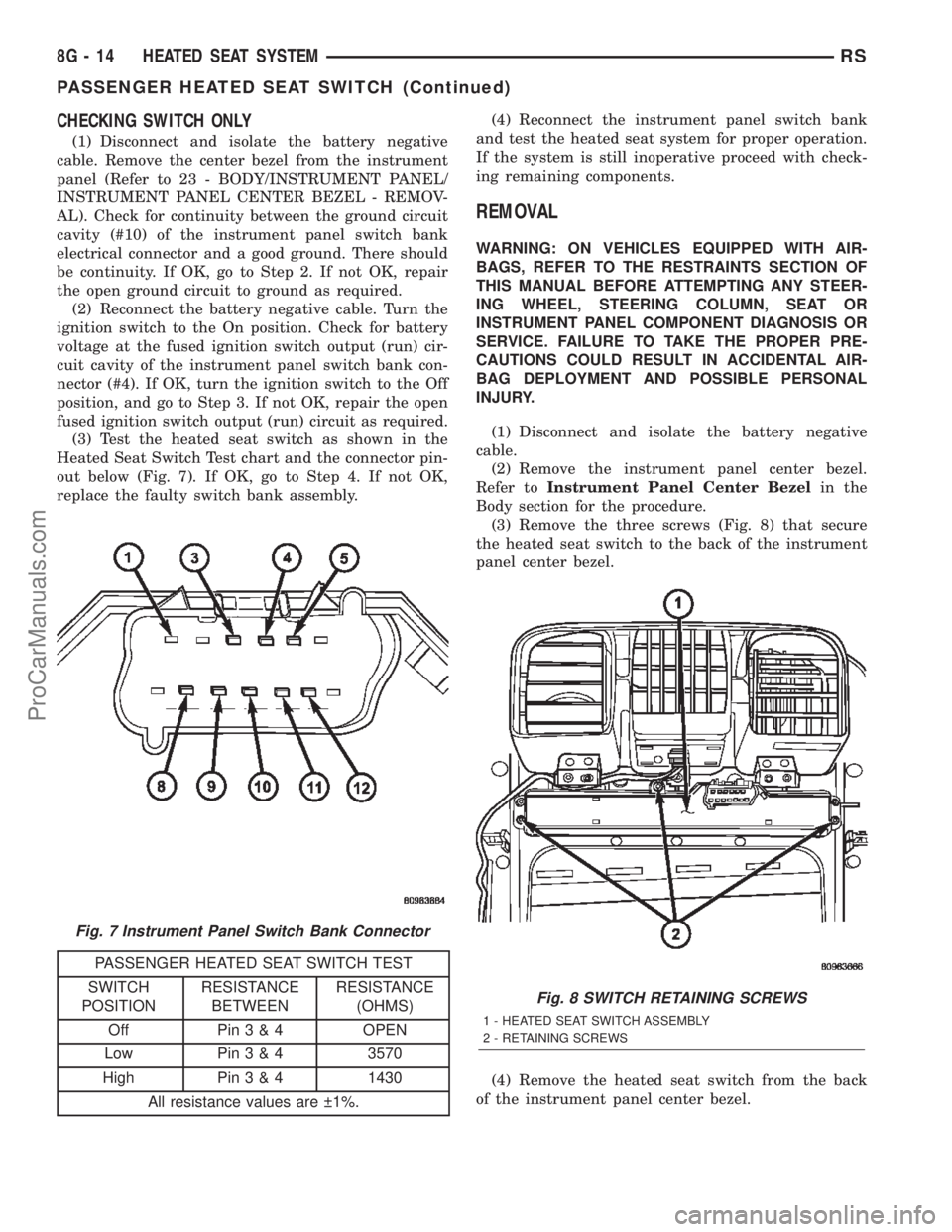

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

(3) Remove the three screws (Fig. 8) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

Fig. 7 Instrument Panel Switch Bank Connector

Fig. 8 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 14 HEATED SEAT SYSTEMRS

PASSENGER HEATED SEAT SWITCH (Continued)

ProCarManuals.com