oil filter CHRYSLER CARAVAN 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1392 of 2399

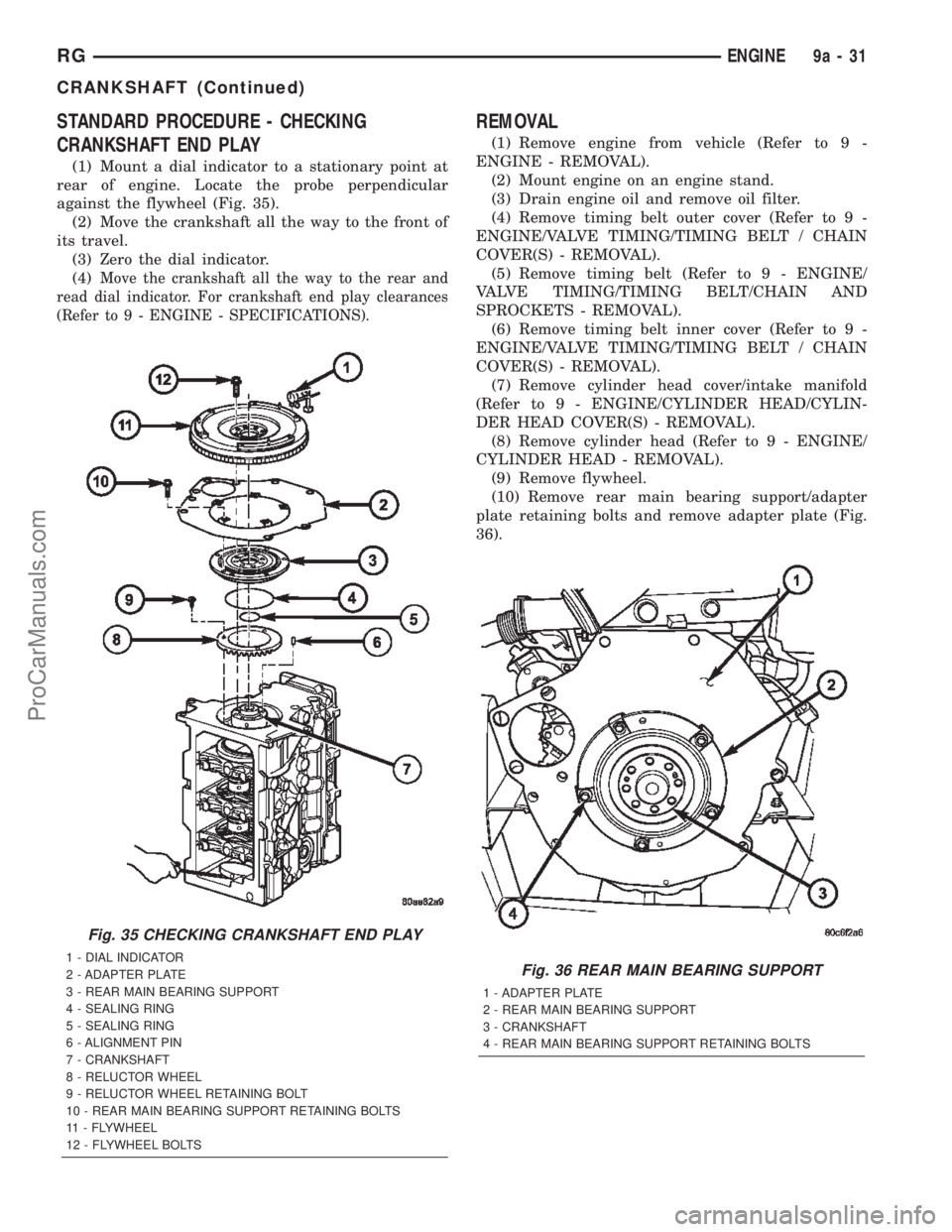

STANDARD PROCEDURE - CHECKING

CRANKSHAFT END PLAY

(1) Mount a dial indicator to a stationary point at

rear of engine. Locate the probe perpendicular

against the flywheel (Fig. 35).

(2) Move the crankshaft all the way to the front of

its travel.

(3) Zero the dial indicator.

(4)

Move the crankshaft all the way to the rear and

read dial indicator. For crankshaft end play clearances

(Refer to 9 - ENGINE - SPECIFICATIONS).

REMOVAL

(1) Remove engine from vehicle (Refer to 9 -

ENGINE - REMOVAL).

(2) Mount engine on an engine stand.

(3) Drain engine oil and remove oil filter.

(4) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(5) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(6) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(7) Remove cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(8) Remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(9) Remove flywheel.

(10) Remove rear main bearing support/adapter

plate retaining bolts and remove adapter plate (Fig.

36).

Fig. 35 CHECKING CRANKSHAFT END PLAY

1 - DIAL INDICATOR

2 - ADAPTER PLATE

3 - REAR MAIN BEARING SUPPORT

4 - SEALING RING

5 - SEALING RING

6 - ALIGNMENT PIN

7 - CRANKSHAFT

8 - RELUCTOR WHEEL

9 - RELUCTOR WHEEL RETAINING BOLT

10 - REAR MAIN BEARING SUPPORT RETAINING BOLTS

11 - FLYWHEEL

12 - FLYWHEEL BOLTSFig. 36 REAR MAIN BEARING SUPPORT

1 - ADAPTER PLATE

2 - REAR MAIN BEARING SUPPORT

3 - CRANKSHAFT

4 - REAR MAIN BEARING SUPPORT RETAINING BOLTS

RGENGINE9a-31

CRANKSHAFT (Continued)

ProCarManuals.com

Page 1411 of 2399

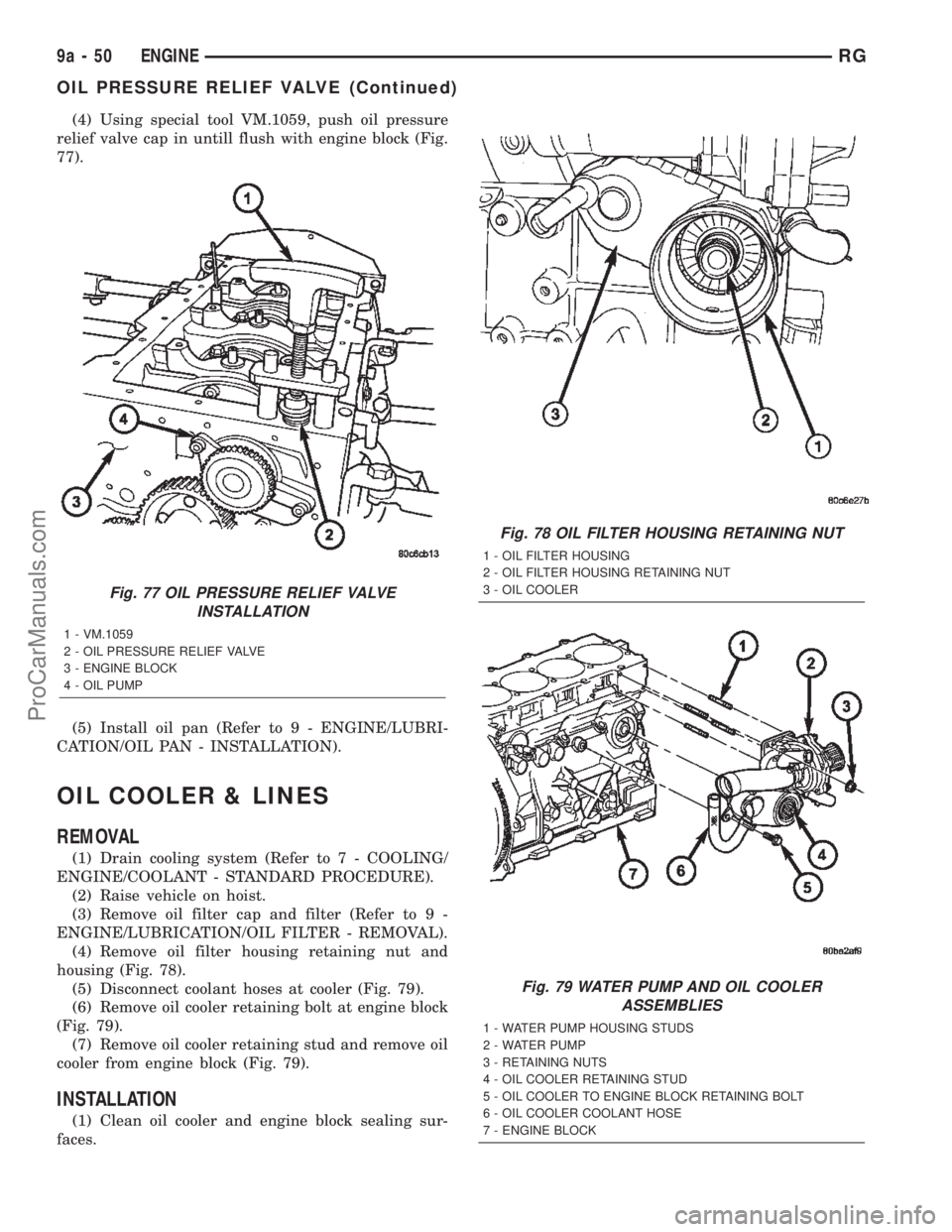

(4) Using special tool VM.1059, push oil pressure

relief valve cap in untill flush with engine block (Fig.

77).

(5) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

OIL COOLER & LINES

REMOVAL

(1) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Raise vehicle on hoist.

(3) Remove oil filter cap and filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER - REMOVAL).

(4) Remove oil filter housing retaining nut and

housing (Fig. 78).

(5) Disconnect coolant hoses at cooler (Fig. 79).

(6) Remove oil cooler retaining bolt at engine block

(Fig. 79).

(7) Remove oil cooler retaining stud and remove oil

cooler from engine block (Fig. 79).

INSTALLATION

(1) Clean oil cooler and engine block sealing sur-

faces.

Fig. 77 OIL PRESSURE RELIEF VALVE

INSTALLATION

1 - VM.1059

2 - OIL PRESSURE RELIEF VALVE

3 - ENGINE BLOCK

4 - OIL PUMP

Fig. 78 OIL FILTER HOUSING RETAINING NUT

1 - OIL FILTER HOUSING

2 - OIL FILTER HOUSING RETAINING NUT

3 - OIL COOLER

Fig. 79 WATER PUMP AND OIL COOLER

ASSEMBLIES

1 - WATER PUMP HOUSING STUDS

2 - WATER PUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

9a - 50 ENGINERG

OIL PRESSURE RELIEF VALVE (Continued)

ProCarManuals.com

Page 1412 of 2399

(2) Install oil cooler, retaining bolt, and stud (Fig.

79). Torque retaining bolt to 47.1N´m and stud to

50N´m.

(3) Connect coolant hoses at cooler (Fig. 79).

(4) Install oil filter housing and retaining nut (Fig.

78). Torque retaining nut to 3.5 Kg.

(5) Install oil filter cartridge and oil filter cap

(Refer to 9 - ENGINE/LUBRICATION/OIL FILTER -

INSTALLATION).

(6) Lower vehicle.

(7) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(8) Start engine and check for leaks.

(9) Check and adjust oil level as necessary.

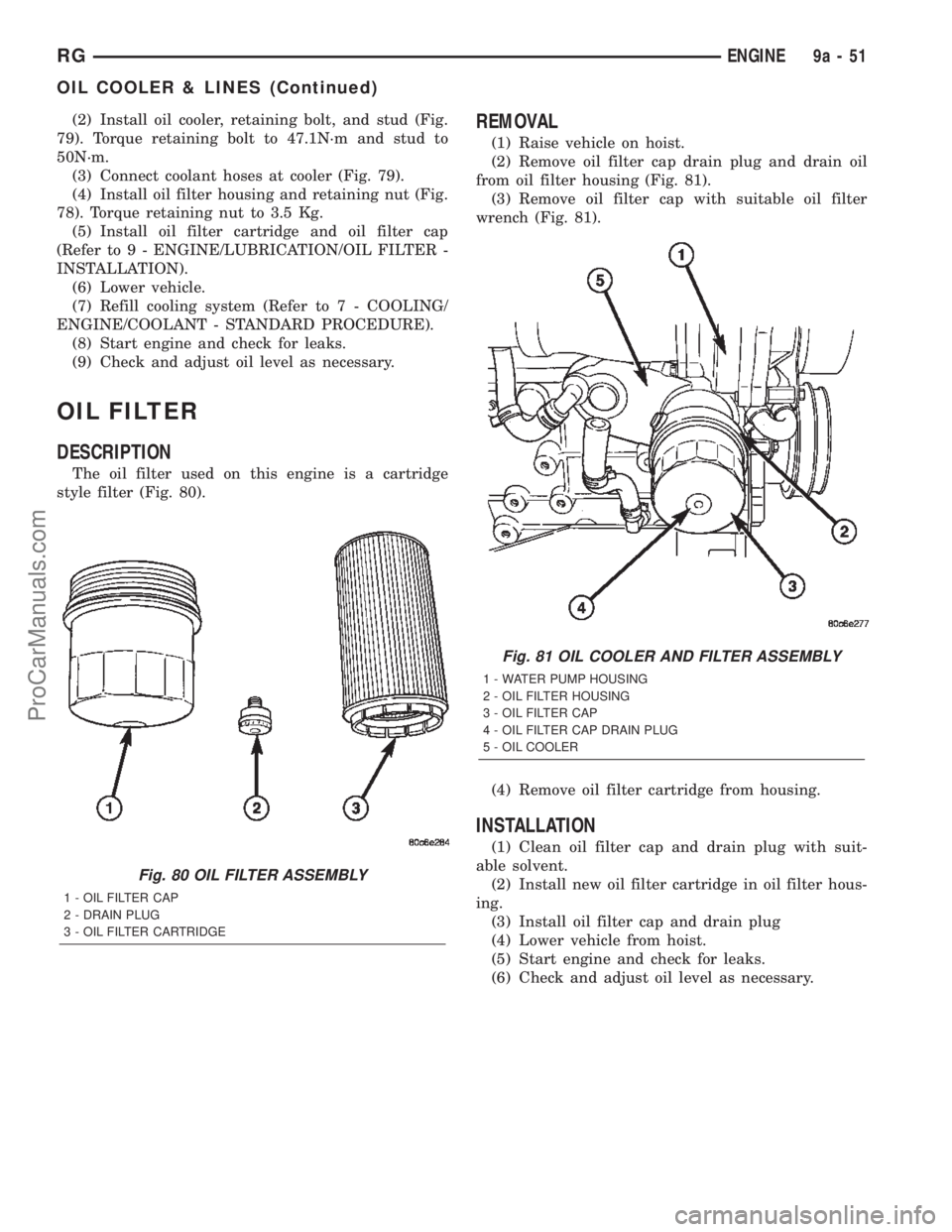

OIL FILTER

DESCRIPTION

The oil filter used on this engine is a cartridge

style filter (Fig. 80).

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove oil filter cap drain plug and drain oil

from oil filter housing (Fig. 81).

(3) Remove oil filter cap with suitable oil filter

wrench (Fig. 81).

(4) Remove oil filter cartridge from housing.

INSTALLATION

(1) Clean oil filter cap and drain plug with suit-

able solvent.

(2) Install new oil filter cartridge in oil filter hous-

ing.

(3) Install oil filter cap and drain plug

(4) Lower vehicle from hoist.

(5) Start engine and check for leaks.

(6) Check and adjust oil level as necessary.

Fig. 80 OIL FILTER ASSEMBLY

1 - OIL FILTER CAP

2 - DRAIN PLUG

3 - OIL FILTER CARTRIDGE

Fig. 81 OIL COOLER AND FILTER ASSEMBLY

1 - WATER PUMP HOUSING

2 - OIL FILTER HOUSING

3 - OIL FILTER CAP

4 - OIL FILTER CAP DRAIN PLUG

5 - OIL COOLER

RGENGINE9a-51

OIL COOLER & LINES (Continued)

ProCarManuals.com

Page 1435 of 2399

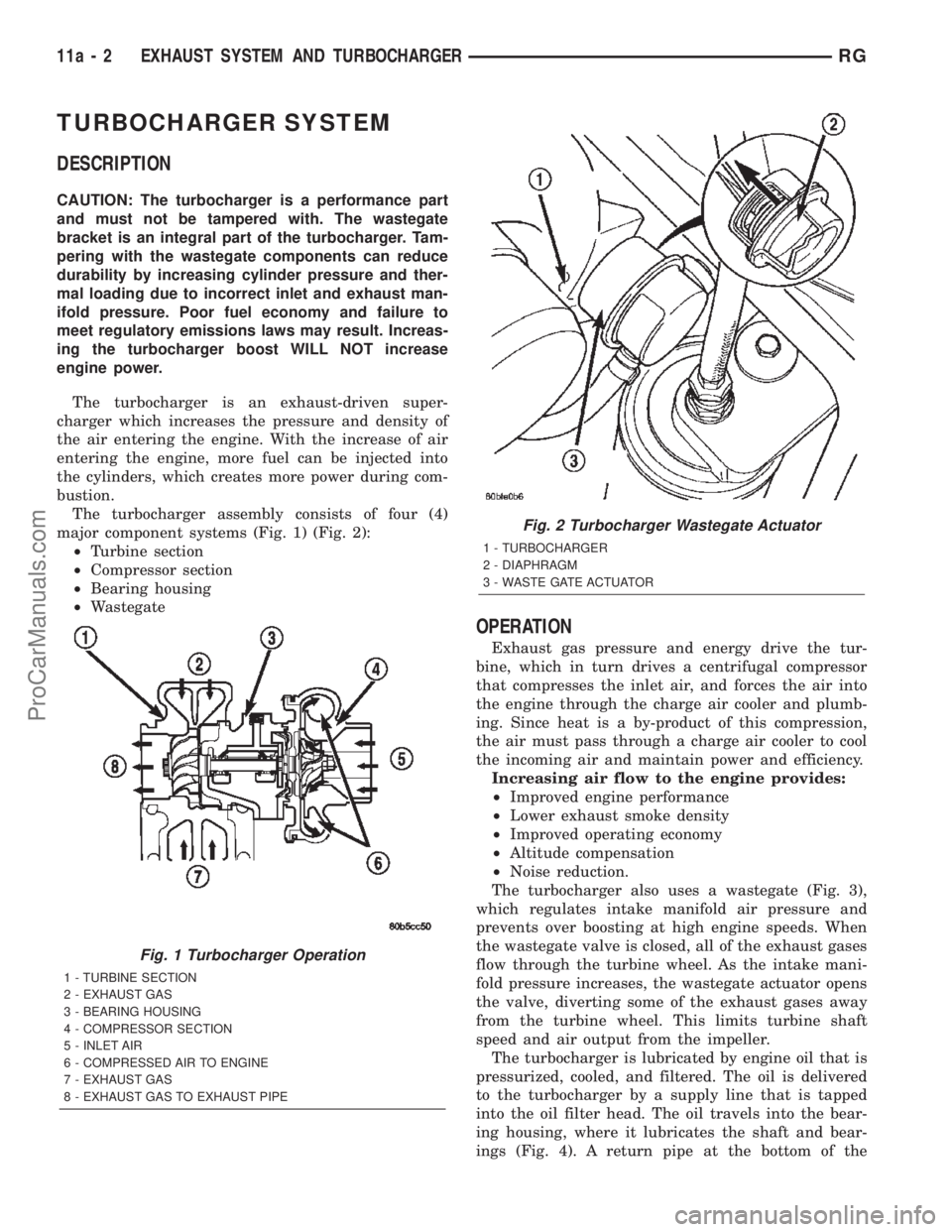

TURBOCHARGER SYSTEM

DESCRIPTION

CAUTION: The turbocharger is a performance part

and must not be tampered with. The wastegate

bracket is an integral part of the turbocharger. Tam-

pering with the wastegate components can reduce

durability by increasing cylinder pressure and ther-

mal loading due to incorrect inlet and exhaust man-

ifold pressure. Poor fuel economy and failure to

meet regulatory emissions laws may result. Increas-

ing the turbocharger boost WILL NOT increase

engine power.

The turbocharger is an exhaust-driven super-

charger which increases the pressure and density of

the air entering the engine. With the increase of air

entering the engine, more fuel can be injected into

the cylinders, which creates more power during com-

bustion.

The turbocharger assembly consists of four (4)

major component systems (Fig. 1) (Fig. 2):

²Turbine section

²Compressor section

²Bearing housing

²Wastegate

OPERATION

Exhaust gas pressure and energy drive the tur-

bine, which in turn drives a centrifugal compressor

that compresses the inlet air, and forces the air into

the engine through the charge air cooler and plumb-

ing. Since heat is a by-product of this compression,

the air must pass through a charge air cooler to cool

the incoming air and maintain power and efficiency.

Increasing air flow to the engine provides:

²Improved engine performance

²Lower exhaust smoke density

²Improved operating economy

²Altitude compensation

²Noise reduction.

The turbocharger also uses a wastegate (Fig. 3),

which regulates intake manifold air pressure and

prevents over boosting at high engine speeds. When

the wastegate valve is closed, all of the exhaust gases

flow through the turbine wheel. As the intake mani-

fold pressure increases, the wastegate actuator opens

the valve, diverting some of the exhaust gases away

from the turbine wheel. This limits turbine shaft

speed and air output from the impeller.

The turbocharger is lubricated by engine oil that is

pressurized, cooled, and filtered. The oil is delivered

to the turbocharger by a supply line that is tapped

into the oil filter head. The oil travels into the bear-

ing housing, where it lubricates the shaft and bear-

ings (Fig. 4). A return pipe at the bottom of the

Fig. 1 Turbocharger Operation

1 - TURBINE SECTION

2 - EXHAUST GAS

3 - BEARING HOUSING

4 - COMPRESSOR SECTION

5 - INLET AIR

6 - COMPRESSED AIR TO ENGINE

7 - EXHAUST GAS

8 - EXHAUST GAS TO EXHAUST PIPE

Fig. 2 Turbocharger Wastegate Actuator

1 - TURBOCHARGER

2 - DIAPHRAGM

3 - WASTE GATE ACTUATOR

11a - 2 EXHAUST SYSTEM AND TURBOCHARGERRG

ProCarManuals.com

Page 1462 of 2399

REMOVAL

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure (Fig. 15).

(2) Disconnect negative cable from battery.

(3) Insert fuel siphon hose into fuel filler neck and

push it into the tank.

(4) Drain fuel tank dry into holding tank or a

properly labeledGASOLINEsafety container.

(5) Raise vehicle on hoist and support.

(6) Use a transmission jack to support fuel tank.

Remove bolts from fuel tank straps.

(7) Lower tank slightly.

(8) Disconnect the fuel filler vent tube. Squeeze

tabs and pull apart (Fig. 16).

(9) Disconnect the fuel fill hose at the fuel tank

filler metal tubeNOT AT THE FUEL TANK(Fig.

16).

(10) Disconnect fuel line and vapor line at the

front of the fuel tank.

The fuel pump module electrical connector

has a retainer that locks it in place.

(11) Slide fuel pump module electrical connector

lock to unlock (Fig. 17).

(12) Push down on connector retainer (Fig. 18) and

pull connector off module.

(13) Lower tank from vehicle. Remove fuel filler

vent tube from frame (Fig. 19).

INSTALLATION

(1) Position fuel tank on transmission jack. Con-

nect rollover valve hose. Connect fuel filler tube vent

hose and tighten clamp.

(2) Raise tank into position and carefully work

filler metal tube into the rubber hose on fuel tank. A

light coating of clean engine oil on the tube end may

be used to aid assembly.

Fig. 15 Fuel Tank

1 - ROLLOVER VALVE

2 - FUEL FILLER INLET

3 - ROLLOVER VALVE

4 - GROUND STRAP

5 - FUEL FILTER

6 - FUEL PUMP MODULEFig. 16 FUEL FILLER AND VENT TUBE

1 - Filler Tube

2 - Vent Tube

Fig. 17 Fuel Line Retainers and Pump Connector

Lock

1 - PUSH

2 - CONNECTOR LOCK

3 - QUICK CONNECT RETAINERS

RSFUEL DELIVERY14-11

FUEL TANK (Continued)

ProCarManuals.com

Page 1464 of 2399

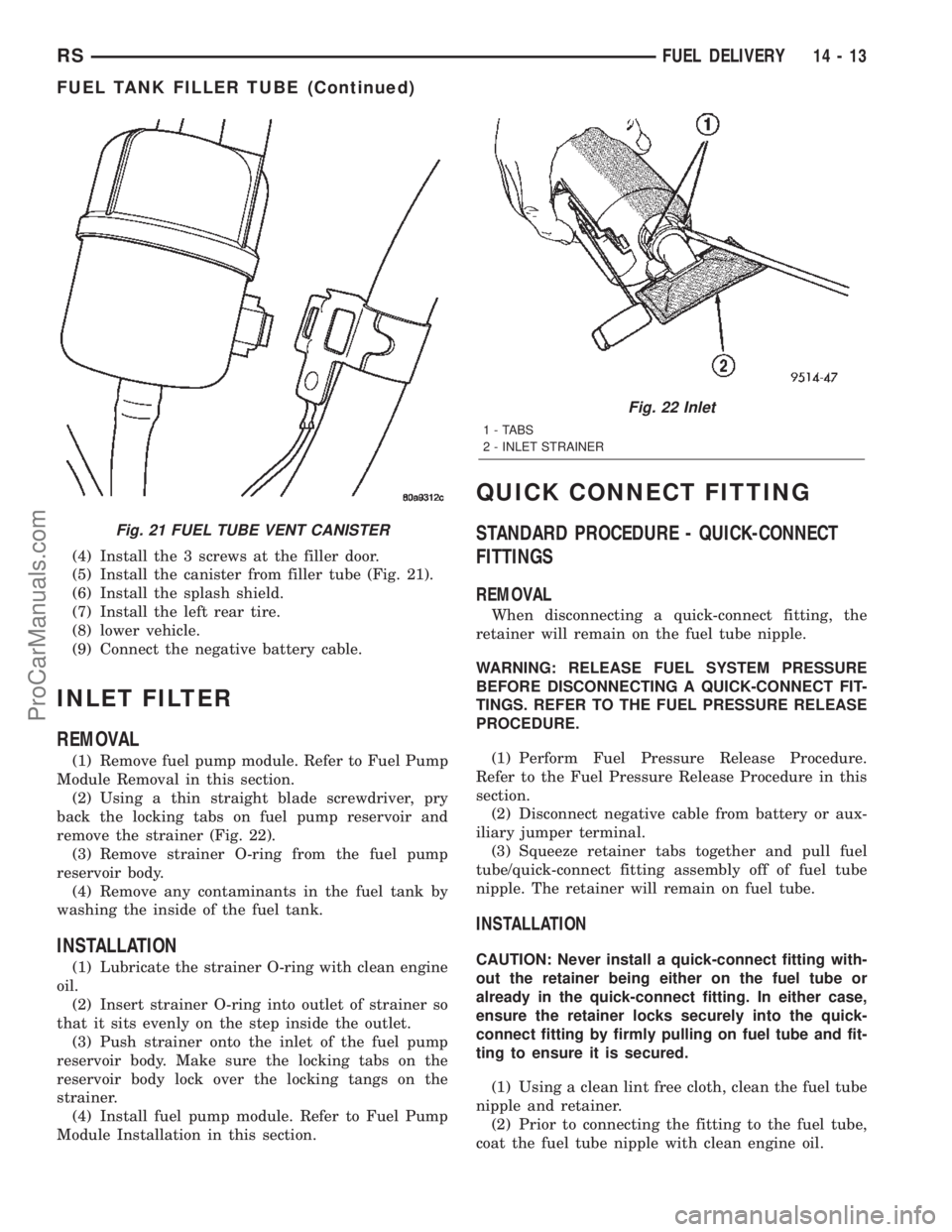

(4) Install the 3 screws at the filler door.

(5) Install the canister from filler tube (Fig. 21).

(6) Install the splash shield.

(7) Install the left rear tire.

(8) lower vehicle.

(9) Connect the negative battery cable.

INLET FILTER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 22).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the

reservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

QUICK CONNECT FITTING

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(2) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting with-

out the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean engine oil.

Fig. 21 FUEL TUBE VENT CANISTER

Fig. 22 Inlet

1 - TABS

2 - INLET STRAINER

RSFUEL DELIVERY14-13

FUEL TANK FILLER TUBE (Continued)

ProCarManuals.com

Page 1489 of 2399

Test all fuel supply lines for restrictions or block-

age. Flush or replace as necessary. Bleed fuel system

of air once a fuel supply line has been replaced. Refer

to Air Bleed Procedure for procedures.

To test for fuel line restrictions, a vacuum restric-

tion test may be performed.

HIGH-PRESSURE LINES

Restricted (kinked or bent) high-pressure lines can

cause starting problems, poor engine performance,

engine mis-fire and white smoke from exhaust.

Examine all high-pressure lines for any damage.

Each radius on each high-pressure line must be

smooth and free of any bends or kinks.

Replace damaged, restricted or leaking high-pres-

sure fuel lines with correct replacement line.

CAUTION: High pressure lines cannot contact each

other or other components. Do not attempt to weld

high-pressure fuel lines or to repair lines that are

damaged. If line is kinked or bent, it must be

replaced. Use only recommended lines when

replacement of high-pressure fuel line is necessary.

STANDARD PROCEDURE

STANDARD PROCEDURES - DRAINING WATER

FROM FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURE - FUEL SYSTEM AIR

PURGE

(1) Remove engine cover (Refer to 9 - ENGINE

COVER - REMOVAL).

(2) Remove cap from air purge fitting on the fuel

supply line. This fitting is located just behind the

alternator (Fig. 1).

(3) Attach a hose of about 1 or 2 meters to this fit-

ting using an appropriate connector.

(4) Direct the end of the hose into an appropriate

fuel container.

(5) Turn the ignition to the ªONº position,Do not

crank the engine.Keep key on until about 1 liter of

fuel has been pumped into the container.

(6) While keeping end of hose below fuel level in

conatiner, turn the ignition ªOFFº.

(7) Remove hose from air purge fitting on the fuel

supply line and replace cap.

(8) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM COMPONENTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines, fuel rail, and fuel injection

pump. Very tight tolerances are used with these

parts. Dirt contamination could cause rapid part

wear and possible plugging of fuel injector nozzle

tip holes. This in turn could lead to possible engine

misfire. Always wash/clean any fuel system compo-

nent thoroughly before disassembly and then air

dry. Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

Fig. 1 AIR PURGE VALVE

1 - AIR PURGE VALVE CAP

2 - AIR PURGE VALVE

3 - ALTERNATOR

4 - ENGINE FRONT COVER

14a - 2 FUEL SYSTEMRG

FUEL SYSTEM 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1491 of 2399

FUEL DELIVERY

TABLE OF CONTENTS

page page

FUEL RAIL

DESCRIPTION..........................4

OPERATION............................4

REMOVAL - FUEL RAIL...................4

INSTALLATION - FUEL RAIL................5

FUEL FILTER / WATER SEPARATOR

DESCRIPTION..........................5

OPERATION............................5

FUEL LINES

DESCRIPTION

DESCRIPTION........................6

DESCRIPTION - HIGH PRESSURE FUEL

LINES...............................6OPERATION - HIGH PRESSURE FUEL LINES . . 6

DIAGNOSIS AND TESTING - HIGH

PRESSURE FUEL LINES.................6

FUEL TRANSFER PUMP

DESCRIPTION..........................7

OPERATION............................7

FUEL INJECTION PUMP

DESCRIPTION..........................7

REMOVAL.............................7

INSTALLATION..........................9

WATER IN FUEL SENSOR

DESCRIPTION.........................10

OPERATION...........................10

FUEL RAIL

DESCRIPTION

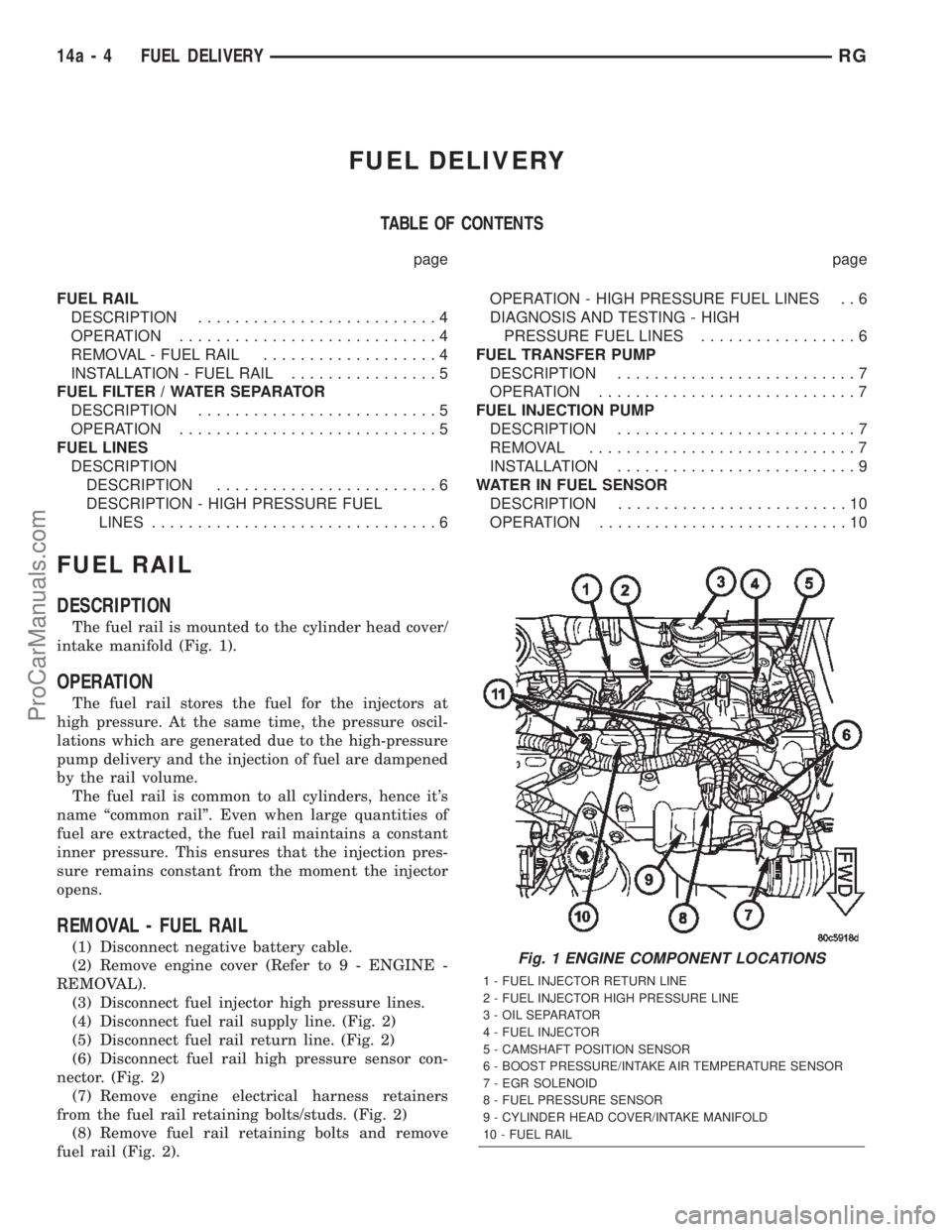

The fuel rail is mounted to the cylinder head cover/

intake manifold (Fig. 1).

OPERATION

The fuel rail stores the fuel for the injectors at

high pressure. At the same time, the pressure oscil-

lations which are generated due to the high-pressure

pump delivery and the injection of fuel are dampened

by the rail volume.

The fuel rail is common to all cylinders, hence it's

name ªcommon railº. Even when large quantities of

fuel are extracted, the fuel rail maintains a constant

inner pressure. This ensures that the injection pres-

sure remains constant from the moment the injector

opens.

REMOVAL - FUEL RAIL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Disconnect fuel injector high pressure lines.

(4) Disconnect fuel rail supply line. (Fig. 2)

(5) Disconnect fuel rail return line. (Fig. 2)

(6) Disconnect fuel rail high pressure sensor con-

nector. (Fig. 2)

(7) Remove engine electrical harness retainers

from the fuel rail retaining bolts/studs. (Fig. 2)

(8) Remove fuel rail retaining bolts and remove

fuel rail (Fig. 2).Fig. 1 ENGINE COMPONENT LOCATIONS

1 - FUEL INJECTOR RETURN LINE

2 - FUEL INJECTOR HIGH PRESSURE LINE

3 - OIL SEPARATOR

4 - FUEL INJECTOR

5 - CAMSHAFT POSITION SENSOR

6 - BOOST PRESSURE/INTAKE AIR TEMPERATURE SENSOR

7 - EGR SOLENOID

8 - FUEL PRESSURE SENSOR

9 - CYLINDER HEAD COVER/INTAKE MANIFOLD

10 - FUEL RAIL

14a - 4 FUEL DELIVERYRG

ProCarManuals.com

Page 1492 of 2399

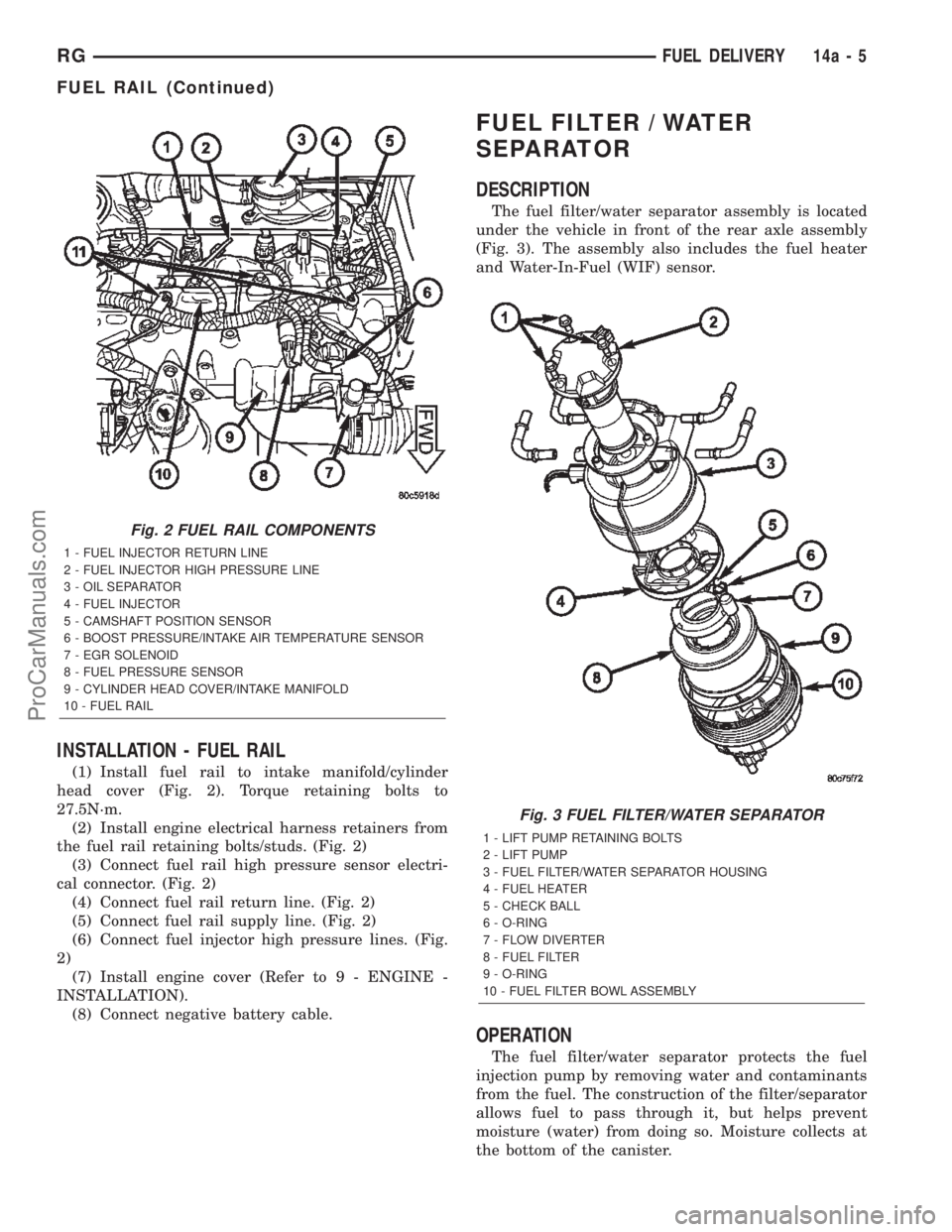

INSTALLATION - FUEL RAIL

(1) Install fuel rail to intake manifold/cylinder

head cover (Fig. 2). Torque retaining bolts to

27.5N´m.

(2) Install engine electrical harness retainers from

the fuel rail retaining bolts/studs. (Fig. 2)

(3) Connect fuel rail high pressure sensor electri-

cal connector. (Fig. 2)

(4) Connect fuel rail return line. (Fig. 2)

(5) Connect fuel rail supply line. (Fig. 2)

(6) Connect fuel injector high pressure lines. (Fig.

2)

(7) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(8) Connect negative battery cable.

FUEL FILTER / WATER

SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located

under the vehicle in front of the rear axle assembly

(Fig. 3). The assembly also includes the fuel heater

and Water-In-Fuel (WIF) sensor.

OPERATION

The fuel filter/water separator protects the fuel

injection pump by removing water and contaminants

from the fuel. The construction of the filter/separator

allows fuel to pass through it, but helps prevent

moisture (water) from doing so. Moisture collects at

the bottom of the canister.

Fig. 2 FUEL RAIL COMPONENTS

1 - FUEL INJECTOR RETURN LINE

2 - FUEL INJECTOR HIGH PRESSURE LINE

3 - OIL SEPARATOR

4 - FUEL INJECTOR

5 - CAMSHAFT POSITION SENSOR

6 - BOOST PRESSURE/INTAKE AIR TEMPERATURE SENSOR

7 - EGR SOLENOID

8 - FUEL PRESSURE SENSOR

9 - CYLINDER HEAD COVER/INTAKE MANIFOLD

10 - FUEL RAIL

Fig. 3 FUEL FILTER/WATER SEPARATOR

1 - LIFT PUMP RETAINING BOLTS

2 - LIFT PUMP

3 - FUEL FILTER/WATER SEPARATOR HOUSING

4 - FUEL HEATER

5 - CHECK BALL

6 - O-RING

7 - FLOW DIVERTER

8 - FUEL FILTER

9 - O-RING

10 - FUEL FILTER BOWL ASSEMBLY

RGFUEL DELIVERY14a-5

FUEL RAIL (Continued)

ProCarManuals.com

Page 1529 of 2399

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION.........................26

OPERATION...........................26

WARNING

WARNINGS AND CAUTIONS.............26

REMOVAL

REMOVAL - LHD GEAR.................26

REMOVAL - RHD GEAR................29INSTALLATION

INSTALLATION - LHD GEAR.............32

INSTALLATION - RHD GEAR.............33

SPECIAL TOOLS

POWER STEERING GEAR..............34

OUTER TIE ROD

REMOVAL.............................34

INSTALLATION.........................34

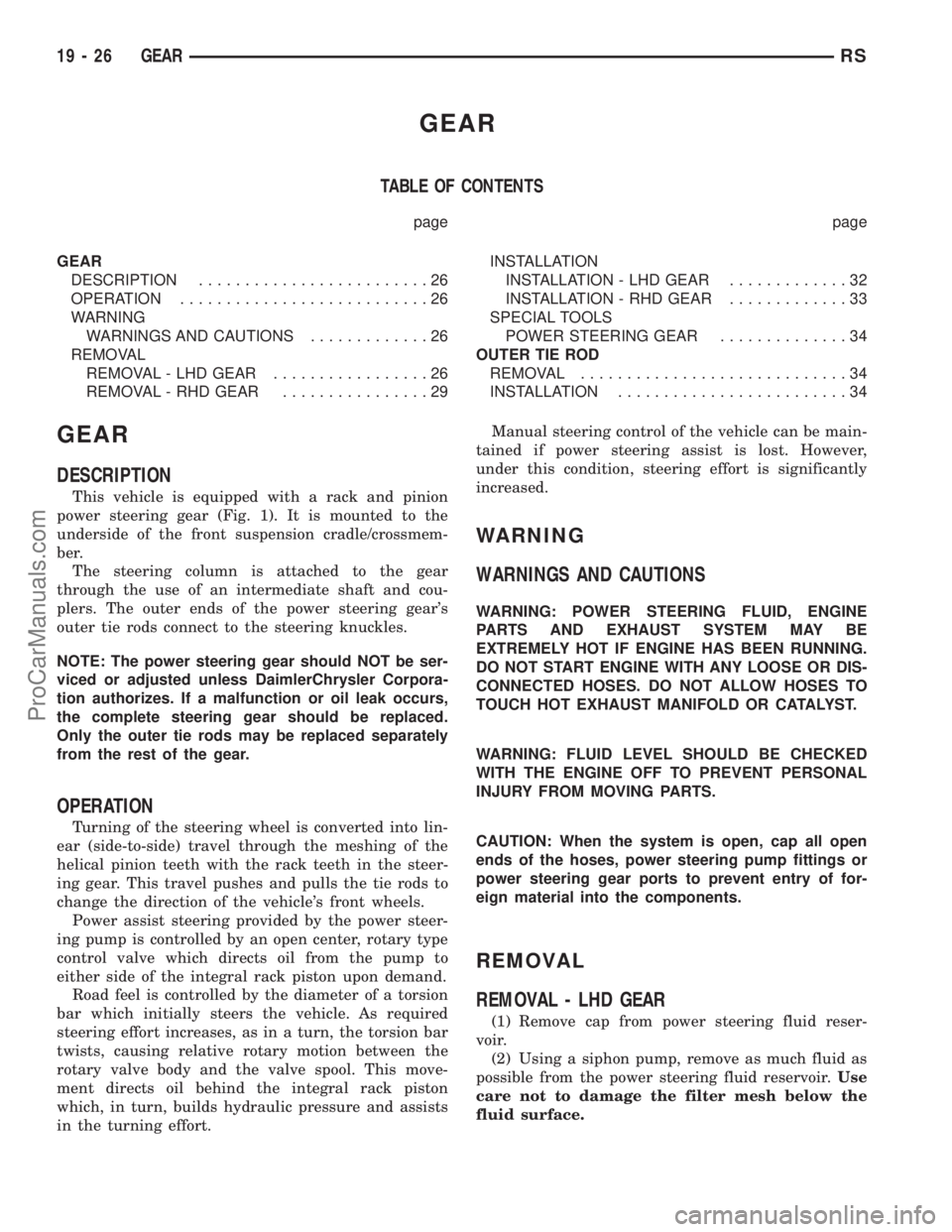

GEAR

DESCRIPTION

This vehicle is equipped with a rack and pinion

power steering gear (Fig. 1). It is mounted to the

underside of the front suspension cradle/crossmem-

ber.

The steering column is attached to the gear

through the use of an intermediate shaft and cou-

plers. The outer ends of the power steering gear's

outer tie rods connect to the steering knuckles.

NOTE: The power steering gear should NOT be ser-

viced or adjusted unless DaimlerChrysler Corpora-

tion authorizes. If a malfunction or oil leak occurs,

the complete steering gear should be replaced.

Only the outer tie rods may be replaced separately

from the rest of the gear.

OPERATION

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth in the steer-

ing gear. This travel pushes and pulls the tie rods to

change the direction of the vehicle's front wheels.

Power assist steering provided by the power steer-

ing pump is controlled by an open center, rotary type

control valve which directs oil from the pump to

either side of the integral rack piston upon demand.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston

which, in turn, builds hydraulic pressure and assists

in the turning effort.Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

WARNING

WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

REMOVAL

REMOVAL - LHD GEAR

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.Use

care not to damage the filter mesh below the

fluid surface.

19 - 26 GEARRS

ProCarManuals.com