transmission fluid CHRYSLER CARAVAN 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1581 of 2399

ries the governor and parking sprag. An integral heli-

cal gear on the transfer shaft drives the differential

ring gear.

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

FIRST 2.69:1

SECOND 1.55:1

THIRD 1.00:1

REVERSE 2.10:1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRELIMINARY

DIAGNOSIS

Automatic transaxle malfunctions are usually

caused by the following general conditions:

²Improper fluid level/condition²Poor engine performance

²Improper engine or transaxle adjustments

²Transaxle hydraulic malfunctions

²Transaxle mechanical malfunctions

Diagnosis of transaxle problems should always

begin with checking the easily accessible variables:

²Fluid level and condition

²Gearshift cable adjustment

²Throttle valve cable adjustment

After verifying or adjusting these variables, road

test the vehicle to determine if the problem has been

corrected or that further diagnosis is necessary. If the

problem still exists, refer to the following diagnosis

charts to aid in determining the source or cause of

failure.

Hydraulic pressure tests should be performed

when a transaxle internal failure is suspected. The

hydraulic flow charts, in the Schematics and Dia-

grams section of this group, outline fluid flow and

hydraulic circuitry. Circuit operation is provided for

all gear ranges. Normal working pressures are also

supplied for each of the gear ranges.

21 - 24 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1582 of 2399

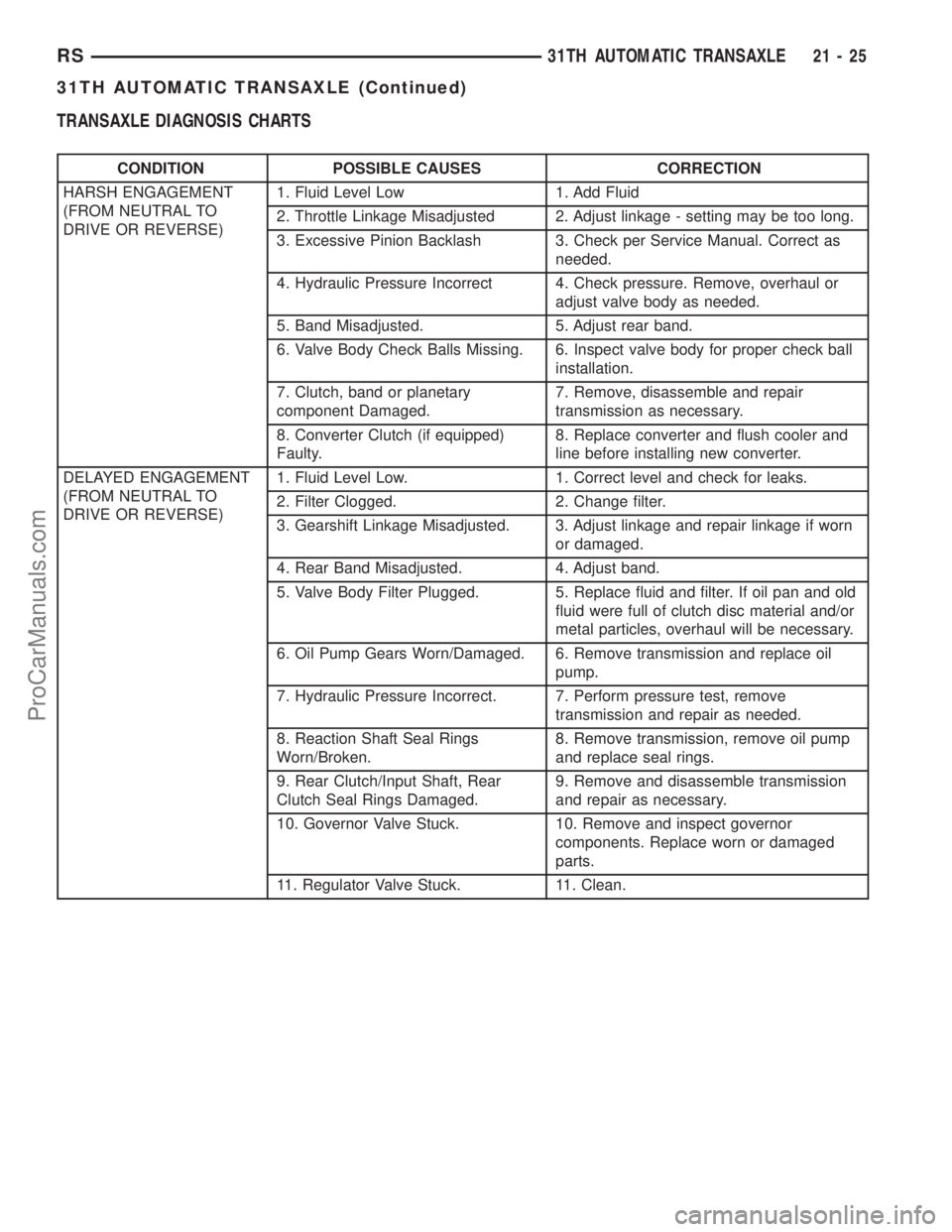

TRANSAXLE DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low 1. Add Fluid

2. Throttle Linkage Misadjusted 2. Adjust linkage - setting may be too long.

3. Excessive Pinion Backlash 3. Check per Service Manual. Correct as

needed.

4. Hydraulic Pressure Incorrect 4. Check pressure. Remove, overhaul or

adjust valve body as needed.

5. Band Misadjusted. 5. Adjust rear band.

6. Valve Body Check Balls Missing. 6. Inspect valve body for proper check ball

installation.

7. Clutch, band or planetary

component Damaged.7. Remove, disassemble and repair

transmission as necessary.

8. Converter Clutch (if equipped)

Faulty.8. Replace converter and flush cooler and

line before installing new converter.

DELAYED ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Misadjusted. 3. Adjust linkage and repair linkage if worn

or damaged.

4. Rear Band Misadjusted. 4. Adjust band.

5. Valve Body Filter Plugged. 5. Replace fluid and filter. If oil pan and old

fluid were full of clutch disc material and/or

metal particles, overhaul will be necessary.

6. Oil Pump Gears Worn/Damaged. 6. Remove transmission and replace oil

pump.

7. Hydraulic Pressure Incorrect. 7. Perform pressure test, remove

transmission and repair as needed.

8. Reaction Shaft Seal Rings

Worn/Broken.8. Remove transmission, remove oil pump

and replace seal rings.

9. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.9. Remove and disassemble transmission

and repair as necessary.

10. Governor Valve Stuck. 10. Remove and inspect governor

components. Replace worn or damaged

parts.

11. Regulator Valve Stuck. 11. Clean.

RS31TH AUTOMATIC TRANSAXLE21-25

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1583 of 2399

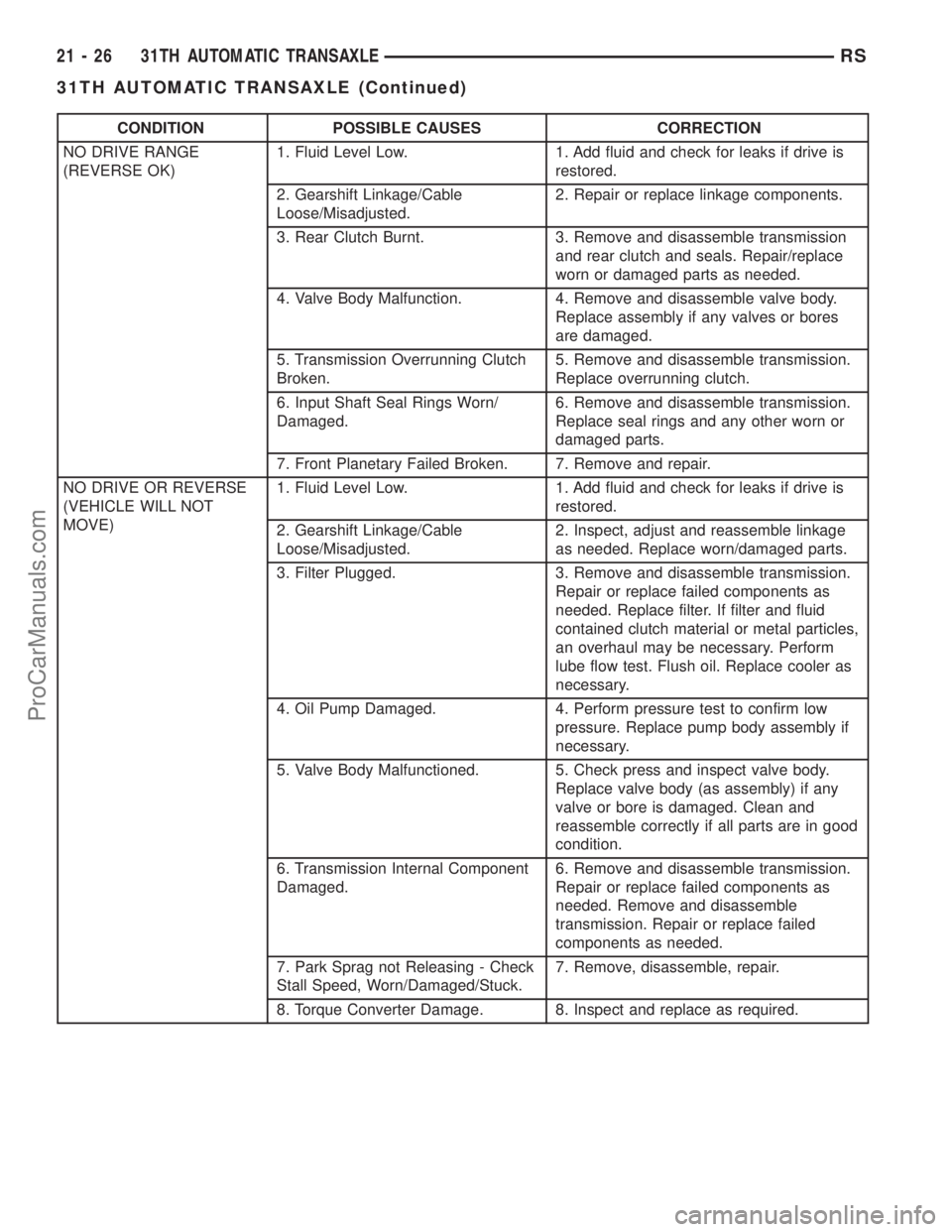

CONDITION POSSIBLE CAUSES CORRECTION

NO DRIVE RANGE

(REVERSE OK)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Repair or replace linkage components.

3. Rear Clutch Burnt. 3. Remove and disassemble transmission

and rear clutch and seals. Repair/replace

worn or damaged parts as needed.

4. Valve Body Malfunction. 4. Remove and disassemble valve body.

Replace assembly if any valves or bores

are damaged.

5. Transmission Overrunning Clutch

Broken.5. Remove and disassemble transmission.

Replace overrunning clutch.

6. Input Shaft Seal Rings Worn/

Damaged.6. Remove and disassemble transmission.

Replace seal rings and any other worn or

damaged parts.

7. Front Planetary Failed Broken. 7. Remove and repair.

NO DRIVE OR REVERSE

(VEHICLE WILL NOT

MOVE)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Inspect, adjust and reassemble linkage

as needed. Replace worn/damaged parts.

3. Filter Plugged. 3. Remove and disassemble transmission.

Repair or replace failed components as

needed. Replace filter. If filter and fluid

contained clutch material or metal particles,

an overhaul may be necessary. Perform

lube flow test. Flush oil. Replace cooler as

necessary.

4. Oil Pump Damaged. 4. Perform pressure test to confirm low

pressure. Replace pump body assembly if

necessary.

5. Valve Body Malfunctioned. 5. Check press and inspect valve body.

Replace valve body (as assembly) if any

valve or bore is damaged. Clean and

reassemble correctly if all parts are in good

condition.

6. Transmission Internal Component

Damaged.6. Remove and disassemble transmission.

Repair or replace failed components as

needed. Remove and disassemble

transmission. Repair or replace failed

components as needed.

7. Park Sprag not Releasing - Check

Stall Speed, Worn/Damaged/Stuck.7. Remove, disassemble, repair.

8. Torque Converter Damage. 8. Inspect and replace as required.

21 - 26 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1584 of 2399

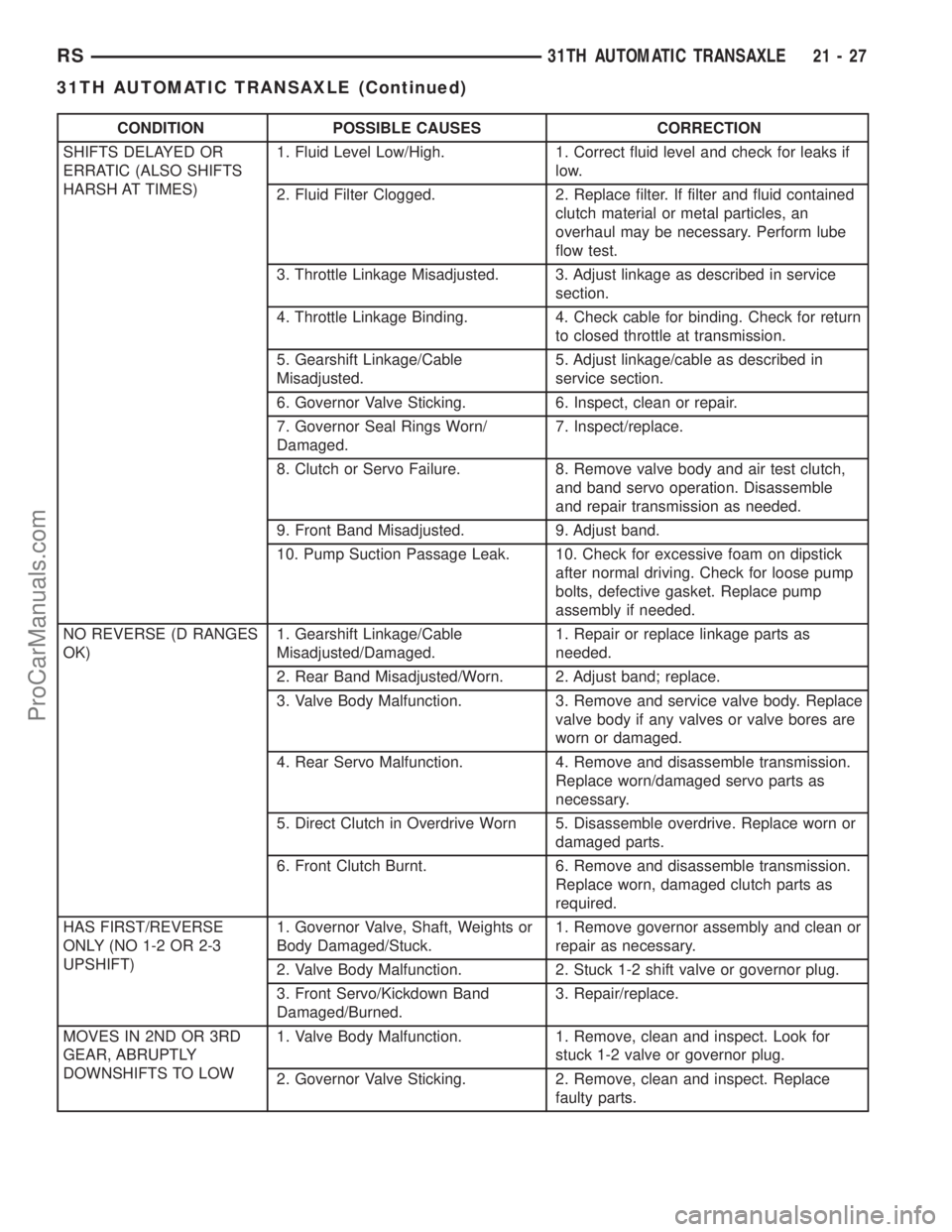

CONDITION POSSIBLE CAUSES CORRECTION

SHIFTS DELAYED OR

ERRATIC (ALSO SHIFTS

HARSH AT TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

clutch material or metal particles, an

overhaul may be necessary. Perform lube

flow test.

3. Throttle Linkage Misadjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

to closed throttle at transmission.

5. Gearshift Linkage/Cable

Misadjusted.5. Adjust linkage/cable as described in

service section.

6. Governor Valve Sticking. 6. Inspect, clean or repair.

7. Governor Seal Rings Worn/

Damaged.7. Inspect/replace.

8. Clutch or Servo Failure. 8. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

9. Front Band Misadjusted. 9. Adjust band.

10. Pump Suction Passage Leak. 10. Check for excessive foam on dipstick

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

NO REVERSE (D RANGES

OK)1. Gearshift Linkage/Cable

Misadjusted/Damaged.1. Repair or replace linkage parts as

needed.

2. Rear Band Misadjusted/Worn. 2. Adjust band; replace.

3. Valve Body Malfunction. 3. Remove and service valve body. Replace

valve body if any valves or valve bores are

worn or damaged.

4. Rear Servo Malfunction. 4. Remove and disassemble transmission.

Replace worn/damaged servo parts as

necessary.

5. Direct Clutch in Overdrive Worn 5. Disassemble overdrive. Replace worn or

damaged parts.

6. Front Clutch Burnt. 6. Remove and disassemble transmission.

Replace worn, damaged clutch parts as

required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Valve, Shaft, Weights or

Body Damaged/Stuck.1. Remove governor assembly and clean or

repair as necessary.

2. Valve Body Malfunction. 2. Stuck 1-2 shift valve or governor plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

stuck 1-2 valve or governor plug.

2. Governor Valve Sticking. 2. Remove, clean and inspect. Replace

faulty parts.

RS31TH AUTOMATIC TRANSAXLE21-27

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1592 of 2399

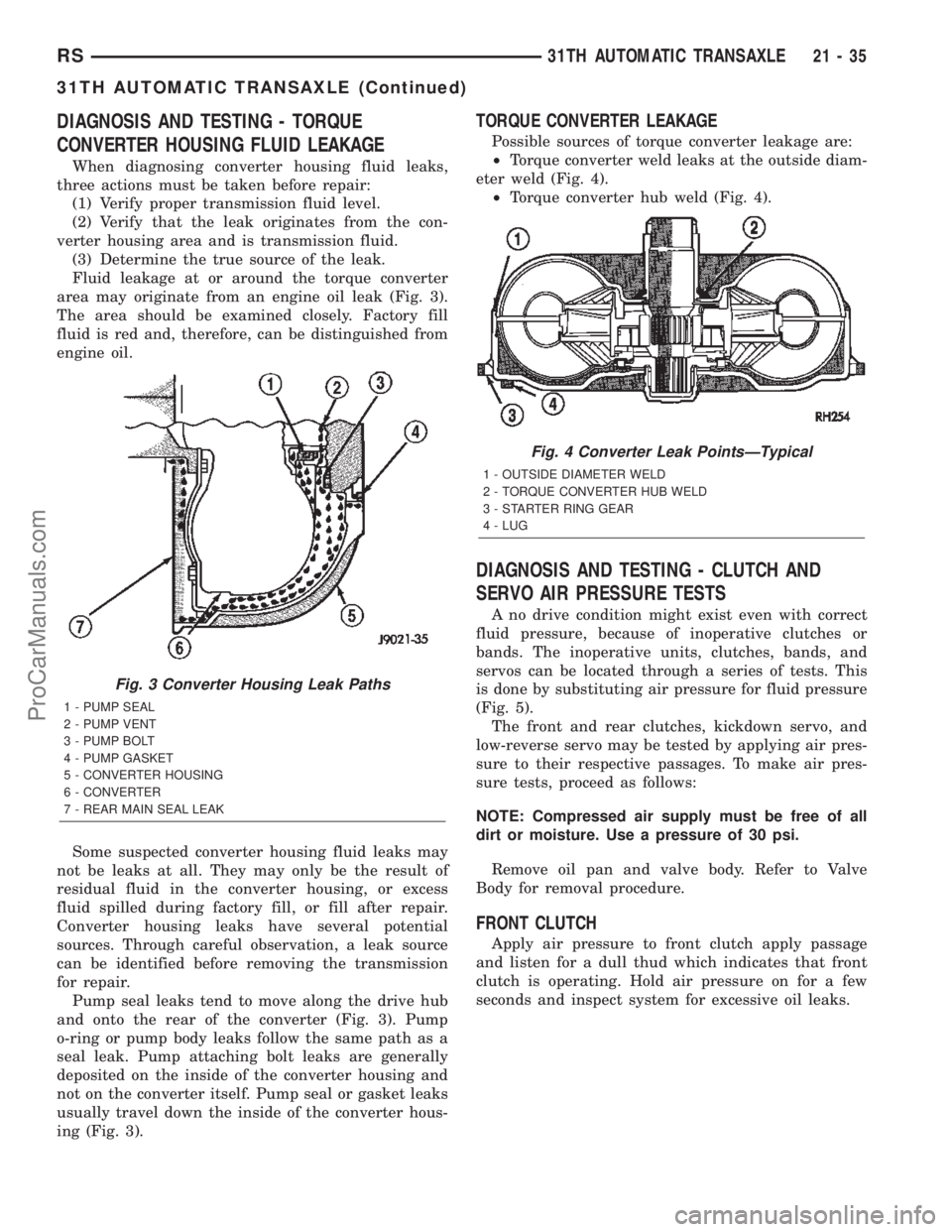

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE

When diagnosing converter housing fluid leaks,

three actions must be taken before repair:

(1) Verify proper transmission fluid level.

(2) Verify that the leak originates from the con-

verter housing area and is transmission fluid.

(3) Determine the true source of the leak.

Fluid leakage at or around the torque converter

area may originate from an engine oil leak (Fig. 3).

The area should be examined closely. Factory fill

fluid is red and, therefore, can be distinguished from

engine oil.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill, or fill after repair.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair.

Pump seal leaks tend to move along the drive hub

and onto the rear of the converter (Fig. 3). Pump

o-ring or pump body leaks follow the same path as a

seal leak. Pump attaching bolt leaks are generally

deposited on the inside of the converter housing and

not on the converter itself. Pump seal or gasket leaks

usually travel down the inside of the converter hous-

ing (Fig. 3).

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside diam-

eter weld (Fig. 4).

²Torque converter hub weld (Fig. 4).

DIAGNOSIS AND TESTING - CLUTCH AND

SERVO AIR PRESSURE TESTS

A no drive condition might exist even with correct

fluid pressure, because of inoperative clutches or

bands. The inoperative units, clutches, bands, and

servos can be located through a series of tests. This

is done by substituting air pressure for fluid pressure

(Fig. 5).

The front and rear clutches, kickdown servo, and

low-reverse servo may be tested by applying air pres-

sure to their respective passages. To make air pres-

sure tests, proceed as follows:

NOTE: Compressed air supply must be free of all

dirt or moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. Refer to Valve

Body for removal procedure.

FRONT CLUTCH

Apply air pressure to front clutch apply passage

and listen for a dull thud which indicates that front

clutch is operating. Hold air pressure on for a few

seconds and inspect system for excessive oil leaks.

Fig. 3 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

Fig. 4 Converter Leak PointsÐTypical

1 - OUTSIDE DIAMETER WELD

2 - TORQUE CONVERTER HUB WELD

3 - STARTER RING GEAR

4 - LUG

RS31TH AUTOMATIC TRANSAXLE21-35

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1620 of 2399

(13) Install halfshafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(14) Lower vehicle.

(15) Torque rear mount bracket-to-transaxle verti-

cal bolts (Fig. 98) to 102 N´m (75 ft. lbs.).

(16) Connect back up lamp switch connector.

(17) Connect gearshift cable to manual valve and

left upper mount bracket (Fig. 102).

(18) Connect throttle valve cable to lever and

bracket (Fig. 103).

(19) Connect torque converter clutch connector.

(20) Install fluid level indicator/tube assembly

(Fig. 104).

(21) Raise vehicle on hoist.

(22) Torque rear mount bracket-to-transaxle case

horizontal bolt (Fig. 98) to 102 N´m (75 ft. lbs.).

(23) Torque rear mount thru-bolt to 54 N´m (40 ft.

lbs.).

(24) Lower vehicle.

(25) Connect battery negative cable.

(26) Fill transaxle with ATF+4 transmission fluid.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/FLUID - STANDARD PROCEDURE)

Fig. 102 Gearshift Cable at Transaxle

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

Fig. 103 Kickdown Cable at TransaxleÐTypical

1 - LEVER

2 - BRACKET

3 - THROTTLE VALVE CABLE

Fig. 104 Fluid Level Indicator Assembly

1 - INDICATOR ASSEMBLY

2 - BOLT

3 - KICKDOWN CABLE BRACKET

4 - SEAL

RS31TH AUTOMATIC TRANSAXLE21-63

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1638 of 2399

(2) Remove transaxle oil pan and drain fluid (Fig.

111) (Fig. 112).

(3) Loosen band adjusting screw locknut 5-6 turns.

Be sure adjusting screw turns freely in lever.

(4) Tighten adjusting screw to 5 N´m (41 in. lbs.)

(Fig. 113).

(5) Back off adjusting screw 3

1¤2turns.

(6) Hold adjusting screw in place and tighten lock-

nut to 14 N´m (125 ft. lbs.) torque.

(7) Install a bead of MopartSilicone Rubber Adhe-

sive Sealant to the oil pan and install to case imme-

diately.

(8) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.).(9) Lower vehicle and refill transmission with

MopartATF Plus 4, Type 9602, fluid.

Fig. 110 Front (Kickdown) Band Adjustment

Location

1 - KICKDOWN BAND ADJUSTING SCREW

Fig. 111 Transaxle Oil Pan Bolts

1 - TRANSAXLE OIL PAN

2 - OIL PAN BOLTS

Fig. 112 Transaxle Oil Pan

1 - TRANSAXLE OIL PAN

2 - OIL FILTER

Fig. 113 Adjust Low/Reverse Band

1 - LOW-REVERSE BAND LEVER

2 - ADJUSTING SCREW

3 - STRUT

4 - LOW-REVERSE BAND

5 - LOCK NUT

6 - LEVER (SHORT)

RS31TH AUTOMATIC TRANSAXLE21-81

BANDS (Continued)

ProCarManuals.com

Page 1639 of 2399

CLUTCH - FRONT

DESCRIPTION

The front clutch assembly (Fig. 119) is composed of

the front clutch retainer, pressure plate, clutch

plates, driving discs, piston, piston return spring,

return spring retainer, and snap-rings. The front

clutch is the forward-most component in the trans-

mission geartrain and is directly behind the oil

pump. It is considered a driving component.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved snap-ring is

used to cushion the application of the clutch pack. In

some transmissions, the snap-ring is selective and

used to adjust clutch pack clearance.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the

clutch retainer. The check-valve is needed to elimi-

nate the possibility of plate drag caused by centrifu-

gal force acting on the residual fluid trapped in the

clutch piston retainer.

DISASSEMBLY

(1) Remove front clutch waved snap ring using a

suitable screwdriver (Fig. 114).

(2) Remove waved snap ring and reaction plate

(Fig. 115).

Fig. 114 Front Clutch Waved Snap Ring

1 - WAVED SNAP RING

2 - SCREWDRIVER

3 - FRONT CLUTCH ASSEMBLY

Fig. 115 Thick Steel Plate and Waved Snap Ring

1 - WAVED SNAP RING

2 - THICK STEEL PLATE

3 - FRONT CLUTCH RETAINER

21 - 82 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1643 of 2399

(5) Using feeler gauge, measure front clutch clear-

ance (Fig. 125).Front clutch clearance should be

within 1.27-2.79 mm (0.050-0.110 in.) and is not

adjustable.

CLUTCH - REAR

DESCRIPTION

The rear clutch assembly (Fig. 132) is composed of

the input shaft, rear clutch retainer, pressure plate,

clutch plates, driving discs, piston, Belleville spring,

and snap-rings. The Belleville spring acts as a lever

to multiply the force applied on to it by the apply pis-

ton. The increased apply force on the rear clutch

pack, in comparison to the front clutch pack, is

needed to hold against the greater torque load

imposed onto the rear pack. The rear clutch is

directly behind the front clutch and is considered a

driving component.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved snap-ring is

used to cushion the application of the clutch pack. In

some transmissions, the snap-ring is selective and

used to adjust clutch pack clearance.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the

clutch retainer. The check-valve is needed to elimi-

nate the possibility of plate drag caused by centrifu-

gal force acting on the residual fluid trapped in the

clutch piston retainer.

Fig. 124 Front Clutch Waved Snap Ring

1 - WAVED SNAP RING

2 - SCREWDRIVER

3 - FRONT CLUTCH ASSEMBLY

Fig. 125 Measuring Front Clutch Plate Clearance

1 - FEELER GAUGE

2 - FRONT CLUTCH ASSEMBLY

21 - 86 31TH AUTOMATIC TRANSAXLERS

CLUTCH - FRONT (Continued)

ProCarManuals.com

Page 1656 of 2399

FLUID

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL AND

CONDITION CHECK

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

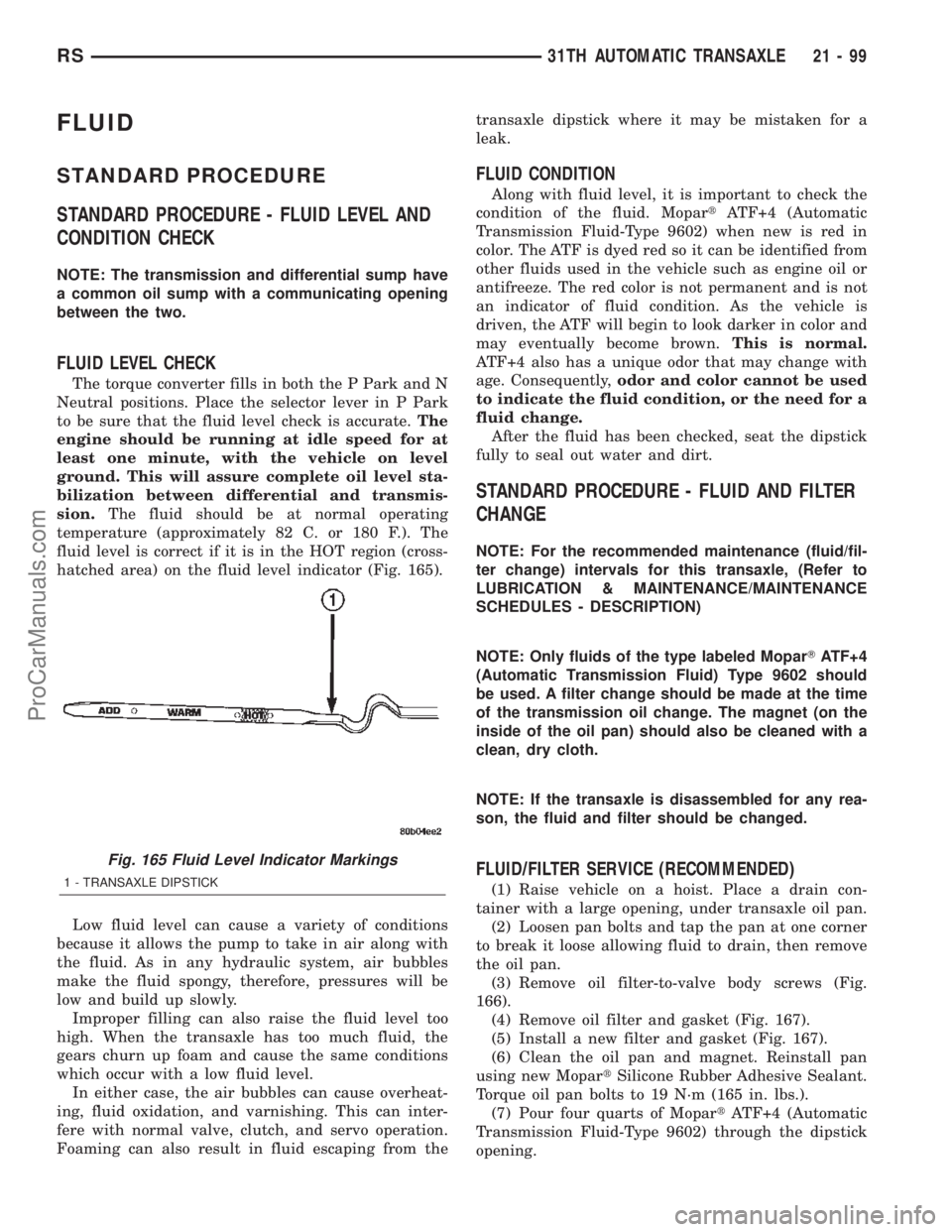

FLUID LEVEL CHECK

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. This will assure complete oil level sta-

bilization between differential and transmis-

sion.The fluid should be at normal operating

temperature (approximately 82 C. or 180 F.). The

fluid level is correct if it is in the HOT region (cross-

hatched area) on the fluid level indicator (Fig. 165).

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming can also result in fluid escaping from thetransaxle dipstick where it may be mistaken for a

leak.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. MopartATF+4 (Automatic

Transmission Fluid-Type 9602) when new is red in

color. The ATF is dyed red so it can be identified from

other fluids used in the vehicle such as engine oil or

antifreeze. The red color is not permanent and is not

an indicator of fluid condition. As the vehicle is

driven, the ATF will begin to look darker in color and

may eventually become brown.This is normal.

ATF+4 also has a unique odor that may change with

age. Consequently,odor and color cannot be used

to indicate the fluid condition, or the need for a

fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

STANDARD PROCEDURE - FLUID AND FILTER

CHANGE

NOTE: For the recommended maintenance (fluid/fil-

ter change) intervals for this transaxle, (Refer to

LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

NOTE: Only fluids of the type labeled MoparTATF+4

(Automatic Transmission Fluid) Type 9602 should

be used. A filter change should be made at the time

of the transmission oil change. The magnet (on the

inside of the oil pan) should also be cleaned with a

clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Place a drain con-

tainer with a large opening, under transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Remove oil filter-to-valve body screws (Fig.

166).

(4) Remove oil filter and gasket (Fig. 167).

(5) Install a new filter and gasket (Fig. 167).

(6) Clean the oil pan and magnet. Reinstall pan

using new MopartSilicone Rubber Adhesive Sealant.

Torque oil pan bolts to 19 N´m (165 in. lbs.).

(7) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid-Type 9602) through the dipstick

opening.

Fig. 165 Fluid Level Indicator Markings

1 - TRANSAXLE DIPSTICK

RS31TH AUTOMATIC TRANSAXLE21-99

ProCarManuals.com