diagram CHRYSLER CARAVAN 2002 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 605 of 2399

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................64

OPERATION...........................64

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................64

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING - VENT WINDOW

MOTOR .............................65

REMOVAL.............................65INSTALLATION.........................65

WINDOW MOTOR

REMOVAL.............................66

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................66

REMOVAL.............................67

INSTALLATION.........................67

POWER WINDOWS

DESCRIPTION

The Power Window System is activated through

switches mounted on the driver and passenger door

panels.

OPERATION

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor

terminal pins will cause the motor to rotate in one

direction. Reversing current through the motor ter-

minals will cause the motor to rotate in the opposite

direction.

The power window motors ground through the

master switch in the driver door by a black wire

attached to the left cowl panel. Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

The power rear vent windows, if equipped, are

operated by switches mounted in the driver door

switch bezel. A separate switch is used for each win-

dow. Permanent magnet type motors connected to a

crank system are used to open and close the rear

vent windows. A battery positive and negative con-

nection to either of the two motor terminals will

cause the motor to rotate in one direction. Reversing

current through these same two connections will

cause the motor to rotate in the opposite direction.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-outinformation and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - POWER

WINDOWS

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove front door trim panel and sound pad as

necessary to gain access to power window motor wire

connector, (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

8N - 64 POWER WINDOWSRS

ProCarManuals.com

Page 606 of 2399

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power window switch and bezel

assembly from the driver door. (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS/POWER WINDOW

SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

25 amp circuit breaker attached to the electrical dis-

tribution wiring bracket. If the circuit breaker is OK,

then check the 40 amp fuse (#28) in the Integrated

Power Module (IPM). If both components are OK,

then check for a broken wire.

²Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING - VENT WINDOW

MOTOR

If the power vent window motor is receiving proper

current and ground and does not operate proceed

with motor test. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

(1) Remove D-pillar trim panel necessary to gain

access to power vent window motor wire connector,

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - REMOVAL) or (Refer to 23 - BODY/

INTERIOR/RIGHT D-PILLAR TRIM PANEL -

REMOVAL).(2) Disconnect power vent window motor wire con-

nector from body harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window open or

closed. If window is all the way open or closed the

motor will grunt and the crank system will flex when

actuated in that one direction.

Reverse jumper probes at the motor connector ter-

minals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely open or closed, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that

crank system is not binding.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove D-pillar trim panel. (Refer to 23 -

BODY/INTERIOR/LEFT D-PILLAR TRIM PANEL -

REMOVAL) or (Refer to 23 - BODY/INTERIOR/

RIGHT D-PILLAR TRIM PANEL - REMOVAL).

(3) Disconnect wire connector from power vent

motor.

(4) Using a flat bladed tool, carefully lift the circu-

lar actuator link tab. Remove link from window ball

socket.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 1).

(6) Remove power vent motor.

INSTALLATION

(1) Obtain new vent window motor.

(2) Snap the actuator link socket onto the quarter

window ball socket. Using a soft rubber mallet, push

the circular link tab flush with link surface.

(3) Install bolts holding power vent motor to D-pil-

lar.

(4) Reconnect wire connector to power vent motor.

(5) Reconnect the battery negative cable.

(6) Cycle quarter window open/close to verify func-

tion.

(7) Install D-pillar trim panel.

RSPOWER WINDOWS8N-65

POWER WINDOWS (Continued)

ProCarManuals.com

Page 634 of 2399

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS,

WARNINGS, BEFORE ATTEMPTING COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System involves the use of

a DRB IIITscan tool. Refer to the proper Body Diag-

nostic Procedures Manual.

The Sentry Key Immobilizer System (SKIS) and

the Programmable Communication Interface (PCI)

bus network should be diagnosed using a DRB IIIt

scan tool. The DRB IIItwill allow confirmation that

the PCI bus is functional, that the Sentry Key Immo-

bilizer Module (SKIM) is placing the proper messages

on the PCI bus, and that the Powertrain Control

Module (PCM) is receiving the PCI bus messages.

Refer to the proper Body Diagnostic Procedures man-

ual, and Wiring Diagrams for complete circuit

descriptions and diagrams.

(1) Check the fuses in the Integrated Power Mod-

ule (IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Disconnect and isolate the battery negative

remote cable from the remote terminal. Unplug the

wire harness connector at the SKIM. Check for con-

tinuity between the ground circuit cavity of the

SKIM wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open circuit to ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the

IPM as required.

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB IIItscan tool

and the proper Body Diagnostic Procedures manual

to complete the diagnosis of the SKIS. If not OK,

repair the open circuit to the fuse in the IPM as

required.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Using a DRB

IIItscan tool. Refer to the proper Body Diagnostic

Procedures Manual for test procedures.

HOOD AJAR SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small flat blade screwdriver, pry trig-

ger switch from the bracket on the left fender well.

(3) Disconnect the hood ajar switch from the wire

connector and remove from vehicle.

INSTALLATION

(1) Connect the hood ajar switch to the wire conec-

tor.

(2) Press the hood ajar switch into position on the

bracket located on the left inner fender well.

(3) Reconnect the battery negative cable.

(4) Close the hood and check for proper operation.

TRANSPONDER KEY

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses a

transponder chip that is integral to each ignition key

(Fig. 1) to communicate with the Sentry Key Immo-

bilizer Module (SKIM). Ignition keys are supplied

with the vehicle when it is shipped from the factory.

The transponder chip is undermolded within the

head of the key. This undermold is hidden beneath

an overmolded rubber cap.

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

9Secret Key9code programmed into it by the manu-

facturer as well. When a Sentry Key is programmed

into the memory of the SKIM, the SKIM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKIM. Once the Sentry Key learns the9Secret

Key9code of the SKIM, it is also permanently pro-

grammed into the transponder's memory. Therefore,

blank keys for the SKIS must be programmed by the

RSVEHICLE THEFT SECURITY8Q-3

VEHICLE THEFT SECURITY (Continued)

ProCarManuals.com

Page 641 of 2399

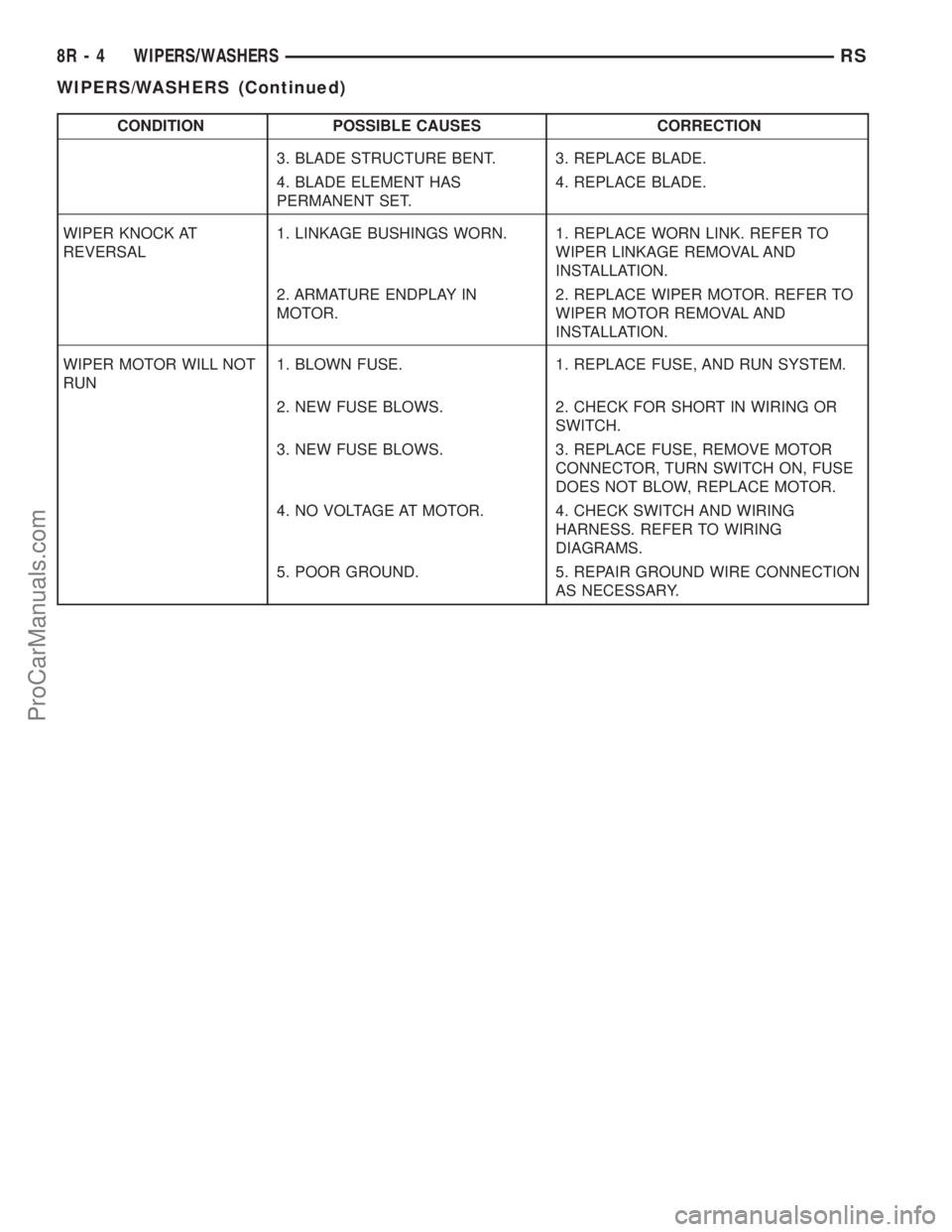

CONDITION POSSIBLE CAUSES CORRECTION

3. BLADE STRUCTURE BENT. 3. REPLACE BLADE.

4. BLADE ELEMENT HAS

PERMANENT SET.4. REPLACE BLADE.

WIPER KNOCK AT

REVERSAL1. LINKAGE BUSHINGS WORN. 1. REPLACE WORN LINK. REFER TO

WIPER LINKAGE REMOVAL AND

INSTALLATION.

2. ARMATURE ENDPLAY IN

MOTOR.2. REPLACE WIPER MOTOR. REFER TO

WIPER MOTOR REMOVAL AND

INSTALLATION.

WIPER MOTOR WILL NOT

RUN1. BLOWN FUSE. 1. REPLACE FUSE, AND RUN SYSTEM.

2. NEW FUSE BLOWS. 2. CHECK FOR SHORT IN WIRING OR

SWITCH.

3. NEW FUSE BLOWS. 3. REPLACE FUSE, REMOVE MOTOR

CONNECTOR, TURN SWITCH ON, FUSE

DOES NOT BLOW, REPLACE MOTOR.

4. NO VOLTAGE AT MOTOR. 4. CHECK SWITCH AND WIRING

HARNESS. REFER TO WIRING

DIAGRAMS.

5. POOR GROUND. 5. REPAIR GROUND WIRE CONNECTION

AS NECESSARY.

8R - 4 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 642 of 2399

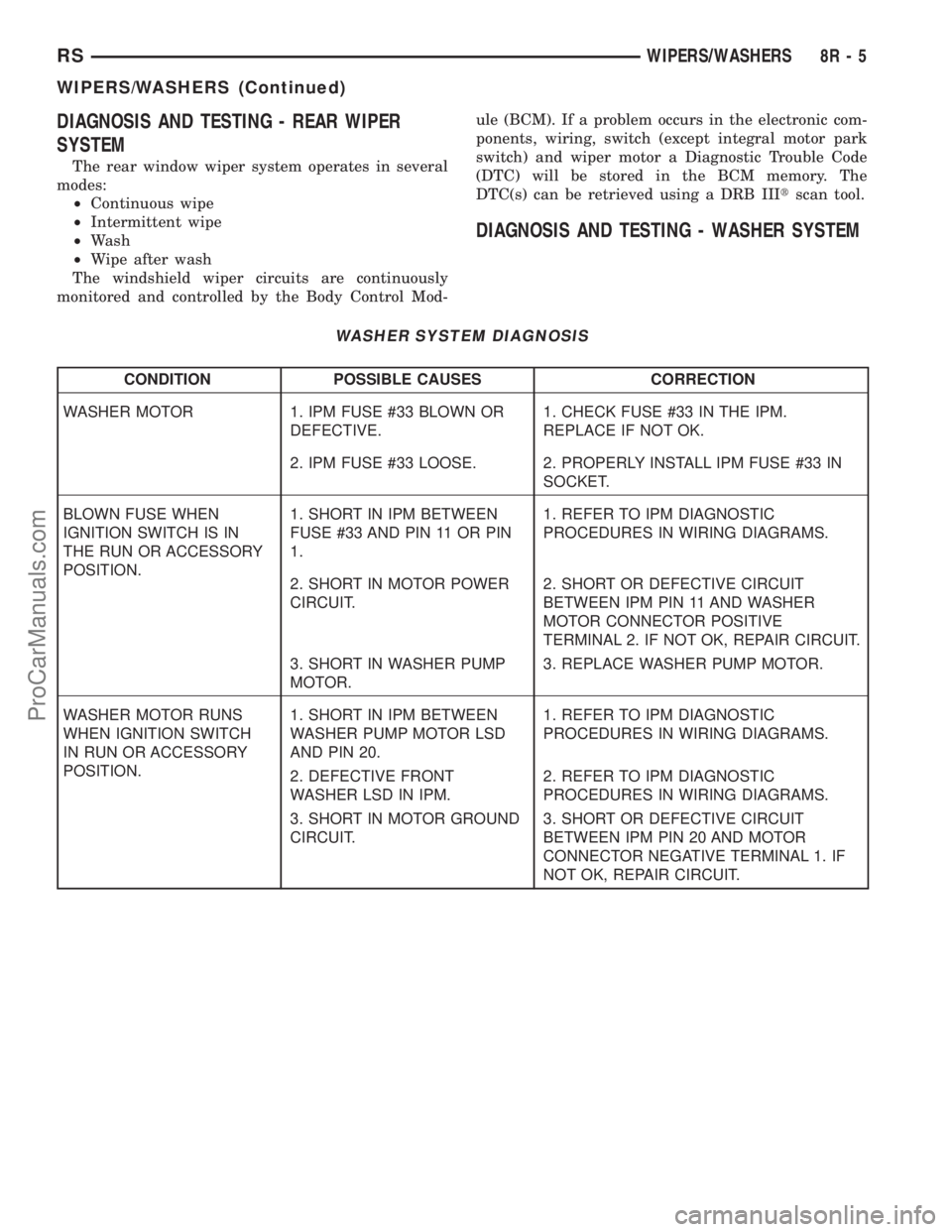

DIAGNOSIS AND TESTING - REAR WIPER

SYSTEM

The rear window wiper system operates in several

modes:

²Continuous wipe

²Intermittent wipe

²Wash

²Wipe after wash

The windshield wiper circuits are continuously

monitored and controlled by the Body Control Mod-ule (BCM). If a problem occurs in the electronic com-

ponents, wiring, switch (except integral motor park

switch) and wiper motor a Diagnostic Trouble Code

(DTC) will be stored in the BCM memory. The

DTC(s) can be retrieved using a DRB IIItscan tool.

DIAGNOSIS AND TESTING - WASHER SYSTEM

WASHER SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

WASHER MOTOR 1. IPM FUSE #33 BLOWN OR

DEFECTIVE.1. CHECK FUSE #33 IN THE IPM.

REPLACE IF NOT OK.

2. IPM FUSE #33 LOOSE. 2. PROPERLY INSTALL IPM FUSE #33 IN

SOCKET.

BLOWN FUSE WHEN

IGNITION SWITCH IS IN

THE RUN OR ACCESSORY

POSITION.1. SHORT IN IPM BETWEEN

FUSE #33 AND PIN 11 OR PIN

1.1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. SHORT IN MOTOR POWER

CIRCUIT.2. SHORT OR DEFECTIVE CIRCUIT

BETWEEN IPM PIN 11 AND WASHER

MOTOR CONNECTOR POSITIVE

TERMINAL 2. IF NOT OK, REPAIR CIRCUIT.

3. SHORT IN WASHER PUMP

MOTOR.3. REPLACE WASHER PUMP MOTOR.

WASHER MOTOR RUNS

WHEN IGNITION SWITCH

IN RUN OR ACCESSORY

POSITION.1. SHORT IN IPM BETWEEN

WASHER PUMP MOTOR LSD

AND PIN 20.1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. DEFECTIVE FRONT

WASHER LSD IN IPM.2. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

3. SHORT IN MOTOR GROUND

CIRCUIT.3. SHORT OR DEFECTIVE CIRCUIT

BETWEEN IPM PIN 20 AND MOTOR

CONNECTOR NEGATIVE TERMINAL 1. IF

NOT OK, REPAIR CIRCUIT.

RSWIPERS/WASHERS8R-5

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 643 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

WASHER SYSTEM WILL

NOT FLOW WASHER

FLUID.1. NO WASHER FLUID IN

RESERVOIR.1. FILL WASHER RESERVOIR.

2. IPM FUSE #33 BLOWN. 2. SHORT OR DEFECTIVE CIRCUIT

BETWEEN IPM PIN 11 AND WASHER

PUMP MOTOR CONNECTOR POSITIVE

TERMINAL 2. INTERNAL SHORT IN IPM. IF

NOT OK, REPAIR CIRCUIT OR REFER TO

IPM DIAGNOSTIC PROCEDURES IN

WIRING DIAGRAMS.

3. WASHER HOSE NOT

FLOWING WASHER FLUID.3. ASSURE WASHER HOSE IS NOT

PINCHED, LOOSE, BROKEN OR

DISCONNECTED. IF NOT OK, PROPERLY

ROUTE OR REPAIR WASHER HOSE.

4. MOTOR CONNECTOR

LOOSE.4. PROPERLY SEAT AND LOCK

CONNECTOR TO MOTOR.

5. MOTOR CONNECTOR

TERMINALS BENT.5. REPAIR TERMINALS AND PROPERLY

SEAT CONNECTOR TO MOTOR.

6. OPEN CIRCUIT TO OR

FROM WASHER SELECT

SWITCH.6. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM BODY CONTROLLER PIN

27 AND WASHER SELECT SWITCH PIN 4,

OR OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM BODY CONTROLLER PIN

22 AND WASHER SELECT SWITCH PIN 2.

IF NOT OK, REPAIR CIRCUIT.

7. OPEN OR DEFECTIVE

WASHER SELECT SWITCH.7. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/MULTI-FUNCTION

SWITCH - DIAGNOSIS AND TESTING).

8. OPEN POWER CIRCUIT TO

MOTOR.8. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM CONNECTOR TERMINAL 11

AND WASHER MOTOR CONNECTOR

POSITIVE TERMINAL 2. INTERNAL OPEN

IN IPM. IF NOT OK, REPAIR CIRCUIT OR

REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

9. OPEN OR DEFECTIVE

MOTOR GROUND CIRCUIT.9. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM CONNECTOR TERMINAL

20 AND WASHER MOTOR CONNECTOR

NEGATIVE TERMINAL 1. INTERNAL OPEN

IN IPM. IF NOT OK, REPAIR CIRCUIT OR

REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

10. OPEN CIRCUIT IN MOTOR. 10. CHECK FOR OPEN CIRCUIT IN MOTOR

BETWEEN POSITIVE TERMINAL 2 AND

NEGATIVE TERMINAL 1. IF NOT OK,

REPLACE WASHER MOTOR.

11. SEIZED MOTOR BEARINGS. 11. APPLY DIRECT BATTERY VOLTAGE TO

MOTOR TERMINALS. IF MOTOR DOES

NOT RUN, REPLACE MOTOR.

8R - 6 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 644 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

COWL GRILLE NOZZLE

WILL NOT FLOW.1. FROZEN NOZZLE. 1. MOVE VEHICLE INTO HEATED AREA TO

ALLOW TIME TO THAW NOZZLE. ASSURE

WASHER FLUID IS PROPERLY BLENDED

FOR AMBIENT OUTSIDE TEMPERATURES.

2. NOZZLE HOSE NOT

FLOWING.2. ASSURE NOZZLE HOSE IS NOT

PINCHED, LOOSE, BROKEN, OR

DISCONNECTED. IF NOT OK, PROPERLY

ROUTE OR REPAIR NOZZLE HOSE.

3. NOZZLE HOSE PLUGGED

BY CONTAMINATION.3. CLEAN NOZZLE HOSE OF

CONTAMINATION. DETERMINE SOURCE

OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

4. NOZZLE PLUGGED BY

CONTAMINATION.4. CLEAN NOZZLE OF CONTAMINATION

OR REPLACE NOZZLE. DETERMINE

SOURCE OF CONTAMINATION. INSPECT

RESERVOIR FOR EXCESSIVE

CONTAMINATION. CLEAN SYSTEM AS

REQUIRED.

5. DEFECTIVE WASHER HOSE

CHECK VALVE.5. REPLACE COWL GRILLE PANEL

WASHER HOSE/CHECK VALVE ASSEMBLY.

WASHER FLUID OUTPUT IS

LOW.1. PARTIALLY PINCHED HOSE. 1. ASSURE WASHER HOSE IS NOT

PARTIALLY PINCHED. IF NOT OK,

PROPERLY ROUTE HOSE.

2. REVERSE POLARITY TO

PUMP.2. CHECK FOR CROSSED CIRCUIT TO

PUMP. IF NOT OK, REPAIR CIRCUIT.

3. WORN OUT WASHER PUMP. 3. REPLACE WASHER PUMP.

COWL GRILLE NOZZLE

STREAM OVERSHOOTS

WINDSHIELD.1. NOZZLE NOT SEATED IN

COWL GRILLE.1. ASSURE NOZZLE IS SNAPPED IN

PLACE.

2. NOZZLE JET(S) OUT OF

ADJUSTMENT.2. ADJUST NOZZLE JET(S) USING A

SAFETY PIN.

WIPER WILL NOT CYCLE

WHEN WASHER SELECT

SWITCH IS DEPRESSED.1. DEFECTIVE IPM. 1. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

2. DEFECTIVE IPM/BODY

CONTROLLER.2. REFER TO IPM/BODY CONTROLLER

DIAGNOSTIC PROCEDURES IN WIRING

DIAGRAMS.

WASHER OPERATES

INTERMITTENTLY.1. INTERMITTENT MOTOR

GROUND.INTERMITTENT GROUND BETWEEN

MOTOR CONNECTOR TERMINAL 1 AND

IPM PIN 20.

2. INTERMITTENT OPEN IN

WASHER SELECT SWITCH.2. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/MULTI-FUNCTION

SWITCH - DIAGNOSIS AND TESTING).

3. DEFECTIVE WASHER

MOTOR.3. REPLACE WASHER MOTOR.

RSWIPERS/WASHERS8R-7

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 645 of 2399

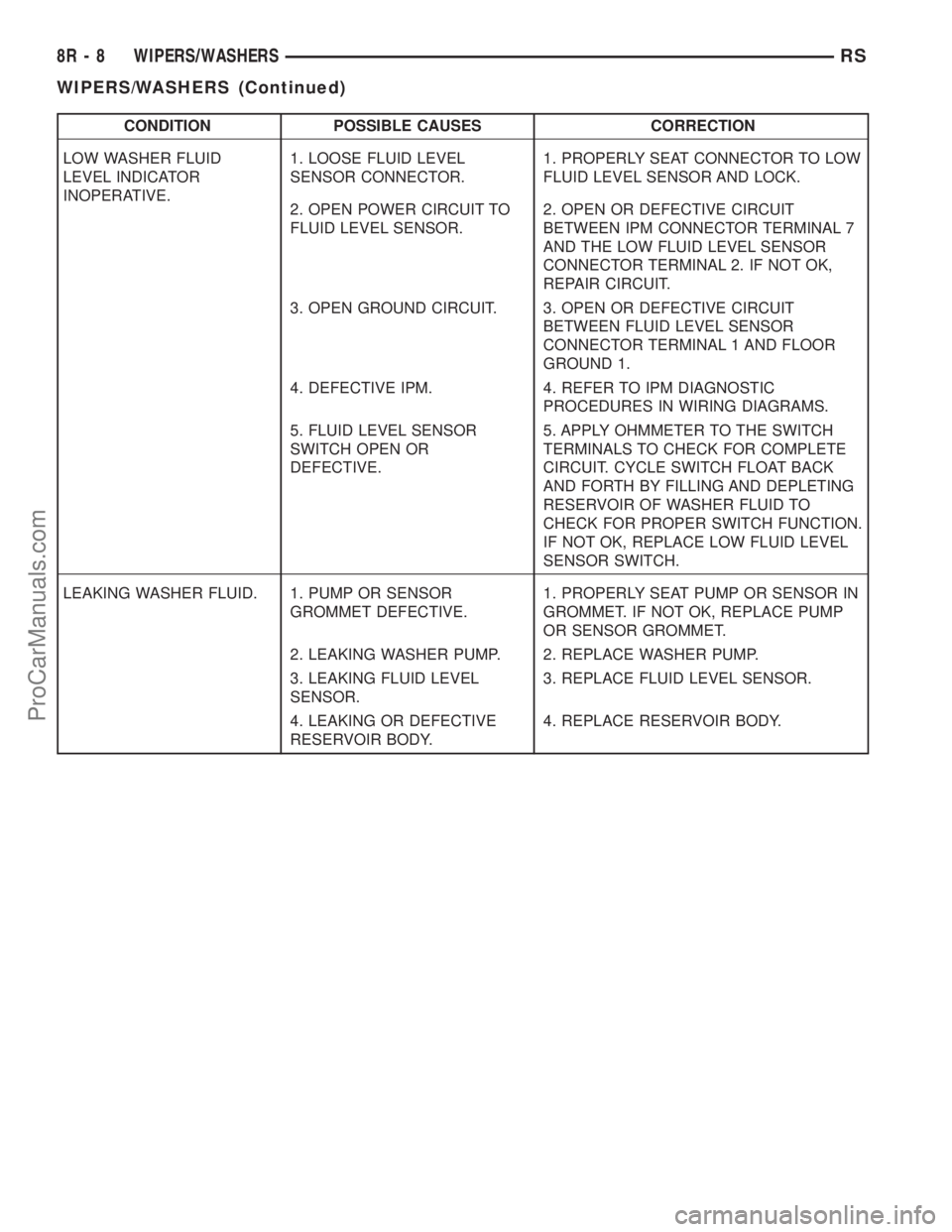

CONDITION POSSIBLE CAUSES CORRECTION

LOW WASHER FLUID

LEVEL INDICATOR

INOPERATIVE.1. LOOSE FLUID LEVEL

SENSOR CONNECTOR.1. PROPERLY SEAT CONNECTOR TO LOW

FLUID LEVEL SENSOR AND LOCK.

2. OPEN POWER CIRCUIT TO

FLUID LEVEL SENSOR.2. OPEN OR DEFECTIVE CIRCUIT

BETWEEN IPM CONNECTOR TERMINAL 7

AND THE LOW FLUID LEVEL SENSOR

CONNECTOR TERMINAL 2. IF NOT OK,

REPAIR CIRCUIT.

3. OPEN GROUND CIRCUIT. 3. OPEN OR DEFECTIVE CIRCUIT

BETWEEN FLUID LEVEL SENSOR

CONNECTOR TERMINAL 1 AND FLOOR

GROUND 1.

4. DEFECTIVE IPM. 4. REFER TO IPM DIAGNOSTIC

PROCEDURES IN WIRING DIAGRAMS.

5. FLUID LEVEL SENSOR

SWITCH OPEN OR

DEFECTIVE.5. APPLY OHMMETER TO THE SWITCH

TERMINALS TO CHECK FOR COMPLETE

CIRCUIT. CYCLE SWITCH FLOAT BACK

AND FORTH BY FILLING AND DEPLETING

RESERVOIR OF WASHER FLUID TO

CHECK FOR PROPER SWITCH FUNCTION.

IF NOT OK, REPLACE LOW FLUID LEVEL

SENSOR SWITCH.

LEAKING WASHER FLUID. 1. PUMP OR SENSOR

GROMMET DEFECTIVE.1. PROPERLY SEAT PUMP OR SENSOR IN

GROMMET. IF NOT OK, REPLACE PUMP

OR SENSOR GROMMET.

2. LEAKING WASHER PUMP. 2. REPLACE WASHER PUMP.

3. LEAKING FLUID LEVEL

SENSOR.3. REPLACE FLUID LEVEL SENSOR.

4. LEAKING OR DEFECTIVE

RESERVOIR BODY.4. REPLACE RESERVOIR BODY.

8R - 8 WIPERS/WASHERSRS

WIPERS/WASHERS (Continued)

ProCarManuals.com

Page 658 of 2399

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

ANTILOCK BRAKES................... 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING-HEATER........... 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1

BODY CONTROL MODULE............. 8W-45-1MESSAGE CENTER................... 8W-46-1

AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION SYSTEM........ 8W-97-1 RSWIRING

8W-1

ProCarManuals.com

Page 660 of 2399

8W-01 WIRING DIAGRAM INFORMATION

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS...........................1

DESCRIPTION - CIRCUIT INFORMATION....5

DESCRIPTION - CIRCUIT FUNCTIONS......6

DESCRIPTION - SECTION IDENTIFICATION

AND INFORMATION....................6

DESCRIPTION - CONNECTOR, GROUND

AND SPLICE INFORMATION..............7

WARNING

WARNINGS - GENERAL.................7

DIAGNOSIS AND TESTING - WIRING

HARNESS............................7

STANDARD PROCEDURE

STANDARD PROCEDURE -

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES...................8

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL...................9

STANDARD PROCEDURE - TESTING FOR

CONTINUITY..........................9STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND...................9

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES

POWERING SEVERAL LOADS...........10

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP......................10

SPECIAL TOOLS

WIRING/TERMINAL....................10

CONNECTOR

REMOVAL.............................11

INSTALLATION.........................11

DIODE

REMOVAL.............................14

INSTALLATION.........................14

TERMINAL

REMOVAL.............................14

INSTALLATION.........................14

WIRE

STANDARD PROCEDURE - WIRE SPLICING . . 15

WIRING DIAGRAM

INFORMATION

DESCRIPTION

DESCRIPTION - HOW TO USE WIRING

DIAGRAMS

DaimlerChrysler Corporation wiring diagrams are

designed to provide information regarding the vehi-

cles wiring content. In order to effectively use the

wiring diagrams to diagnose and repair

DaimlerChrysler Corporation vehicles, it is important

to understand all of their features and characteris-

tics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page (Fig. 1).

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition (Fig. 2).Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around the component indi-

cates that the component is being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

SYMBOLS

International symbols are used throughout the wir-

ing diagrams. These symbols are consistent with

those being used around the world (Fig. 3).

RS8W-01 WIRING DIAGRAM INFORMATION8W-01-1

ProCarManuals.com