sensor CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1695 of 2177

OPERATION

The relay is supplied fused B+ voltage, energized

by the PCM/TCM, and is used to supply power to the

solenoid pack when the transmission is in normal

operating mode. When the relay is ªoffº, no power is

supplied to the solenoid pack and the transmission is

in ªlimp-inº mode. After a controller reset (ignition

key turned to the ªrunº position or after cranking

engine), the PCM/TCM energizes the relay. Prior to

this, the PCM/TCM verifies that the contacts are

open by checking for no voltage at the switched bat-

tery terminals. After this is verified, the voltage at

the solenoid pack pressure switches is checked. After

the relay is energized, the PCM/TCM monitors the

terminals to verify that the voltage is greater than 3

volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

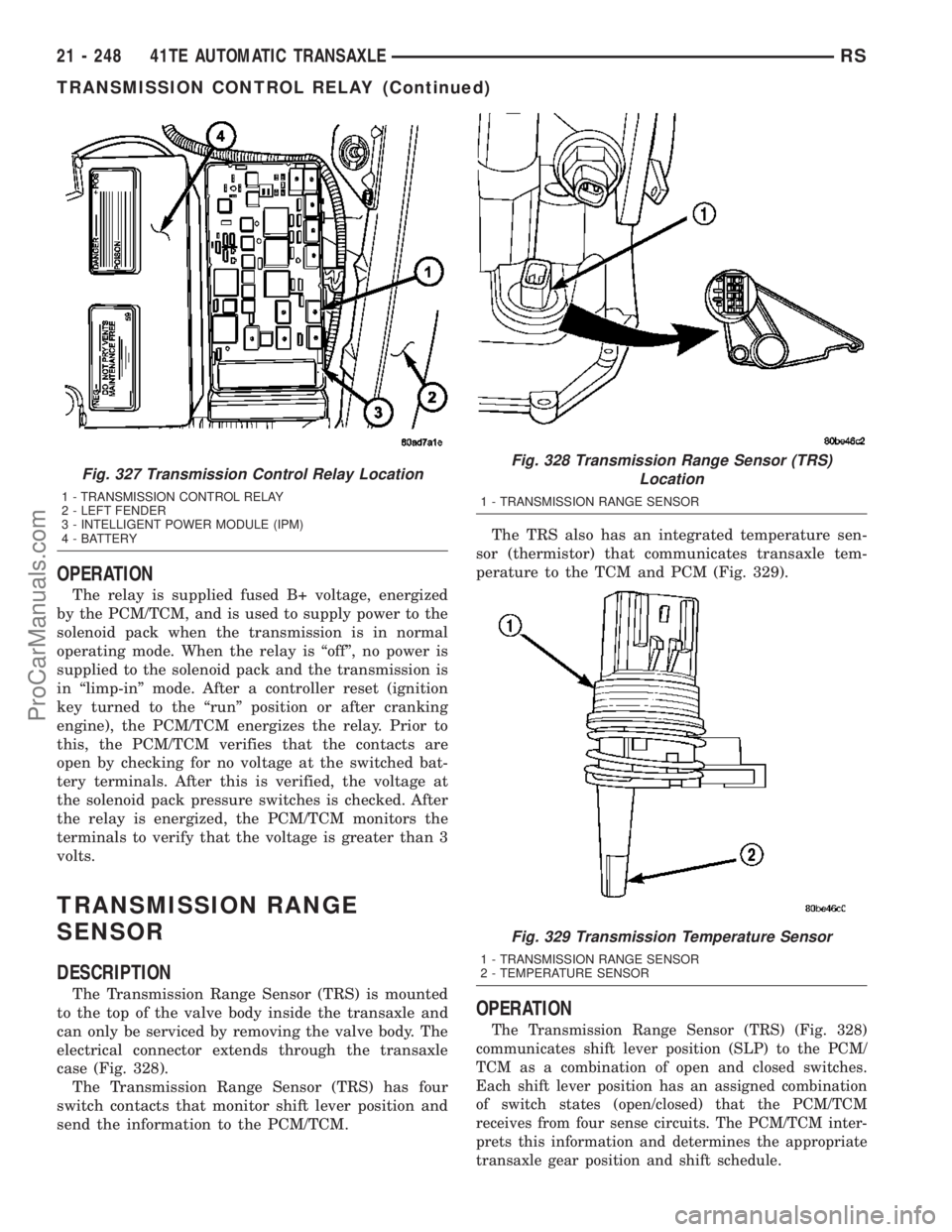

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle and

can only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 328).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 329).

OPERATION

The Transmission Range Sensor (TRS) (Fig. 328)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combination

of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM inter-

prets this information and determines the appropriate

transaxle gear position and shift schedule.

Fig. 327 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 328 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 329 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 248 41TE AUTOMATIC TRANSAXLERS

TRANSMISSION CONTROL RELAY (Continued)

ProCarManuals.com

Page 1696 of 2177

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 329)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 330).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 330) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

TRD LINK

DESCRIPTION

The Torque Reduction Link (TRD) is a wire

between the PCM and TCM that is used by the TCM

to request torque management. Torque management

controls or reduces torque output of the engine dur-

ing certain shift sequences, reducing torque applied

to the transaxle clutches.

OPERATION

The torque management signal is basically a

12-volt pull-up supplied by the PCM to the TCM over

the torque reduction link (TRD). Torque management

is requested when the TCM pulses this signal to

ground. The PCM recognizes this request and

responds by retarding ignition timing, killing fuel

injectors, etc. The PCM sends a confirmation of the

request to the TCM via the communication bus.

Torque reduction is not noticable by the driver, and

usually lasts for a very short period of time.

If the confirmation signal is not received by the

TCM after two sequential request messages, a diag-

nostic trouble code will be set.

Fig. 330 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS41TE AUTOMATIC TRANSAXLE21 - 249

TRANSMISSION RANGE SENSOR (Continued)

ProCarManuals.com

Page 1700 of 2177

(1) Remove manual shaft seal (Fig. 338).

(2) Remove Transmission Range Sensor retaining

screw (Fig. 339).(3) Remove Manual Shaft/Rooster Comb and

Transmission Range Sensor (Fig. 340).

(4) Remove 2/4 Accumulator Retaining Plate (Fig.

341).

Fig. 338 Manual Shaft Seal

1 - SEAL

2 - MANUAL SHAFT

Fig. 339 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

Fig. 340 Manual Shaft/Rooster Comb and

Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL SHAFT

3 - ROOSTER COMB

Fig. 341 2/4 Accumulator Retaining Plate

1 - 2±4 ACCUMULATOR RETAINING PLATE

2 - DETENT SPRING

RS41TE AUTOMATIC TRANSAXLE21 - 253

VALVE BODY (Continued)

ProCarManuals.com

Page 1708 of 2177

(12) Install 2/4 Accumulator components as shown

in (Fig. 364).

(13) Torque 2/4 Accumulator retainer to 5 N´m (45

in. lbs.) (Fig. 365).(14) Install Manual Shaft/Rooster Comb and

Transmission Range Sensor (Fig. 366).

(15) Make sure Manual Valve control pin is con-

tained within the rooster comb slot (Fig. 367). Install

Transmission Range Sensor retaining screw (Fig.

367) and torque to 5 N´m (45 in. lbs.).

Fig. 364 2/4 Accumulator Assembly

1 - VALVE BODY

2 - RETAINER PLATE

3 - DETENT SPRING

4 - SPRINGS

5 - SEALS

6 - PISTON

Fig. 365 2/4 Accumulator Retaining Plate

1 - 2±4 ACCUMULATOR RETAINING PLATE

2 - DETENT SPRING

Fig. 366 Install Manual Shaft/Rooster Comb and

Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL SHAFT

3 - ROOSTER COMB

Fig. 367 Install Transmission Range Sensor

Retaining Screw

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS41TE AUTOMATIC TRANSAXLE21 - 261

VALVE BODY (Continued)

ProCarManuals.com

Page 1710 of 2177

(3) Ensure the transaxle oil pan and transaxle

case sealing surfaces are clean and dry. Install an

1/8º bead of MopartSilicone Rubber Adhesive Seal-

ant to the oil pan and install (Fig. 372). Torque oil

pan-to-transaxle case bolts (Fig. 373) to 19 N´m (165

in. lbs.).

(4) Lower vehicle.

(5) Connect transmission range sensor connector.(6) Install manual valve lever to manual shaft.

(7) Install gearshift cable to manual valve lever.

(8) Connect battery negative cable.

(9) Fill transaxle with MopartATF +4 Transmis-

sion fluid. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 372 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

Fig. 373 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

RS41TE AUTOMATIC TRANSAXLE21 - 263

VALVE BODY (Continued)

ProCarManuals.com

Page 1712 of 2177

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL VIBRATION.....................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................5

STANDARD PROCEDURE - TIRE AND

WHEEL MATCH MOUNTING..............7

STANDARD PROCEDURE - TIRE AND

WHEEL ROTATION.....................7

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)....................7

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL).......................8

INSTALLATION

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (ALUMINUM WHEEL)..........8

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (STEEL WHEEL)..............8

TIRE PRESSURE MONITORING

DESCRIPTION..........................9

OPERATION............................9

SENSOR - TPM

DESCRIPTION.........................10

OPERATION...........................10

CAUTION.............................10

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR............................10

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN....................10

REMOVAL.............................11

INSTALLATION.........................12

TIRES

DESCRIPTION

DESCRIPTION - TIRE..................13

DESCRIPTION - RADIAL-PLY TIRES.......14DESCRIPTION - REPLACEMENT TIRES....14

DESCRIPTION - SPARE TIRE

(TEMPORARY).......................14

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE . . . 14

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD...............................14

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS..........................16

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS.........................16

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE INFLATION

PRESSURES.........................16

STANDARD PROCEDURE - TIRE

PRESSURE FOR HIGH SPEED

OPERATION.........................17

STANDARD PROCEDURE - TIRE LEAK

REPAIRING..........................17

CLEANING - TIRES.....................17

WHEELS

DESCRIPTION - WHEEL..................18

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................18

CLEANING - ALUMINUM WHEEL CARE......18

SPECIFICATIONS

WHEEL.............................19

WHEEL COVER

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................19

WHEEL MOUNTING STUDS - FRONT

REMOVAL.............................20

INSTALLATION.........................21

WHEEL MOUNTING STUDS - REAR

REMOVAL.............................21

INSTALLATION.........................22

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

VIBRATION

Tire and wheel imbalance, runout and force varia-

tion can cause vehicles to exhibit steering wheel

vibration.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended

prior to road testing or performing any other proce-

dure. Raise vehicle on a suitable hoist. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

Inspect for the following:

²Verify correct (OEM) wheel and tire, as well as

correct wheel weights. Aluminum wheels require

RSTIRES/WHEELS22-1

ProCarManuals.com

Page 1720 of 2177

(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires (excludes spare).

Pressure in the spare tire is not monitored.

There is a sensor (transmitter) in each of the vehi-

cle's four road wheels. The system alerts the driver

when tire pressure falls outside predetermined

thresholds (pressure too low or too high). A message

is then displayed on the Electronic Vehicle Informa-

tion Center (EVIC) located in the overhead console.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit tire pressure read-

ings to a receiver located in the overhead console.

These transmissions occur once every minute at

speeds over 20 mph (32 km/h). The Tire Pressure

Monitoring system remains active even if no tire

pressure related message is displayed in the EVIC.

If any road tire pressure has exceeded the low or

high pressure threshold (refer to chart below), the

TPM system will display a message in the EVIC and

sound a chime. This message will be displayed for

the rest of the ignition cycle, or until either the Low/

High Tire pressure condition has been corrected. If

the C/T, MENU, STEP or RESET button is pressed,

the message is replaced by the new message

requested; however, if the Low/High Tire condition

has not been corrected, the Low/High Tire pressure

message will again be displayed.

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1721 of 2177

If a road tire is replaced by the spare, the TPM

system will detect the swap and the message9SPARE

TIRE IN USE? Y/N9(along with a chime) will be dis-

played.

For further information, refer to the Owners Man-

ual or the Appropriate Diagnostic Information.

TPM THRESHOLD PRESSURES

High Pressure ON Threshold 48 PSI (331 kPa)

High Pressure OFF Threshold 43 PSI (296 kPa)

Placard Pressure (Cold) 36 PSI (248 kPa)

Low Pressure OFF Threshold 33 PSI (228 kPa)

Low Pressure ON Threshold 28 PSI (193 kPa)

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each

wheel (Fig. 19). Each sensor has an internal battery

that lasts up to 10 years. The battery is not service-

able. At the time of battery failure, the sensor must

be replaced. The serviceable components of the tire

pressure sensor are:

²Sensor-To-Wheel Grommet

²Valve Stem Cap

²Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

CAUTION: Do not try to install a tire pressure sen-

sor in a steel wheel or aftermarket wheel. Use only

in original style factory wheels.

OPERATION

Tire pressure sensors are battery operated. They

transmit tire pressure data once every minute at

speeds above 20 mph (32 km/h) or up to once every

hour when stationary (parked). For additional infor-

mation, refer to Appropriate Diagnostic Information.

CAUTION

CAUTION: The use of tire sealants is strictly prohib-

ited for vehicles equipped with the Tire Pressure

Monitoring system. Tire sealants can clog tire pres-

sure sensors.

CAUTION: Tire pressure sensor valve stem caps

and cores are specially designed for the sensors.

Due to risk of corrosion, do not use a standard

valve stem cap or core in a tire pressure sensor in

place of the original equipment style sensor cap

and core.

CAUTION: Do not attempt to install a tire pressure

sensor in a steel wheel or aftermarket wheel. Use

tire pressure sensors in original style factory

wheels only.

NOTE: TPM thresholds have been established for

the original tire size equipped on the vehicle. Use

original size tires only to maintain system accuracy.

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR

NOTE: Tire pressure may increase from 2 to 6 psi

(14 to 41 kPa) during normal driving conditions. Do

NOT reduce this normal pressure build up.

If a fault in the system is detected, always check

air pressure in the tires first with a known accurate

air gauge and correct the inflation pressure. If any

tire is low, inspectalltires.

If gauge-read pressure in the tires does not reflect

the reading on the EVIC, retrain the sensors, then

reevaluate (Refer to 22 - TIRES/WHEELS/TIRE

PRESSURE MONITORING/SENSOR - STANDARD

PROCEDURE). Refer to the appropriate diagnostic

information for complete diagnosis of the Tire Pres-

sure Monitoring System.

STANDARD PROCEDURE - TIRE PRESSURE

SENSOR RETRAIN

WARNING: DEATH OR SERIOUS INJURY CAN

OCCUR IF MAGNETICALLY SENSITIVE DEVICES

ARE EXPOSED TO THE RELEARN MAGNET. MAG-

NETS CAN AFFECT PACEMAKERS.

22 - 10 TIRES/WHEELSRS

TIRE PRESSURE MONITORING (Continued)

ProCarManuals.com

Page 1722 of 2177

CAUTION: Never attempt to train more than one

vehicle at a time. System is capable of reading tire

pressure sensor transmissions from other near-by

vehicles.

Each time a wheel rotation or tire pressure sensor

replacement occurs the tire pressure sensors must be

retrained. This is necessary to inform the Electronic

Vehicle Information Center (EVIC) that a sensor

change was made and where. Retraining is accom-

plished through the EVIC used in conjunction with a

Re-learn Magnet, Special Tool 8821.

NOTE: Use the following procedure to retrain all

four (4) road wheel tire pressure sensors. No

attempt should be made to retrain individual sen-

sors.

(1) Retrieve Re-learn Magnet, Special Tool 8821.

(2) Press MENU Button on EVIC until9RETRAIN

TIRE SENSORS - NO9is displayed.

(3) Press STEP button to select9YES9.

NOTE: There is a 60 second timer for training the

first sensor and a 60 second timer between training

the remaining sensors. If any of these timers expire,

the EVIC will abort the training procedure.

NOTE: If at any time the EVIC display reads(TRAIN-

ING ABORTED(, move the vehicle ahead at least

one foot and repeat the entire retraining procedure.

(4) Press MENU button to start retraining. Dis-

play will read9TRAIN LEFT FRONT TIRE9

NOTE: The order for retraining all four sensors is:

²Left Front

²Right Front

²Right Rear

²Left Rear

(5) Starting at left front tire, place Re-learn Mag-

net over valve stem (Fig. 17). Within approximately 5

seconds, vehicle horn will chirp indicating training

complete at that particular sensor. Remove the mag-

net.

(6) Repeat step (5) on remaining sensors as indi-

cated by EVIC until all four TPM sensors positions

are trained.

(7) Once EVIC displays9TRAINING COMPLETE9,

pressing either STEP, C/T, RESET or MENU button

will exit training routine.

REMOVAL

(1) Remove tire and wheel assembly from vehicle.

(Refer to 22 - TIRES/WHEELS - REMOVAL)

CAUTION: The cap used on this valve stem con-

tains an O-ring seal to prevent contamination and

moisture from entering the valve stem. Retain this

valve stem cap for reuse. Do not substitute a regu-

lar valve stem cap in its place.

CAUTION: The valve stem used on this vehicle is

made of aluminum and the core is nickel plated

brass. The original valve stem core must be rein-

stalled and not substituted with a valve stem core

made of a different material. This is required to pre-

vent corrosion in the valve stem caused by the dif-

ferent metals.

(2) Dismount tire from wheel following tire

changer manufacturers instructions while paying

special attention to the following to avoid damaging

the pressure sensor:

(a) When breaking the tire bead loose from the

wheel rim, avoid using the Bead Breaker in the

area of the sensor. That includes both front and

rear beads of the tire.

(b) When preparing to dismount the tire from

the wheel, carefully insert the mounting/dimount-

ing tool at the valve stem 10É (Fig. 18), then pro-

ceed to dismount the tire from the wheel. Use this

process on both the upper and lower tire beads.

(3) Using a thin wall socket, remove special nut

retaining sensor to wheel (Fig. 19).

(4) Remove sensor from wheel (Fig. 19).

Fig. 17 Magnet Placement Over Valve Stem

1 - RE-LEARN MAGNET

2 - VALVE STEM

RSTIRES/WHEELS22-11

SENSOR - TPM (Continued)

ProCarManuals.com

Page 1723 of 2177

INSTALLATION

NOTE: Before reinstalling a tire pressure sensor,

replace sealing grommet at base of valve stem.

(1) Wipe area clean where sensor sealing grommet

contacts wheel. Make sure surface of wheel is not

damaged.

(2) Install sensor in wheel as shown (Fig. 19). Do

not attempt to mount sensor otherwise, damage may

occur.

(3) Using a thin wall socket, install special sensor

nut (Fig. 19). Tighten nut to 4 N´m (35 in. lbs.)

torque.

CAUTION: Over-torquing the sensor nut by as little

as 12 N´m (106 in. lbs.) may result in sensor sepa-

ration from the valve stem. Under this condition,

the sensor may still function, however, the condi-

tion should be corrected immediately.

(4) Mount tire on wheel following tire changer

manufacturers instructions, paying special attention

to the following to avoid damaging tire pressure sen-

sor:

(a) Rotating Wheel Tire Changers - Once the

wheel is mounted to the changer, position the sen-

sor valve stem approximately 210É from the head

of the changer in a clockwise direction before rotat-

ing the wheel (also in a clockwise direction) to

mount the tire (Fig. 20). Use this procedure on

both the upper and lower tire beads.

(b) Rotating Tool Tire Changers - Position the

wheel on the changer so that the sensor valve stem

is approximately 210É from the head of the changer

in a clockwise direction from the mounting end of

the tool (Fig. 21) Make sure the sensor is clear of

the lower bead breaker area to avoid damaging the

sensor when the breaker rises (Fig. 21). Rotate the

tool in a counterclockwise direction to mount the

tire. Use this procedure on both the upper and

lower tire beads.

(5) Install wheel and tire assembly on vehicle.

(Refer to 22 - TIRES/WHEELS - INSTALLATION)

(6) Retrain tire pressure sensors. (Refer to 22 -

TIRES/WHEELS/TIRE PRESSURE MONITORING/

SENSOR - STANDARD PROCEDURE)

Fig. 18 Start Mount/Dismount Tool Within 10

Degrees Of Valve Stem

Fig. 19 Sensor Mounting To Wheel

1 - TIRE PRESSURE SENSOR

2 - WHEEL

3 - NUT

22 - 12 TIRES/WHEELSRS

SENSOR - TPM (Continued)

ProCarManuals.com