ESP CHRYSLER CARAVAN 2003 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 336 of 2177

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indices

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

²Diagnostic capabilities (with DRB scan tool)

CLUTCH VOLUME INDEX (CVI)

An important function of the TCM is to monitor

Clutch Volume Index (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

The TCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the TCM that represents input shaft rpm. The Out-

put Speed Sensor provides the TCM with output

shaft speed information.

By comparing the two inputs, the TCM can deter-

mine transaxle gear ratio. This is important to the

CVI calculation because the TCM determines CVIs

by monitoring how long it takes for a gear change to

occur (Fig. 17).

Gear ratios can be determined by using the DRB

Scan Tool and reading the Input/Output Speed Sen-

sor values in the ªMonitorsº display. Gear ratio can

be obtained by dividing the Input Speed Sensor value

by the Output Speed Sensor value.

For example, if the input shaft is rotating at 1000

rpm and the output shaft is rotating at 500 rpm,

then the TCM can determine that the gear ratio is

2:1. In direct drive (3rd gear), the gear ratio changes

to 1:1. The gear ratio changes as clutches are applied

and released. By monitoring the length of time it

takes for the gear ratio to change following a shift

request, the TCM can determine the volume of fluid

used to apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated foradaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.

Certain mechanical problems within the clutch

assemblies (broken return springs, out of position

snap rings, excessive clutch pack clearance, improper

assembly, etc.) can cause inadequate or out-of-range

clutch volumes. Also, defective Input/Output Speed

Sensors and wiring can cause these conditions. The

following chart identifies the appropriate clutch vol-

umes and when they are monitored/updated:

CLUTCH VOLUMES

ClutchWhen Updated

Proper Clutch

Volume

Shift Sequence Oil Temperature Throttle Angle

L/R2-1 or 3-1 coast

downshift>70É <5É 35to83

2/4 1-2 shift

> 110É5 - 54É20 to 77

OD 2-3 shift 48 to 150

UD 4-3 or 4-2 shift > 5É 24 to 70

Fig. 17 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

RSELECTRONIC CONTROL MODULES8E-21

TRANSMISSION CONTROL MODULE (Continued)

ProCarManuals.com

Page 347 of 2177

service, the composition of this battery reduces gas-

sing and water loss at normal charge rates. However

these batteries may require additional distilled water

after years of service.

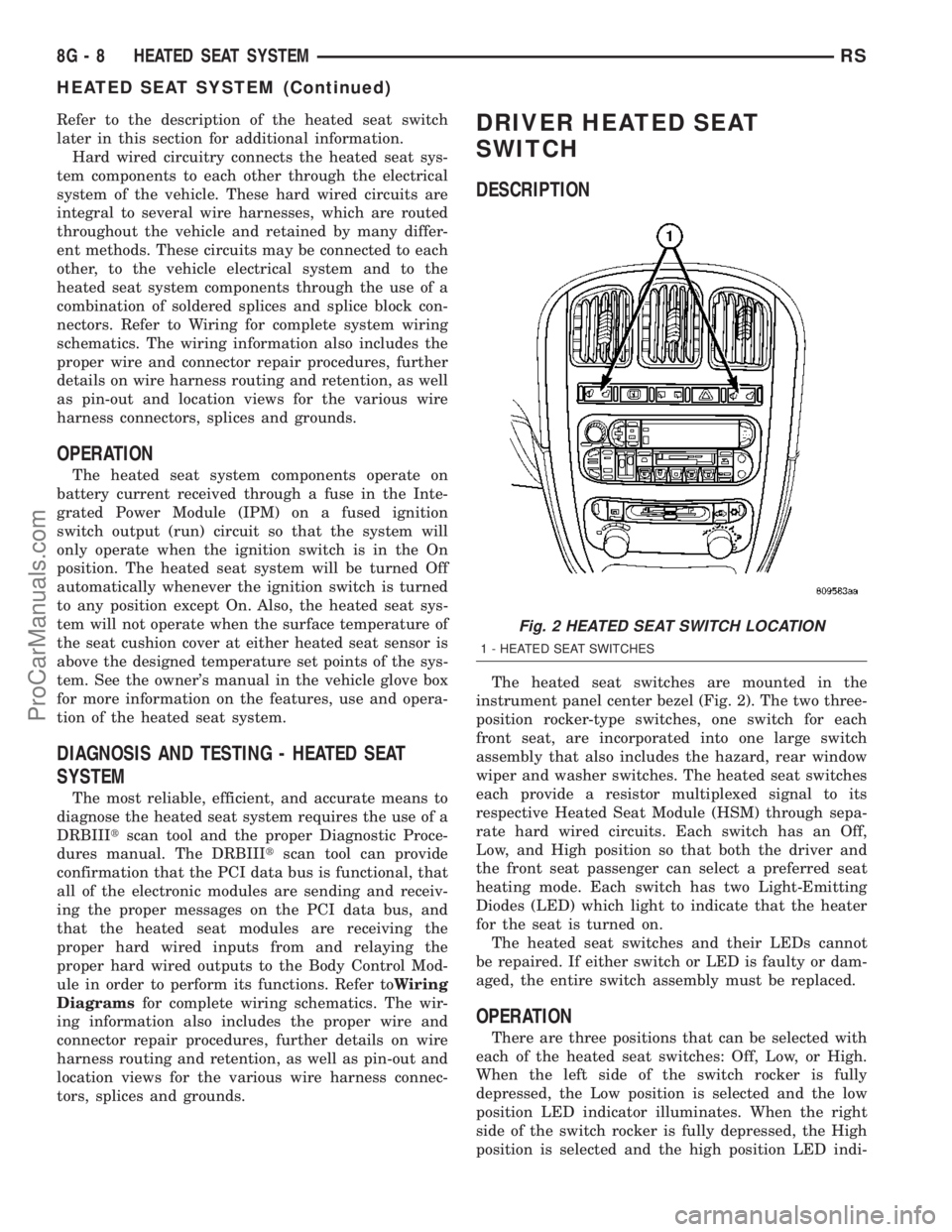

Maintenance-free batteriesare standard facto-

ry-installed equipment on all domestic versions of

this model. Male post type terminals made of a soft

lead material protrude from the top of the molded

plastic battery case (Fig. 6)to provide the means for

connecting the battery to the vehicle electrical sys-

tem. The battery positive terminal post is visibly

larger in diameter than the negative terminal post,

for easy identification. The lettersPOSandNEGare

also molded into the top of the battery case adjacent

to their respective positive and negative terminal

posts for additional identification confirmation.

This battery is designed to provide a safe, efficient

and reliable means of storing electrical energy in a

chemical form. This means of energy storage allows

the battery to produce the electrical energy required

to operate the engine starting system, as well as to

operate many of the other vehicle accessory systems

for limited durations while the engine and/or the

charging system are not operating. The battery is

made up of six individual cells that are connected in

series. Each cell contains positively charged plate

groups that are connected with lead straps to the

positive terminal post, and negatively charged plate

groups that are connected with lead straps to thenegative terminal post. Each plate consists of a stiff

mesh framework or grid coated with lead dioxide

(positive plate) or sponge lead (negative plate). Insu-

lators or plate separators made of a non-conductive

material are inserted between the positive and nega-

tive plates to prevent them from contacting or short-

ing against one another. These dissimilar metal

plates are submerged in a sulfuric acid and water

solution called an electrolyte.

Some factory-installed batteries have a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. For more information on the use of the built-in

test indicator, refer toStandard Procedures. The

chemical composition of the metal coated plates

within the low-maintenance battery used in export

models reduces battery gassing and water loss at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, distilled water must be added. How-

ever, rapid loss of electrolyte can be caused by an

overcharging condition. Be certain to diagnose the

charging system after replenishing the water in the

battery for a low electrolyte condition and before

returning the vehicle to service. Refer toCharging

Systemfor additional information.

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

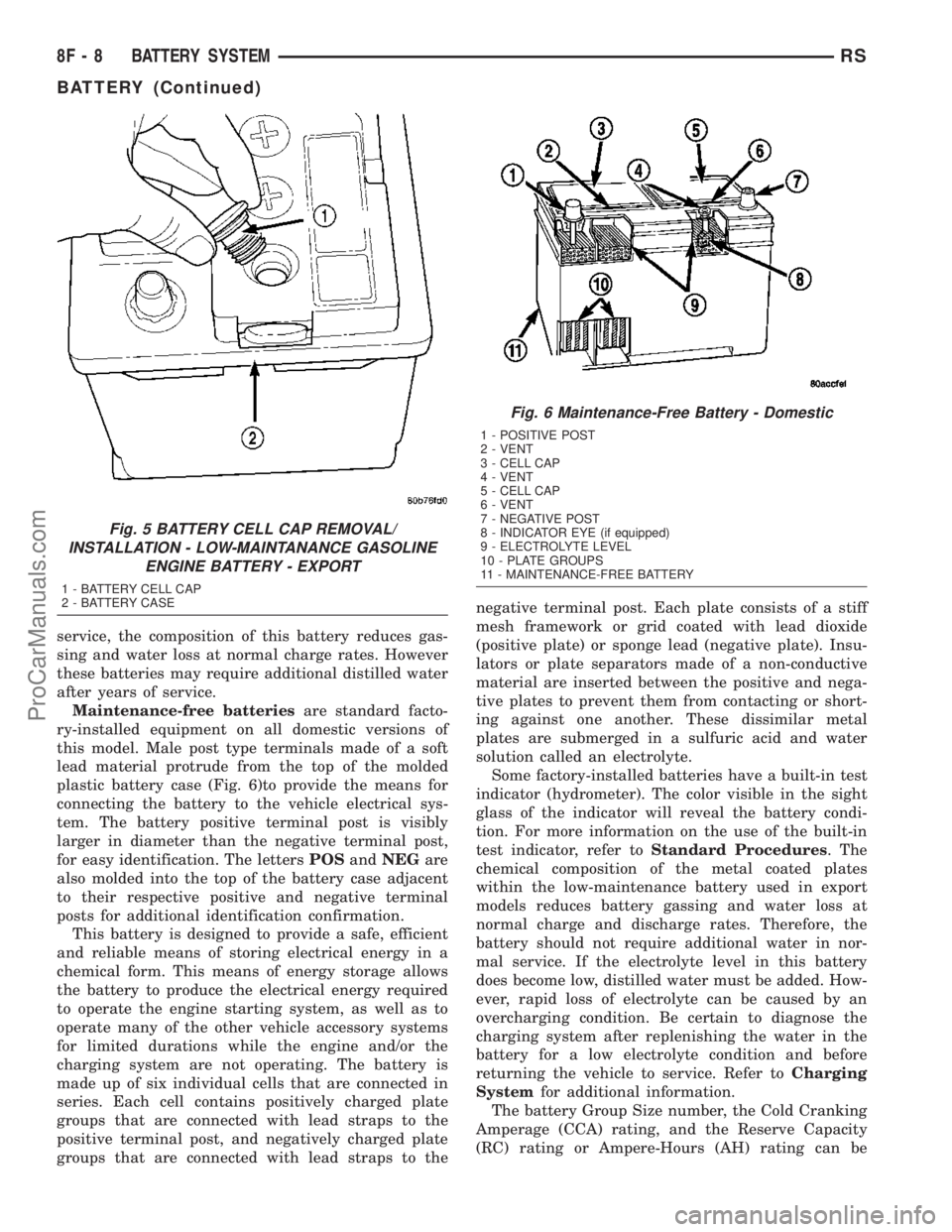

Fig. 5 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTANANCE GASOLINE

ENGINE BATTERY - EXPORT

1 - BATTERY CELL CAP

2 - BATTERY CASE

Fig. 6 Maintenance-Free Battery - Domestic

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - VENT

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

8 - INDICATOR EYE (if equipped)

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - MAINTENANCE-FREE BATTERY

8F - 8 BATTERY SYSTEMRS

BATTERY (Continued)

ProCarManuals.com

Page 383 of 2177

Refer to the description of the heated seat switch

later in this section for additional information.

Hard wired circuitry connects the heated seat sys-

tem components to each other through the electrical

system of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

heated seat system components through the use of a

combination of soldered splices and splice block con-

nectors. Refer to Wiring for complete system wiring

schematics. The wiring information also includes the

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

The heated seat system components operate on

battery current received through a fuse in the Inte-

grated Power Module (IPM) on a fused ignition

switch output (run) circuit so that the system will

only operate when the ignition switch is in the On

position. The heated seat system will be turned Off

automatically whenever the ignition switch is turned

to any position except On. Also, the heated seat sys-

tem will not operate when the surface temperature of

the seat cushion cover at either heated seat sensor is

above the designed temperature set points of the sys-

tem. See the owner's manual in the vehicle glove box

for more information on the features, use and opera-

tion of the heated seat system.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

The most reliable, efficient, and accurate means to

diagnose the heated seat system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual. The DRBIIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the heated seat modules are receiving the

proper hard wired inputs from and relaying the

proper hard wired outputs to the Body Control Mod-

ule in order to perform its functions. Refer toWiring

Diagramsfor complete wiring schematics. The wir-

ing information also includes the proper wire and

connector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

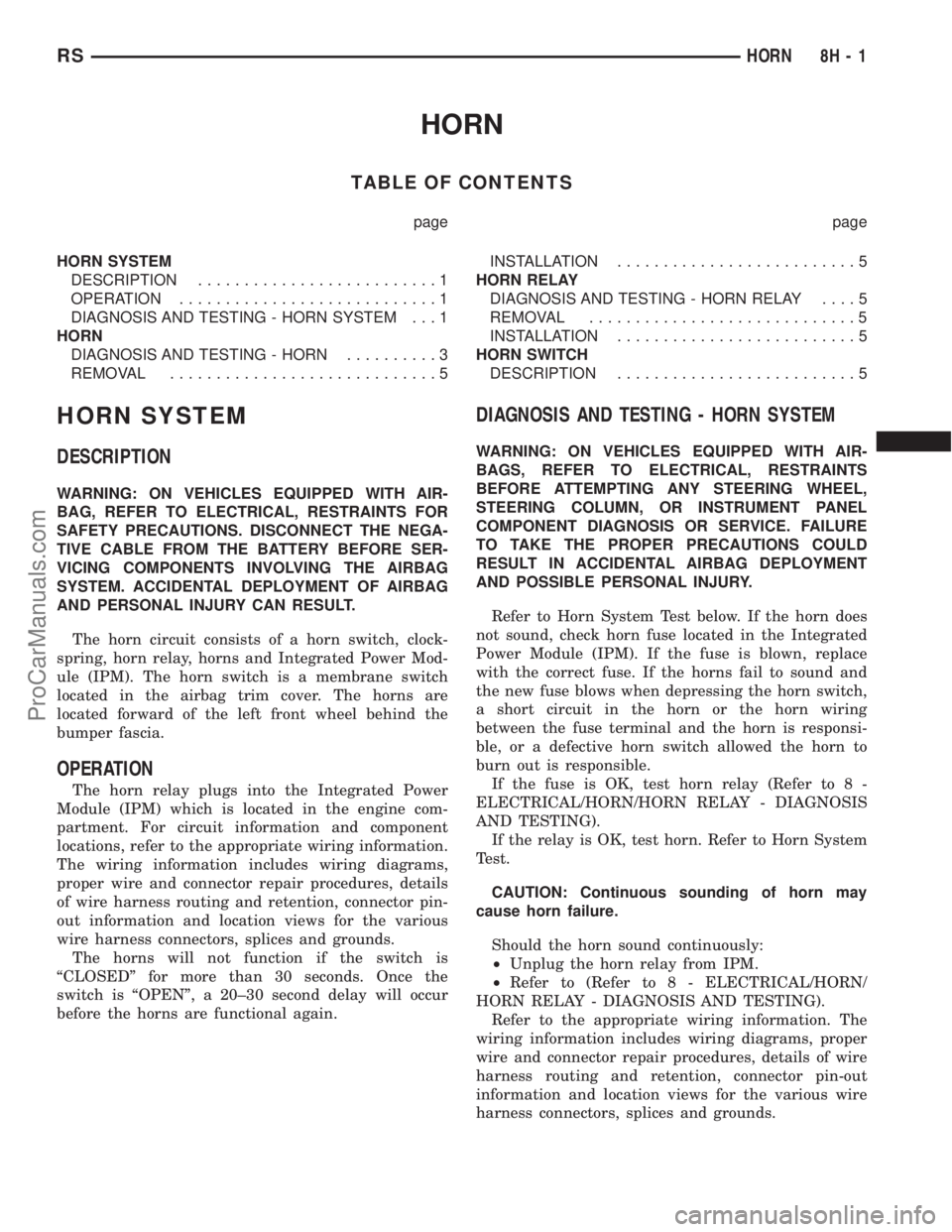

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 2). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

each provide a resistor multiplexed signal to its

respective Heated Seat Module (HSM) through sepa-

rate hard wired circuits. Each switch has an Off,

Low, and High position so that both the driver and

the front seat passenger can select a preferred seat

heating mode. Each switch has two Light-Emitting

Diodes (LED) which light to indicate that the heater

for the seat is turned on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-

Fig. 2 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

8G - 8 HEATED SEAT SYSTEMRS

HEATED SEAT SYSTEM (Continued)

ProCarManuals.com

Page 384 of 2177

cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Each switch provides separate resistor multiplexed

hard wire inputs to its respective Heated Seat Mod-

ule (HSM) to indicate the selected switch position.

The heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - DRIVER HEATED

SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Place the heated seat switch in the LO posi-

tion. Using an Ohmmeter, check the resistance

between cavities 2 and 3 of the gray connector noted

above. Resistance should be about 3.5 kilohms (3500

ohms). If not OK, check resistance directly at switch,

as noted below. If OK, proceed to the next step. If not

OK, replace the faulty switch.

(4) Place the heated seat switch in the HI position.

Using an ohmmeter, check the resistance between

cavities 2 and 3 of the gray connector noted above.

Resistance should be about 1.4 kilohms (1400 ohms).

If not OK, check resistance directly at switch, as

noted below. If OK, proceed. If not OK replace the

faulty switch.

(5) With the system ON in the HI position, check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

not OK, repair open or shorted wiring.

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL). Check for continuity between the ground circuit

cavity (#10) of the instrument panel switch bank

electrical connector and a good ground. There should

be continuity. If OK, go to Step 2. If not OK, repair

the open ground circuit to ground as required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 3). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

DRIVER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin4&5OPEN

Low Pin4&53570

High Pin4&51430

All resistance values are 1%.

Fig. 3 Instrument Panel Switch Bank Connector

RSHEATED SEAT SYSTEM8G-9

DRIVER HEATED SEAT SWITCH (Continued)

ProCarManuals.com

Page 387 of 2177

OPERATION

The temperature sensor is a NTC thermistor.

When the temperature of the seat cushion cover

rises, the resistance of the sensor decreases. The

heated seat module supplies a five-volt current to one

side of each sensor, and monitors the voltage drop

through the sensor on a return circuit. The heated

seat module uses this temperature sensor input to

monitor the temperature of the seat, and regulates

the current flow to the seat heating elements accord-

ingly.

DIAGNOSIS AND TESTING - HEATED SEAT

SENSOR

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable. Disconnect the green 4-way heated seat mod-

ule wire harness connector.

(2) Using an ohmmeter, check the resistance

between cavities 2 and 3. The sensor resistance

should be between 50 kilohms at 15É C (60É F) and 2

kilohms at 30É C (85É F). If not OK, replace the

faulty seat element and sensor assembly.

PASSENGER HEATED SEAT

SWITCH

DESCRIPTION

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 6). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazard, rear window

wiper and washer switches. The heated seat switches

each provide a resistor multiplexed signal to its

respective Heated Seat Module (HSM) through sepa-

rate hard wired circuits. Each switch has an Off,

Low, and High position so that both the driver and

the front seat passenger can select a preferred seat

heating mode. Each switch has two Light-Emitting

Diodes (LED) which light to indicate that the heater

for the seat is turned on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-

Fig. 5 HEATING ELEMENT INSTALLED - TYPICAL

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

Fig. 6 HEATED SEAT SWITCH LOCATION

1 - HEATED SEAT SWITCHES

8G - 12 HEATED SEAT SYSTEMRS

HEATED SEAT SENSOR (Continued)

ProCarManuals.com

Page 388 of 2177

cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Each switch provides separate resistor multiplexed

hard wire inputs to its respective Heated Seat Mod-

ule (HSM) to indicate the selected switch position.

The heated seat module responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL). Check for continuity between the ground circuit

cavity (#10) of the instrument panel switch bank

electrical connector and a good ground. There should

be continuity. If OK, go to Step 2. If not OK, repair

the open ground circuit to ground as required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 7). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are 1%.

Fig. 7 Instrument Panel Switch Bank Connector

RSHEATED SEAT SYSTEM8G-13

PASSENGER HEATED SEAT SWITCH (Continued)

ProCarManuals.com

Page 390 of 2177

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........3

REMOVAL.............................5INSTALLATION..........................5

HORN RELAY

DIAGNOSIS AND TESTING - HORN RELAY....5

REMOVAL.............................5

INSTALLATION..........................5

HORN SWITCH

DESCRIPTION..........................5

HORN SYSTEM

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, REFER TO ELECTRICAL, RESTRAINTS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and Integrated Power Mod-

ule (IPM). The horn switch is a membrane switch

located in the airbag trim cover. The horns are

located forward of the left front wheel behind the

bumper fascia.

OPERATION

The horn relay plugs into the Integrated Power

Module (IPM) which is located in the engine com-

partment. For circuit information and component

locations, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING - HORN SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the Integrated

Power Module (IPM). If the fuse is blown, replace

with the correct fuse. If the horns fail to sound and

the new fuse blows when depressing the horn switch,

a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble, or a defective horn switch allowed the horn to

burn out is responsible.

If the fuse is OK, test horn relay (Refer to 8 -

ELECTRICAL/HORN/HORN RELAY - DIAGNOSIS

AND TESTING).

If the relay is OK, test horn. Refer to Horn System

Test.

CAUTION: Continuous sounding of horn may

cause horn failure.

Should the horn sound continuously:

²Unplug the horn relay from IPM.

²Refer to (Refer to 8 - ELECTRICAL/HORN/

HORN RELAY - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

RSHORN8H-1

ProCarManuals.com

Page 403 of 2177

KNOCK SENSOR

DESCRIPTION

The knock sensor threads into the cylinder block.

The knock sensor is designed to detect engine vibra-

tion that is caused by detonation.

OPERATION

When the knock sensor detects a knock in one of

the cylinders, it sends an input signal to the PCM. In

response, the PCM retards ignition timing for all cyl-

inders by a scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives as an input the knock sensor voltage signal.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except WOT.

The PCM, using short term memory, can respond

quickly to retard timing when engine knock is

detected. Short term memory is lost any time the

ignition key is turned off.

NOTE: Over or under tightening affects knock sen-

sor performance, possibly causing improper spark

control.

REMOVAL

REMOVAL - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Disconnect electrical connector from knock sen-

sor.(2) Use a crow foot socket to remove the knock

sensors.

REMOVAL - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) On All Wheel Drive vehicles remove the PTU

(Power Transfer Unit), refer to the Transmission sec-

tion for more information.

(4) Disconnect electrical connector from knock sen-

sor.

(5) Use a crow foot socket to remove the knock

sensor.

INSTALLATION

INSTALLATION - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

Fig. 12 Knock Sensor

1 - GENERATOR

2 - INTAKE MANIFOLD

3 - KNOCK SENSOR

4-STARTER

8I - 8 IGNITION CONTROLRS

ProCarManuals.com

Page 408 of 2177

INSTRUMENT CLUSTER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INSTRUMENT CLUSTER

INOPERATIVE. NO

RESPONSE FROM

INSTRUMENT CLUSTER.NO PCI BUS MESSAGES

FROM THE BCM.USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

IF OK, LOOK FOR ANOTHER POSSIBLE CAUSE

FOR CLUSTER FAILURE. IF NOT OK, REFER TO

THE PROPER BODY DIAGNOSTIC PROCEDURES

MANUAL.

SPREAD TERMINAL(S)

ON WIRING HARNESS

CLUSTER CONNECTOR.REMOVE CLUSTER FROM INSTRUMENT PANEL

AND CHECK WIRING HARNESS CONNECTOR FOR

SPREAD TERMINAL. IF OK, LOOK FOR ANOTHER

POSSIBLE CAUSE FOR THE CLUSTER FAILURE. IF

NOT OK, REPAIR CONNECTOR.

BCM IS NOT RECEIVING

PROPER INPUT FROM

THE IGNITION SWITCH.1. USE A DRB IIITSCAN TOOL TO VERIFY IGNITION

SWITCH STATUS INTO THE BCM. IF NOT OK, GO

TO STEP (2). IF OK, LOOK AT ANOTHER POSSIBLE

CAUSE OF FAILURE.

2. CHECK IGNITION SWITCH FUNCTION AND

WIRING.

INTERNAL CLUSTER

FAILURE.REPLACE CLUSTER.

WAKE UP CIRCUIT

FAULTY.VERIFY CONTINUITY OF WAKE UP CIRCUIT FROM

BCM TO MIC. CIRCUIT SHALL BE LOW WHENEVER

BCM IS AWAKE.

POWER OR GROUND

MISSING.IF NO RESPONSE FROM THE MIC, CHECK FOR

POWER AND GROUND AT THE MIC CONNECTOR.

REFER TO WIRING DIAGRAMS FOR CONNECTOR

CALL OUTS.

RSINSTRUMENT CLUSTER8J-3

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 445 of 2177

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this section may be

required to restore proper compass operation.

DESCRIPTION - TEMPERATURE

All the available overhead consoles on this model

include Temperature information. The temperature

displays the outside ambient temperature in whole

degrees. The temperature display can be toggled

from Fahrenheit to Celsius by selecting the desired

U.S./Metric option from the customer programmable

features. The displayed temperature is not an instant

reading of conditions, but an average temperature. It

may take the temperature display several minutes to

respond to a major temperature change, such as driv-

ing out of a heated garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the electronic control modules (CT, CMTC, EVIC)

memory. When the ignition switch is turned to the

On position again, the electronic module will display

the memory temperature for one minute; then update

the display to the current average temperature read-

ing within five minutes.

The temperature function is supported by an ambi-

ent temperature sensor. The sensor is mounted out-

side the passenger compartment near the front and

center of the vehicle, and is hard wired to the Front

Control Module (FCM). The FCM sends temperature

status messages to the module over the J1850 PCI

data bus circuit.

Following are general descriptions of the major

components used in the overhead console. Refer to

Wiring Diagrams for complete circuit schematics.

OPERATION

Refer to the vehicle Owner's Manual for specific

operation of each overhead console and its systems.

DIAGNOSIS AND TESTING - OVERHEAD

CONSOLE

If the problem with the overhead console is an

inaccurate or scrambled display, refer toSelf-Diag-

nostic Testbelow. If the problem with the overhead

console is incorrect Vacuum Fluorescent Display

(VFD) dimming levels, use a DRB IIItscan tool and

the proper Diagnostic Procedures manual to test for

the correct dimming message inputs being received

from the Body Control Module (BCM) or Front Con-

trol Module (FCM) over the J1850 Programmable

Communications Interface (PCI) data bus circuit. If

the problem is a no-display condition, use the follow-

ing procedures. For complete circuit diagrams, refer

toOverhead Consolein the Wiring Diagrams sec-

tion of the service manual.(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

fused B(+) fuse in the integrated power module as

required.

(3) Check the fused ignition switch output (run/

start) fuse in the integrated power module. If OK, go

to Step 4. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the integrated power mod-

ule. If OK, go to Step 5. If not OK, repair the open

fused ignition switch output (run/start) circuit to the

ignition switch as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavity of the roof wire

harness connector for the electronics module and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the electronics mod-

ule. If OK, go to Step 7. If not OK, repair the open

fused B(+) circuit to the fused B(+) fuse in the inte-

grated power module as required.

(7)

Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the electronics module. If OK, refer

toSelf-Diagnostic Test

later this group for further

diagnosis of the electronics module and the J1850

PCI data bus circuit. If not OK, repair the open fused

ignition switch output (run/start) circuit to the fuse

in the integrated power module as required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

electronics module is operating properly, and that all

the J1850 PCI data bus messages are being received

for initial operation. Initiate the self-diagnostic test

as follows:

(1) With the ignition switch in the Off position, on

Electronic Vehicle Information Center (EVIC) and

Compass Mini-Trip Computer (CMTC) equipped vehi-

cles simultaneously depress and hold theSTEP and

the RESET buttons. On Compass Temperature

Module (CT) equipped vehicles depress theC/T and

the US/M push buttons.

8M - 2 MESSAGE SYSTEMSRS

OVERHEAD CONSOLE (Continued)

ProCarManuals.com