bulb CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 330 of 2177

OPERATION - SENSOR RETURN - PCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the Powertrain Control Module

(PCM).

OPERATION - DATA BUS COMMUNICATION

RECEIVE - PCM INPUT

The PCM uses the SCI communication bus to pre-

form engine diagnostics and flash operations. The

transmission side of the PCM uses the SCI commu-

nication bus to flash new software. However, diagnos-

tics is performed via the vehicles J1850 bus for the

transmission side of the PCM.

OPERATION - IGNITION SENSE - PCM INPUT

The ignition sense input informs the Powertrain

Control Module (PCM) that the ignition switch is in

the crank or run position.

OPERATION - PCM GROUND

Ground is provided through multiple pins of the

PCM connector. Depending on the vehicle there may

be as many as two different ground pins. There are

power grounds and sensor grounds.

The power grounds are used to control the ground

side relays, solenoids, ignition coil or injectors. The

signal ground is used for any input that uses sensor

return for ground, and the ground side of any inter-

nal processing component.

The PCM case is shielded to prevent RFI and EMI.

The PCM case is grounded and must be firmly

attached to a good, clean body ground.

Internally all grounds are connected together, how-

ever there is noise suppression on the sensor ground.

For EMI and RFI protection the housing and cover

are also grounded separately from the ground pins.

OPERATION

OPERATION - 8-VOLT SUPPLY - PCM OUTPUT

- SBEC CONTROLLER

The PCM supplies 8 volts to the crankshaft posi-

tion sensor, camshaft position sensor.

OPERATION - 5 VOLT SUPPLY - PCM OUTPUT

The PCM supplies 5 volts to the following sensors:

²A/C pressure transducer

²Ambient Temperature sensor

²Battery temperature

²Camshaft Position Sensor (NGC)

²Crankshaft Position Sensor (NGC)

²Electronic Throttle Control (1.6L)²Engine coolant temperature sensor

²Inlet Air Temperature Sensor

²Knock sensor

²Linear EGR solenoid (if equipped)

²Manifold absolute pressure sensor

²Oil Pressure Switch

²Pedal Position Sensor (1.6L)

²Throttle position sensor

²Vehicle Speed Sensor

STANDARD PROCEDURE

STANDARD PROCEDURE - OBTAINING

DIAGNOSTIC TROUBLE CODES

BULB CHECK

Key on: Bulb illuminated until vehicle starts, as

long as all once per trip (readiness) monitors com-

pleted. If monitors havenotbeen completed, then:

Key on: bulb check for about 5 to 8 seconds, lamp

then flashes if once per trip (readiness) monitors

havenotbeen completed until vehicle is started,

then MIL is extinguished.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

STANDARD PROCEDURE - PINION FACTOR

SETTING

NOTE: This procedure must be performed if the

PCM/TCM has been replaced with a NEW or

replacement unit. Failure to perform this procedure

will result in an inoperative or improperly calibrated

speedometer.

The vehicle speed readings for the speedometer are

taken from the output speed sensor. The PCM/TCM

must be calibrated to the different combinations of

equipment (final drive and tires) available. Pinion

Factor allows the technician to set the Powertrain/

Transmission Control Module initial setting so that

the speedometer readings will be correct. To properly

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 406 of 2177

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................2REMOVAL.............................10

INSTALLATION.........................10

CLUSTER LENS

REMOVAL.............................10

INSTALLATION.........................10

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The Mechanical Instrument Cluster (MIC) with a

tachometer is equipped with a electronic vacuum flu-

orescent transmission range indicator (PRND3L),

odometer, and trip odometer display.

The MIC without a tachometer is equipped with a

Light Emitting Diode (LED) transmission range indi-

cator (PRND3L) and a vacuum fluorescent odometer

display.

The MIC is equipped with the following warning

lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Oil Pressure

²MIL (Malfunction Indicator Lamp)

²VTSS/SKIS Indicator

²Airbag

²Traction Control

²Autostick

The MIC without a tachometer also has the follow-

ing warning lamps:

²Turns Signals

²High Beam

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the message

center. When moisture is found within the fuel sys-

tem, the sensor sends a message via the PCI data

bus to the instrument cluster. The MIC illuminates

the bulb in the message center, The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

ProCarManuals.com

Page 407 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic prob-

lems. Prior to any test, perform the Self-Diagnostic

Test. The self diagnostic system displays instrument

cluster stored fault codes in the odometer display,

sweeps the gauges to the calibration points, and bulb

checks the warning indicators. When the key is in the

ON position with the engine not running, the MIL will

remain illuminated for regulatory purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

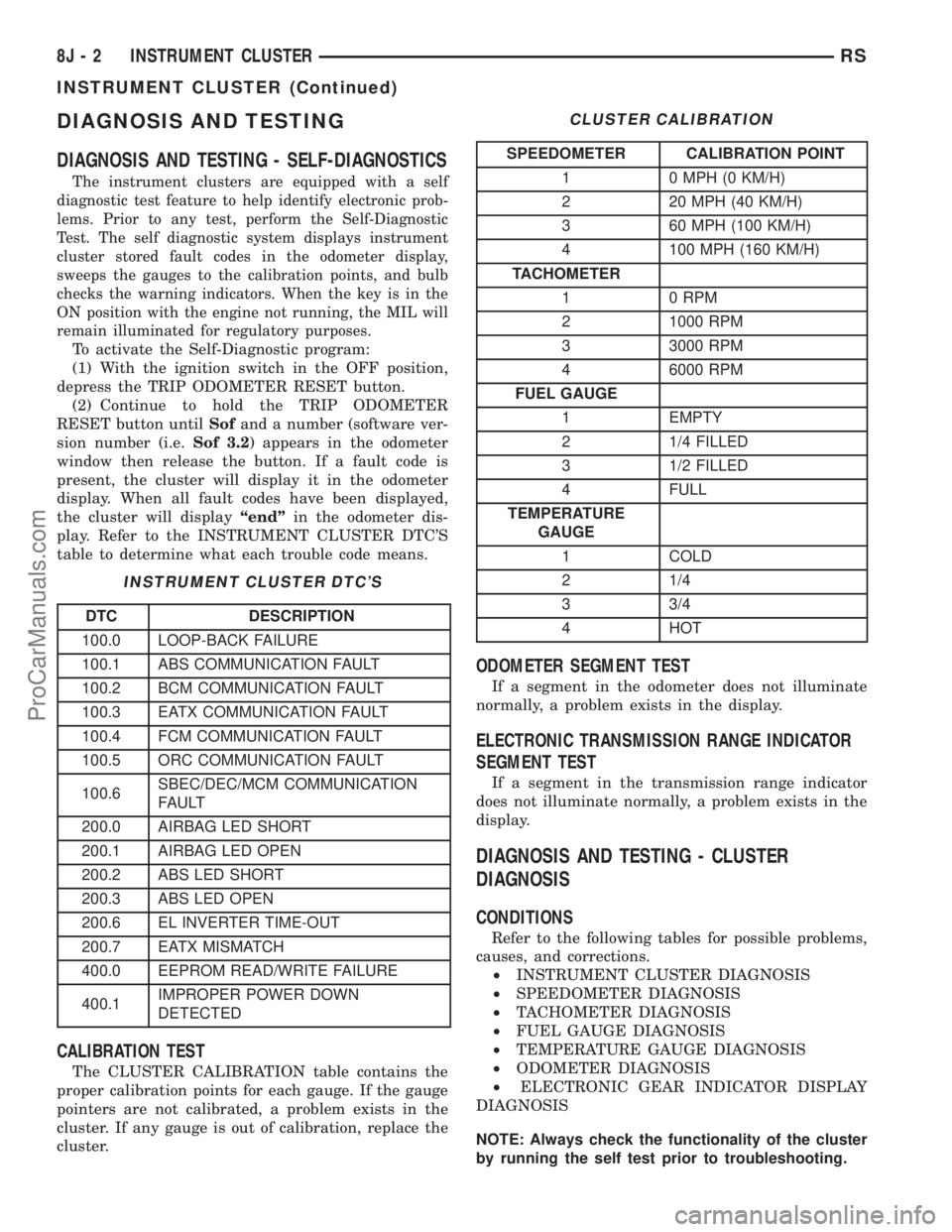

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS

CONDITIONS

Refer to the following tables for possible problems,

causes, and corrections.

²INSTRUMENT CLUSTER DIAGNOSIS

²SPEEDOMETER DIAGNOSIS

²TACHOMETER DIAGNOSIS

²FUEL GAUGE DIAGNOSIS

²TEMPERATURE GAUGE DIAGNOSIS

²ODOMETER DIAGNOSIS

²ELECTRONIC GEAR INDICATOR DISPLAY

DIAGNOSIS

NOTE: Always check the functionality of the cluster

by running the self test prior to troubleshooting.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 417 of 2177

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM.....21

OPERATION - TURN SIGNAL SYSTEM.......21

DIAGNOSIS AND TESTING - MULTI-

FUNCTION SWITCH...................21

REMOVAL.............................21

INSTALLATION.........................21

PARK/TURN SIGNAL LAMP

REMOVAL.............................21

INSTALLATION.........................21

PARK/TURN SIGNAL LAMP - EXPORT

REMOVAL.............................22

INSTALLATION.........................22

REAR FOG LAMP - EXPORT

DESCRIPTION.........................22REPEATER LAMP - EXPORT

REMOVAL.............................22

INSTALLATION.........................22

TAIL LAMP

REMOVAL.............................22

INSTALLATION.........................22

TAIL LAMP - EXPORT

REMOVAL.............................23

INSTALLATION.........................23

TAIL LAMP UNIT

REMOVAL.............................23

INSTALLATION.........................23

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

LAMP SYSTEMS

Lighting circuits are protected by fuses. Lighting

circuits require an overload protected power and high

side drivers source, ON/OFF device, lamps and body

grounds to operate properly. Plastic lamps require a

wire in the harness to supply body ground to the

lamp socket. Replace sockets and bulbs that are cor-

roded.

Some of the interior and exterior lighting functions

are governed by the Body Control Module (BCM).

The headlamp, dome, and the door ajar switches pro-

vide signals to the BCM. The BCM in turn sends a

Programmable Communication Interface (PCI) bus

message to the Front Control Module (FCM) to

enable the necessary drivers to set the required illu-

mination configuration.

Wire connectors can make intermittent contact or

become corroded. Before coupling wire connectors,

inspect the terminals inside the connector. Male ter-

minals should not be bent or disengaged from the

insulator. Female terminals should not be sprung

open or disengaged from the insulator. Bent and

sprung terminals can be repaired using needle nose

pliers and pick tool. Corroded terminals appear

chalky or green. Corroded terminals should be

replaced to avoid recurrence of the problem symp-

toms.

Begin electrical system failure diagnosis by testing

related fuses in the fuse block and intelligent power

module. Verify that bulbs are in good condition and

test continuity of the circuit ground. Refer to the

appropriate wiring information.

AUTOMATIC HEADLAMP SYSTEM

The Automatic Headlamp system turns the instru-

mentation and exterior illumination lamps ON when

the ambient light levels are Night and the engine

RPM is 450 or above, and OFF when light levels are

Day.

DAYTIME RUNNING LAMPS

Operating the high-beam headlamps at reduced

power provides daytime running lamps, which are

required on all new Canadian vehicles.

HEADLAMPS ON WITH WINDSHIELD WIPERS

For vehicles equipped with the Automatic Head-

lamp System, the instrumentation and exterior illu-

mination lamps will be turned ON when the

headlamp switch is in the AUTO position, RPM >

450 and the windshield wipers have been in the

intermittent, low or high mode of operation for more

than ten seconds. When the windshield wipers are

turned OFF the Body Control Module will determine

if the instrumentation and exterior illumination

lamps should remain ON base upon the current

ambient light level.

HEADLAMP SYSTEM

The configuration of the headlamp system of head-

lamps, park lamps and fog lamps is determined by

the BCM. The BCM determines the lighting configu-

ration as a result of the inputs from the ignition

switch, headlamp switch and multi-function switch. A

PCI bus is transmitted from the BCM to the FCM to

enable the necessary drivers to set the illumination

configuration. Four wires are connected between the

headlamp switch and the BCM. The first wire con-

tains information regarding the position of the head-

lamp switch (Off, Automatic Headlamps, Automatic

Headlamp switch fog, Park with Fog, Head, or Head

with Fog Lamps). The second wire contains informa-

tion regarding the position of the dimmer switch

8L - 2 LAMPS/LIGHTING - EXTERIORRS

ProCarManuals.com

Page 419 of 2177

WARNING

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

CAUTION: Do not use bulbs other than those listed

in the Bulb Application Table. Damage to lamp can

result. Do not touch halogen bulbs with fingers or

other oily surfaces. Bulb life will be reduced.

SPECIFICATIONS

EXTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

BACK-UP 3057

CHMSL 921

FRONT SIDE MARKER/PARK/

TURN3157A

FRONT FOG 9040

HEADLAMP 9007

LICENSE 168

TAIL, STOP 3057

TURN SIGNAL 3057

BULB APPLICATION TABLE - EXPORT

LAMP BULB

HEADLAMP LOW/HIGH BEAM H7

FRONT FOG H3

FRONT POSITION W5W

FRONT TURN SIGNAL PY21W

SIDE REPEATER T4W

LICENSE PLATE W5W/168

REAR TAIL AND STOP P21/5W

REAR TURN SIGNAL PY21W

BACK-UP P21W

REAR FOG P21W

CHMSL W16W/921

BRAKE LAMP SWITCH

DESCRIPTION

The brake lamp switch is located under the instru-

ment panel, at the brake pedal arm (Fig. 3). It has

three internal switches controlling various functions

of the vehicle. It's main function is to control opera-

tion of the vehicle's brake lamps. Other functions

include speed control deactivation, brake sense for

the antilock brake system and brake sense for the

brake transmission shift interlock.

CAUTION: The switch can only be adjusted once.

That is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

OPERATION

When the brake pedal is pressed, the plunger on

the outside of the brake lamp switch extends out-

ward. This action opens or closes the contacts of the

three switches inside the brake lamp switch.

With the brake pedal pressed down (plunger

extended), the switch for terminals 1 and 2 is closed

completing the circuit. The switch for terminals 3

and 4 is open and so is the switch for terminals 5

and 6.

When the brake pedal is released (plunger pushed

in), the three switches assume the opposite positions.

The switch for terminals 1 and 2 is now open while

the other two switches are now closed, completing

their circuits.

A lever on the back of the switch is used to set the

switch into the ªadjustedº position. A non-adjusted

switch will have the lever set to the diagonal position

in relation to the switch housing. The plunger can be

moved in and out, but the states of the internal

switches will not change.

CAUTION: Never move the adjustment lever of the

new brake lamp switch without it being properly

installed in the vehicle first. Such action will render

the switch unusable and the switch must be dis-

carded.

Once installed in the vehicle as described in the

brake lamp switch installation procedure (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION), the new

switch's adjustment lever is rotated to the adjusted

position as indicated (Fig. 4). This action locks the

plunger to the internal switches.Once in this posi-

tion the switch is permanently adjusted (or

8L - 4 LAMPS/LIGHTING - EXTERIORRS

LAMPS/LIGHTING - EXTERIOR (Continued)

ProCarManuals.com

Page 421 of 2177

(b) Install the switch in its bracket by aligning

the index tab on the switch with the slot in the

mounting bracket.

(c) When the switch is fully seated in its

bracket, rotate the switch clockwise approximately

30É to lock the switch into place.

(d) With the brake pedal in the fully released

position, move the lever on the back of the brake

lamp switch from the angled non-adjusted position

to the full vertical position as shown (Fig. 4). This

will adjust the brake lamp switch to the vehicle.(2) Install silencer panel below steering column

knee blocker.

(3) Reconnect the battery negative terminal.

(4) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

(5) Road test the vehicle to ensure proper opera-

tion of the brakes including ABS and speed control (if

equipped).

CENTER HIGH MOUNTED

STOP LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove two retaining screws (Fig. 5).

(3) Twist socket counter-clockwise and remove

from lamp.

(4) Pull bulb from socket (Fig. 7).

INSTALLATION

(1) Push bulb into socket.

(2) Install socket into the lamp unit.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two retaining screws (Fig. 5).

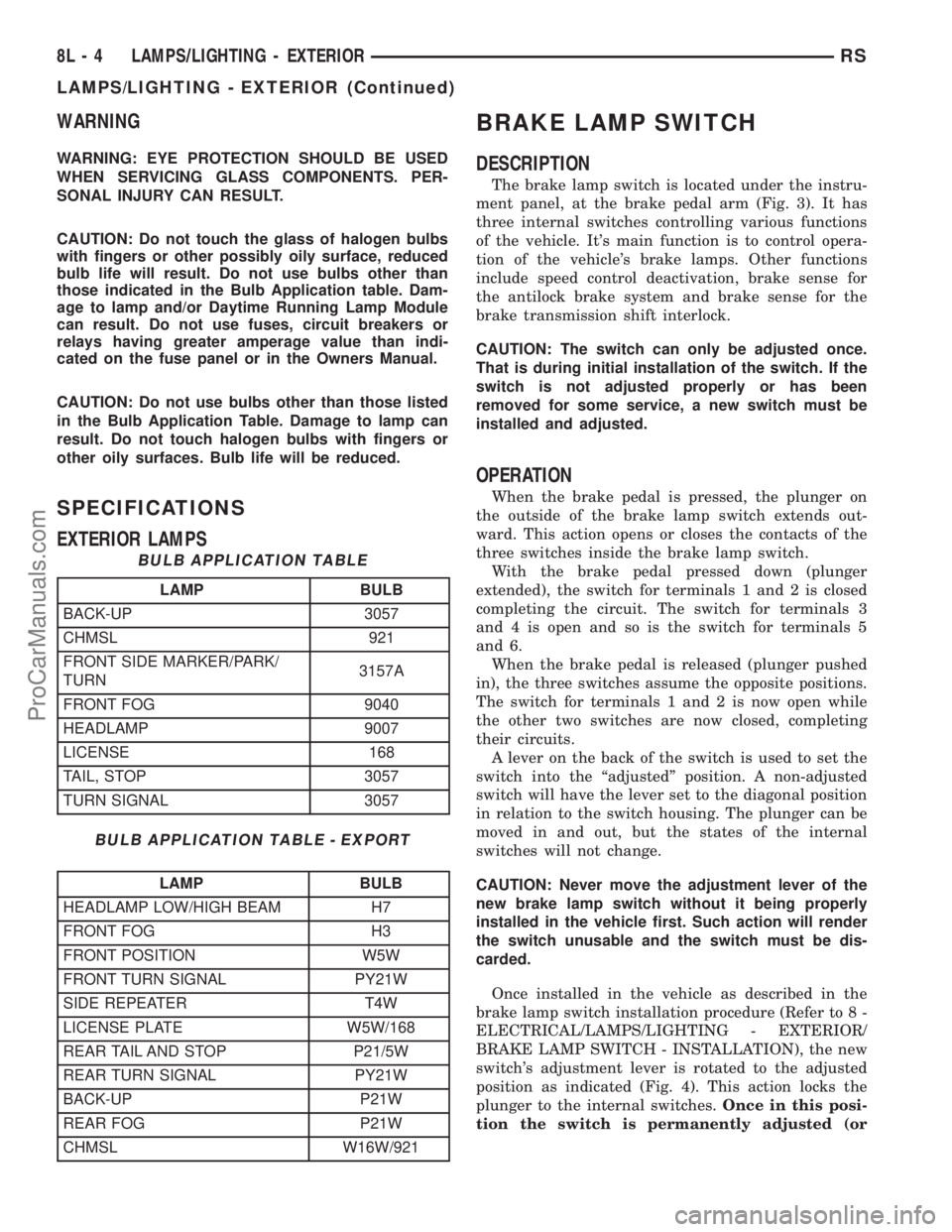

(3) Disconnect the rear window washer nozzle

assembly (Fig. 6).

Fig. 3 Brake Lamp Switch And Pedal With Bracket

1 - BRAKE LAMP SWITCH

2 - WIRING CONNECTOR

3 - PEDAL AND BRACKET

Fig. 4 Adjustment Lever Movement

Fig. 5 CHMSL UNIT

1 - CHMSL UNIT

2 - LIFTGATE

8L - 6 LAMPS/LIGHTING - EXTERIORRS

BRAKE LAMP SWITCH (Continued)

ProCarManuals.com

Page 422 of 2177

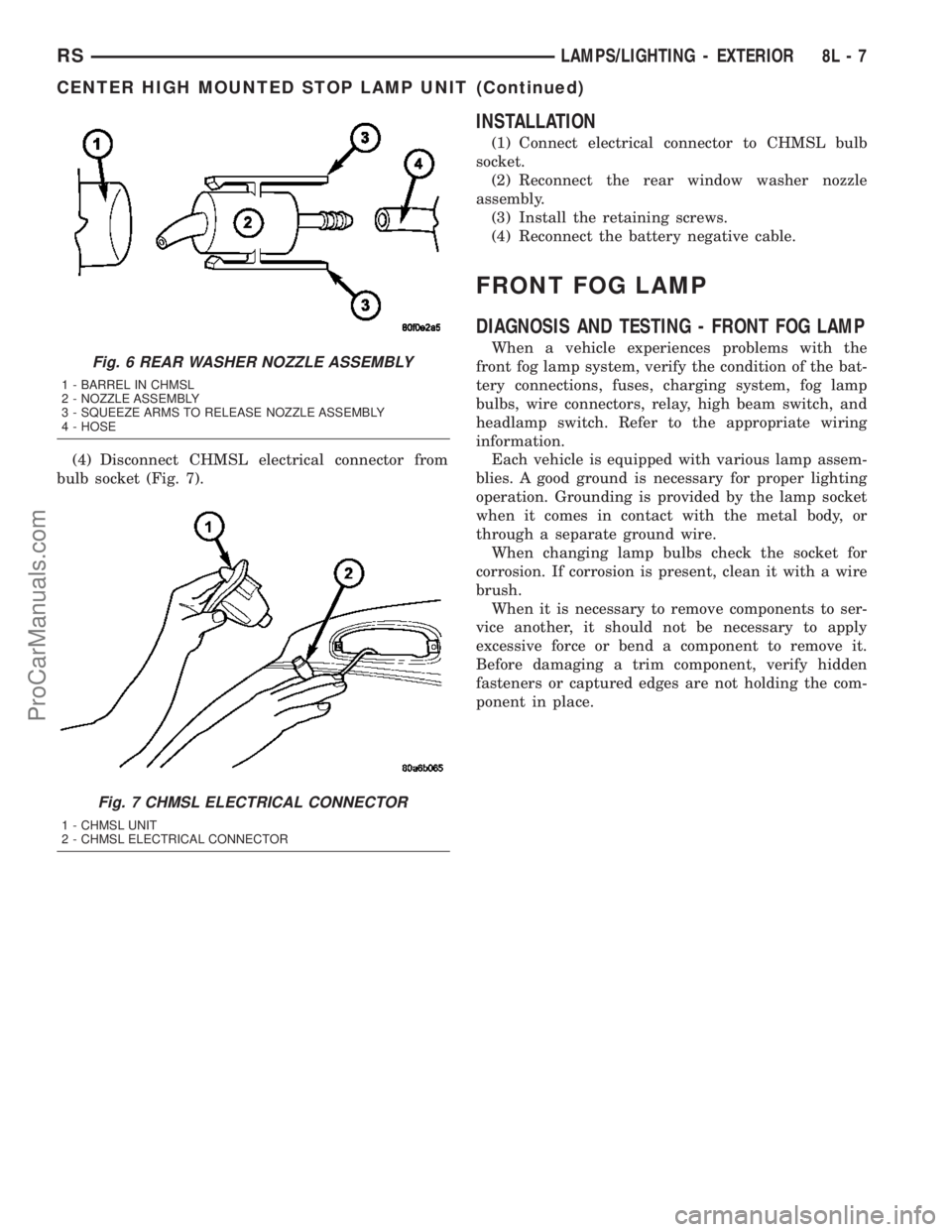

(4) Disconnect CHMSL electrical connector from

bulb socket (Fig. 7).

INSTALLATION

(1) Connect electrical connector to CHMSL bulb

socket.

(2) Reconnect the rear window washer nozzle

assembly.

(3) Install the retaining screws.

(4) Reconnect the battery negative cable.

FRONT FOG LAMP

DIAGNOSIS AND TESTING - FRONT FOG LAMP

When a vehicle experiences problems with the

front fog lamp system, verify the condition of the bat-

tery connections, fuses, charging system, fog lamp

bulbs, wire connectors, relay, high beam switch, and

headlamp switch. Refer to the appropriate wiring

information.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.Fig. 6 REAR WASHER NOZZLE ASSEMBLY

1 - BARREL IN CHMSL

2 - NOZZLE ASSEMBLY

3 - SQUEEZE ARMS TO RELEASE NOZZLE ASSEMBLY

4 - HOSE

Fig. 7 CHMSL ELECTRICAL CONNECTOR

1 - CHMSL UNIT

2 - CHMSL ELECTRICAL CONNECTOR

RSLAMPS/LIGHTING - EXTERIOR8L-7

CENTER HIGH MOUNTED STOP LAMP UNIT (Continued)

ProCarManuals.com

Page 423 of 2177

FRONT FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery

cables.1. Clean and secure battery cable clamps and

posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of-charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical, Battery

System.

6. Poor lighting circuit Z349/Z248

ground.6. Test for voltage drop across Z349/248

ground locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS

BURN OUT

FREQUENTLY1. Charging system output too

high.1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

FOG LAMPS ARE DIM

WITH ENGINE

RUNNING ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z349/Z248

ground.2. Test for voltage drop across Z349/Z248

ground locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp

circuit.3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z349/Z248

ground.1. Test for voltage drop across Z349/Z248

ground locations. Refer to Electrical, Wiring

Information.

2. Variable resistance in fog lamp

circuit.2. Test amperage draw of fog lamp circuit.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and splices.

Refer to Electrical, Wiring Information.

5. Is relay engaging properly? 5. Verify function of fog lamp relay in IPM.

6. PCI Bus Communication. 6. Verify PCI bus message (fog lamp info)

transmitted from BCM and received by FCM.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No Z349/Z248 ground at fog

lamps.2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Broken connector terminal or

wire splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Faulty or burned out bulb. 5. Replace bulb.

6. Is relay engaging? 6. Verify function of fog lamp relay in IPM.

7. PCI Bus Communication. 7. Verify PCI bus message (fog lamp info)

transmitted from BCM and received by FCM.

8L - 8 LAMPS/LIGHTING - EXTERIORRS

FRONT FOG LAMP (Continued)

ProCarManuals.com

Page 424 of 2177

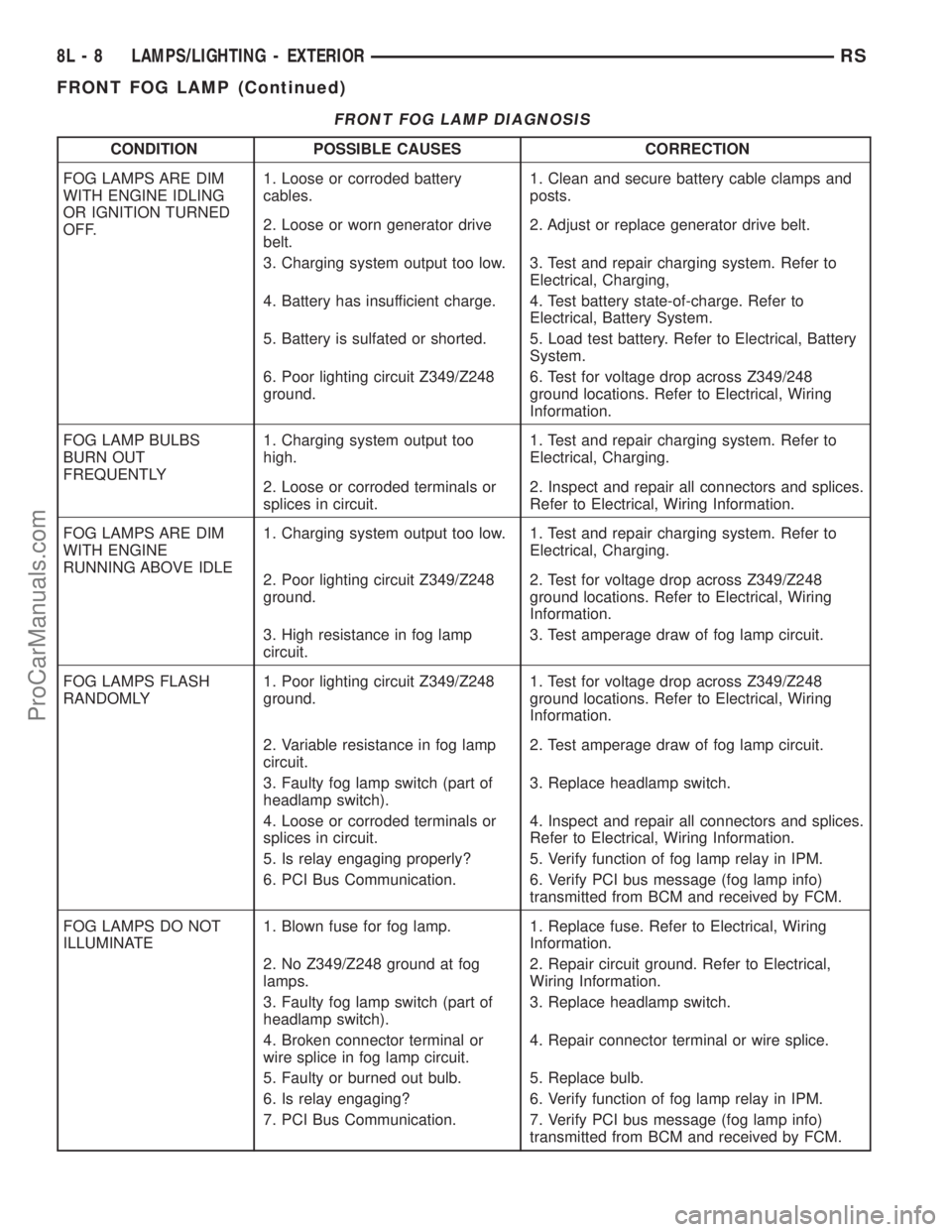

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) From behind the bumper fascia, twist bulb

counter-clockwise, and remove bulb. (Fig. 8).

(3) Remove the wire connector from the fog lamp

bulb.

INSTALLATION

(1) Reconnect wire harness to bulb.

(2) Install bulb and twist clockwise.

(3) Install battery negative cable.

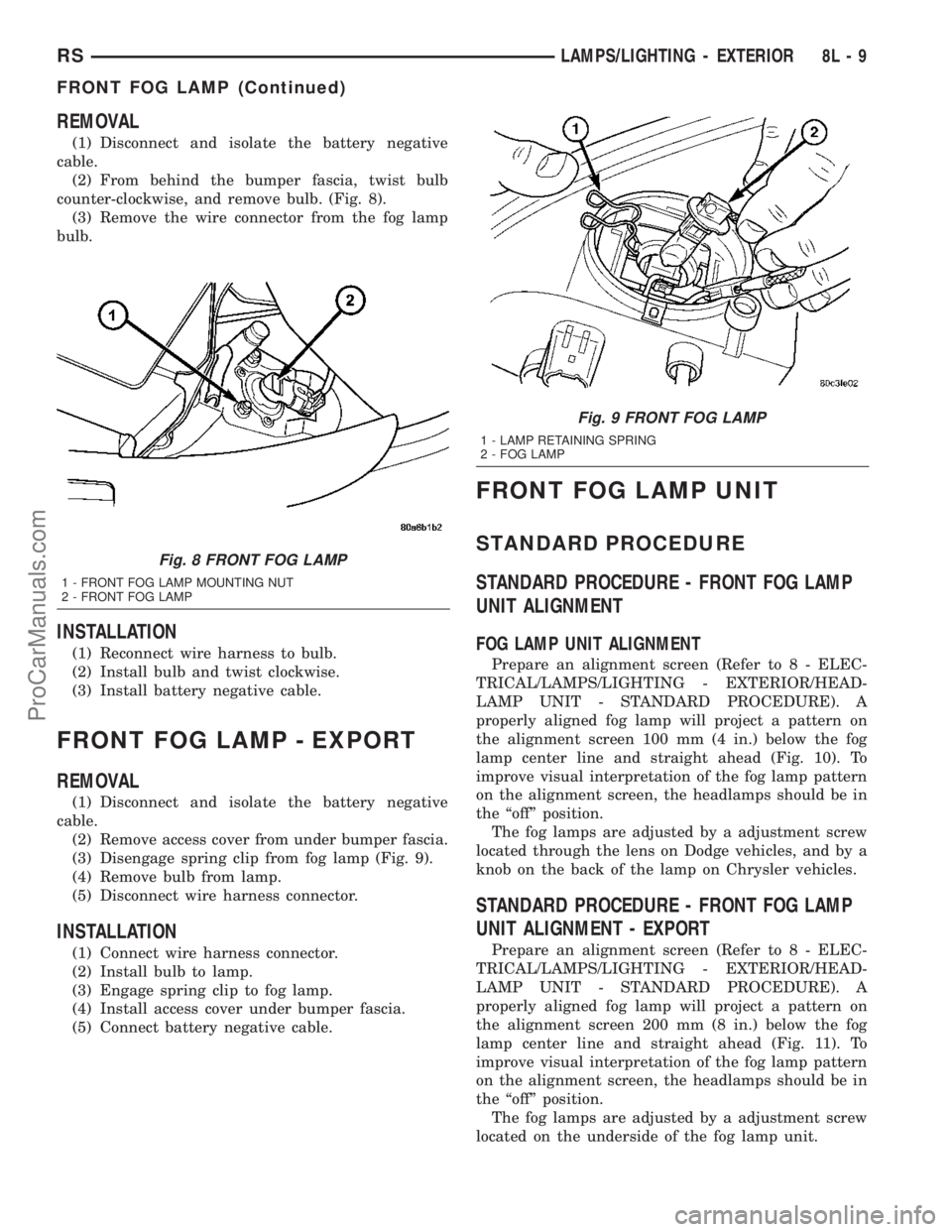

FRONT FOG LAMP - EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove access cover from under bumper fascia.

(3) Disengage spring clip from fog lamp (Fig. 9).

(4) Remove bulb from lamp.

(5) Disconnect wire harness connector.

INSTALLATION

(1) Connect wire harness connector.

(2) Install bulb to lamp.

(3) Engage spring clip to fog lamp.

(4) Install access cover under bumper fascia.

(5) Connect battery negative cable.

FRONT FOG LAMP UNIT

STANDARD PROCEDURE

STANDARD PROCEDURE - FRONT FOG LAMP

UNIT ALIGNMENT

FOG LAMP UNIT ALIGNMENT

Prepare an alignment screen (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - STANDARD PROCEDURE). A

properly aligned fog lamp will project a pattern on

the alignment screen 100 mm (4 in.) below the fog

lamp center line and straight ahead (Fig. 10). To

improve visual interpretation of the fog lamp pattern

on the alignment screen, the headlamps should be in

the ªoffº position.

The fog lamps are adjusted by a adjustment screw

located through the lens on Dodge vehicles, and by a

knob on the back of the lamp on Chrysler vehicles.

STANDARD PROCEDURE - FRONT FOG LAMP

UNIT ALIGNMENT - EXPORT

Prepare an alignment screen (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - STANDARD PROCEDURE). A

properly aligned fog lamp will project a pattern on

the alignment screen 200 mm (8 in.) below the fog

lamp center line and straight ahead (Fig. 11). To

improve visual interpretation of the fog lamp pattern

on the alignment screen, the headlamps should be in

the ªoffº position.

The fog lamps are adjusted by a adjustment screw

located on the underside of the fog lamp unit.

Fig. 8 FRONT FOG LAMP

1 - FRONT FOG LAMP MOUNTING NUT

2 - FRONT FOG LAMP

Fig. 9 FRONT FOG LAMP

1 - LAMP RETAINING SPRING

2 - FOG LAMP

RSLAMPS/LIGHTING - EXTERIOR8L-9

FRONT FOG LAMP (Continued)

ProCarManuals.com

Page 425 of 2177

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) From behind the bumper fascia, disconnect the

wire harness from the fog lamp bulb (Fig. 8).

(3) Remove mounting nuts.

INSTALLATION

(1) Install mounting nuts.

(2) Reconnect the wire harness to the fog lamp

bulb.

(3) Reconnect the battery negative cable.

FRONT POSITION LAMP -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp unit (Fig. 12).

(3) Remove the plastic cover from the back of the

headlamp unit.

(4) Pull front position lamp socket from headlamp

unit.

(5) Pull bulb straight out of socket.

INSTALLATION

(1) Push bulb into the bulb socket.

(2) Insert bulb socket into headlamp unit.

(3) Install cover to the back of the headlamp unit.

(4) Install the headlamp unit.

(5) Connect the battery negative cable.

Fig. 10 FRONT FOG LAMP UNIT ALIGNMENT

1 - HIGH INTENSITY AREA 4 - 100MM (4 IN.)

2 - CENTER OF VEHICLE 5 - 7.62 METERS (25 FT.)

3 - HORIZONTAL CENTER OF FOG LAMP 6 - FRONT OF FOG LAMP

8L - 10 LAMPS/LIGHTING - EXTERIORRS

FRONT FOG LAMP UNIT (Continued)

ProCarManuals.com