wheel CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1992 of 2177

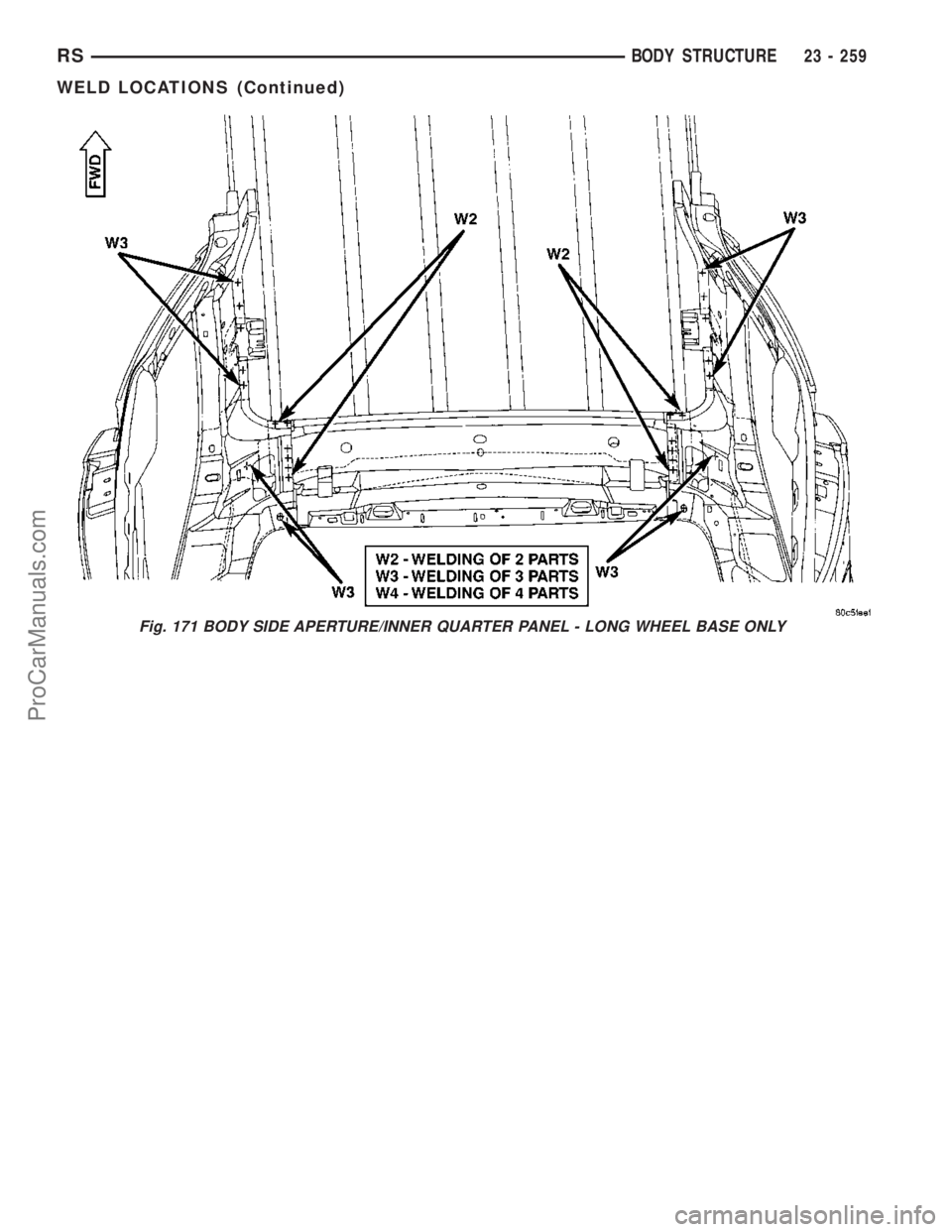

Fig. 171 BODY SIDE APERTURE/INNER QUARTER PANEL - LONG WHEEL BASE ONLY

RSBODY STRUCTURE23 - 259

WELD LOCATIONS (Continued)

ProCarManuals.com

Page 1993 of 2177

Fig. 172 REAR JACKING REINFORCEMENT - SHORT WHEEL BASE ONLY

23 - 260 BODY STRUCTURERS

WELD LOCATIONS (Continued)

ProCarManuals.com

Page 1994 of 2177

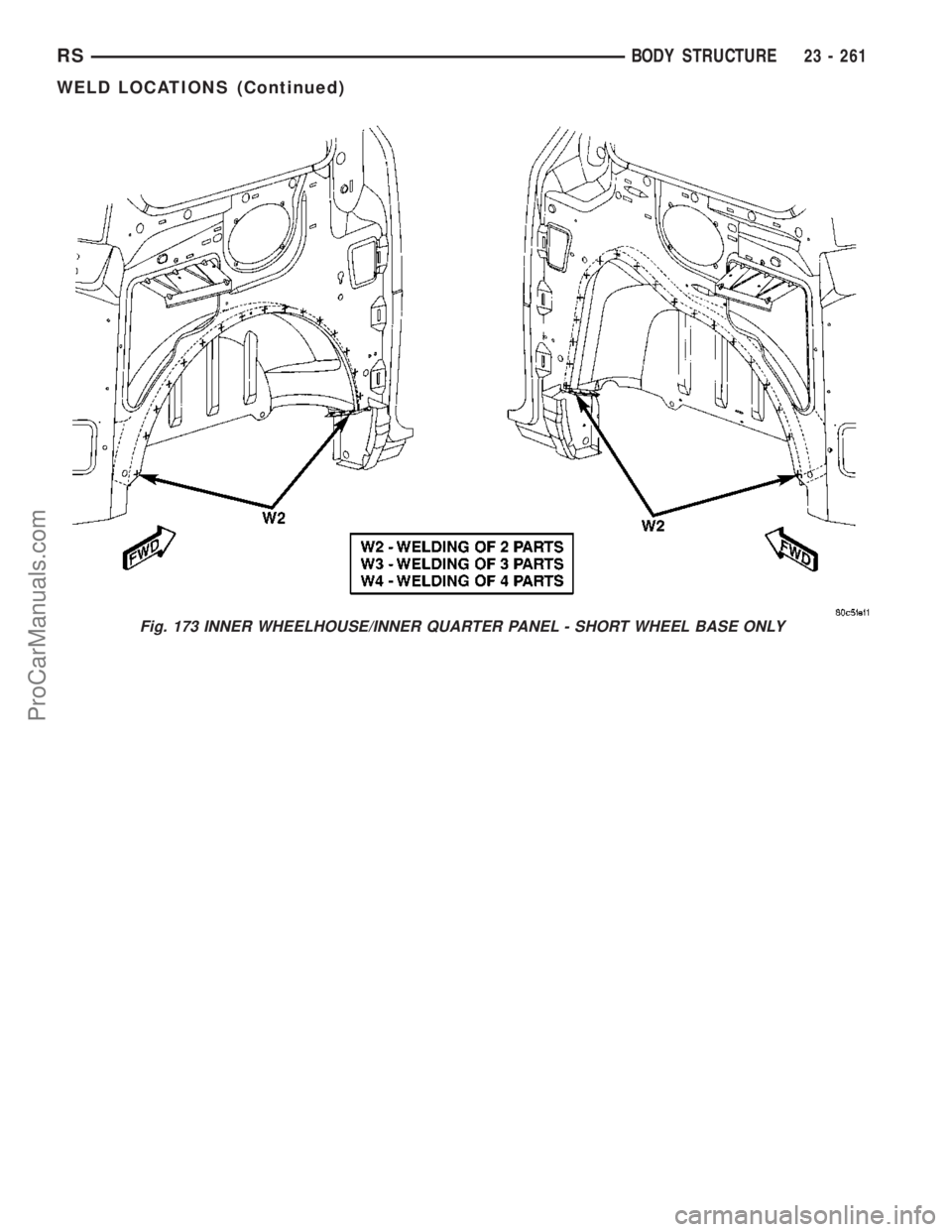

Fig. 173 INNER WHEELHOUSE/INNER QUARTER PANEL - SHORT WHEEL BASE ONLY

RSBODY STRUCTURE23 - 261

WELD LOCATIONS (Continued)

ProCarManuals.com

Page 1995 of 2177

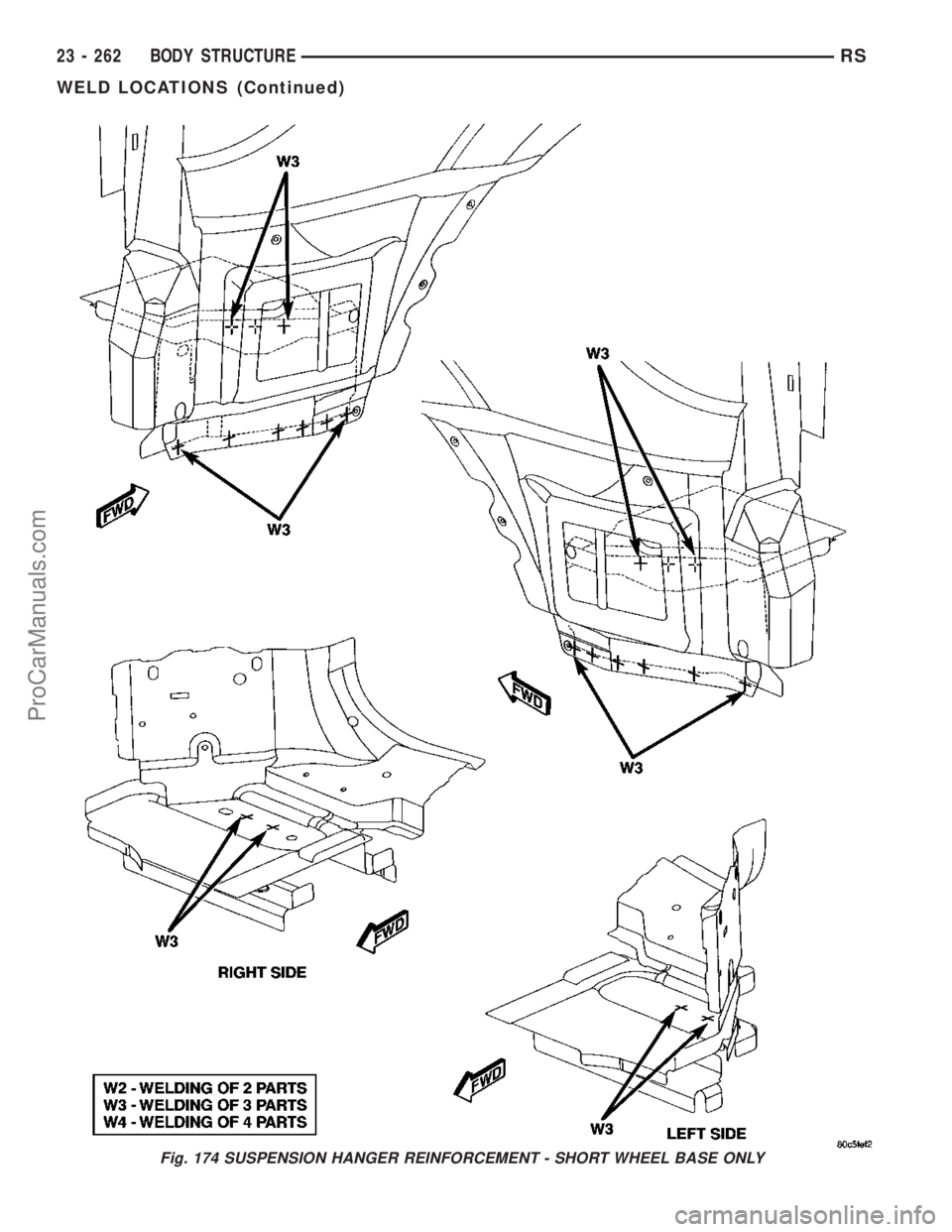

Fig. 174 SUSPENSION HANGER REINFORCEMENT - SHORT WHEEL BASE ONLY

23 - 262 BODY STRUCTURERS

WELD LOCATIONS (Continued)

ProCarManuals.com

Page 1996 of 2177

Fig. 175 LOWER LIFTGATE OPENING - SHORT WHEEL BASE ONLY

RSBODY STRUCTURE23 - 263

WELD LOCATIONS (Continued)

ProCarManuals.com

Page 1997 of 2177

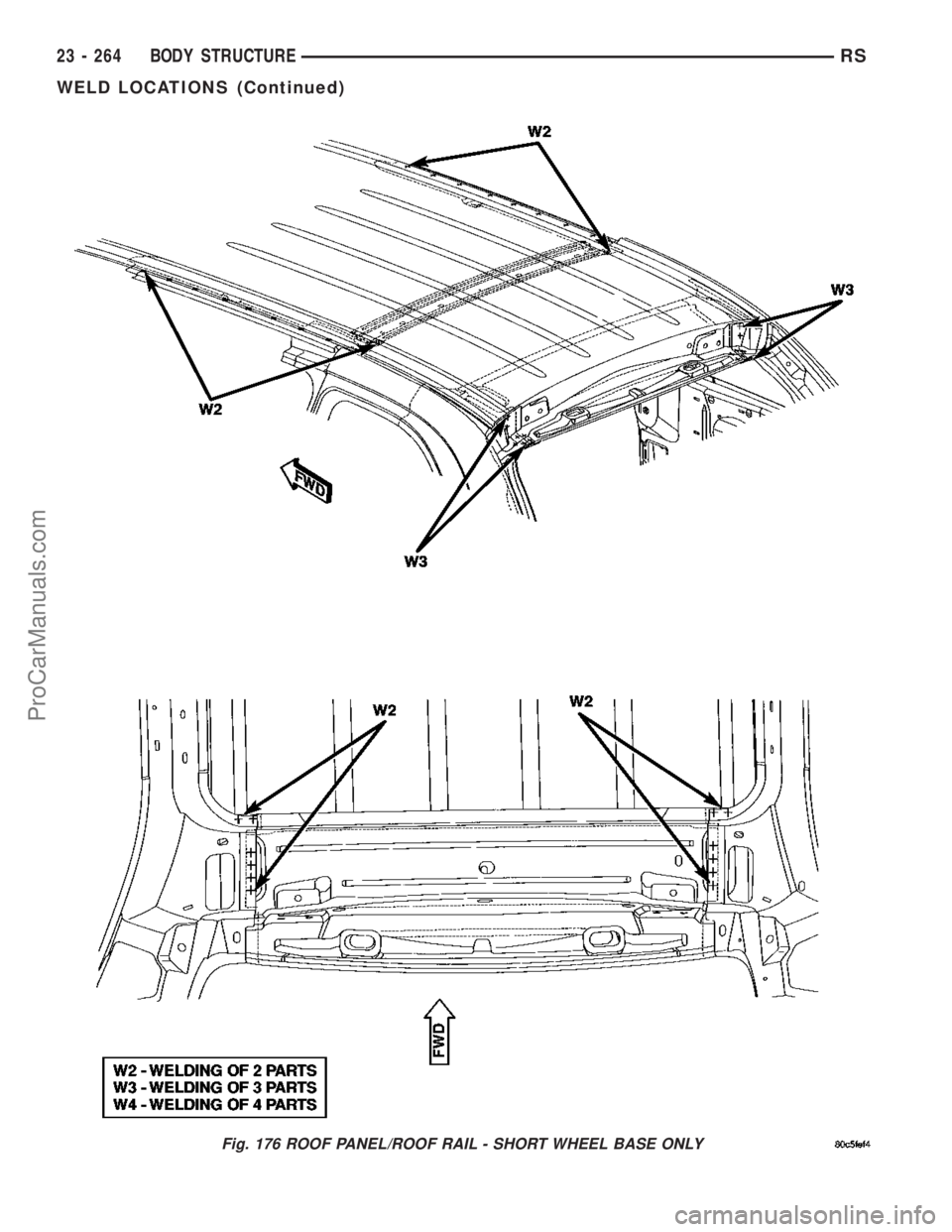

Fig. 176 ROOF PANEL/ROOF RAIL - SHORT WHEEL BASE ONLY

23 - 264 BODY STRUCTURERS

WELD LOCATIONS (Continued)

ProCarManuals.com

Page 2006 of 2177

(ATC) heater-A/C control Delay and Recirculation

graphics will begin to flash when the calibration pro-

cedure has begun.

(3) The calibration procedure should take less than

two minutes to complete for the manual heater-A/C

control, and less than twenty seconds for the ATC

heater-A/C control. When the LEDs or graphics stop

flashing, the calibration procedure is complete.

(4) If the LEDs or graphics continue to flash

beyond the normal three minute (manual) or twenty

second (ATC) calibration time, it indicates that the

heater-A/C control has detected a failure and a Diag-

nostic Trouble Code (DTC) has been set. Use a

DRBIIItscan tool to perform further diagnosis. Refer

to the appropriate diagnostic information. The LEDs

or graphics will continue to flash even after the igni-

tion switch is cycled Off and On, until a successful

calibration is completed or until the vehicle has been

driven about 13 kilometers (8 miles).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(3) Place the instrument panel center bezel unit

face down on a suitable work surface. Take the

proper precautions to protect the center bezel from

cosmetic damage.

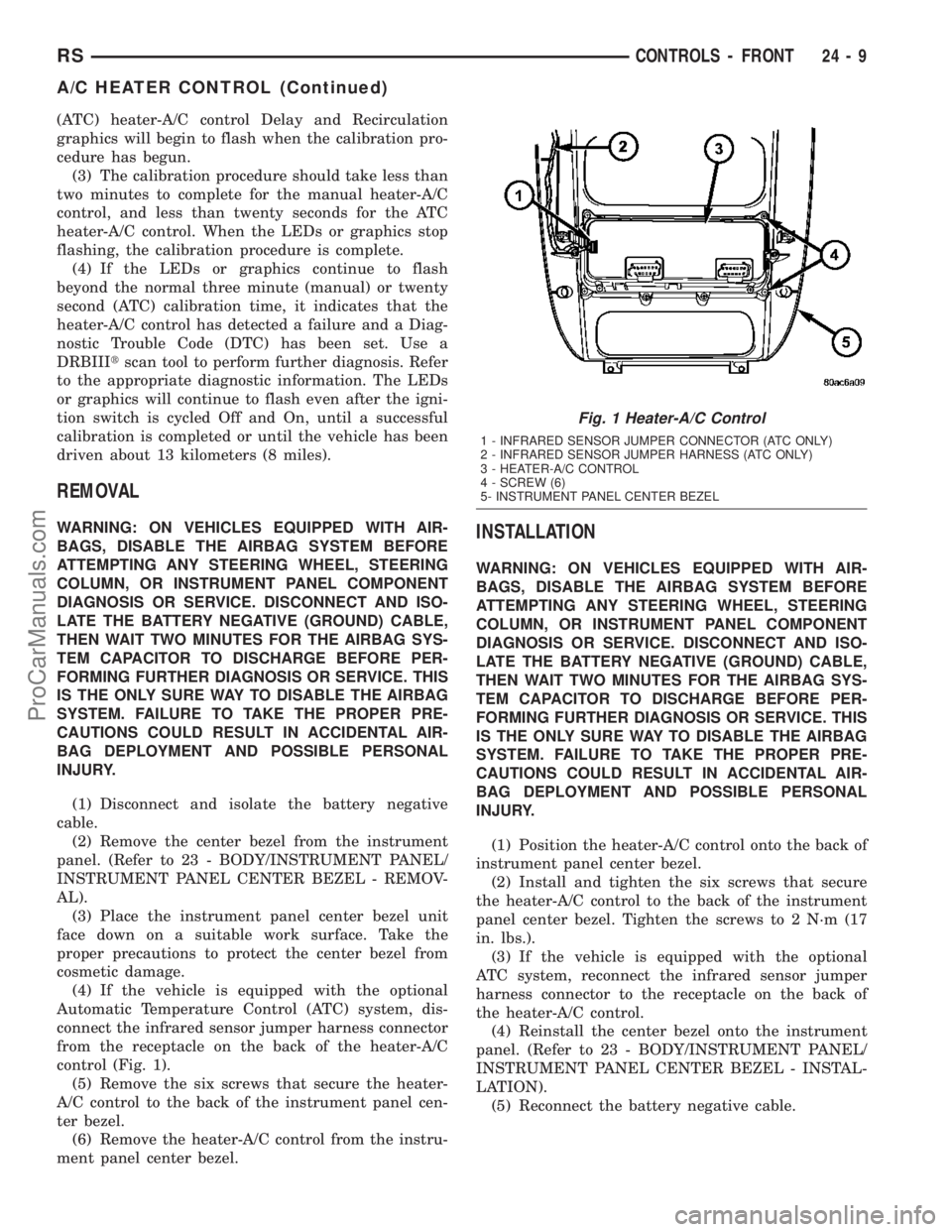

(4) If the vehicle is equipped with the optional

Automatic Temperature Control (ATC) system, dis-

connect the infrared sensor jumper harness connector

from the receptacle on the back of the heater-A/C

control (Fig. 1).

(5) Remove the six screws that secure the heater-

A/C control to the back of the instrument panel cen-

ter bezel.

(6) Remove the heater-A/C control from the instru-

ment panel center bezel.INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the heater-A/C control onto the back of

instrument panel center bezel.

(2) Install and tighten the six screws that secure

the heater-A/C control to the back of the instrument

panel center bezel. Tighten the screws to 2 N´m (17

in. lbs.).

(3) If the vehicle is equipped with the optional

ATC system, reconnect the infrared sensor jumper

harness connector to the receptacle on the back of

the heater-A/C control.

(4) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(5) Reconnect the battery negative cable.

Fig. 1 Heater-A/C Control

1 - INFRARED SENSOR JUMPER CONNECTOR (ATC ONLY)

2 - INFRARED SENSOR JUMPER HARNESS (ATC ONLY)

3 - HEATER-A/C CONTROL

4 - SCREW (6)

5- INSTRUMENT PANEL CENTER BEZEL

RSCONTROLS - FRONT24-9

A/C HEATER CONTROL (Continued)

ProCarManuals.com

Page 2009 of 2177

REMOVAL

The single zone heating and air conditioning sys-

tem is equipped with a single blend door actuator.

The dual zone system has two blend door actuators,

one for the driver side blend air door and one for the

passenger side blend air door. The same service pro-

cedures can be used for each of these actuators.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the silencer from beneath the driver

side end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

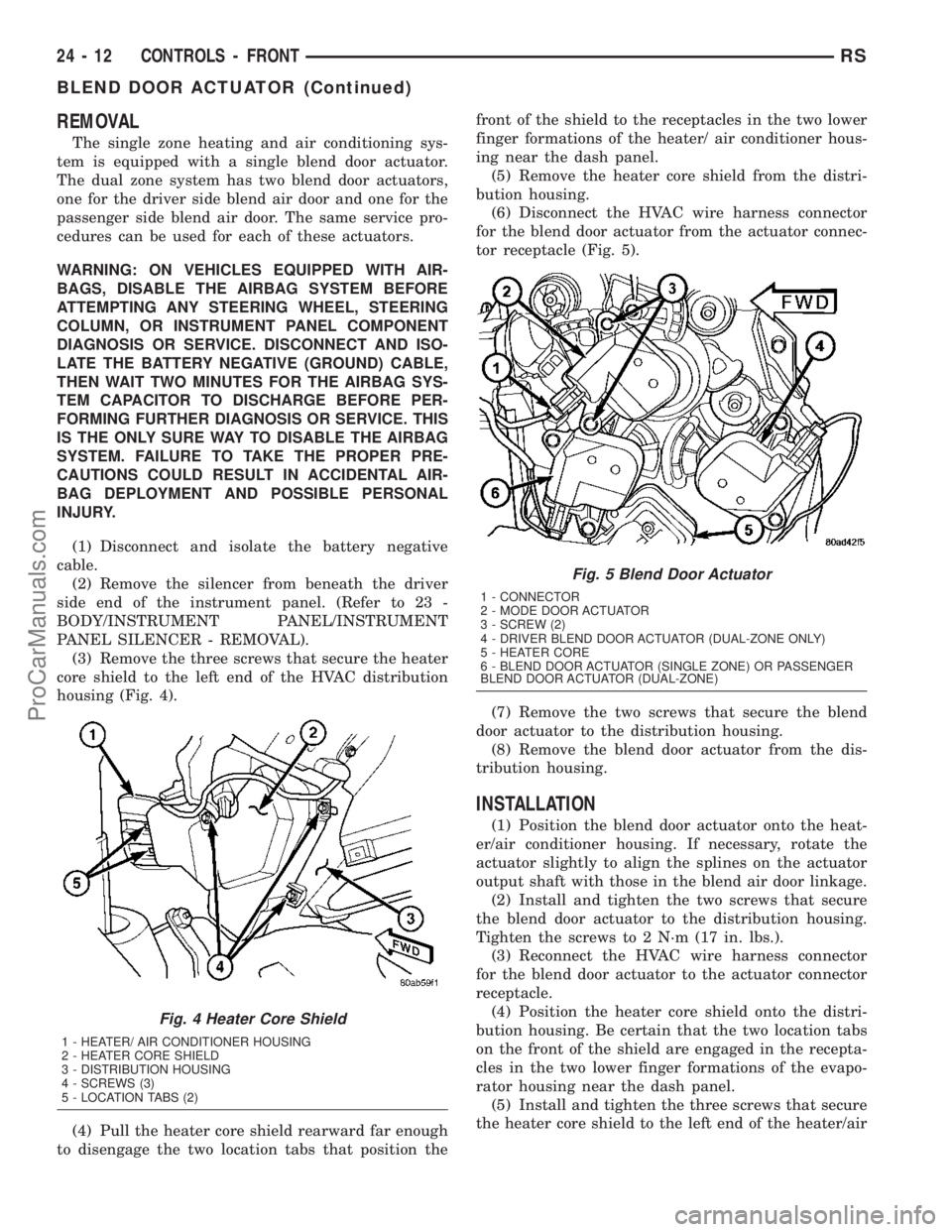

(3) Remove the three screws that secure the heater

core shield to the left end of the HVAC distribution

housing (Fig. 4).

(4) Pull the heater core shield rearward far enough

to disengage the two location tabs that position thefront of the shield to the receptacles in the two lower

finger formations of the heater/ air conditioner hous-

ing near the dash panel.

(5) Remove the heater core shield from the distri-

bution housing.

(6) Disconnect the HVAC wire harness connector

for the blend door actuator from the actuator connec-

tor receptacle (Fig. 5).

(7) Remove the two screws that secure the blend

door actuator to the distribution housing.

(8) Remove the blend door actuator from the dis-

tribution housing.

INSTALLATION

(1) Position the blend door actuator onto the heat-

er/air conditioner housing. If necessary, rotate the

actuator slightly to align the splines on the actuator

output shaft with those in the blend air door linkage.

(2) Install and tighten the two screws that secure

the blend door actuator to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the blend door actuator to the actuator connector

receptacle.

(4) Position the heater core shield onto the distri-

bution housing. Be certain that the two location tabs

on the front of the shield are engaged in the recepta-

cles in the two lower finger formations of the evapo-

rator housing near the dash panel.

(5) Install and tighten the three screws that secure

the heater core shield to the left end of the heater/air

Fig. 4 Heater Core Shield

1 - HEATER/ AIR CONDITIONER HOUSING

2 - HEATER CORE SHIELD

3 - DISTRIBUTION HOUSING

4 - SCREWS (3)

5 - LOCATION TABS (2)

Fig. 5 Blend Door Actuator

1 - CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE ONLY)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)

24 - 12 CONTROLS - FRONTRS

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2012 of 2177

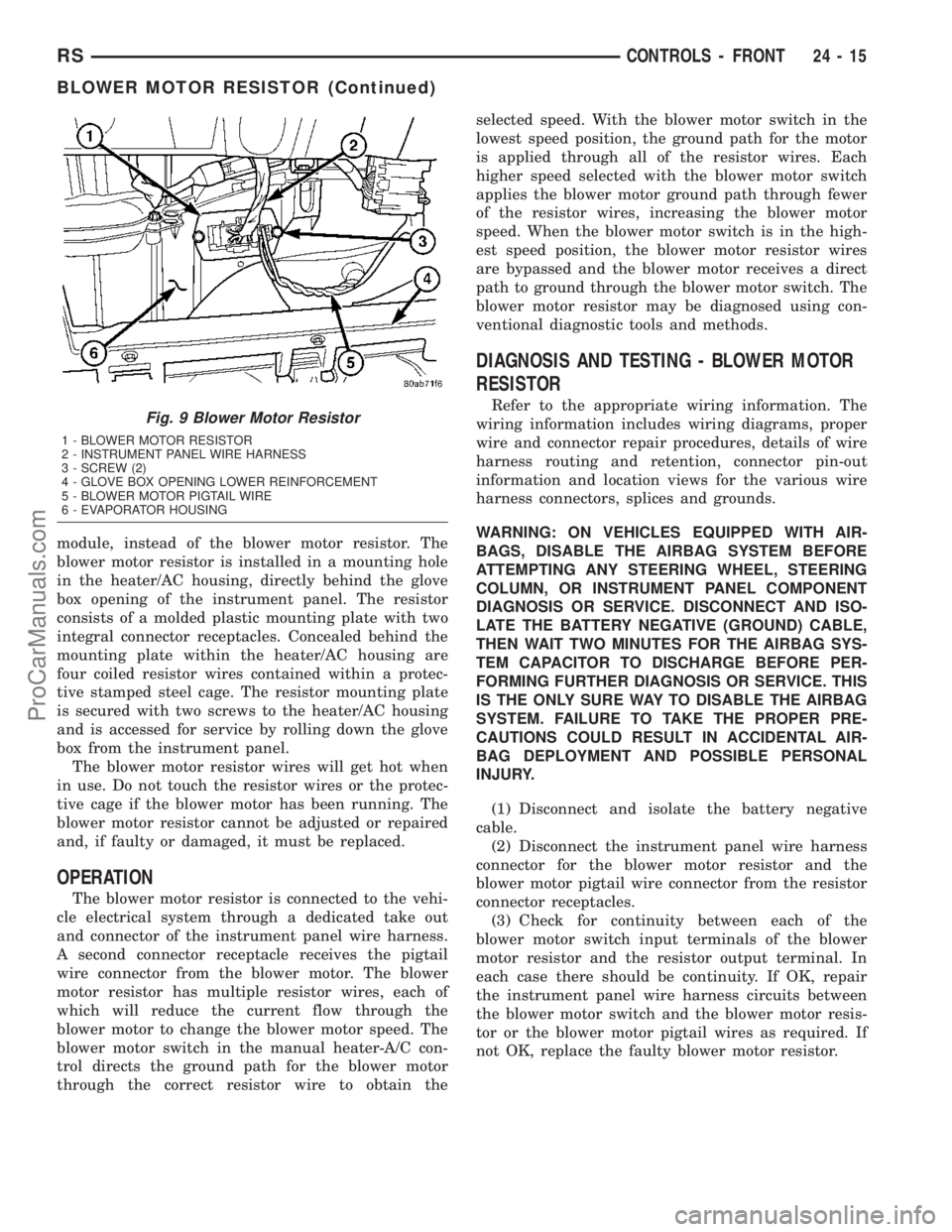

module, instead of the blower motor resistor. The

blower motor resistor is installed in a mounting hole

in the heater/AC housing, directly behind the glove

box opening of the instrument panel. The resistor

consists of a molded plastic mounting plate with two

integral connector receptacles. Concealed behind the

mounting plate within the heater/AC housing are

four coiled resistor wires contained within a protec-

tive stamped steel cage. The resistor mounting plate

is secured with two screws to the heater/AC housing

and is accessed for service by rolling down the glove

box from the instrument panel.

The blower motor resistor wires will get hot when

in use. Do not touch the resistor wires or the protec-

tive cage if the blower motor has been running. The

blower motor resistor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The blower motor resistor is connected to the vehi-

cle electrical system through a dedicated take out

and connector of the instrument panel wire harness.

A second connector receptacle receives the pigtail

wire connector from the blower motor. The blower

motor resistor has multiple resistor wires, each of

which will reduce the current flow through the

blower motor to change the blower motor speed. The

blower motor switch in the manual heater-A/C con-

trol directs the ground path for the blower motor

through the correct resistor wire to obtain theselected speed. With the blower motor switch in the

lowest speed position, the ground path for the motor

is applied through all of the resistor wires. Each

higher speed selected with the blower motor switch

applies the blower motor ground path through fewer

of the resistor wires, increasing the blower motor

speed. When the blower motor switch is in the high-

est speed position, the blower motor resistor wires

are bypassed and the blower motor receives a direct

path to ground through the blower motor switch. The

blower motor resistor may be diagnosed using con-

ventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the instrument panel wire harness

connector for the blower motor resistor and the

blower motor pigtail wire connector from the resistor

connector receptacles.

(3) Check for continuity between each of the

blower motor switch input terminals of the blower

motor resistor and the resistor output terminal. In

each case there should be continuity. If OK, repair

the instrument panel wire harness circuits between

the blower motor switch and the blower motor resis-

tor or the blower motor pigtail wires as required. If

not OK, replace the faulty blower motor resistor.Fig. 9 Blower Motor Resistor

1 - BLOWER MOTOR RESISTOR

2 - INSTRUMENT PANEL WIRE HARNESS

3 - SCREW (2)

4 - GLOVE BOX OPENING LOWER REINFORCEMENT

5 - BLOWER MOTOR PIGTAIL WIRE

6 - EVAPORATOR HOUSING

RSCONTROLS - FRONT24-15

BLOWER MOTOR RESISTOR (Continued)

ProCarManuals.com

Page 2013 of 2177

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE BLOWER MOTOR RESISTOR MAY

GET VERY HOT DURING NORMAL OPERATION. IF

THE BLOWER MOTOR WAS TURNED ON, WAIT

FIVE MINUTES TO ALLOW THE BLOWER MOTOR

RESISTOR TO COOL BEFORE PERFORMING DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THIS PRE-

CAUTION CAN RESULT IN PERSONAL INJURY.

CAUTION: Do not operate the blower motor with the

blower motor resistor removed from the circuit.

Failure to take this precaution can result in vehicle

damage.

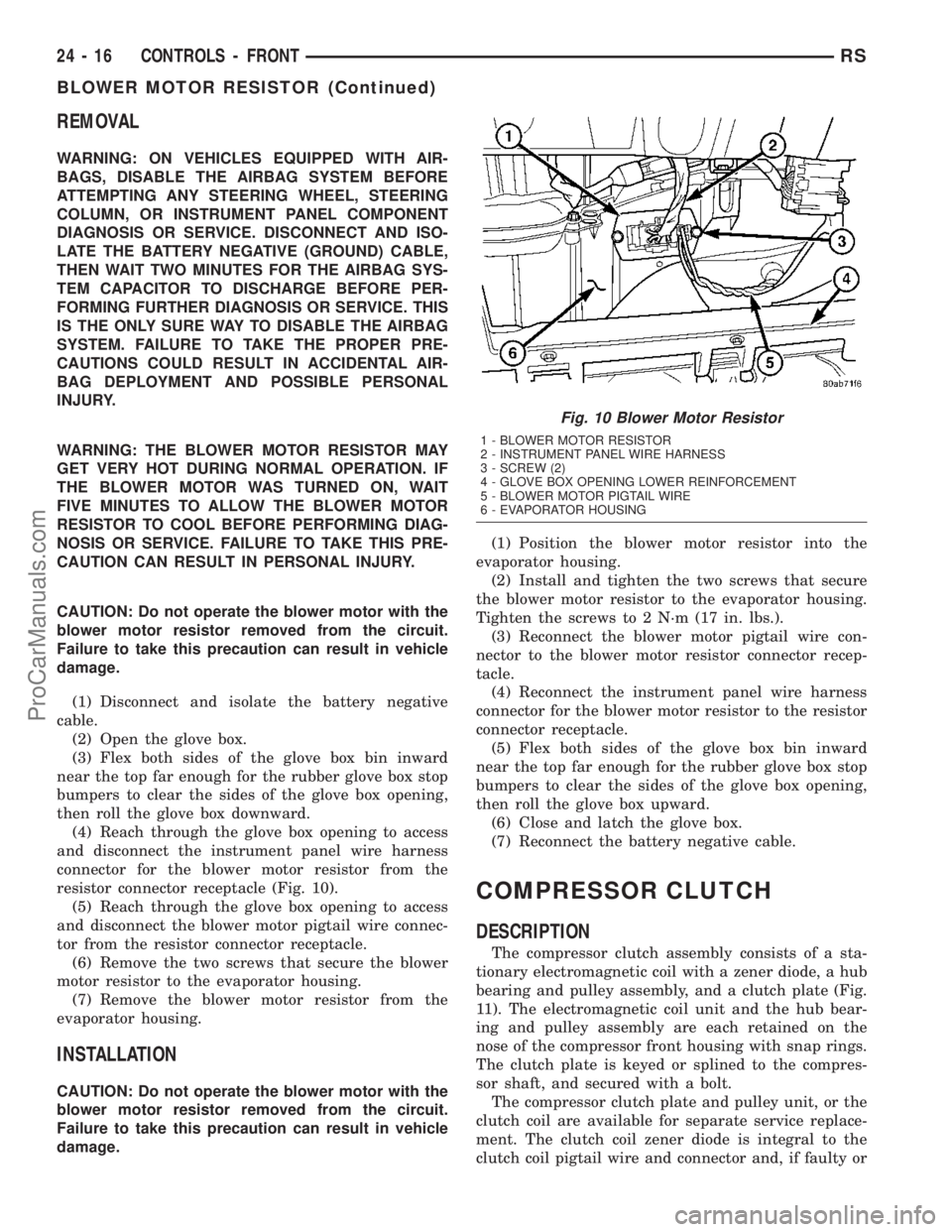

(1) Disconnect and isolate the battery negative

cable.

(2) Open the glove box.

(3) Flex both sides of the glove box bin inward

near the top far enough for the rubber glove box stop

bumpers to clear the sides of the glove box opening,

then roll the glove box downward.

(4) Reach through the glove box opening to access

and disconnect the instrument panel wire harness

connector for the blower motor resistor from the

resistor connector receptacle (Fig. 10).

(5) Reach through the glove box opening to access

and disconnect the blower motor pigtail wire connec-

tor from the resistor connector receptacle.

(6) Remove the two screws that secure the blower

motor resistor to the evaporator housing.

(7) Remove the blower motor resistor from the

evaporator housing.

INSTALLATION

CAUTION: Do not operate the blower motor with the

blower motor resistor removed from the circuit.

Failure to take this precaution can result in vehicle

damage.(1) Position the blower motor resistor into the

evaporator housing.

(2) Install and tighten the two screws that secure

the blower motor resistor to the evaporator housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the blower motor pigtail wire con-

nector to the blower motor resistor connector recep-

tacle.

(4) Reconnect the instrument panel wire harness

connector for the blower motor resistor to the resistor

connector receptacle.

(5) Flex both sides of the glove box bin inward

near the top far enough for the rubber glove box stop

bumpers to clear the sides of the glove box opening,

then roll the glove box upward.

(6) Close and latch the glove box.

(7) Reconnect the battery negative cable.

COMPRESSOR CLUTCH

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil with a zener diode, a hub

bearing and pulley assembly, and a clutch plate (Fig.

11). The electromagnetic coil unit and the hub bear-

ing and pulley assembly are each retained on the

nose of the compressor front housing with snap rings.

The clutch plate is keyed or splined to the compres-

sor shaft, and secured with a bolt.

The compressor clutch plate and pulley unit, or the

clutch coil are available for separate service replace-

ment. The clutch coil zener diode is integral to the

clutch coil pigtail wire and connector and, if faulty or

Fig. 10 Blower Motor Resistor

1 - BLOWER MOTOR RESISTOR

2 - INSTRUMENT PANEL WIRE HARNESS

3 - SCREW (2)

4 - GLOVE BOX OPENING LOWER REINFORCEMENT

5 - BLOWER MOTOR PIGTAIL WIRE

6 - EVAPORATOR HOUSING

24 - 16 CONTROLS - FRONTRS

BLOWER MOTOR RESISTOR (Continued)

ProCarManuals.com