maintenance schedule CHRYSLER CARAVAN 2003 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1518 of 2177

If end play measurement indicates a thrust washer

change is necessary, the differential must be disas-

sembled. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/MANUAL/DIFFERENTIAL - DISASSEMBLY)FLUID

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

NOTE: For proper fluid level check intervals, (Refer

to LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

The fluid required in this transaxle is Mopart

ATF+4. Use of substitute fluids may result in

improper transaxle operation and/or failure.

(1) Raise vehicle on hoist.

(2) Remove transaxle fill plug (Fig. 126).

(3) Inspect fluid level. Fluid should be within 3/16º

below fill hole. Add MopartATF+4 as neccessary.

(4) Install fill plug, ensuring it is properly seated.

(5) Lower vehicle.

STANDARD PROCEDURE - FLUID DRAIN AND

FILL

NOTE: For proper fluid change intervals, (Refer to

LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

The fluid required in this transaxle is Mopart

ATF+4. Use of substitute fluids may result in

improper transaxle operation and/or failure.

Fig. 124 Side Gear End Play Measurement

1 - FEELER GAUGE

Fig. 125 Available Side Gear Thrust Washers

1 - (PLAIN) 0.79-0.84 mm (0.031-0.033 in.)

2 - ( TRIANGLE) 0.91-0.97 mm (0.036-0.038 in.)

3 - (SQUARE) 1.04-1.10 mm (0.041-0.043 in.)

4 - (DIAMOND) 1.17-1.22 mm (0.046-0.048 in.)

Fig. 126 Transaxle Fill Plug

1 - FILL PLUG

2 - END COVER

RST850 MANUAL TRANSAXLE21-71

DIFFERENTIAL (Continued)

ProCarManuals.com

Page 1650 of 2177

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparTATF+4

(Automatic Transmission Fluid) should be used. A

filter change should be made at the time of the

transmission oil change. The magnet (on the inside

of the oil pan) should also be cleaned with a clean,

dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

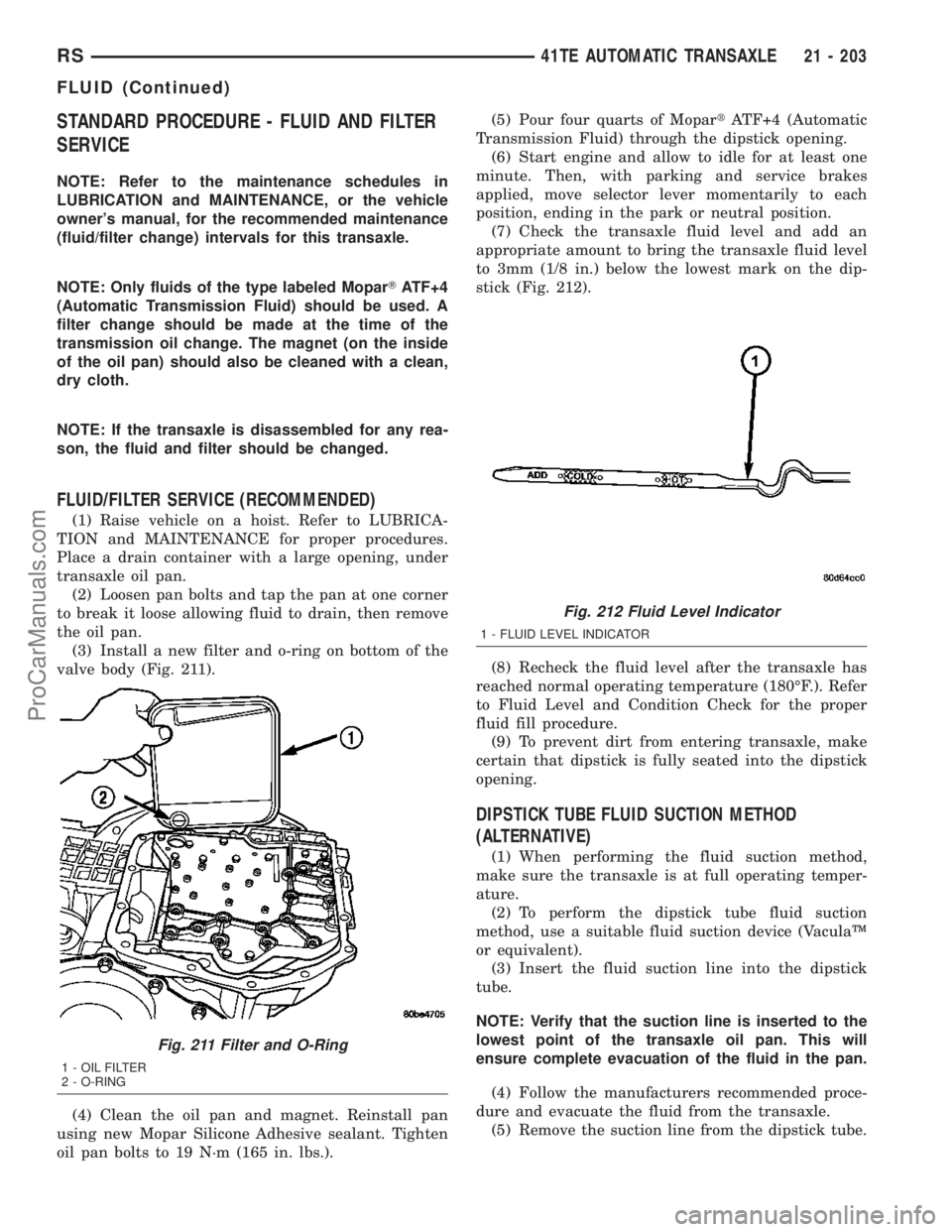

(3) Install a new filter and o-ring on bottom of the

valve body (Fig. 211).

(4) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.).(5) Pour four quarts of MopartATF+4 (Automatic

Transmission Fluid) through the dipstick opening.

(6) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

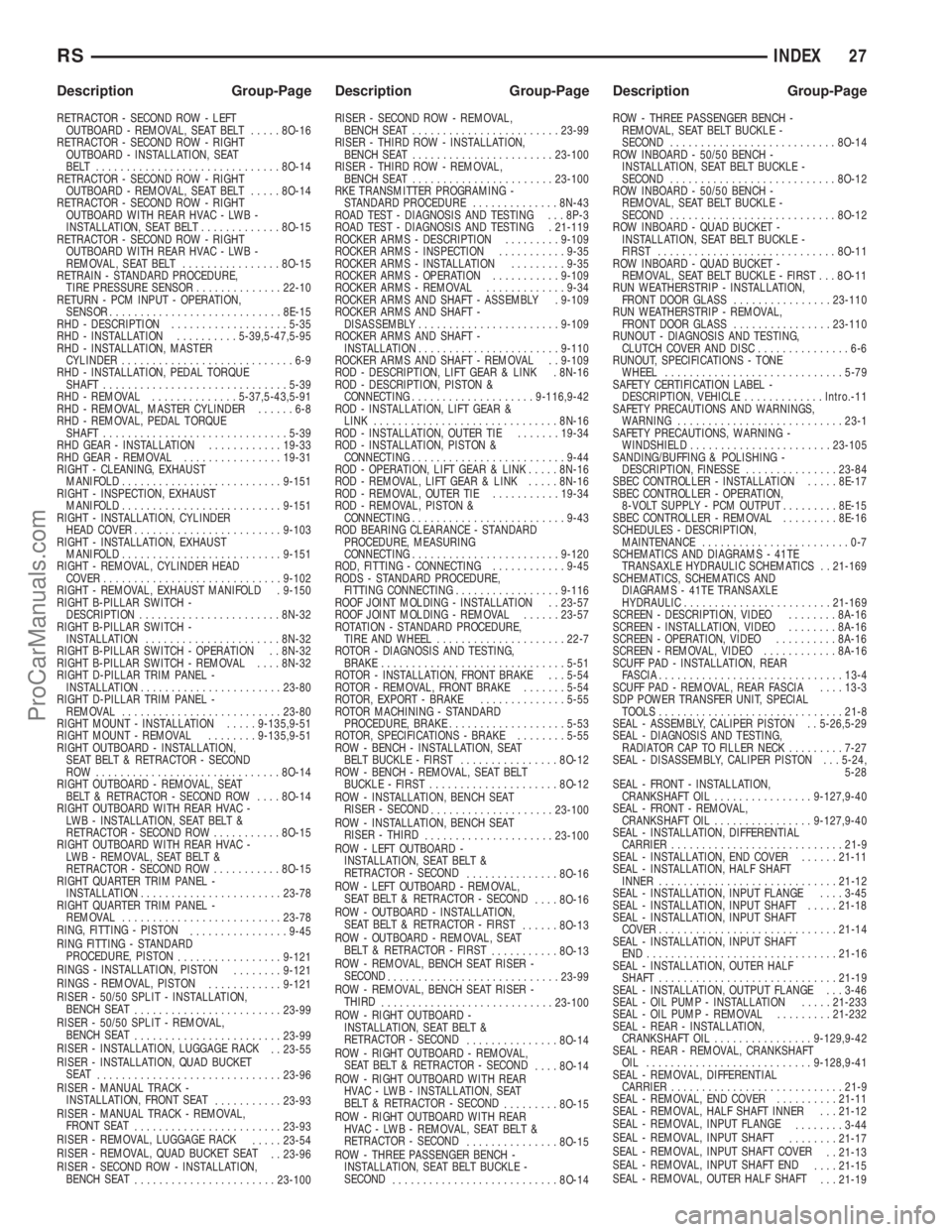

(7) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 212).

(8) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.). Refer

to Fluid Level and Condition Check for the proper

fluid fill procedure.

(9) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

Fig. 211 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 212 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

RS41TE AUTOMATIC TRANSAXLE21 - 203

FLUID (Continued)

ProCarManuals.com

Page 2158 of 2177

LIFTGATE MOTOR - OPERATION.........8N-15

LIFTGATE MOTOR - REMOVAL..........8N-15

LIFTGATE SIDE - INSTALLATION.........23-43

LIFTGATE SIDE - REMOVAL............23-43

LIFTGATE SILL PLATE - INSTALLATION . . . 23-77

LIFTGATE SILL PLATE - REMOVAL.......23-77

LIFTGATE SPOILER - INSTALLATION......23-41

LIFTGATE SPOILER - REMOVAL.........23-41

LIFTGATE SYSTEM - DESCRIPTION,

POWER.............................8N-2

LIFTGATE SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LIFTGATE SYSTEM - OPERATION,

POWER.............................8N-3

LIMITS - DESCRIPTION, HIGH AND LOW . . . 25-8

LINE - INSTALLATION, DISCHARGE......24-69

LINE - INSTALLATION, FUEL...........24-110

LINE - INSTALLATION, LIQUID..........24-82

LINE - INSTALLATION, SUCTION . . . 24-102,24-91

LINE - REMOVAL, DISCHARGE..........24-68

LINE - REMOVAL, FUEL...............24-109

LINE - REMOVAL, LIQUID..............24-80

LINE - REMOVAL, SUCTION......24-101,24-90

LINE AND TERMINAL REPAIR -

STANDARD PROCEDURE, GRID..........8G-3

LINE EXTENSION - INSTALLATION,

EVAPORATOR.......................24-96

LINE EXTENSION - REMOVAL,

EVAPORATOR.......................24-95

LINE REPAIR REAR - STANDARD

PROCEDURE, GRID....................8G-2

LINES - DESCRIPTION, OIL COOLER.....9-138

LINES - DESCRIPTION, UNDERBODY....24-103

LINES - INSTALLATION, OIL COOLER.....9-138

LINES - INSTALLATION, REAR AIR

CONDITIONING.....................24-105

LINES - INSTALLATION, REAR HEATER . . 24-105

LINES - INSTALLATION, TRANSMISSION

OIL COOLER.........................7-38

LINES - OPERATION, OIL COOLER.......9-138

LINES - OPERATION, UNDERBODY......24-103

LINES - REMOVAL, OIL COOLER........9-138

LINES - REMOVAL, REAR AIR

CONDITIONING.....................24-104

LINES - REMOVAL, REAR HEATER......24-104

LINES - REMOVAL, TRANSMISSION OIL

COOLER.............................7-38

LINES/HOSES AND CLAMPS -

DESCRIPTION, FUEL...................14-6

LINING - INSPECTION, REAR DRUM

BRAKE SHOE.........................5-22

LINK - DESCRIPTION, TRD............21-249

LINK - INSTALLATION, FUEL FILL DOOR

BLOCKER LOCKOUT..................23-53

LINK - OPERATION, TRD..............21-249

LINK - REMOVAL, FUEL FILL DOOR

BLOCKER LOCKOUT..................23-52

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-6

LINK CONNECTOR - OPERATION, DATA....8E-7

LINK ROD - DESCRIPTION, LIFT GEAR . . . 8N-16

LINK ROD - INSTALLATION, LIFT GEAR . . . 8N-16

LINK ROD - OPERATION, LIFT GEAR.....8N-16

LINK ROD - REMOVAL, LIFT GEAR.......8N-16

LINKAGE - INSTALLATION, WIPER.......8R-18

LINKAGE - REMOVAL, WIPER...........8R-17

LIQUID LINE - INSTALLATION...........24-82

LIQUID LINE - REMOVAL

..............24-80

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL

.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE

...................8W-91-1

LOCATIONS - DESCRIPTION, FLUID

FILL/CHECK

...........................0-7

LOCATIONS - SPECIFICATIONS, BODY

SEALING

..........................23-127

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE

..............23-153

LOCATIONS - SPECIFICATIONS, WELD

. . . 23-161

LOCK ASSEMBLY - INSTALLATION,

LATCH

.............................23-27

LOCK ASSEMBLY - REMOVAL, LATCH

....23-26

LOCK CYLINDER - INSTALLATION

. . 23-20,23-41

LOCK CYLINDER - REMOVAL

......23-19,23-41

LOCK CYLINDER HOUSING -

INSTALLATION

.......................19-19

LOCK CYLINDER HOUSING - REMOVAL

. . . 19-17LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR.....................8N-41

LOCK MOTOR - INSTALLATION, SLIDING

DOOR.............................8N-44

LOCK MOTOR - REMOVAL, SLIDING

DOOR.............................8N-44

LOCK SWITCH - DESCRIPTION, DOOR

CYLINDER..........................8N-40

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR.....................8N-41

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR CYLINDER............8N-40

LOCK SWITCH - INSTALLATION, DOOR . . . 8N-42

LOCK SWITCH - INSTALLATION, DOOR

CYLINDER..........................8N-41

LOCK SWITCH - OPERATION, DOOR

CYLINDER..........................8N-40

LOCK SWITCH - REMOVAL, DOOR.......8N-42

LOCK SWITCH - REMOVAL, DOOR

CYLINDER..........................8N-41

LOCKED ENGINE - STANDARD

PROCEDURE, HYDROSTATIC.........9-10,9-85

LOCK/LATCH - INSTALLATION, UNDER

SEAT STORAGE BIN.................23-104

LOCK/LATCH - REMOVAL, UNDER SEAT

STORAGE BIN......................23-104

LOCKOUT LINK - INSTALLATION, FUEL

FILL DOOR BLOCKER.................23-53

LOCKOUT LINK - REMOVAL, FUEL FILL

DOOR BLOCKER.....................23-52

LOCKS - DESCRIPTION, POWER........8N-38

LOCKS - OPERATION, POWER..........8N-39

LOUVER - INSTALLATION, REAR HVAC . . . 23-79

LOUVER - REMOVAL, REAR HVAC.......23-79

LOW LIMITS - DESCRIPTION, HIGH.......25-8

LOWER - CLEANING, INTAKE MANIFOLD . . 9-148

LOWER - INSPECTION, INTAKE

MANIFOLD......................9-148,9-60

LOWER - INSTALLATION, INTAKE

MANIFOLD...........................9-60

LOWER - INSTALLATION, SHROUD.......19-22

LOWER - REMOVAL, INTAKE MANIFOLD . . . 9-60

LOWER - REMOVAL, SHROUD..........19-21

LOWER BALL JOINT - DESCRIPTION......2-10

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-10

LOWER BALL JOINT - OPERATION........2-10

LOWER CONSOLE - INSTALLATION......23-68

LOWER CONSOLE - REMOVAL..........23-68

LOWER CONTROL ARM - DESCRIPTION . . . 2-12

LOWER CONTROL ARM - INSPECTION.....2-14

LOWER CONTROL ARM - INSTALLATION . . . 2-15

LOWER CONTROL ARM - OPERATION.....2-12

LOWER CONTROL ARM - REMOVAL......2-12

LOWER CONTROL ARM (REAR BUSHING

- HYDRO) - ASSEMBLY.................2-14

LOWER CONTROL ARM (REAR BUSHING

- HYDRO) - DISASSEMBLY..............2-14

LOWER CONTROL ARM (REAR BUSHING

- STANDARD) - ASSEMBLY..............2-14

LOWER CONTROL ARM (REAR BUSHING

- STANDARD) - DISASSEMBLY...........2-13

LOWER DRIVE UNIT - DESCRIPTION.....8N-32

LOWER DRIVE UNIT - INSTALLATION....8N-33

LOWER DRIVE UNIT - OPERATION.......8N-32

LOWER DRIVE UNIT - REMOVAL

........8N-33

LOWER DRIVE UNIT TRACK & RACK -

DESCRIPTION

.......................8N-34

LOWER DRIVE UNIT TRACK & RACK -

INSTALLATION

......................8N-34

LOWER DRIVE UNIT TRACK & RACK -

OPERATION

.........................8N-34

LOWER DRIVE UNIT TRACK & RACK -

REMOVAL

..........................8N-34

LOWER EXTENSION TRIM -

INSTALLATION, A-PILLAR

..............23-73

LOWER EXTENSION TRIM - REMOVAL,

A-PILLAR

...........................23-73

LOWER HINGE - INSTALLATION

.........23-28

LOWER HINGE - REMOVAL

.............23-28

LOWER INSTRUMENT PANEL -

INSTALLATION

.......................23-68

LOWER INSTRUMENT PANEL -

REMOVAL

..........................23-68

LOWER INTAKE MANIFOLD -

INSTALLATION

.......................9-149

LOWER INTAKE MANIFOLD - REMOVAL

. . . 9-148LOWER STEERING COLUMN COVER -

INSTALLATION.......................23-69

LOWER STEERING COLUMN COVER -

REMOVAL..........................23-69

LOWER TRIM - INSTALLATION,

B-PILLAR...........................23-74

LOWER TRIM - REMOVAL, B-PILLAR.....23-73

LUBRICANTS - DESCRIPTION, ENGINE

OIL .................................0-1

LUBRICATION - DESCRIPTION......9-136,9-52

LUBRICATION - OPERATION........9-136,9-52

LUBRICATION - STANDARD PROCEDURE....2-2

LUBRICATION POINTS - DESCRIPTION......0-7

LUBRICATION, SPECIFICATIONS - BODY . . 23-12

LUGGAGE RACK CROSSBAR -

INSTALLATION.......................23-56

LUGGAGE RACK CROSSBAR - REMOVAL . . 23-55

LUGGAGE RACK RISER - INSTALLATION . . 23-55

LUGGAGE RACK RISER - REMOVAL......23-54

LUMBAR SUPPORT - INSTALLATION....23-104

LUMBAR SUPPORT - REMOVAL........23-104

LWB - INSTALLATION, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC..........8O-15

LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC..........8O-15

MACHINING - STANDARD PROCEDURE,

BRAKE ROTOR.......................5-53

MAIN BEARING FITTING - STANDARD

PROCEDURE..........................9-123

MAIN BEARINGS - INSTALLATION,

CRANKSHAFT.......................9-124

MAIN BEARINGS - REMOVAL,

CRANKSHAFT.......................9-124

MAINTENANCE SCHEDULES -

DESCRIPTION.........................0-7

MANAGER - DESCRIPTION, TASK........25-24

MANAGER - OPERATION, TASK.........25-24

MANIFOLD - CLEANING, EXHAUST........9-61

MANIFOLD - DESCRIPTION, INTAKE . . 9-144,9-58

MANIFOLD - INSPECTION, EXHAUST......9-61

MANIFOLD - INSTALLATION, EXHAUST....9-61

MANIFOLD - INSTALLATION, LOWER

INTAKE ............................9-149

MANIFOLD - INSTALLATION, UPPER

INTAKE ............................9-147

MANIFOLD - LEFT - CLEANING,

EXHAUST...........................9-152

MANIFOLD - LEFT - INSPECTION,

EXHAUST...........................9-152

MANIFOLD - LEFT - INSTALLATION,

EXHAUST...........................9-152

MANIFOLD - LEFT - REMOVAL, EXHAUST . 9-152

MANIFOLD - LOWER - CLEANING,

INTAKE ............................9-148

MANIFOLD - LOWER - INSPECTION,

INTAKE ........................9-148,9-60

MANIFOLD - LOWER - INSTALLATION,

INTAKE .............................9-60

MANIFOLD - LOWER - REMOVAL,

INTAKE .............................9-60

MANIFOLD - REMOVAL, EXHAUST........9-61

MANIFOLD - REMOVAL, LOWER INTAKE . . 9-148

MANIFOLD - REMOVAL, UPPER INTAKE . . . 9-145

MANIFOLD - RIGHT - CLEANING,

EXHAUST...........................9-151

MANIFOLD - RIGHT - INSPECTION,

EXHAUST...........................9-151

MANIFOLD - RIGHT - INSTALLATION,

EXHAUST...........................9-151

MANIFOLD - RIGHT - REMOVAL,

EXHAUST...........................9-150

MANIFOLD - UPPER - INSPECTION,

INTAKE .............................9-59

MANIFOLD - UPPER - INSTALLATION,

INTAKE .............................9-59

MANIFOLD - UPPER - REMOVAL, INTAKE . . 9-58

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE

................9-145,9-58

MANIFOLD STRIPPED THREAD REPAIR -

STANDARD PROCEDURE

...............9-145

MANIFOLD VACUUM PORT REPAIR -

STANDARD PROCEDURE, INTAKE

........9-145

MANUAL - INSTALLATION, WINDOW

REGULATOR

........................23-23

MANUAL - REMOVAL, WINDOW

REGULATOR

........................23-23

RSINDEX19

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2166 of 2177

RETRACTOR - SECOND ROW - LEFT

OUTBOARD - REMOVAL, SEAT BELT.....8O-16

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD - INSTALLATION, SEAT

BELT ..............................8O-14

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD - REMOVAL, SEAT BELT.....8O-14

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC - LWB -

INSTALLATION, SEAT BELT.............8O-15

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC - LWB -

REMOVAL, SEAT BELT................8O-15

RETRAIN - STANDARD PROCEDURE,

TIRE PRESSURE SENSOR..............22-10

RETURN - PCM INPUT - OPERATION,

SENSOR............................8E-15

RHD - DESCRIPTION...................5-35

RHD - INSTALLATION..........5-39,5-47,5-95

RHD - INSTALLATION, MASTER

CYLINDER............................6-9

RHD - INSTALLATION, PEDAL TORQUE

SHAFT..............................5-39

RHD - REMOVAL..............5-37,5-43,5-91

RHD - REMOVAL, MASTER CYLINDER......6-8

RHD - REMOVAL, PEDAL TORQUE

SHAFT..............................5-39

RHD GEAR - INSTALLATION............19-33

RHD GEAR - REMOVAL................19-31

RIGHT - CLEANING, EXHAUST

MANIFOLD..........................9-151

RIGHT - INSPECTION, EXHAUST

MANIFOLD...........................9-151

RIGHT - INSTALLATION, CYLINDER

HEAD COVER........................9-103

RIGHT - INSTALLATION, EXHAUST

MANIFOLD..........................9-151

RIGHT - REMOVAL, CYLINDER HEAD

COVER.............................9-102

RIGHT - REMOVAL, EXHAUST MANIFOLD . 9-150

RIGHT B-PILLAR SWITCH -

DESCRIPTION.......................8N-32

RIGHT B-PILLAR SWITCH -

INSTALLATION......................8N-32

RIGHT B-PILLAR SWITCH - OPERATION . . 8N-32

RIGHT B-PILLAR SWITCH - REMOVAL....8N-32

RIGHT D-PILLAR TRIM PANEL -

INSTALLATION.......................23-80

RIGHT D-PILLAR TRIM PANEL -

REMOVAL..........................23-80

RIGHT MOUNT - INSTALLATION.....9-135,9-51

RIGHT MOUNT - REMOVAL........9-135,9-51

RIGHT OUTBOARD - INSTALLATION,

SEAT BELT & RETRACTOR - SECOND

ROW ..............................8O-14

RIGHT OUTBOARD - REMOVAL, SEAT

BELT & RETRACTOR - SECOND ROW....8O-14

RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT BELT &

RETRACTOR - SECOND ROW...........8O-15

RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW...........8O-15

RIGHT QUARTER TRIM PANEL -

INSTALLATION.......................23-78

RIGHT QUARTER TRIM PANEL -

REMOVAL..........................23-78

RING, FITTING - PISTON

................9-45

RING FITTING - STANDARD

PROCEDURE, PISTON

.................9-121

RINGS - INSTALLATION, PISTON

........9-121

RINGS - REMOVAL, PISTON

............9-121

RISER - 50/50 SPLIT - INSTALLATION,

BENCH SEAT

........................23-99

RISER - 50/50 SPLIT - REMOVAL,

BENCH SEAT

........................23-99

RISER - INSTALLATION, LUGGAGE RACK

. . 23-55

RISER - INSTALLATION, QUAD BUCKET

SEAT

..............................23-96

RISER - MANUAL TRACK -

INSTALLATION, FRONT SEAT

...........23-93

RISER - MANUAL TRACK - REMOVAL,

FRONT SEAT

........................23-93

RISER - REMOVAL, LUGGAGE RACK

.....23-54

RISER - REMOVAL, QUAD BUCKET SEAT

. . 23-96

RISER - SECOND ROW - INSTALLATION,

BENCH SEAT

.......................23-100RISER - SECOND ROW - REMOVAL,

BENCH SEAT........................23-99

RISER - THIRD ROW - INSTALLATION,

BENCH SEAT.......................23-100

RISER - THIRD ROW - REMOVAL,

BENCH SEAT.......................23-100

RKE TRANSMITTER PROGRAMING -

STANDARD PROCEDURE..............8N-43

ROAD TEST - DIAGNOSIS AND TESTING . . . 8P-3

ROAD TEST - DIAGNOSIS AND TESTING . 21-119

ROCKER ARMS - DESCRIPTION.........9-109

ROCKER ARMS - INSPECTION...........9-35

ROCKER ARMS - INSTALLATION.........9-35

ROCKER ARMS - OPERATION...........9-109

ROCKER ARMS - REMOVAL.............9-34

ROCKER ARMS AND SHAFT - ASSEMBLY . 9-109

ROCKER ARMS AND SHAFT -

DISASSEMBLY.......................9-109

ROCKER ARMS AND SHAFT -

INSTALLATION.......................9-110

ROCKER ARMS AND SHAFT - REMOVAL . . 9-109

ROD - DESCRIPTION, LIFT GEAR & LINK . 8N-16

ROD - DESCRIPTION, PISTON &

CONNECTING....................9-116,9-42

ROD - INSTALLATION, LIFT GEAR &

LINK..............................8N-16

ROD - INSTALLATION, OUTER TIE.......19-34

ROD - INSTALLATION, PISTON &

CONNECTING.........................9-44

ROD - OPERATION, LIFT GEAR & LINK.....8N-16

ROD - REMOVAL, LIFT GEAR & LINK.....8N-16

ROD - REMOVAL, OUTER TIE...........19-34

ROD - REMOVAL, PISTON &

CONNECTING.........................9-43

ROD BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING

CONNECTING........................9-120

ROD, FITTING - CONNECTING............9-45

RODS - STANDARD PROCEDURE,

FITTING CONNECTING.................9-116

ROOF JOINT MOLDING - INSTALLATION . . 23-57

ROOF JOINT MOLDING - REMOVAL......23-57

ROTATION - STANDARD PROCEDURE,

TIRE AND WHEEL.....................22-7

ROTOR - DIAGNOSIS AND TESTING,

BRAKE..............................5-51

ROTOR - INSTALLATION, FRONT BRAKE . . . 5-54

ROTOR - REMOVAL, FRONT BRAKE.......5-54

ROTOR, EXPORT - BRAKE..............5-55

ROTOR MACHINING - STANDARD

PROCEDURE, BRAKE...................5-53

ROTOR, SPECIFICATIONS - BRAKE........5-55

ROW - BENCH - INSTALLATION, SEAT

BELT BUCKLE - FIRST................8O-12

ROW - BENCH - REMOVAL, SEAT BELT

BUCKLE - FIRST.....................8O-12

ROW - INSTALLATION, BENCH SEAT

RISER - SECOND

....................23-100

ROW - INSTALLATION, BENCH SEAT

RISER - THIRD

.....................23-100

ROW - LEFT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR - SECOND

...............8O-16

ROW - LEFT OUTBOARD - REMOVAL,

SEAT BELT & RETRACTOR - SECOND

....8O-16

ROW - OUTBOARD - INSTALLATION,

SEAT BELT & RETRACTOR - FIRST

......8O-13

ROW - OUTBOARD - REMOVAL, SEAT

BELT & RETRACTOR - FIRST

...........8O-13

ROW - REMOVAL, BENCH SEAT RISER -

SECOND

............................23-99

ROW - REMOVAL, BENCH SEAT RISER -

THIRD

............................23-100

ROW - RIGHT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR - SECOND

...............8O-14

ROW - RIGHT OUTBOARD - REMOVAL,

SEAT BELT & RETRACTOR - SECOND

....8O-14

ROW - RIGHT OUTBOARD WITH REAR

HVAC - LWB - INSTALLATION, SEAT

BELT & RETRACTOR - SECOND

.........8O-15

ROW - RIGHT OUTBOARD WITH REAR

HVAC - LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND

...............8O-15

ROW - THREE PASSENGER BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND

...........................8O-14ROW - THREE PASSENGER BENCH -

REMOVAL, SEAT BELT BUCKLE -

SECOND...........................8O-14

ROW INBOARD - 50/50 BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND...........................8O-12

ROW INBOARD - 50/50 BENCH -

REMOVAL, SEAT BELT BUCKLE -

SECOND...........................8O-12

ROW INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE -

FIRST.............................8O-11

ROW INBOARD - QUAD BUCKET -

REMOVAL, SEAT BELT BUCKLE - FIRST . . . 8O-11

RUN WEATHERSTRIP - INSTALLATION,

FRONT DOOR GLASS................23-110

RUN WEATHERSTRIP - REMOVAL,

FRONT DOOR GLASS................23-110

RUNOUT - DIAGNOSIS AND TESTING,

CLUTCH COVER AND DISC...............6-6

RUNOUT, SPECIFICATIONS - TONE

WHEEL.............................5-79

SAFETY CERTIFICATION LABEL -

DESCRIPTION, VEHICLE.............Intro.-11

SAFETY PRECAUTIONS AND WARNINGS,

WARNING...........................23-1

SAFETY PRECAUTIONS, WARNING -

WINDSHIELD.......................23-105

SANDING/BUFFING & POLISHING -

DESCRIPTION, FINESSE...............23-84

SBEC CONTROLLER - INSTALLATION.....8E-17

SBEC CONTROLLER - OPERATION,

8-VOLT SUPPLY - PCM OUTPUT.........8E-15

SBEC CONTROLLER - REMOVAL.........8E-16

SCHEDULES - DESCRIPTION,

MAINTENANCE........................0-7

SCHEMATICS AND DIAGRAMS - 41TE

TRANSAXLE HYDRAULIC SCHEMATICS . . 21-169

SCHEMATICS, SCHEMATICS AND

DIAGRAMS - 41TE TRANSAXLE

HYDRAULIC........................21-169

SCREEN - DESCRIPTION, VIDEO........8A-16

SCREEN - INSTALLATION, VIDEO........8A-16

SCREEN - OPERATION, VIDEO..........8A-16

SCREEN - REMOVAL, VIDEO............8A-16

SCUFF PAD - INSTALLATION, REAR

FASCIA..............................13-4

SCUFF PAD - REMOVAL, REAR FASCIA....13-3

SDP POWER TRANSFER UNIT, SPECIAL

TOOLS..............................21-8

SEAL - ASSEMBLY, CALIPER PISTON . . 5-26,5-29

SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP TO FILLER NECK.........7-27

SEAL - DISASSEMBLY, CALIPER PISTON . . . 5-24,

5-28

SEAL - FRONT - INSTALLATION,

CRANKSHAFT OIL................9-127,9-40

SEAL - FRONT - REMOVAL,

CRANKSHAFT OIL................9-127,9-40

SEAL - INSTALLATION, DIFFERENTIAL

CARRIER............................21-9

SEAL - INSTALLATION, END COVER......21-11

SEAL - INSTALLATION, HALF SHAFT

INNER.............................21-12

SEAL - INSTALLATION, INPUT FLANGE....3-45

SEAL - INSTALLATION, INPUT SHAFT.....21-18

SEAL - INSTALLATION, INPUT SHAFT

COVER.............................21-14

SEAL - INSTALLATION, INPUT SHAFT

END ...............................21-16

SEAL - INSTALLATION, OUTER HALF

SHAFT.............................21-19

SEAL - INSTALLATION, OUTPUT FLANGE . . . 3-46

SEAL - OIL PUMP - INSTALLATION.....21-233

SEAL - OIL PUMP - REMOVAL.........21-232

SEAL - REAR - INSTALLATION,

CRANKSHAFT OIL................9-129,9-42

SEAL - REAR - REMOVAL, CRANKSHAFT

OIL ...........................9-128,9-41

SEAL - REMOVAL, DIFFERENTIAL

CARRIER............................21-9

SEAL - REMOVAL, END COVER..........21-11

SEAL - REMOVAL, HALF SHAFT INNER . . . 21-12

SEAL - REMOVAL, INPUT FLANGE

........3-44

SEAL - REMOVAL, INPUT SHAFT

........21-17

SEAL - REMOVAL, INPUT SHAFT COVER

. . 21-13

SEAL - REMOVAL, INPUT SHAFT END

....21-15

SEAL - REMOVAL, OUTER HALF SHAFT

. . . 21-19

RSINDEX27

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com