reset CHRYSLER CARAVAN 2003 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 479 of 2177

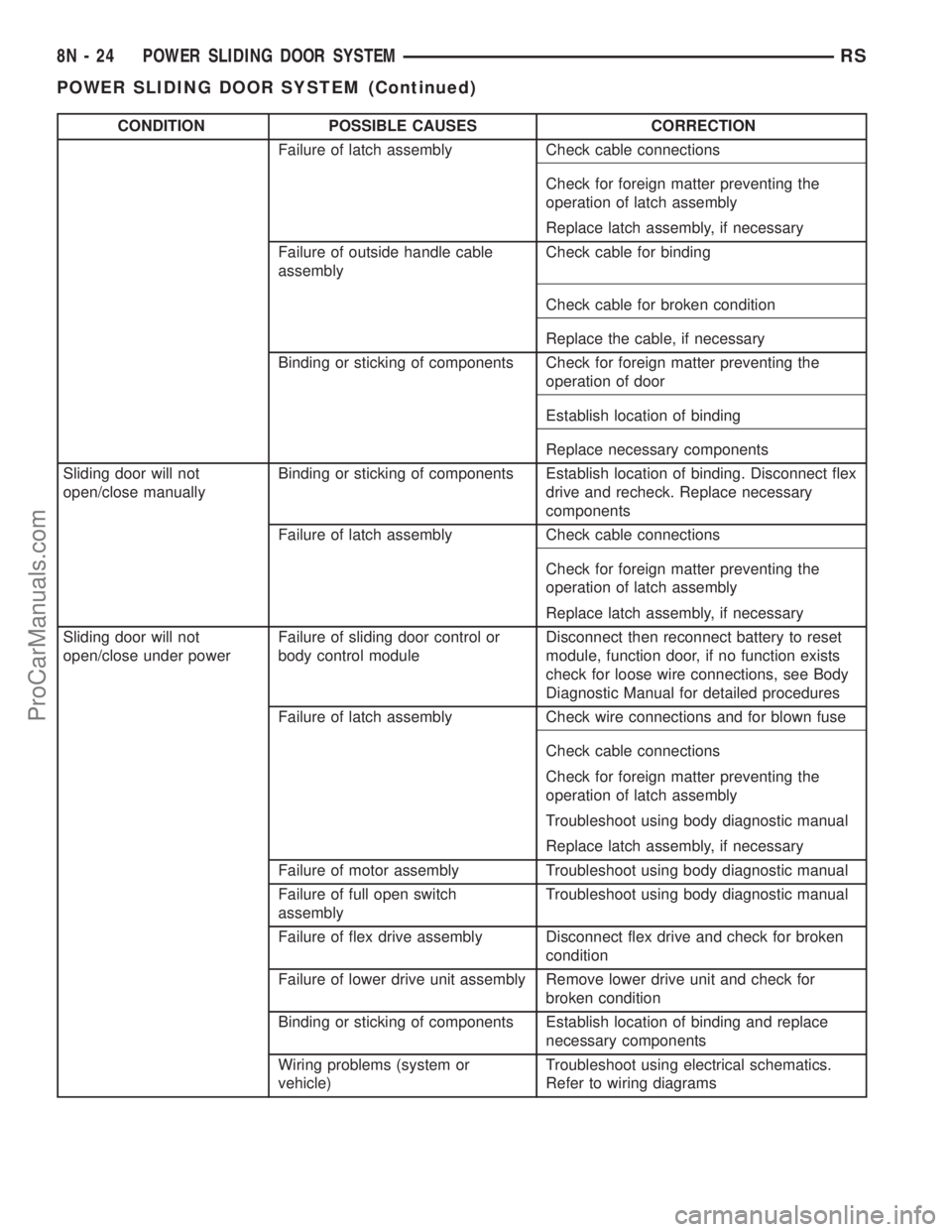

CONDITION POSSIBLE CAUSES CORRECTION

Failure of latch assembly Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Replace latch assembly, if necessary

Failure of outside handle cable

assemblyCheck cable for binding

Check cable for broken condition

Replace the cable, if necessary

Binding or sticking of components Check for foreign matter preventing the

operation of door

Establish location of binding

Replace necessary components

Sliding door will not

open/close manuallyBinding or sticking of components Establish location of binding. Disconnect flex

drive and recheck. Replace necessary

components

Failure of latch assembly Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Replace latch assembly, if necessary

Sliding door will not

open/close under powerFailure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of motor assembly Troubleshoot using body diagnostic manual

Failure of full open switch

assemblyTroubleshoot using body diagnostic manual

Failure of flex drive assembly Disconnect flex drive and check for broken

condition

Failure of lower drive unit assembly Remove lower drive unit and check for

broken condition

Binding or sticking of components Establish location of binding and replace

necessary components

Wiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

8N - 24 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

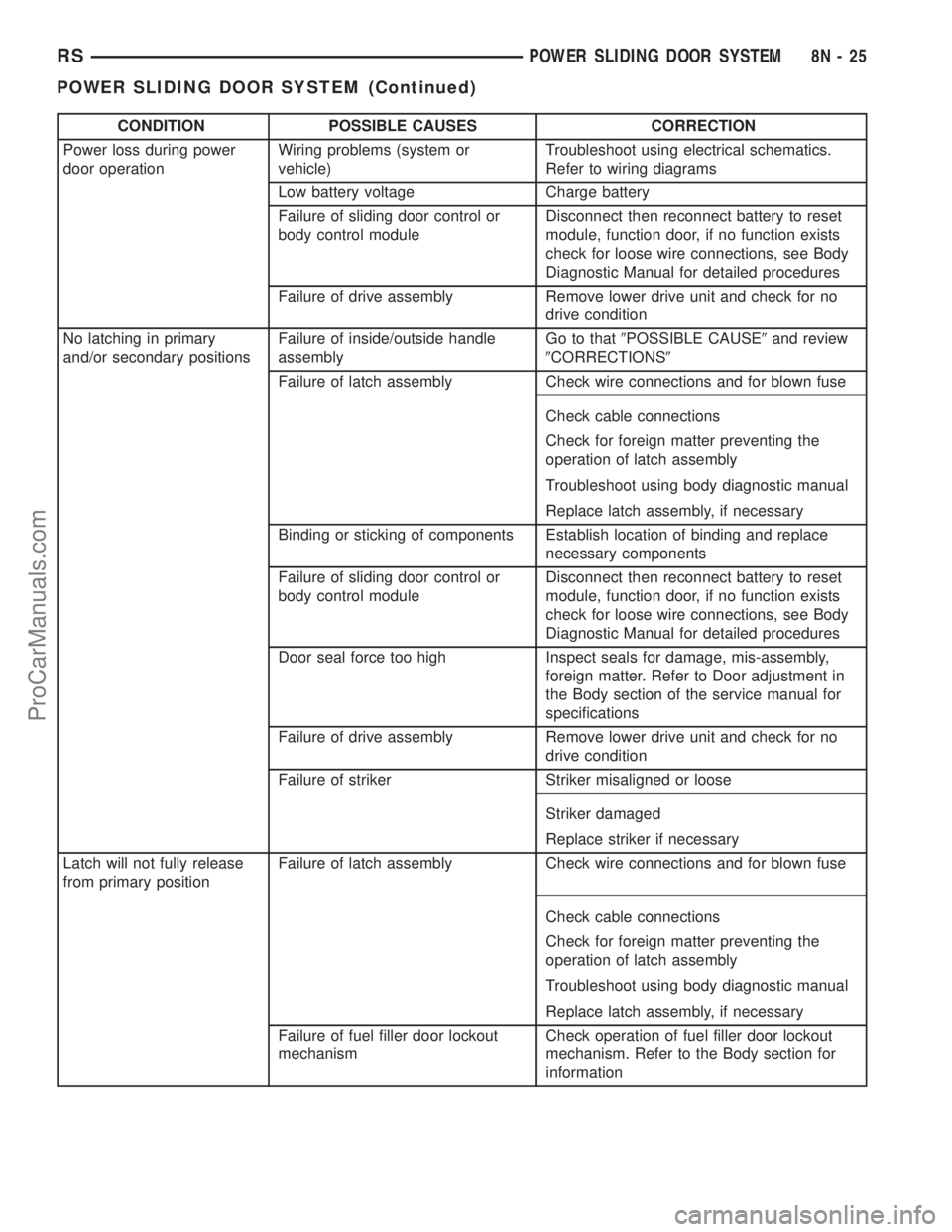

Page 480 of 2177

CONDITION POSSIBLE CAUSES CORRECTION

Power loss during power

door operationWiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

Low battery voltage Charge battery

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of drive assembly Remove lower drive unit and check for no

drive condition

No latching in primary

and/or secondary positionsFailure of inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Failure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Door seal force too high Inspect seals for damage, mis-assembly,

foreign matter. Refer to Door adjustment in

the Body section of the service manual for

specifications

Failure of drive assembly Remove lower drive unit and check for no

drive condition

Failure of striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Latch will not fully release

from primary positionFailure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of fuel filler door lockout

mechanismCheck operation of fuel filler door lockout

mechanism. Refer to the Body section for

information

RSPOWER SLIDING DOOR SYSTEM8N-25

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

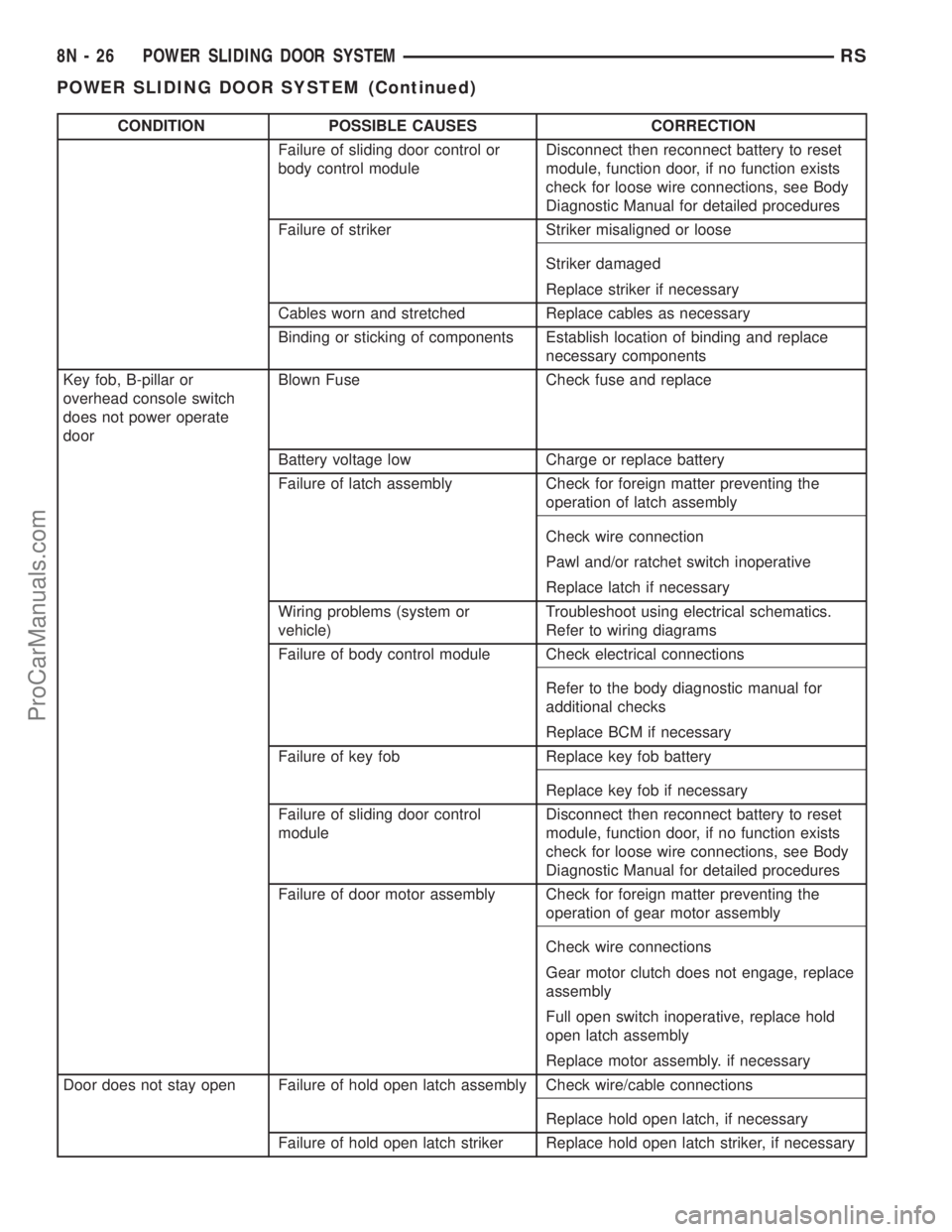

Page 481 of 2177

CONDITION POSSIBLE CAUSES CORRECTION

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Cables worn and stretched Replace cables as necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Key fob, B-pillar or

overhead console switch

does not power operate

doorBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery

Failure of latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

Failure of body control module Check electrical connections

Refer to the body diagnostic manual for

additional checks

Replace BCM if necessary

Failure of key fob Replace key fob battery

Replace key fob if necessary

Failure of sliding door control

moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of door motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Gear motor clutch does not engage, replace

assembly

Full open switch inoperative, replace hold

open latch assembly

Replace motor assembly. if necessary

Door does not stay open Failure of hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Failure of hold open latch striker Replace hold open latch striker, if necessary

8N - 26 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 482 of 2177

CONDITION POSSIBLE CAUSES CORRECTION

High inside/outside opening

effortFailure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Binding or sticking of components Establish location of binding and replace

necessary components

Door continues to cinch

closed during power modeFailure of latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Wiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door continues to open

during power mode

(runaway motor)Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Failure of drive assembly Remove lower drive unit and check for no

drive condition

Wiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door opens very slowly Failure of door motor assembly Check wire/cable connections

Replace motor assembly, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Squeaks, Noises and rattles Foreign material in door

compartmentRemove foreign material

Loose components Check and tighten loose components

Poor door track lubrication Lubricate the front portions of the side door

tracks with9Door EaseT9or equivalent

RSPOWER SLIDING DOOR SYSTEM8N-27

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 506 of 2177

The power seat system includes the following com-

ponents:

²Power seat recliners

²Power seat switches

²Power seat tracks

²Circuit breaker

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Heated Seat Module (HSM)

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

²Programmable Communications Interface (PCI)

data bus network

Refer to Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions and opera-

tions for the major components in the power seat

system and memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is available on some

models. The memory system is able to store and

recall the driver side power seat positions (including

the power recliner position) and both outside side

view mirrors positions for two drivers. On vehicles

equipped with a factory radio, the memory system is

also able to store and recall radio station presets fortwo drivers. The memory system also will store and

recall the last station listened to for each driver, even

if it is not one of the preset stations.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

EVIC module, which is located in the overhead con-

sole.

A Memory Seat Mirror Module (MSMM) is used on

some models to control and integrate the many elec-

tronic functions and features included in the memory

seat and mirror systems.

The memory system includes the following compo-

nents:

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Position potentiometers on both outside side

view mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Electronic Vehicle Information Center (EVIC)

²Radio receiver (if PCI data bus capable).

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) J1850 data bus network. The PCI

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor

current loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and

allows the addition of many new feature capabilities.

Initial diagnosis of these electronic modules or the

PCI data bus network requires the use of a DRBIIIt

scan tool and the proper Diagnostic Procedures man-

ual. If this method does not prove conclusive, the use

of a automotive meter such as the Fluket, the proper

wiring schematics and the service manual diagnostic

routines are required.

The other electronic modules that may affect mem-

ory system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²Powertrain Control Module (PCM)- Refer to

Powertrain Control Modulein Electronic Control

Modules for more information.

²Transmission Control Module (TCM)- Refer

toTransmission Control Modulein Electronic

Control Modules for more information.

Fig. 1 Identifying a Side Airbag Equipped Seat

1 - Airbag Label

RSPOWER SEAT SYSTEM8N-51

POWER SEAT SYSTEM (Continued)

ProCarManuals.com

Page 507 of 2177

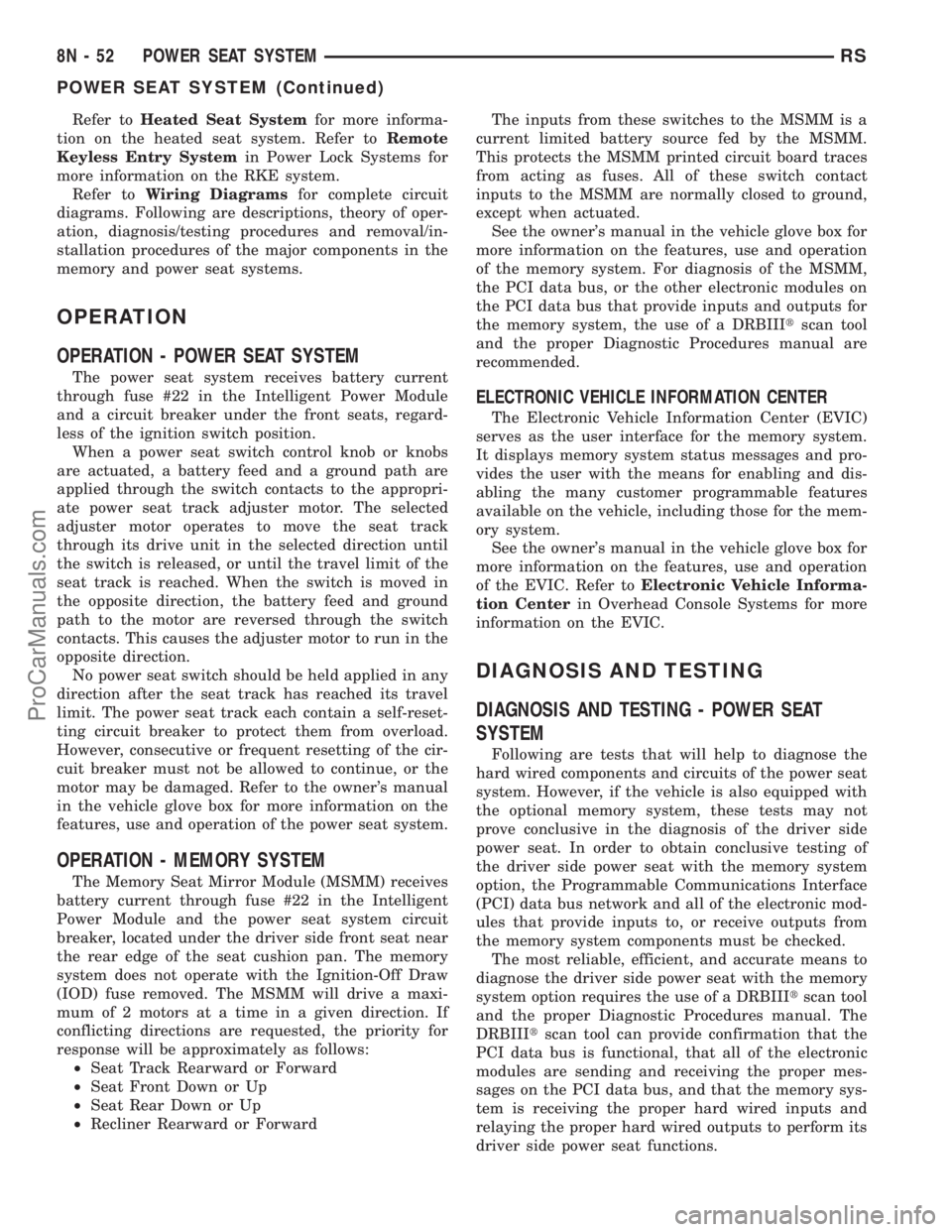

Refer toHeated Seat Systemfor more informa-

tion on the heated seat system. Refer toRemote

Keyless Entry Systemin Power Lock Systems for

more information on the RKE system.

Refer toWiring Diagramsfor complete circuit

diagrams. Following are descriptions, theory of oper-

ation, diagnosis/testing procedures and removal/in-

stallation procedures of the major components in the

memory and power seat systems.

OPERATION

OPERATION - POWER SEAT SYSTEM

The power seat system receives battery current

through fuse #22 in the Intelligent Power Module

and a circuit breaker under the front seats, regard-

less of the ignition switch position.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction.

No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat track each contain a self-reset-

ting circuit breaker to protect them from overload.

However, consecutive or frequent resetting of the cir-

cuit breaker must not be allowed to continue, or the

motor may be damaged. Refer to the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

The Memory Seat Mirror Module (MSMM) receives

battery current through fuse #22 in the Intelligent

Power Module and the power seat system circuit

breaker, located under the driver side front seat near

the rear edge of the seat cushion pan. The memory

system does not operate with the Ignition-Off Draw

(IOD) fuse removed. The MSMM will drive a maxi-

mum of 2 motors at a time in a given direction. If

conflicting directions are requested, the priority for

response will be approximately as follows:

²Seat Track Rearward or Forward

²Seat Front Down or Up

²Seat Rear Down or Up

²Recliner Rearward or ForwardThe inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory system. For diagnosis of the MSMM,

the PCI data bus, or the other electronic modules on

the PCI data bus that provide inputs and outputs for

the memory system, the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual are

recommended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer toElectronic Vehicle Informa-

tion Centerin Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual. The

DRBIIItscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

8N - 52 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

ProCarManuals.com

Page 509 of 2177

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's

manual in the vehicle glove box for more information

on the power seat switch functions and the seat

adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER SEAT

SWITCH

(1) Remove the power seat switch, refer to the

Switch Removal and Installation procedures in this

section.

(2) Using an ohmmeter, check pin #1 in the power

seat switch connector receptacle for continuity to

ground. It should be present. If OK, go to Step 3. If

not OK, repair the open ground circuit as required.

(3) Using an voltmeter, check pin #5 of the wire

harness connector for the power seat switch for bat-

tery current. It should be present. If OK, go to Step

4. If not OK, repair the open voltage supply circuit as

required.

(4) Using an ohmmeter, test the power seat switch

continuity as shown in the Test Table at the pins in

the switch connector receptacle (Fig. 3). If there is no

continuity at any of the switch positions, replace the

power seat switch.

DRIVER SEAT SWITCH CONTINUITY TEST

TABLE

SWITCH

POSITIONCONTINUITY BETWEEN

PINS

DRIVER

OFF PIN5&4

PIN5&3

PIN5&2

PIN5&10

PIN5&9

PIN5&8

PIN5&7

PIN5&6

FRONT RISER

UPPIN5&6

PIN1&9

FRONT RISER

DOWNPIN5&9

PIN1&6

CENTER

SWITCH

FORWARDPIN5&3

PIN1&10

CENTER

SWITCH

REARWARDPIN5&10

PIN3&1

REAR RISER UP PIN5&7

PIN1&8

REAR RISER

DOWNPIN5&8

PIN1&7

RECLINER UP PIN5&2

PIN4&1

RECLINER

DOWNPIN5&4

PIN2&1

Fig. 3 Seat Switch Pin Call-Out

8N - 54 POWER SEAT SYSTEMRS

DRIVER SEAT SWITCH (Continued)

ProCarManuals.com

Page 511 of 2177

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. When the memory set

switch is depressed, a resistance value is sent to the

Body Control Module via hard wired connections.

When the memory system is in ªsetº mode a chime

will be generated by the body control module.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch.

DIAGNOSIS AND TESTING - MEMORY SWITCH

(1) Remove the memory set switch from the driv-

ers door panel (Refer to 8 - ELECTRICAL/POWER

SEATS/MEMORY SET SWITCH - REMOVAL).

(2) Using an ohmmeter, check the continuity of the

memory select switch MUX circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

3. If not OK, repair the open or shorted MUX circuit

as required.

(3) Using an ohmmeter, check the continuity of the

memory select switch return circuit between the C2

wire harness connector for the body control module

and the wire harness connector for the memory

switch. There should be continuity. If OK, go to Step

4. If not OK, repair the open or shorted return circuit

as required.

(4) Using an ohmmeter, test the resistances of the

memory switch at the pins in the switch connector

receptacle in each switch position. See the Memory

Switch Test Table. If OK, refer toDiagnosis and

Testing Memory Systemin this section. If not OK,

replace the faulty memory set switch.

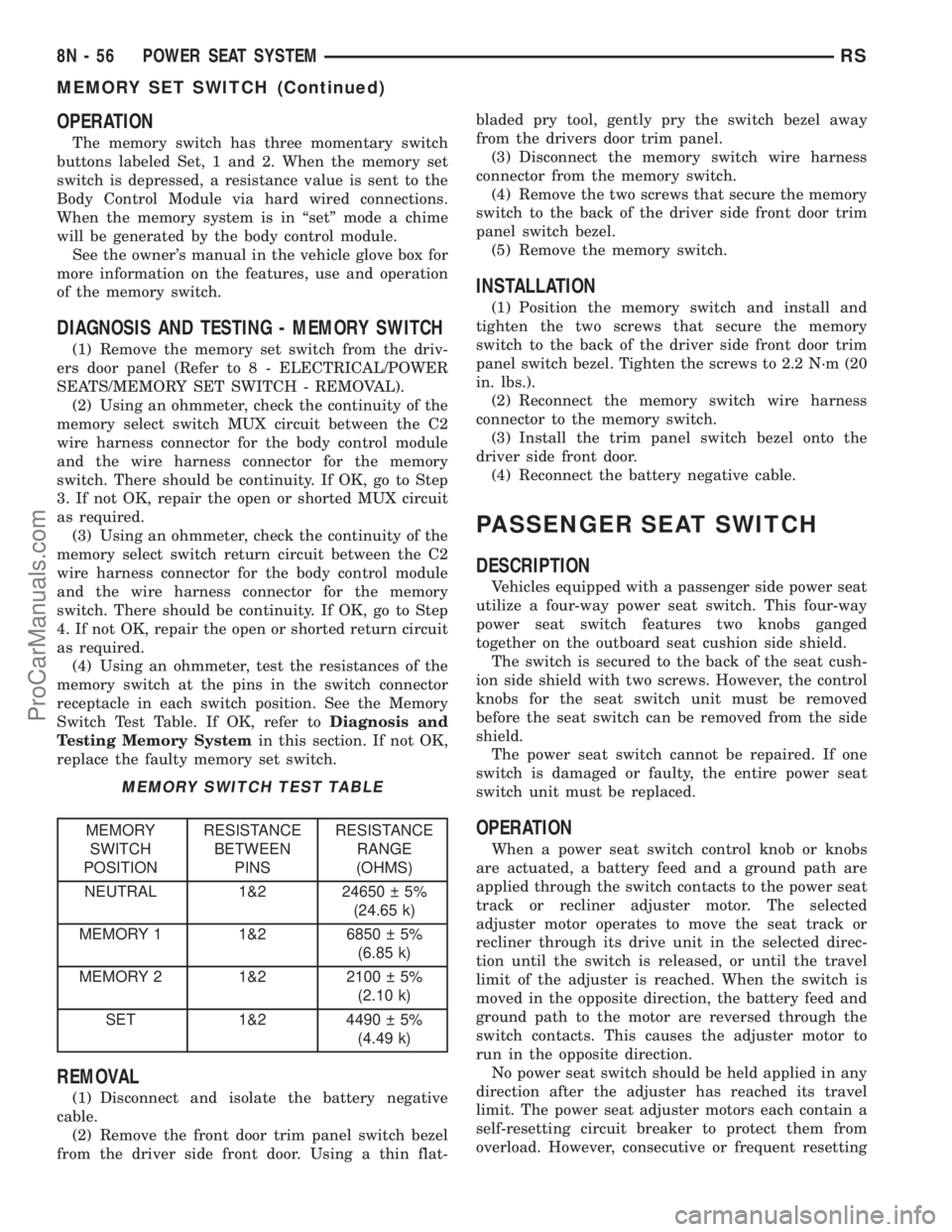

MEMORY SWITCH TEST TABLE

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEEN

PINSRESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24650 5%

(24.65 k)

MEMORY 1 1&2 6850 5%

(6.85 k)

MEMORY 2 1&2 2100 5%

(2.10 k)

SET 1&2 4490 5%

(4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel.

(5) Remove the memory switch.

INSTALLATION

(1) Position the memory switch and install and

tighten the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel. Tighten the screws to 2.2 N´m (20

in. lbs.).

(2) Reconnect the memory switch wire harness

connector to the memory switch.

(3) Install the trim panel switch bezel onto the

driver side front door.

(4) Reconnect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

Vehicles equipped with a passenger side power seat

utilize a four-way power seat switch. This four-way

power seat switch features two knobs ganged

together on the outboard seat cushion side shield.

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

8N - 56 POWER SEAT SYSTEMRS

MEMORY SET SWITCH (Continued)

ProCarManuals.com

Page 513 of 2177

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Install the switch knobs on the switch control

levers, if equipped.

(7) Reconnect the battery negative cable.

DRIVER POWER SEAT TRACK

DESCRIPTION

The eight-way driver side power seat option

includes a electrically operated power seat track

located under the driver side front seat. The front

power seat track on the driver side of the vehicle also

provides the mounting location for the Memory Seat/

Mirror Module (MSMM). The power seat circuit

breakers are mounted on the rear of the driver side

power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

pan to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.

The power seat track unit includes four reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the four power seat

track motors used on models equipped with the

optional memory system incorporates a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position. This

enables the memory system to function by referenc-

ing the motor positions programmed into the memory

seat/mirror module.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

The forth motor is the recliner adjustment motor,

which moves the seat back in the forward and rear-

ward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any componentin this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When the driver side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the driver side power seat switch to move

all three power seat track adjusters in each direction.

The power seat track adjusters should move in each

of the selected directions. If a power seat track

adjuster fails to operate in only one direction, move

the adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switchin this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer toWiring

Diagrams.

8N - 58 POWER SEAT SYSTEMRS

PASSENGER SEAT SWITCH (Continued)

ProCarManuals.com

Page 515 of 2177

ward and rearward directions. The recliner adjust-

ment motor moves the seat back in the forward and

rearward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any component

in this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When a passenger side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - POWER SEAT

TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the passenger side power seat switch to

move the power seat track adjuster in each direction.

The power seat track adjuster should move in each of

the selected directions. If a power seat track adjuster

fails to operate in only one direction, move the

adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switchin this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toDiagnosis

and Testing Power Seat Switchin this section. If

the switch tests OK, test the circuits of the power

seat wire harness between the inoperative power seat

track adjuster motor and the power seat switch for

shorts or opens. If the circuits check OK, replace the

faulty power seat track unit. If the circuits are not

OK, repair the power seat wire harness as required.

8N - 60 POWER SEAT SYSTEMRS

PASSENGER POWER SEAT TRACK (Continued)

ProCarManuals.com