charging CHRYSLER CARAVAN 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 2083 of 2177

K thermocouple. If a digital multimeter is not avail-

able, this tool is also available through the PSE pro-

gram.

NOTE: When connecting the service equipment

couplings to the refrigerant system service ports,

be certain that the valve of each coupling is fully

closed. This will reduce the amount of effort

required to make the connection.

(1) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set or a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 to the refriger-

ant system.

(2) Attach a clamp-on thermocouple to the liquid

line. The thermocouple must be placed as close to the

A/C pressure transducer as possible to accurately

observe liquid line temperature.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run at idle under the following condi-

tions for five minutes.

(a) Front windows are open.

(b) Transaxle in Park.

(c) Front heater-A/C controls set to outside air,

full cool, panel mode, blower high, and compressor

engaged.

(d) If the vehicle is so equipped, the rear heater-

A/C controls must be set to full cool and blower

high.

(4) Raise the liquid line (discharge) pressure to

about 1793 kPa (260 psi) by placing a piece of card-

board over part of the front side of the condenser. To

place the cardboard properly, remove the upper radi-

ator sight shield from the front fascia. Cover only

enough of the condenser to raise and maintain the

liquid line pressure at the specified level.

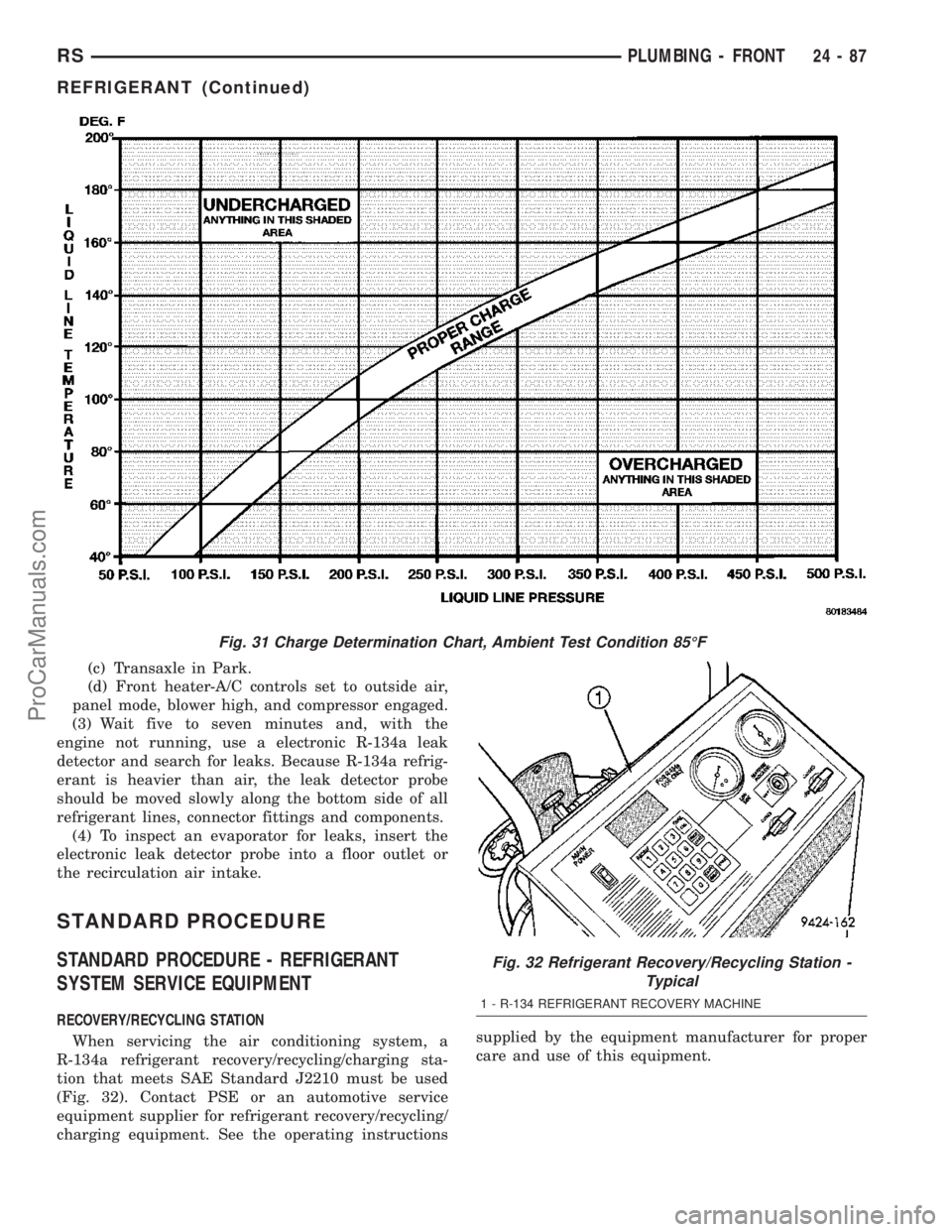

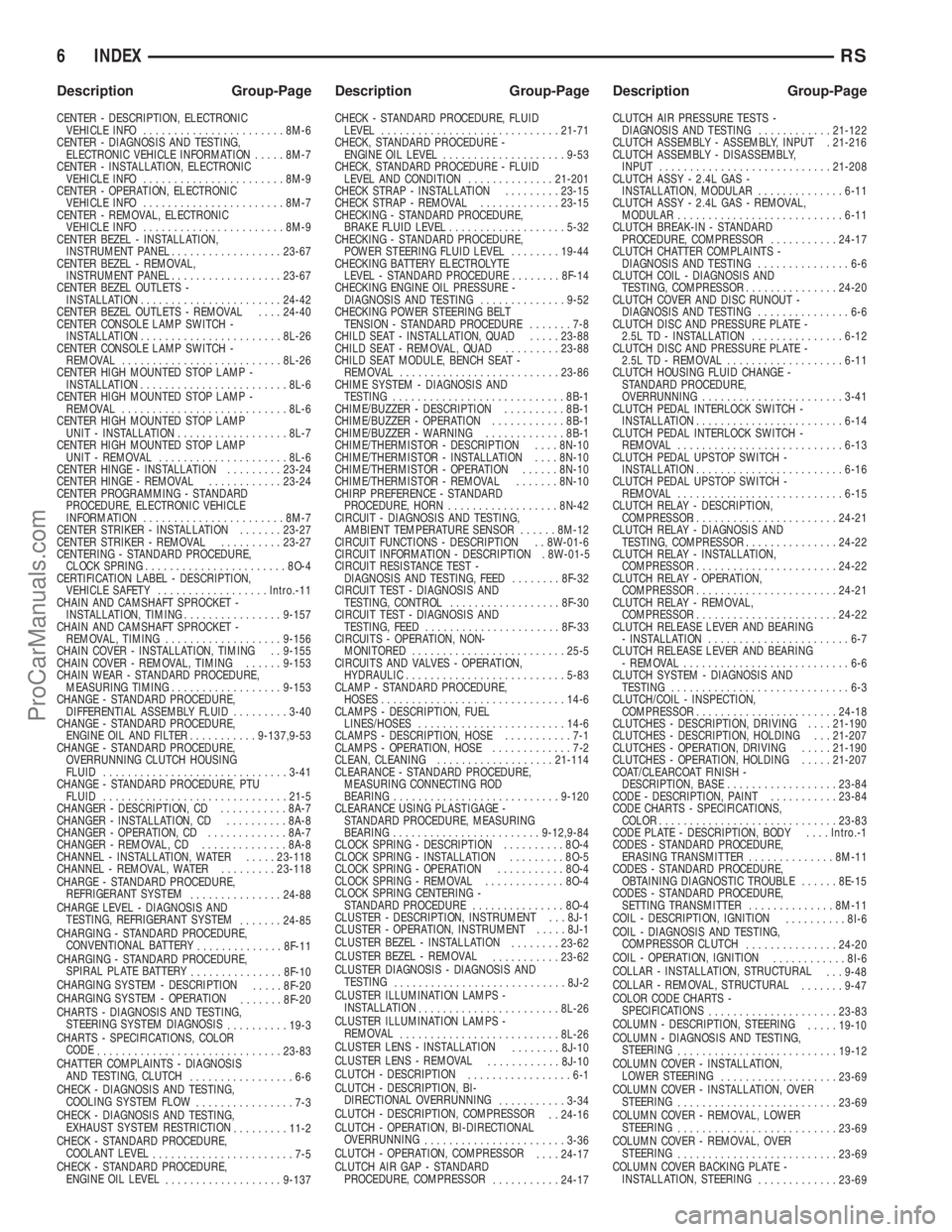

(5) Observe the liquid line (discharge) pressure

and liquid line temperature. Using the Charge Deter-

mination Chart (Fig. 31), determine whether the

refrigerant system is operating within the Proper

Charge Range.

(a) If the refrigerant system is operating in the

Undercharged area of the chart, add 0.057 kilo-

gram (0.125 pound or 2 ounces) of refrigerant to

the system.

(b) If the refrigerant system is operating in the

Overcharged area of the chart, reclaim 0.057 kilo-

gram (0.125 pound or 2 ounces) of refrigerant from

the system.

(6) Recheck the system charge level following each

refrigerant adjustment. Continue this process until

the system readings are in the Proper Charge Range

area on the Charge Determination Chart.DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

If the air conditioning system is not cooling prop-

erly, determine if the refrigerant system is fully-

charged. (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - FRONT/REFRIGER-

ANT - DIAGNOSIS AND TESTING - REFRIGER-

ANT SYSTEM CHARGE LEVEL).

If the refrigerant system is low or empty; a leak at

a refrigerant line, connector fitting, component, or

component seal is likely. While an oily residue on or

near refrigerant system lines, connector fittings, com-

ponents, or component seals can indicate the general

location of a possible refrigerant leak, the exact leak

location should be confirmed with an electronic leak

detector prior to component repair or replacement.

An electronic leak detector designed for R-134a

refrigerant is recommended for locating and confirm-

ing refrigerant system leaks. See the operating

instructions supplied by the equipment manufacturer

for proper care and use of this equipment.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

results of the refrigerant system charge level test.

SYSTEM EMPTY

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(2) Connect and dispense 0.283 kilograms (0.625

pounds or 10 ounces) of R-134a refrigerant into the

evacuated refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - FRONT/

REFRIGERANT - STANDARD PROCEDURE -

REFRIGERANT SYSTEM CHARGE).

(3) Proceed to the SYSTEM LOW procedures.

SYSTEM LOW

(1) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(2) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run at idle under the following condi-

tions for five minutes, then turning the engine off.

(a) Front windows are open.

(b) Rear air conditioner Off (if equipped).

24 - 86 PLUMBING - FRONTRS

REFRIGERANT (Continued)

ProCarManuals.com

Page 2084 of 2177

(c) Transaxle in Park.

(d) Front heater-A/C controls set to outside air,

panel mode, blower high, and compressor engaged.

(3) Wait five to seven minutes and, with the

engine not running, use a electronic R-134a leak

detector and search for leaks. Because R-134a refrig-

erant is heavier than air, the leak detector probe

should be moved slowly along the bottom side of all

refrigerant lines, connector fittings and components.

(4) To inspect an evaporator for leaks, insert the

electronic leak detector probe into a floor outlet or

the recirculation air intake.

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

RECOVERY/RECYCLING STATION

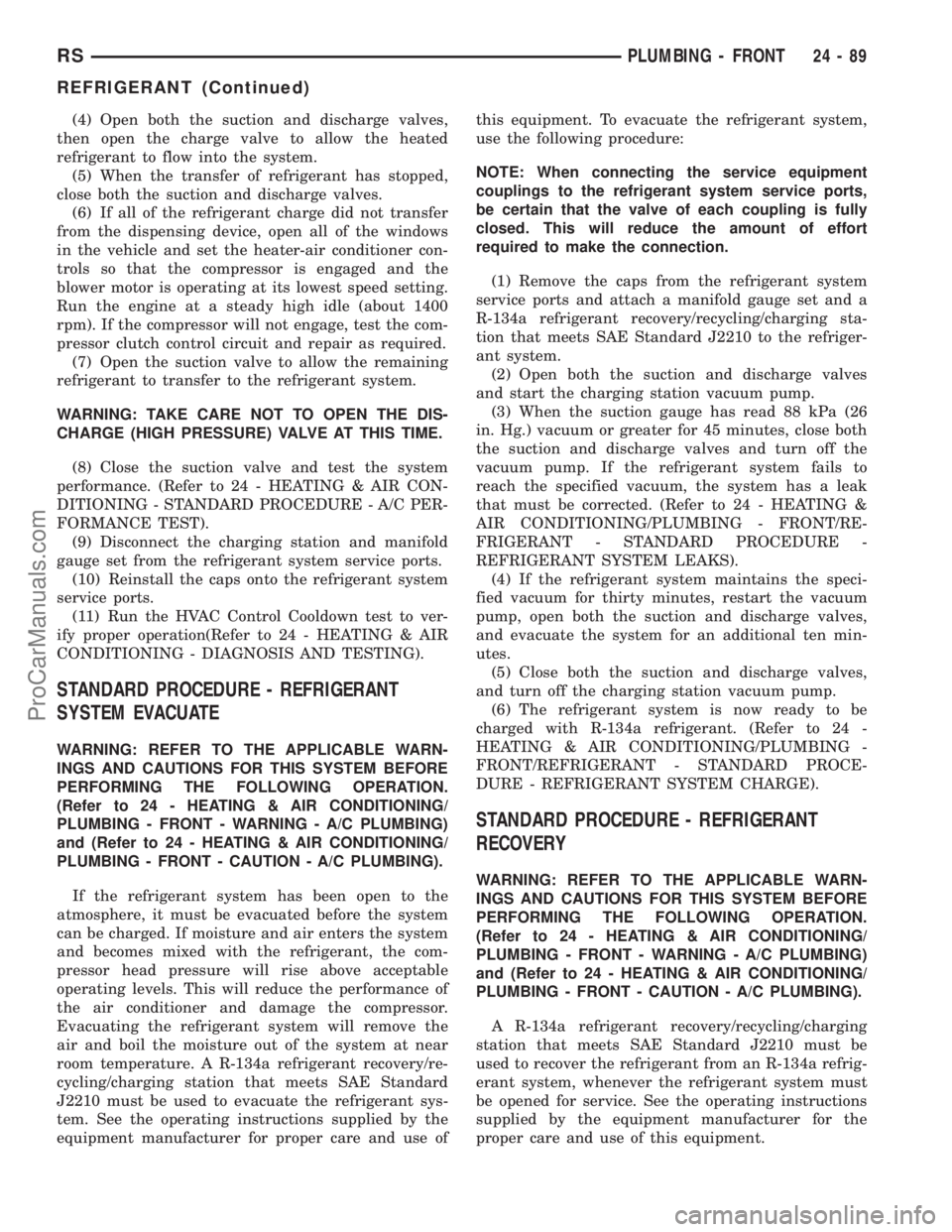

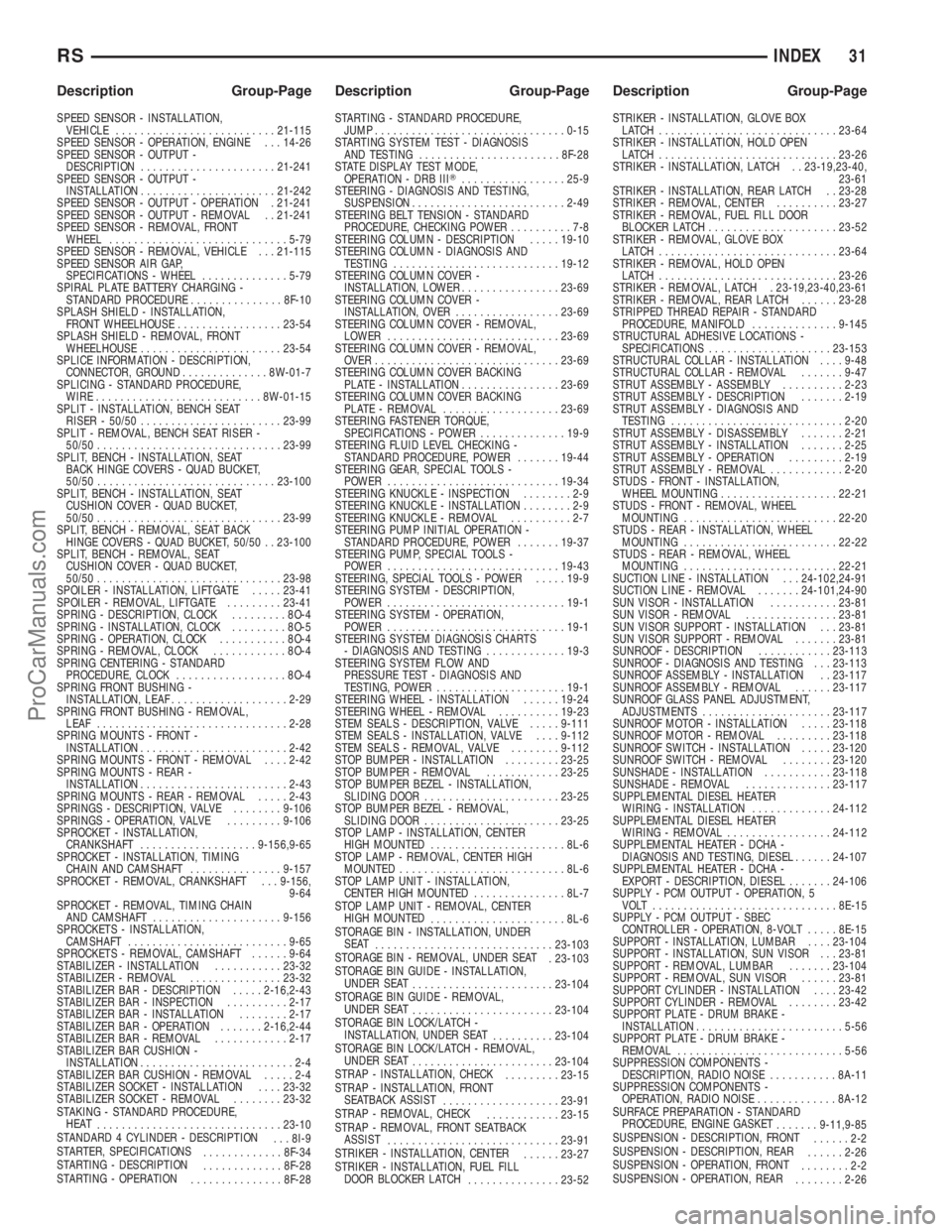

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used

(Fig. 32). Contact PSE or an automotive service

equipment supplier for refrigerant recovery/recycling/

charging equipment. See the operating instructionssupplied by the equipment manufacturer for proper

care and use of this equipment.

Fig. 31 Charge Determination Chart, Ambient Test Condition 85ÉF

Fig. 32 Refrigerant Recovery/Recycling Station -

Typical

1 - R-134 REFRIGERANT RECOVERY MACHINE

RSPLUMBING - FRONT24-87

REFRIGERANT (Continued)

ProCarManuals.com

Page 2085 of 2177

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 33). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

²LOW PRESSURE GAUGE HOSE- The low

pressure hose (Blue with Black stripe) attaches to

the suction (low side) service port. This port is

located on the suction line, near the compressor at

the front of the engine compartment.

²HIGH PRESSURE GAUGE HOSE- The high

pressure hose (Red with Black stripe) attaches to the

discharge (high side) service port. This port is located

on the liquid line near the filter-drier at the rear of

the engine compartment.

²RECOVERY/RECYCLING/EVACUATION/

CHARGING HOSE- The center manifold hose (Yel-

low, or White, with Black stripe) is used to recover,

evacuate, and charge the refrigerant system. When

the low or high pressure valves on the manifoldgauge set are opened, the refrigerant in the system

will escape through this hose.

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

After all refrigerant system leaks have been

repaired and the refrigerant system has been evacu-

ated, a refrigerant charge can be injected into the

system. For the proper amount of the refrigerant

charge, refer to REFRIGERANT CHARGE CAPAC-

ITY . A R-134a refrigerant recovery/recycling/charg-

ing station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. See the operating instructions supplied

by the equipment manufacturer for proper care and

use of this equipment.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle is:

²Single or Dual Zone (Front Unit Only - with

2.5L Turbo Diesel)0.79 kilograms (1.75 pounds or

28 ounces)

²Single or Dual Zone (Front Unit Only)- 0.88

kilograms (1.94 pounds or 31 ounces)

²Three Zone (Front and Rear Units)- 1.21

kilograms (2.69 pounds or 43 ounces)

NOTE: Always refer to the underhood HVAC Speci-

fication Tag for the latest fill specification for the

vehicle being serviced.

CHARGING PROCEDURE

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(2) A manifold gauge set and a R-134a refrigerant

recovery/recycling/charging station that meets SAE

Standard J2210 should still be connected to the

refrigerant system.

(3) Measure the proper amount of refrigerant and

heat it to 52É C (125É F) with the charging station.

See the operating instructions supplied by the equip-

ment manufacturer for proper use of this equipment.

Fig. 33 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK STRIPE)

4 - HIGH PRESSURE HOSE (RED W/BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

24 - 88 PLUMBING - FRONTRS

REFRIGERANT (Continued)

ProCarManuals.com

Page 2086 of 2177

(4) Open both the suction and discharge valves,

then open the charge valve to allow the heated

refrigerant to flow into the system.

(5) When the transfer of refrigerant has stopped,

close both the suction and discharge valves.

(6) If all of the refrigerant charge did not transfer

from the dispensing device, open all of the windows

in the vehicle and set the heater-air conditioner con-

trols so that the compressor is engaged and the

blower motor is operating at its lowest speed setting.

Run the engine at a steady high idle (about 1400

rpm). If the compressor will not engage, test the com-

pressor clutch control circuit and repair as required.

(7) Open the suction valve to allow the remaining

refrigerant to transfer to the refrigerant system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH PRESSURE) VALVE AT THIS TIME.

(8) Close the suction valve and test the system

performance. (Refer to 24 - HEATING & AIR CON-

DITIONING - STANDARD PROCEDURE - A/C PER-

FORMANCE TEST).

(9) Disconnect the charging station and manifold

gauge set from the refrigerant system service ports.

(10) Reinstall the caps onto the refrigerant system

service ports.

(11) Run the HVAC Control Cooldown test to ver-

ify proper operation(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING).

STANDARD PROCEDURE - REFRIGERANT

SYSTEM EVACUATE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be charged. If moisture and air enters the system

and becomes mixed with the refrigerant, the com-

pressor head pressure will rise above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor.

Evacuating the refrigerant system will remove the

air and boil the moisture out of the system at near

room temperature. A R-134a refrigerant recovery/re-

cycling/charging station that meets SAE Standard

J2210 must be used to evacuate the refrigerant sys-

tem. See the operating instructions supplied by the

equipment manufacturer for proper care and use ofthis equipment. To evacuate the refrigerant system,

use the following procedure:

NOTE: When connecting the service equipment

couplings to the refrigerant system service ports,

be certain that the valve of each coupling is fully

closed. This will reduce the amount of effort

required to make the connection.

(1) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set and a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 to the refriger-

ant system.

(2) Open both the suction and discharge valves

and start the charging station vacuum pump.

(3) When the suction gauge has read 88 kPa (26

in. Hg.) vacuum or greater for 45 minutes, close both

the suction and discharge valves and turn off the

vacuum pump. If the refrigerant system fails to

reach the specified vacuum, the system has a leak

that must be corrected. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - FRONT/RE-

FRIGERANT - STANDARD PROCEDURE -

REFRIGERANT SYSTEM LEAKS).

(4) If the refrigerant system maintains the speci-

fied vacuum for thirty minutes, restart the vacuum

pump, open both the suction and discharge valves,

and evacuate the system for an additional ten min-

utes.

(5) Close both the suction and discharge valves,

and turn off the charging station vacuum pump.

(6) The refrigerant system is now ready to be

charged with R-134a refrigerant. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

STANDARD PROCEDURE - REFRIGERANT

RECOVERY

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system, whenever the refrigerant system must

be opened for service. See the operating instructions

supplied by the equipment manufacturer for the

proper care and use of this equipment.

RSPLUMBING - FRONT24-89

REFRIGERANT (Continued)

ProCarManuals.com

Page 2094 of 2177

OPERATION

A mechanical sensor in the expansion valve control

head monitors the temperature and pressure of the

refrigerant leaving the evaporator coil through the

suction line, and adjusts the orifice size at the liquid

line to let the proper amount of refrigerant into the

evaporator coil to meet the vehicle cooling require-

ments. Controlling the refrigerant flow through the

evaporator ensures that none of the refrigerant leav-

ing the evaporator is still in a liquid state, which

could damage the compressor.

DIAGNOSIS AND TESTING - EXPANSION VALVE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The expansion valve should only be tested

following testing of the compressor.

NOTE: Liquid CO

2is required to test the expansion

valve. This material is available from most welding

supply facilities. Liquid CO

2is also available from

companies which service and sell fire extinguish-

ers.

When testing the expansion valve, the work area

and the vehicle temperature must be 21É to 27É C

(70É to 85É F). To test the expansion valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set the heater-air conditioner controls so that

the compressor is operating, the temperature control

is in the highest temperature position, the mode door

is directing the output to the floor outlets, and the

blower is operating at the highest speed setting.

(4) Start the engine and allow it to idle at 1000

rpm. After the engine has reached normal operating

temperature, allow the passenger compartment to

heat up. This will create the need for maximum

refrigerant flow into the evaporator.

(5) If the refrigerant charge is sufficient, the dis-

charge (high pressure) gauge should read 965 to 1655

kPa (140 to 240 psi). The suction (low pressure)

gauge should read 140 kPa to 207 kPa (20 psi to 30

psi). If OK, go to Step 6. If not OK, replace the faulty

expansion valve.WARNING: PROTECT THE SKIN AND EYES FROM

EXPOSURE TO LIQUID CO

2. PERSONAL INJURY

CAN RESULT.

(6) If the suction (low pressure) gauge reads

within the specified range, freeze the expansion valve

control head for 30 seconds using liquid CO

2or

another suitable super-cold material.Do not spray

R-134a or R-12 refrigerant on the expansion

valve control head for this test.The suction (low

pressure) gauge reading should drop by 10 psi. If OK,

go to Step 7 If not OK, replace the faulty expansion

valve.

(7) Allow the expansion valve control head to thaw.

The suction (low pressure) gauge reading should sta-

bilize at 140 kPa to 240 kPa (20 psi to 30 psi). If not

OK, replace the faulty expansion valve.

(8) When expansion valve testing is complete, test

the overall air conditioner performance. (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE TEST).

Remove all test equipment before returning the vehi-

cle to service.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING),

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING),

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - HEATER PLUMB-

ING).

(1) Remove the rear heater-A/C unit housing from

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/REAR HEATER-

A/C HOUSING - REMOVAL).

(2) Carefully remove the foam insulator wrap from

the rear expansion valve.

(3) Remove the rear evaporator line extension from

the expansion valve. (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - REAR/EVAPORA-

TOR - REMOVAL - EVAPORATOR LINE EXTEN-

SION).

(4) Remove the two screws that secure the expan-

sion valve to the evaporator tube sealing plate.

(5) Remove the expansion valve from the evapora-

tor tubes.

(6) Remove the seals from the evaporator tube fit-

tings and discard.

(7) Install plugs in, or tape over the opened evap-

orator tube fittings and both expansion valve ports.

RSPLUMBING - REAR24-97

EXPANSION VALVE (Continued)

ProCarManuals.com

Page 2141 of 2177

ANTILOCK BRAKE SYSTEM -

DESCRIPTION........................5-75

ANTILOCK BRAKE SYSTEM - OPERATION . . 5-76

ANTILOCK BRAKE SYSTEM BLEEDING -

STANDARD PROCEDURE................5-78

ANTILOCK BRAKE SYSTEM (EXPORT) -

DESCRIPTION........................5-75

A-PILLAR LOWER EXTENSION TRIM -

INSTALLATION.......................23-73

A-PILLAR LOWER EXTENSION TRIM -

REMOVAL..........................23-73

A-PILLAR TRIM - INSTALLATION........23-73

A-PILLAR TRIM - REMOVAL............23-73

A-PILLAR-HEADER, OR B-PILLAR -

INSTALLATION.......................23-17

A-PILLAR-HEADER, OR B-PILLAR -

REMOVAL..........................23-17

APPLIQUE - INSTALLATION.............23-14

APPLIQUE - REMOVAL................23-14

ARM - DESCRIPTION, LOWER CONTROL . . . 2-12

ARM - INSPECTION, LOWER CONTROL....2-14

ARM - INSTALLATION, LOWER CONTROL . . 2-15

ARM - INSTALLATION, REAR WIPER.....8R-14

ARM - INSTALLATION, TORQUE..........3-44

ARM - OPERATION, LOWER CONTROL.....2-12

ARM - REMOVAL, LOWER CONTROL......2-12

ARM - REMOVAL, REAR WIPER.........8R-14

ARM - REMOVAL, TORQUE..............3-44

ARM ALIGNMENT - STANDARD

PROCEDURE, FRONT WIPER............8R-8

ARM (REAR BUSHING - HYDRO) -

ASSEMBLY, LOWER CONTROL...........2-14

ARM (REAR BUSHING - HYDRO) -

DISASSEMBLY, LOWER CONTROL........2-14

ARM (REAR BUSHING - STANDARD) -

ASSEMBLY, LOWER CONTROL...........2-14

ARM (REAR BUSHING - STANDARD) -

DISASSEMBLY, LOWER CONTROL........2-13

ARMREST - INSTALLATION.............23-90

ARMREST - REMOVAL................23-90

ARMS - DESCRIPTION, ROCKER........9-109

ARMS - INSPECTION, ROCKER...........9-35

ARMS - INSTALLATION, FRONT WIPER....8R-9

ARMS - INSTALLATION, ROCKER.........9-35

ARMS - OPERATION, ROCKER..........9-109

ARMS - REMOVAL, FRONT WIPER........8R-9

ARMS - REMOVAL, ROCKER.............9-34

ARMS AND SHAFT - ASSEMBLY,

ROCKER............................9-109

ARMS AND SHAFT - DISASSEMBLY,

ROCKER............................9-109

ARMS AND SHAFT - INSTALLATION,

ROCKER............................9-110

ARMS AND SHAFT - REMOVAL, ROCKER . . 9-109

ASSIST HANDLE - INSTALLATION........23-73

ASSIST HANDLE - REMOVAL...........23-73

ASSIST STRAP - INSTALLATION, FRONT

SEATBACK..........................23-91

ASSIST STRAP - REMOVAL, FRONT

SEATBACK..........................23-91

ATC - OPERATION, THREE ZONE.........24-3

ATC - OPERATION, TWO ZONE.........24-106

ATTACHED - INSTALLATION, EXTERIOR

NAME PLATES - ADHESIVE.............23-50

ATTACHED - INSTALLATION, EXTERIOR

NAME PLATES - TAPE.................23-50

ATTACHED - REMOVAL, EXTERIOR NAME

PLATES - ADHESIVE..................23-50

ATTACHED - REMOVAL, EXTERIOR NAME

PLATES - TAPE ......................23-50

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO/VIDEO - DESCRIPTION...........8A-1

AUDIO/VIDEO - OPERATION.............8A-2

AUTO SHUT DOWN RELAY -

DESCRIPTION.........................8I-3

AUTO SHUT DOWN RELAY - OPERATION . . . 8I-3

AUTOMATIC ADJUSTER - DIAGNOSIS

AND TESTING, DRUM BRAKE

............5-13

AUTOMATIC ADJUSTER TENSION

RELEASE - STANDARD PROCEDURE,

PARKING BRAKE

......................5-58

AUTOMATIC ADJUSTER TENSION RESET

- STANDARD PROCEDURE, PARKING

BRAKE

..............................5-59

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION

.......................8N-47

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING

.............8N-47AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-47

AUTOMATIC TEMPERATURE CONTROL -

DESCRIPTION........................24-2

AUTOMATIC TRANSAXLE -

DESCRIPTION, 41TE.................21-117

AUTOMATIC TRANSAXLE - OPERATION,

41TE.............................21-119

AUTOMATIC TRANSAXLE, SPECIAL

TOOLS - 41TE......................21-183

AUTOSTICK SWITCH - DESCRIPTION....21-189

AUTOSTICK SWITCH - OPERATION......21-189

AWD - INSTALLATION..............2-39,2-44

AWD - INSTALLATION, REAR WHEEL

SPEED SENSOR.......................5-80

AWD - REMOVAL.................2-38,2-44

AWD - REMOVAL, REAR WHEEL SPEED

SENSOR............................5-80

AWD AND HEAVY DUTY - INSTALLATION . . . 2-35

AWD AND HEAVY DUTY - REMOVAL......2-35

AXLE SEALS - INSTALLATION...........21-61

AXLE SEALS - REMOVAL..............21-61

B OR C-PILLAR - INSTALLATION, SEAT

BELT HEIGHT ADJUSTER..............8O-12

B OR C-PILLAR - REMOVAL, SEAT BELT

HEIGHT ADJUSTER...................8O-12

BACK - INSTALLATION, BENCH SEAT....23-101

BACK - QUAD BUCKET - INSTALLATION,

BUCKET SEAT.......................23-97

BACK - QUAD BUCKET - REMOVAL,

BUCKET SEAT.........................23-97

BACK - REMOVAL, BENCH SEAT........23-101

BACK COVER - INSTALLATION, BENCH

SEAT .............................23-102

BACK COVER - REMOVAL, BENCH SEAT . . 23-102

BACK HINGE - REMOVAL, BENCH SEAT . . 23-100

BACK HINGE COVERS - QUAD BUCKET,

50/50 SPLIT, BENCH - INSTALLATION,

SEAT .............................23-100

BACK HINGE COVERS - QUAD BUCKET,

50/50 SPLIT, BENCH - REMOVAL, SEAT . . 23-100

BACKING PLATE - INSTALLATION,

STEERING COLUMN COVER............23-69

BACKING PLATE - REMOVAL, STEERING

COLUMN COVER.....................23-69

BACK-UP LAMP SWITCH -

INSTALLATION.......................21-62

BACK-UP LAMP SWITCH - REMOVAL.....21-62

BAG RETAINER - INSTALLATION,

PLASTIC GROCERY..................23-103

BAG RETAINER - REMOVAL, PLASTIC

GROCERY.........................23-103

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL.....................22-5

BALANCE SHAFTS AND CARRIER

ASSEMBLY - DESCRIPTION.............9-69

BALANCE SHAFTS AND CARRIER

ASSEMBLY - INSTALLATION.............9-72

BALANCE SHAFTS AND CARRIER

ASSEMBLY - OPERATION...............9-69

BALANCE SHAFTS AND CARRIER

ASSEMBLY - REMOVAL.................9-69

BALL BEARING - INSTALLATION, END

COVER.............................21-10

BALL BEARING - REMOVAL, END COVER . . . 21-9

BALL JOINT - DESCRIPTION, LOWER......2-10

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.............................2-10

BALL JOINT - OPERATION, LOWER.......2-10

BALL JOINT SEAL BOOT - INSTALLATION . . 2-11

BALL JOINT SEAL BOOT - REMOVAL......2-11

BAR - DESCRIPTION, STABILIZER....2-16,2-43

BAR - DESCRIPTION, TRACK............2-44

BAR - INSPECTION, STABILIZER..........2-17

BAR - INSTALLATION, STABILIZER........2-17

BAR - INSTALLATION, TRACK............2-45

BAR - OPERATION, STABILIZER......2-16,2-44

BAR - OPERATION, TRACK..............2-44

BAR - REMOVAL, STABILIZER...........2-17

BAR - REMOVAL, TRACK...............2-44

BAR CUSHION - INSTALLATION,

STABILIZER

...........................2-4

BAR CUSHION - REMOVAL, STABILIZER

....2-4

BASE BRAKE BLEEDING - STANDARD

PROCEDURE

..........................5-7

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING

.............................5-4

BASE BRAKE SYSTEM, SPECIAL TOOLS

....5-10BASE BRAKES - DESCRIPTION............5-3

BASE BRAKES - OPERATION..............5-3

BASE BRAKES (EXPORT) - DESCRIPTION . . . 5-3

BASE COAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-84

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-9

BATTERY - OPERATION.................8F-9

BATTERY - REMOVAL.................8F-15

BATTERY CABLE - DIAGNOSIS AND

TESTING...........................8F-16

BATTERY CABLES - DESCRIPTION.......8F-16

BATTERY CABLES - INSTALLATION.......8F-18

BATTERY CABLES - OPERATION.........8F-16

BATTERY CABLES - REMOVAL..........8F-18

BATTERY CHARGING - STANDARD

PROCEDURE, CONVENTIONAL..........8F-11

BATTERY CHARGING - STANDARD

PROCEDURE, SPIRAL PLATE............8F-10

BATTERY ELECTROLYTE LEVEL -

STANDARD PROCEDURE, CHECKING.....8F-14

BATTERY HOLDDOWN - DESCRIPTION....8F-15

BATTERY HOLDDOWN - INSTALLATION . . . 8F-16

BATTERY HOLDDOWN - OPERATION.....8F-15

BATTERY HOLDDOWN - REMOVAL.......8F-16

BATTERY REPLACEMENT - STANDARD

PROCEDURE........................8N-42

BATTERY, SPECIFICATIONS.............8N-43

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-5

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-23

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-23

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-23

BATTERY TEMPERATURE SENSOR -

SPECIFICATIONS.....................8F-22

BATTERY TRAY - DESCRIPTION.........8F-18

BATTERY TRAY - INSTALLATION.........8F-19

BATTERY TRAY - OPERATION...........8F-19

BATTERY TRAY - REMOVAL............8F-19

BEARING - DESCRIPTION, HUB.......2-30,2-5

BEARING - DIAGNOSIS AND TESTING,

HUB.............................2-30,2-5

BEARING - INSTALLATION, CLUTCH

RELEASE LEVER.......................6-7

BEARING - INSTALLATION, END COVER

BALL..............................21-10

BEARING - INSTALLATION, HUB.......2-32,2-5

BEARING - OPERATION, HUB.........2-30,2-5

BEARING - REMOVAL, CLUTCH RELEASE

LEVER...............................6-6

BEARING - REMOVAL, END COVER BALL . . . 21-9

BEARING - REMOVAL, HUB..........2-31,2-5

BEARING CLEARANCE - STANDARD

PROCEDURE, MEASURING

CONNECTING ROD...................9-120

BEARING CLEARANCE USING

PLASTIGAGE - STANDARD

PROCEDURE, MEASURING..........9-12,9-84

BEARING FITTING - STANDARD

PROCEDURE, MAIN...................9-123

BEARING PRELOAD - ADJUSTMENT,

DIFFERENTIAL......................21-199

BEARINGS - INSTALLATION,

CRANKSHAFT MAIN..................9-124

BEARINGS - REMOVAL, CRANKSHAFT

MAIN..............................9-124

BEARINGS (IN BLOCK) - DESCRIPTION,

CAMSHAFT.........................9-115

BEARINGS (IN BLOCK) - INSPECTION,

CAMSHAFT.........................9-115

BEARINGS (IN BLOCK) - INSTALLATION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - OPERATION,

CAMSHAFT

.........................9-115

BEARINGS (IN BLOCK) - REMOVAL,

CAMSHAFT

.........................9-115

BELLCRANK - INSTALLATION

...........23-34

BELLCRANK - REMOVAL

...............23-34

2 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2145 of 2177

CENTER - DESCRIPTION, ELECTRONIC

VEHICLE INFO.......................8M-6

CENTER - DIAGNOSIS AND TESTING,

ELECTRONIC VEHICLE INFORMATION.....8M-7

CENTER - INSTALLATION, ELECTRONIC

VEHICLE INFO.......................8M-9

CENTER - OPERATION, ELECTRONIC

VEHICLE INFO.......................8M-7

CENTER - REMOVAL, ELECTRONIC

VEHICLE INFO.......................8M-9

CENTER BEZEL - INSTALLATION,

INSTRUMENT PANEL..................23-67

CENTER BEZEL - REMOVAL,

INSTRUMENT PANEL..................23-67

CENTER BEZEL OUTLETS -

INSTALLATION.......................24-42

CENTER BEZEL OUTLETS - REMOVAL....24-40

CENTER CONSOLE LAMP SWITCH -

INSTALLATION.......................8L-26

CENTER CONSOLE LAMP SWITCH -

REMOVAL..........................8L-26

CENTER HIGH MOUNTED STOP LAMP -

INSTALLATION........................8L-6

CENTER HIGH MOUNTED STOP LAMP -

REMOVAL...........................8L-6

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION..................8L-7

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL.....................8L-6

CENTER HINGE - INSTALLATION.........23-24

CENTER HINGE - REMOVAL............23-24

CENTER PROGRAMMING - STANDARD

PROCEDURE, ELECTRONIC VEHICLE

INFORMATION.......................8M-7

CENTER STRIKER - INSTALLATION.......23-27

CENTER STRIKER - REMOVAL..........23-27

CENTERING - STANDARD PROCEDURE,

CLOCK SPRING.......................8O-4

CERTIFICATION LABEL - DESCRIPTION,

VEHICLE SAFETY..................Intro.-11

CHAIN AND CAMSHAFT SPROCKET -

INSTALLATION, TIMING................9-157

CHAIN AND CAMSHAFT SPROCKET -

REMOVAL, TIMING...................9-156

CHAIN COVER - INSTALLATION, TIMING . . 9-155

CHAIN COVER - REMOVAL, TIMING......9-153

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-153

CHANGE - STANDARD PROCEDURE,

DIFFERENTIAL ASSEMBLY FLUID.........3-40

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER...........9-137,9-53

CHANGE - STANDARD PROCEDURE,

OVERRUNNING CLUTCH HOUSING

FLUID..............................3-41

CHANGE - STANDARD PROCEDURE, PTU

FLUID..............................21-5

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-8

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-8

CHANNEL - INSTALLATION, WATER.....23-118

CHANNEL - REMOVAL, WATER.........23-118

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM

...............24-88

CHARGE LEVEL - DIAGNOSIS AND

TESTING, REFRIGERANT SYSTEM

.......24-85

CHARGING - STANDARD PROCEDURE,

CONVENTIONAL BATTERY

..............8F-11

CHARGING - STANDARD PROCEDURE,

SPIRAL PLATE BATTERY

...............8F-10

CHARGING SYSTEM - DESCRIPTION

.....8F-20

CHARGING SYSTEM - OPERATION

.......8F-20

CHARTS - DIAGNOSIS AND TESTING,

STEERING SYSTEM DIAGNOSIS

..........19-3

CHARTS - SPECIFICATIONS, COLOR

CODE

..............................23-83

CHATTER COMPLAINTS - DIAGNOSIS

AND TESTING, CLUTCH

.................6-6

CHECK - DIAGNOSIS AND TESTING,

COOLING SYSTEM FLOW

................7-3

CHECK - DIAGNOSIS AND TESTING,

EXHAUST SYSTEM RESTRICTION

.........11-2

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL

.......................7-5

CHECK - STANDARD PROCEDURE,

ENGINE OIL LEVEL

...................9-137CHECK - STANDARD PROCEDURE, FLUID

LEVEL.............................21-71

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-53

CHECK, STANDARD PROCEDURE - FLUID

LEVEL AND CONDITION..............21-201

CHECK STRAP - INSTALLATION.........23-15

CHECK STRAP - REMOVAL.............23-15

CHECKING - STANDARD PROCEDURE,

BRAKE FLUID LEVEL...................5-32

CHECKING - STANDARD PROCEDURE,

POWER STEERING FLUID LEVEL........19-44

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-14

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING..............9-52

CHECKING POWER STEERING BELT

TENSION - STANDARD PROCEDURE.......7-8

CHILD SEAT - INSTALLATION, QUAD.....23-88

CHILD SEAT - REMOVAL, QUAD.........23-88

CHILD SEAT MODULE, BENCH SEAT -

REMOVAL..........................23-86

CHIME SYSTEM - DIAGNOSIS AND

TESTING............................8B-1

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CHIME/BUZZER - WARNING.............8B-1

CHIME/THERMISTOR - DESCRIPTION....8N-10

CHIME/THERMISTOR - INSTALLATION....8N-10

CHIME/THERMISTOR - OPERATION......8N-10

CHIME/THERMISTOR - REMOVAL.......8N-10

CHIRP PREFERENCE - STANDARD

PROCEDURE, HORN..................8N-42

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION . . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING, FEED........8F-32

CIRCUIT TEST - DIAGNOSIS AND

TESTING, CONTROL..................8F-30

CIRCUIT TEST - DIAGNOSIS AND

TESTING, FEED......................8F-33

CIRCUITS - OPERATION, NON-

MONITORED.........................25-5

CIRCUITS AND VALVES - OPERATION,

HYDRAULIC..........................5-83

CLAMP - STANDARD PROCEDURE,

HOSES..............................14-6

CLAMPS - DESCRIPTION, FUEL

LINES/HOSES........................14-6

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEAN, CLEANING...................21-114

CLEARANCE - STANDARD PROCEDURE,

MEASURING CONNECTING ROD

BEARING...........................9-120

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING........................9-12,9-84

CLOCK SPRING - DESCRIPTION..........8O-4

CLOCK SPRING - INSTALLATION.........8O-5

CLOCK SPRING - OPERATION...........8O-4

CLOCK SPRING - REMOVAL.............8O-4

CLOCK SPRING CENTERING -

STANDARD PROCEDURE...............8O-4

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT.....8J-1

CLUSTER BEZEL - INSTALLATION

........23-62

CLUSTER BEZEL - REMOVAL

...........23-62

CLUSTER DIAGNOSIS - DIAGNOSIS AND

TESTING

............................8J-2

CLUSTER ILLUMINATION LAMPS -

INSTALLATION

.......................8L-26

CLUSTER ILLUMINATION LAMPS -

REMOVAL

..........................8L-26

CLUSTER LENS - INSTALLATION

........8J-10

CLUSTER LENS - REMOVAL

............8J-10

CLUTCH - DESCRIPTION

.................6-1

CLUTCH - DESCRIPTION, BI-

DIRECTIONAL OVERRUNNING

...........3-34

CLUTCH - DESCRIPTION, COMPRESSOR

. . 24-16

CLUTCH - OPERATION, BI-DIRECTIONAL

OVERRUNNING

.......................3-36

CLUTCH - OPERATION, COMPRESSOR

....24-17

CLUTCH AIR GAP - STANDARD

PROCEDURE, COMPRESSOR

...........24-17CLUTCH AIR PRESSURE TESTS -

DIAGNOSIS AND TESTING............21-122

CLUTCH ASSEMBLY - ASSEMBLY, INPUT . 21-216

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT............................21-208

CLUTCH ASSY - 2.4L GAS -

INSTALLATION, MODULAR..............6-11

CLUTCH ASSY - 2.4L GAS - REMOVAL,

MODULAR...........................6-11

CLUTCH BREAK-IN - STANDARD

PROCEDURE, COMPRESSOR...........24-17

CLUTCH CHATTER COMPLAINTS -

DIAGNOSIS AND TESTING...............6-6

CLUTCH COIL - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-20

CLUTCH COVER AND DISC RUNOUT -

DIAGNOSIS AND TESTING...............6-6

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - INSTALLATION...............6-12

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - REMOVAL...................6-11

CLUTCH HOUSING FLUID CHANGE -

STANDARD PROCEDURE,

OVERRUNNING.......................3-41

CLUTCH PEDAL INTERLOCK SWITCH -

INSTALLATION........................6-14

CLUTCH PEDAL INTERLOCK SWITCH -

REMOVAL...........................6-13

CLUTCH PEDAL UPSTOP SWITCH -

INSTALLATION........................6-16

CLUTCH PEDAL UPSTOP SWITCH -

REMOVAL...........................6-15

CLUTCH RELAY - DESCRIPTION,

COMPRESSOR........................24-21

CLUTCH RELAY - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-22

CLUTCH RELAY - INSTALLATION,

COMPRESSOR.......................24-22

CLUTCH RELAY - OPERATION,

COMPRESSOR.......................24-21

CLUTCH RELAY - REMOVAL,

COMPRESSOR.......................24-22

CLUTCH RELEASE LEVER AND BEARING

- INSTALLATION.......................6-7

CLUTCH RELEASE LEVER AND BEARING

- REMOVAL...........................6-6

CLUTCH SYSTEM - DIAGNOSIS AND

TESTING.............................6-3

CLUTCH/COIL - INSPECTION,

COMPRESSOR.......................24-18

CLUTCHES - DESCRIPTION, DRIVING....21-190

CLUTCHES - DESCRIPTION, HOLDING . . . 21-207

CLUTCHES - OPERATION, DRIVING.....21-190

CLUTCHES - OPERATION, HOLDING.....21-207

COAT/CLEARCOAT FINISH -

DESCRIPTION, BASE..................23-84

CODE - DESCRIPTION, PAINT...........23-84

CODE CHARTS - SPECIFICATIONS,

COLOR.............................23-83

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER..............8M-11

CODES - STANDARD PROCEDURE,

OBTAINING DIAGNOSTIC TROUBLE......8E-15

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER..............8M-11

COIL - DESCRIPTION, IGNITION

..........8I-6

COIL - DIAGNOSIS AND TESTING,

COMPRESSOR CLUTCH

...............24-20

COIL - OPERATION, IGNITION

............8I-6

COLLAR - INSTALLATION, STRUCTURAL

. . . 9-48

COLLAR - REMOVAL, STRUCTURAL

.......9-47

COLOR CODE CHARTS -

SPECIFICATIONS

.....................23-83

COLUMN - DESCRIPTION, STEERING

.....19-10

COLUMN - DIAGNOSIS AND TESTING,

STEERING

..........................19-12

COLUMN COVER - INSTALLATION,

LOWER STEERING

...................23-69

COLUMN COVER - INSTALLATION, OVER

STEERING

..........................23-69

COLUMN COVER - REMOVAL, LOWER

STEERING

..........................23-69

COLUMN COVER - REMOVAL, OVER

STEERING

..........................23-69

COLUMN COVER BACKING PLATE -

INSTALLATION, STEERING

.............23-69

6 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2146 of 2177

COLUMN COVER BACKING PLATE -

REMOVAL, STEERING.................23-69

COLUMN TORQUE, SPECIFICATIONS.....19-14

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER........................9-83,9-9

COMMON PROBLEM CAUSES -

DIAGNOSIS AND TESTING.............21-30

COMMUNICATION RECEIVE - PCM INPUT

- OPERATION, DATA BUS..............8E-15

COMMUNICATIONS INTERFACE (PCI)

BUS, OPERATION - PROGRAMMABLE....14-21

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING.............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-5

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-9

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-10

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-10

COMPLAINTS - DIAGNOSIS AND

TESTING, CLUTCH CHATTER..............6-6

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER . . 9-83,9-9

COMPRESSOR - 2.4/3.3/3.8L ENGINES -

REMOVAL............................24-64

COMPRESSOR - DESCRIPTION, A/C......24-63

COMPRESSOR - INSTALLATION.........24-65

COMPRESSOR - OPERATION, A/C........24-63

COMPRESSOR CLUTCH - DESCRIPTION . . 24-16

COMPRESSOR CLUTCH - OPERATION....24-17

COMPRESSOR CLUTCH AIR GAP -

STANDARD PROCEDURE...............24-17

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-17

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-20

COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-21

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING.............24-22

COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-22

COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-21

COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-22

COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-18

COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE - INSTALLATION...........24-66

COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE - REMOVAL..............24-65

COMPRESSOR NOISE DIAGNOSIS -

DIAGNOSIS AND TESTING.............24-63

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-9

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP

.................8M-10

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP

.........................8M-10

COMPUTER - OPERATION, COMPASS/

MINI-TRIP

..........................8M-9

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP

.........................8M-10

CONCENTRATION TESTING - DIAGNOSIS

AND TESTING, COOLANT

...............7-19

CONDENSER - DESCRIPTION

...........24-66

CONDENSER - INSTALLATION

...........24-67

CONDENSER - OPERATION

.............24-66

CONDENSER - REMOVAL

..............24-66

CONDITION CHECK, STANDARD

PROCEDURE - FLUID LEVEL

...........21-201

CONDITIONING LINES - INSTALLATION,

REAR AIR

.........................24-105

CONDITIONING LINES - REMOVAL, REAR

AIR

..............................24-104

CONNECTING ROD - DESCRIPTION,

PISTON

........................9-116,9-42CONNECTING ROD - INSTALLATION,

PISTON.............................9-44

CONNECTING ROD - REMOVAL, PISTON . . . 9-43

CONNECTING ROD BEARING

CLEARANCE - STANDARD

PROCEDURE, MEASURING.............9-120

CONNECTING ROD, FITTING.............9-45

CONNECTING RODS - STANDARD

PROCEDURE, FITTING.................9-116

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-6

CONNECTOR - INSTALLATION.......8W-01-11

CONNECTOR - OPERATION, DATA LINK....8E-7

CONNECTOR - REMOVAL...........8W-01-11

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD....8M-1

CONSOLE - DIAGNOSIS AND TESTING,

OVERHEAD..........................8M-2

CONSOLE - INSTALLATION, LOWER......23-68

CONSOLE - OPERATION, OVERHEAD......8M-2

CONSOLE - REMOVAL, LOWER..........23-68

CONSOLE - REMOVAL, OVERHEAD.......8M-6

CONSOLE LAMP SWITCH -

INSTALLATION, CENTER...............8L-26

CONSOLE LAMP SWITCH - REMOVAL,

CENTER............................8L-26

CONSOLE, SPECIAL TOOLS - OVERHEAD . . 8M-6

CONSOLE TRAY - BRACKET ASSEMBLY -

INSTALLATION, FLOOR................23-82

CONSOLE TRAY - BRACKET ASSEMBLY -

REMOVAL, FLOOR....................23-82

CONSOLE TRAY - INSTALLATION, FLOOR . . 23-81

CONSOLE TRAY - REMOVAL, FLOOR.....23-81

CONTAINER - DESCRIPTION, COOLANT

RECOVERY..........................7-19

CONTAINER - INSTALLATION, COOLANT

RECOVERY..........................7-20

CONTAINER - OPERATION, COOLANT

RECOVERY..........................7-19

CONTAINER - REMOVAL, COOLANT

RECOVERY..........................7-20

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-32

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL (4 SPEED EATX ONLY) -

OPERATION, INTERACTIVE SPEED........8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-12

CONTROL ARM - INSPECTION, LOWER....2-14

CONTROL ARM - INSTALLATION, LOWER . . 2-15

CONTROL ARM - OPERATION, LOWER.....2-12

CONTROL ARM - REMOVAL, LOWER......2-12

CONTROL ARM (REAR BUSHING -

HYDRO) - ASSEMBLY, LOWER...........2-14

CONTROL ARM (REAR BUSHING -

HYDRO) - DISASSEMBLY, LOWER........2-14

CONTROL ARM (REAR BUSHING -

STANDARD) - ASSEMBLY, LOWER........2-14

CONTROL ARM (REAR BUSHING -

STANDARD) - DISASSEMBLY, LOWER.....2-13

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-35

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-35

CONTROL CALIBRATION - STANDARD

PROCEDURE, HEATER-A/C..............24-8

CONTROL CIRCUIT TEST - DIAGNOSIS

AND TESTING.......................8F-30

CONTROL INFORMATION LABEL -

DESCRIPTION, VEHICLE EMISSION.......25-1

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-3

CONTROL MODULE - DESCRIPTION,

FRONT..............................8E-7

CONTROL MODULE - DESCRIPTION,

POWER LIFTGATE....................8E-10

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG

.................8O-17

CONTROL MODULE - DESCRIPTION,

SLIDING DOOR

......................8E-19

CONTROL MODULE - DESCRIPTION,

TRANSMISSION

......................8E-20

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT

......................8E-7

CONTROL MODULE - INSTALLATION,

BODY

...............................8E-5CONTROL MODULE - INSTALLATION,

FRONT..............................8E-8

CONTROL MODULE - INSTALLATION,

POWER LIFTGATE....................8E-11

CONTROL MODULE - INSTALLATION,

SIDE IMPACT AIRBAG.................8O-17

CONTROL MODULE - INSTALLATION,

SLIDING DOOR......................8E-20

CONTROL MODULE - OPERATION, BODY . . . 8E-3

CONTROL MODULE - OPERATION,

FRONT..............................8E-7

CONTROL MODULE - OPERATION,

POWER LIFTGATE....................8E-11

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-17

CONTROL MODULE - OPERATION,

SLIDING DOOR......................8E-19

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-20

CONTROL MODULE - REMOVAL, BODY....8E-4

CONTROL MODULE - REMOVAL, FRONT . . . 8E-8

CONTROL MODULE - REMOVAL, POWER

LIFTGATE...........................8E-11

CONTROL MODULE - REMOVAL, SIDE

IMPACT AIRBAG.....................8O-17

CONTROL MODULE - REMOVAL,

SLIDING DOOR......................8E-19

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-28

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-29

CONTROL MOTOR - OPERATION, IDLE

AIR.................................14-28

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-29

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-247

CONTROL RELAY - OPERATION,

TRANSMISSION.....................21-248

CONTROL SWITCH - DIAGNOSIS AND

TESTING, TRACTION...................5-82

CONTROL SYSTEM - DESCRIPTION,

TRACTION...........................5-76

CONTROL SYSTEM - OPERATION,

EVAPORATION.......................25-10

CONTROL SYSTEM - OPERATION,

TRACTION...........................5-77

CONTROLLER - DESCRIPTION,

OCCUPANT RESTRAINT................8O-7

CONTROLLER - INSTALLATION,

OCCUPANT RESTRAINT................8O-7

CONTROLLER - INSTALLATION, SBEC....8E-17

CONTROLLER - OPERATION, 8-VOLT

SUPPLY - PCM OUTPUT - SBEC.........8E-15

CONTROLLER - OPERATION, OCCUPANT

RESTRAINT..........................8O-7

CONTROLLER - REMOVAL, NGC.........8E-17

CONTROLLER - REMOVAL, OCCUPANT

RESTRAINT..........................8O-7

CONTROLLER - REMOVAL, SBEC........8E-16

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-5

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-6

CONTROLLER ANTILOCK BRAKE -

OPERATION..........................8E-5

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-6

CONVENTIONAL BATTERY CHARGING -

STANDARD PROCEDURE...............8F-11

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-4

CONVERTER - DESCRIPTION, TORQUE . . . 21-242

CONVERTER - INSPECTION, CATALYTIC....11-5

CONVERTER - INSTALLATION, CATALYTIC . . 11-6

CONVERTER - INSTALLATION, TORQUE . . 21-247

CONVERTER - OPERATION, CATALYTIC....11-4

CONVERTER - OPERATION, TORQUE....21-245

CONVERTER - REMOVAL, CATALYTIC......11-5

CONVERTER - REMOVAL, TORQUE......21-247

CONVERTER HOUSING FLUID LEAKAGE -

DIAGNOSIS AND TESTING, TORQUE.....21-123

COOL DOWN TEST - DIAGNOSIS AND

TESTING, A/C

........................24-4

COOLANT - DESCRIPTION, ENGINE

.......7-19

COOLANT - DESCRIPTION, ENGINE

........0-3

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL

...................7-5

COOLANT CONCENTRATION TESTING -

DIAGNOSIS AND TESTING

..............7-19

RSINDEX7

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2162 of 2177

PARKING BRAKE CABLES -

ADJUSTMENT........................5-64

PARKING BRAKE LEVER AND FRONT

CABLE - INSTALLATION................5-66

PARKING BRAKE LEVER AND FRONT

CABLE - REMOVAL....................5-65

PARKING BRAKE SHOES - ADJUSTMENT . . . 5-73

PARK/TURN SIGNAL LAMP - EXPORT -

INSTALLATION.......................8L-22

PARK/TURN SIGNAL LAMP - EXPORT -

REMOVAL..........................8L-22

PARK/TURN SIGNAL LAMP -

INSTALLATION.......................8L-21

PARK/TURN SIGNAL LAMP - REMOVAL . . . 8L-21

PARTS - DESCRIPTION, FFV

REPLACEMENT.......................14-2

PASSENGER AIRBAG - DESCRIPTION.....8O-7

PASSENGER AIRBAG - INSTALLATION.....8O-9

PASSENGER AIRBAG - OPERATION.......8O-8

PASSENGER AIRBAG - REMOVAL........8O-8

PASSENGER BENCH - INSTALLATION,

SEAT BELT BUCKLE - SECOND ROW -

THREE.............................8O-14

PASSENGER BENCH - REMOVAL, SEAT

BELT BUCKLE - SECOND ROW - THREE . . . 8O-14

PASSENGER HEATED SEAT SWITCH -

DESCRIPTION.......................8G-12

PASSENGER HEATED SEAT SWITCH -

DIAGNOSIS AND TESTING.............8G-13

PASSENGER HEATED SEAT SWITCH -

INSTALLATION......................8G-14

PASSENGER HEATED SEAT SWITCH -

OPERATION.........................8G-12

PASSENGER HEATED SEAT SWITCH -

REMOVAL..........................8G-14

PASSENGER POWER SEAT TRACK -

DESCRIPTION.......................8N-59

PASSENGER POWER SEAT TRACK -

INSTALLATION......................8N-61

PASSENGER POWER SEAT TRACK -

OPERATION.........................8N-60

PASSENGER POWER SEAT TRACK -

REMOVAL..........................8N-61

PASSENGER SEAT SWITCH -

DESCRIPTION.......................8N-56

PASSENGER SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8N-57

PASSENGER SEAT SWITCH -

INSTALLATION......................8N-57

PASSENGER SEAT SWITCH - OPERATION . 8N-56

PASSENGER SEAT SWITCH - REMOVAL . . . 8N-57

PATTERNS - DIAGNOSIS AND TESTING,

TIRE WEAR.........................22-16

PCM GROUND - OPERATION...........8E-15

PCM INPUT - OPERATION, DATA BUS

COMMUNICATION RECEIVE.............8E-15

PCM INPUT - OPERATION, IGNITION

SENSE.............................8E-15

PCM INPUT - OPERATION, SENSOR

RETURN............................8E-15

PCM OUTPUT - OPERATION, 5 VOLT

SUPPLY............................8E-15

PCM OUTPUT - SBEC CONTROLLER -

OPERATION, 8-VOLT SUPPLY...........8E-15

PCM/SKIM PROGRAMMING - STANDARD

PROCEDURE.........................8E-2

PCV SYSTEM - DIAGNOSIS AND

TESTING...........................25-17

PCV VALVE - DESCRIPTION............25-16

PCV VALVE - OPERATION..............25-16

PEDAL - INSTALLATION, ACCELERATOR . . . 14-24

PEDAL - REMOVAL, ACCELERATOR......14-23

PEDAL INTERLOCK SWITCH -

INSTALLATION, CLUTCH................6-14

PEDAL INTERLOCK SWITCH - REMOVAL,

CLUTCH.............................6-13

PEDAL TORQUE SHAFT - RHD -

INSTALLATION........................5-39

PEDAL TORQUE SHAFT - RHD -

REMOVAL

...........................5-39

PEDAL UPSTOP SWITCH -

INSTALLATION, CLUTCH

................6-16

PEDAL UPSTOP SWITCH - REMOVAL,

CLUTCH

.............................6-15

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS

........9-4,9-78

PERFORMANCE TEST - DIAGNOSIS AND

TESTING, A/C

........................24-5PERFORMANCE TEST - DIAGNOSIS AND

TESTING, HEATER.....................24-6

PIN BUSHINGS (DISC/DISC BRAKES) -

ASSEMBLY, CALIPER GUIDE.............5-25

PIN BUSHINGS (DISC/DISC BRAKES) -

DISASSEMBLY, CALIPER GUIDE..........5-24

PINCH SENSOR - DESCRIPTION.........8N-17

PINCH SENSOR - INSTALLATION........8N-17

PINCH SENSOR - OPERATION..........8N-17

PINCH SENSOR - REMOVAL............8N-17

PINION FACTOR SETTING - STANDARD

PROCEDURE...................8E-15,8E-23

PINS (DISC/DRUM BRAKES) -

INSTALLATION, DISC BRAKE CALIPER

GUIDE..............................5-31

PINS (DISC/DRUM BRAKES) - REMOVAL,

DISC BRAKE CALIPER GUIDE............5-31

PIPE - 3.3/3.8L - INSTALLATION,

CROSS-OVER........................11-6

PIPE - 3.3/3.8L - REMOVAL, CROSS-

OVER...............................11-6

PIPE - INSTALLATION, AIR INTAKE......24-113

PIPE - REMOVAL, AIR INTAKE.........24-112

PISTON & CONNECTING ROD -

DESCRIPTION...................9-116,9-42

PISTON & CONNECTING ROD -

INSTALLATION........................9-44

PISTON & CONNECTING ROD -

REMOVAL...........................9-43

PISTON AND SEAL - ASSEMBLY,

CALIPER........................5-26,5-29

PISTON AND SEAL - DISASSEMBLY,

CALIPER........................5-24,5-28

PISTON RING, FITTING.................9-45

PISTON RING FITTING - STANDARD

PROCEDURE........................9-121

PISTON RINGS - INSTALLATION.........9-121

PISTON RINGS - REMOVAL............9-121

PISTON TO CYLINDER BORE FITTING -

STANDARD PROCEDURE................9-42

PISTONS - STANDARD PROCEDURE,

FITTING............................9-117

PLANETARY GEARTRAIN - DESCRIPTION . 21-232

PLANETARY GEARTRAIN - OPERATION . . 21-232

PLASTIC BODY PANEL REPAIR -

STANDARD PROCEDURE................23-3

PLASTIC GROCERY BAG RETAINER -

INSTALLATION......................23-103

PLASTIC GROCERY BAG RETAINER -

REMOVAL.........................23-103

PLASTIGAGE - STANDARD PROCEDURE,

MEASURING BEARING CLEARANCE

USING..........................9-12,9-84

PLATE - 2.5L TD - INSTALLATION,

CLUTCH DISC AND PRESSURE...........6-12

PLATE - 2.5L TD - REMOVAL, CLUTCH

DISC AND PRESSURE..................6-11

PLATE - DESCRIPTION, BODY CODE....Intro.-1

PLATE - DESCRIPTION, MANUFACTURER . Intro.-11

PLATE - DRUM BRAKE - INSTALLATION,

SUPPORT...........................5-56

PLATE - DRUM BRAKE - REMOVAL,

SUPPORT...........................5-56

PLATE - INSTALLATION, DOOR SILL

TRIM..............................23-76

PLATE - INSTALLATION, FLEX...........9-131

PLATE - INSTALLATION, LIFTGATE SILL

. . . 23-77

PLATE - INSTALLATION, SLIDING DOOR

SILL

...............................23-80

PLATE - INSTALLATION, STEERING

COLUMN COVER BACKING

.............23-69

PLATE - REMOVAL, DOOR SILL TRIM

....23-76

PLATE - REMOVAL, FLEX

..............9-131

PLATE - REMOVAL, LIFTGATE SILL

.......23-77

PLATE - REMOVAL, SLIDING DOOR SILL

. . 23-80

PLATE - REMOVAL, STEERING COLUMN

COVER BACKING

.....................23-69

PLATE BATTERY CHARGING -

STANDARD PROCEDURE, SPIRAL

........8F-10

PLATE MISALIGNMENT - DIAGNOSIS

AND TESTING, DRIVE

...................6-6

PLATES - ADHESIVE ATTACHED -

INSTALLATION, EXTERIOR NAME

........23-50

PLATES - ADHESIVE ATTACHED -

REMOVAL, EXTERIOR NAME

............23-50

PLATES - TAPE ATTACHED -

INSTALLATION, EXTERIOR NAME

........23-50PLATES - TAPE ATTACHED - REMOVAL,

EXTERIOR NAME.....................23-50

PLATINUM PLUGS - DESCRIPTION........8I-9

PLAY - ADJUSTMENT, DIFFERENTIAL

SIDE GEAR END.....................21-70

PLAY - STANDARD PROCEDURE,

CRANKSHAFT END....................9-36

PLAY - STANDARD PROCEDURE,

MEASURING CAMSHAFT END............9-29

PLAY - STANDARD PROCEDURE,

MEASURING CRANKSHAFT END.........9-125

PLAYER - DESCRIPTION, DVD...........8A-8

PLAYER - INSTALLATION, DVD...........8A-8

PLAYER - OPERATION, DVD.............8A-8

PLAYER - REMOVAL, DVD..............8A-8

PLUG CABLE - DESCRIPTION, SPARK.....8I-10

PLUG CABLE RESISTANCE,

SPECIFICATIONS - SPARK...............8I-2

PLUG, SPECIFICATIONS - SPARK.........8I-2

PLUGS - DESCRIPTION, PLATINUM........8I-9

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY....9-10,9-86

PLUMBING - CAUTION, A/C............24-61

PLUMBING - WARNING, A/C............24-61

POINTS - DESCRIPTION, LUBRICATION.....0-7

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING...................23-84

PORT REPAIR - STANDARD

PROCEDURE, INTAKE MANIFOLD

VACUUM...........................9-145

PORTS - INSTALLATION, SERVICE.......24-93

PORTS - REMOVAL, SERVICE...........24-92

POSITION LAMP - EXPORT -

INSTALLATION, FRONT................8L-10

POSITION LAMP - EXPORT - REMOVAL,

FRONT.............................8L-10

POSITION SENSOR - DESCRIPTION,

CAMSHAFT...........................8I-3

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT.......................14-24

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-36

POSITION SENSOR - OPERATION,

CAMSHAFT...........................8I-3

POSITION SENSOR - OPERATION,

CRANKSHAFT.......................14-24

POSITION SENSOR - OPERATION,

THROTTLE..........................14-36

POSITION SENSOR - REMOVAL,

CRANKSHAFT.......................14-25

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER - INSTALLATION, WINDOW

REGULATOR........................23-22

POWER - REMOVAL, WINDOW

REGULATOR........................23-22

POWER ADJUSTER - INSTALLATION,

FRONT SEAT TRACK..................23-94

POWER ADJUSTER - REMOVAL, FRONT

SEAT TRACK........................23-94

POWER BRAKE BOOSTER -

DESCRIPTION........................5-40

POWER BRAKE BOOSTER - DIAGNOSIS

AND TESTING

........................5-41

POWER BRAKE BOOSTER - OPERATION

. . . 5-41

POWER DISTRIBUTION SYSTEM -

DESCRIPTION

.....................8W-97-1

POWER DISTRIBUTION SYSTEM -

OPERATION

.......................8W-97-1

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS

...................8W-97-2

POWER DOOR LEARN CYCLE -

STANDARD PROCEDURE

..............8N-28

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - DESCRIPTION

...............8N-48

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - INSTALLATION

..............8N-49

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - OPERATION

................8N-48

POWER FOLDAWAY MIRROR SWITCH -

EXPORT - REMOVAL

..................8N-48

POWER LIFTGATE CONTROL MODULE -

DESCRIPTION

.......................8E-10

POWER LIFTGATE CONTROL MODULE -

INSTALLATION

.......................8E-11

POWER LIFTGATE CONTROL MODULE -

OPERATION

.........................8E-11

RSINDEX23

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com

Page 2170 of 2177

SPEED SENSOR - INSTALLATION,

VEHICLE..........................21-115

SPEED SENSOR - OPERATION, ENGINE . . . 14-26

SPEED SENSOR - OUTPUT -

DESCRIPTION......................21-241

SPEED SENSOR - OUTPUT -

INSTALLATION......................21-242

SPEED SENSOR - OUTPUT - OPERATION . 21-241

SPEED SENSOR - OUTPUT - REMOVAL . . 21-241

SPEED SENSOR - REMOVAL, FRONT

WHEEL.............................5-79

SPEED SENSOR - REMOVAL, VEHICLE . . . 21-115

SPEED SENSOR AIR GAP,

SPECIFICATIONS - WHEEL..............5-79

SPIRAL PLATE BATTERY CHARGING -

STANDARD PROCEDURE...............8F-10

SPLASH SHIELD - INSTALLATION,

FRONT WHEELHOUSE.................23-54

SPLASH SHIELD - REMOVAL, FRONT

WHEELHOUSE.......................23-54

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-7

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-15

SPLIT - INSTALLATION, BENCH SEAT

RISER - 50/50.......................23-99

SPLIT - REMOVAL, BENCH SEAT RISER -

50/50..............................23-99

SPLIT, BENCH - INSTALLATION, SEAT

BACK HINGE COVERS - QUAD BUCKET,

50/50.............................23-100

SPLIT, BENCH - INSTALLATION, SEAT

CUSHION COVER - QUAD BUCKET,

50/50..............................23-99

SPLIT, BENCH - REMOVAL, SEAT BACK

HINGE COVERS - QUAD BUCKET, 50/50 . . 23-100

SPLIT, BENCH - REMOVAL, SEAT

CUSHION COVER - QUAD BUCKET,

50/50..............................23-98

SPOILER - INSTALLATION, LIFTGATE.....23-41

SPOILER - REMOVAL, LIFTGATE.........23-41

SPRING - DESCRIPTION, CLOCK.........8O-4

SPRING - INSTALLATION, CLOCK.........8O-5

SPRING - OPERATION, CLOCK...........8O-4

SPRING - REMOVAL, CLOCK............8O-4

SPRING CENTERING - STANDARD

PROCEDURE, CLOCK..................8O-4

SPRING FRONT BUSHING -

INSTALLATION, LEAF...................2-29

SPRING FRONT BUSHING - REMOVAL,

LEAF...............................2-28

SPRING MOUNTS - FRONT -

INSTALLATION........................2-42

SPRING MOUNTS - FRONT - REMOVAL....2-42

SPRING MOUNTS - REAR -

INSTALLATION........................2-43

SPRING MOUNTS - REAR - REMOVAL.....2-43

SPRINGS - DESCRIPTION, VALVE........9-106

SPRINGS - OPERATION, VALVE.........9-106

SPROCKET - INSTALLATION,

CRANKSHAFT...................9-156,9-65

SPROCKET - INSTALLATION, TIMING

CHAIN AND CAMSHAFT...............9-157

SPROCKET - REMOVAL, CRANKSHAFT . . . 9-156,

9-64

SPROCKET - REMOVAL, TIMING CHAIN

AND CAMSHAFT.....................9-156

SPROCKETS - INSTALLATION,

CAMSHAFT..........................9-65

SPROCKETS - REMOVAL, CAMSHAFT......9-64

STABILIZER - INSTALLATION...........23-32

STABILIZER - REMOVAL...............23-32

STABILIZER BAR - DESCRIPTION.....2-16,2-43

STABILIZER BAR - INSPECTION..........2-17

STABILIZER BAR - INSTALLATION........2-17

STABILIZER BAR - OPERATION.......2-16,2-44

STABILIZER BAR - REMOVAL............2-17

STABILIZER BAR CUSHION -

INSTALLATION.........................2-4

STABILIZER BAR CUSHION - REMOVAL.....2-4

STABILIZER SOCKET - INSTALLATION....23-32

STABILIZER SOCKET - REMOVAL........23-32

STAKING - STANDARD PROCEDURE,

HEAT

..............................23-10

STANDARD 4 CYLINDER - DESCRIPTION

. . . 8I-9

STARTER, SPECIFICATIONS

.............8F-34

STARTING - DESCRIPTION

.............8F-28

STARTING - OPERATION

...............8F-28STARTING - STANDARD PROCEDURE,

JUMP...............................0-15

STARTING SYSTEM TEST - DIAGNOSIS

AND TESTING.......................8F-28

STATE DISPLAY TEST MODE,

OPERATION - DRB IIIT.................25-9

STEERING - DIAGNOSIS AND TESTING,

SUSPENSION.........................2-49

STEERING BELT TENSION - STANDARD

PROCEDURE, CHECKING POWER..........7-8

STEERING COLUMN - DESCRIPTION.....19-10

STEERING COLUMN - DIAGNOSIS AND

TESTING...........................19-12

STEERING COLUMN COVER -

INSTALLATION, LOWER................23-69

STEERING COLUMN COVER -

INSTALLATION, OVER.................23-69

STEERING COLUMN COVER - REMOVAL,

LOWER............................23-69

STEERING COLUMN COVER - REMOVAL,

OVER..............................23-69

STEERING COLUMN COVER BACKING

PLATE - INSTALLATION................23-69

STEERING COLUMN COVER BACKING

PLATE - REMOVAL...................23-69

STEERING FASTENER TORQUE,

SPECIFICATIONS - POWER..............19-9

STEERING FLUID LEVEL CHECKING -

STANDARD PROCEDURE, POWER.......19-44

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-34

STEERING KNUCKLE - INSPECTION........2-9

STEERING KNUCKLE - INSTALLATION........2-9

STEERING KNUCKLE - REMOVAL..........2-7

STEERING PUMP INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-37

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-43

STEERING, SPECIAL TOOLS - POWER.....19-9

STEERING SYSTEM - DESCRIPTION,

POWER.............................19-1

STEERING SYSTEM - OPERATION,

POWER.............................19-1

STEERING SYSTEM DIAGNOSIS CHARTS

- DIAGNOSIS AND TESTING.............19-3

STEERING SYSTEM FLOW AND

PRESSURE TEST - DIAGNOSIS AND

TESTING, POWER.....................19-1

STEERING WHEEL - INSTALLATION......19-24

STEERING WHEEL - REMOVAL..........19-23

STEM SEALS - DESCRIPTION, VALVE.....9-111

STEM SEALS - INSTALLATION, VALVE....9-112

STEM SEALS - REMOVAL, VALVE........9-112

STOP BUMPER - INSTALLATION.........23-25

STOP BUMPER - REMOVAL............23-25

STOP BUMPER BEZEL - INSTALLATION,

SLIDING DOOR......................23-25

STOP BUMPER BEZEL - REMOVAL,

SLIDING DOOR......................23-25

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED......................8L-6

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED...........................8L-6

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED...............8L-7

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED

......................8L-6

STORAGE BIN - INSTALLATION, UNDER

SEAT

.............................23-103

STORAGE BIN - REMOVAL, UNDER SEAT

. 23-103

STORAGE BIN GUIDE - INSTALLATION,

UNDER SEAT

.......................23-104

STORAGE BIN GUIDE - REMOVAL,

UNDER SEAT

.......................23-104

STORAGE BIN LOCK/LATCH -

INSTALLATION, UNDER SEAT

..........23-104

STORAGE BIN LOCK/LATCH - REMOVAL,

UNDER SEAT

.......................23-104

STRAP - INSTALLATION, CHECK

.........23-15

STRAP - INSTALLATION, FRONT

SEATBACK ASSIST

...................23-91

STRAP - REMOVAL, CHECK

............23-15

STRAP - REMOVAL, FRONT SEATBACK

ASSIST

............................23-91

STRIKER - INSTALLATION, CENTER

......23-27

STRIKER - INSTALLATION, FUEL FILL

DOOR BLOCKER LATCH

...............23-52STRIKER - INSTALLATION, GLOVE BOX

LATCH .............................23-64

STRIKER - INSTALLATION, HOLD OPEN

LATCH .............................23-26

STRIKER - INSTALLATION, LATCH . . 23-19,23-40,

23-61

STRIKER - INSTALLATION, REAR LATCH . . 23-28

STRIKER - REMOVAL, CENTER..........23-27

STRIKER - REMOVAL, FUEL FILL DOOR

BLOCKER LATCH.....................23-52

STRIKER - REMOVAL, GLOVE BOX

LATCH .............................23-64

STRIKER - REMOVAL, HOLD OPEN

LATCH .............................23-26

STRIKER - REMOVAL, LATCH . 23-19,23-40,23-61

STRIKER - REMOVAL, REAR LATCH......23-28

STRIPPED THREAD REPAIR - STANDARD

PROCEDURE, MANIFOLD..............9-145

STRUCTURAL ADHESIVE LOCATIONS -

SPECIFICATIONS....................23-153

STRUCTURAL COLLAR - INSTALLATION....9-48

STRUCTURAL COLLAR - REMOVAL.......9-47

STRUT ASSEMBLY - ASSEMBLY..........2-23

STRUT ASSEMBLY - DESCRIPTION.......2-19

STRUT ASSEMBLY - DIAGNOSIS AND

TESTING............................2-20

STRUT ASSEMBLY - DISASSEMBLY.......2-21

STRUT ASSEMBLY - INSTALLATION.......2-25

STRUT ASSEMBLY - OPERATION.........2-19

STRUT ASSEMBLY - REMOVAL............2-20

STUDS - FRONT - INSTALLATION,

WHEEL MOUNTING...................22-21

STUDS - FRONT - REMOVAL, WHEEL

MOUNTING.........................22-20

STUDS - REAR - INSTALLATION, WHEEL

MOUNTING.........................22-22

STUDS - REAR - REMOVAL, WHEEL

MOUNTING.........................22-21

SUCTION LINE - INSTALLATION . . . 24-102,24-91

SUCTION LINE - REMOVAL.......24-101,24-90

SUN VISOR - INSTALLATION...........23-81

SUN VISOR - REMOVAL...............23-81

SUN VISOR SUPPORT - INSTALLATION . . . 23-81

SUN VISOR SUPPORT - REMOVAL.......23-81

SUNROOF - DESCRIPTION............23-113

SUNROOF - DIAGNOSIS AND TESTING . . . 23-113

SUNROOF ASSEMBLY - INSTALLATION . . 23-117

SUNROOF ASSEMBLY - REMOVAL......23-117

SUNROOF GLASS PANEL ADJUSTMENT,

ADJUSTMENTS.....................23-117

SUNROOF MOTOR - INSTALLATION.....23-118

SUNROOF MOTOR - REMOVAL.........23-118

SUNROOF SWITCH - INSTALLATION.....23-120

SUNROOF SWITCH - REMOVAL........23-120

SUNSHADE - INSTALLATION...........23-118

SUNSHADE - REMOVAL..............23-117

SUPPLEMENTAL DIESEL HEATER

WIRING - INSTALLATION.............24-112

SUPPLEMENTAL DIESEL HEATER

WIRING - REMOVAL.................24-112

SUPPLEMENTAL HEATER - DCHA -

DIAGNOSIS AND TESTING, DIESEL......24-107

SUPPLEMENTAL HEATER - DCHA -

EXPORT - DESCRIPTION, DIESEL.......24-106

SUPPLY - PCM OUTPUT - OPERATION, 5

VOLT ..............................8E-15

SUPPLY - PCM OUTPUT - SBEC

CONTROLLER - OPERATION, 8-VOLT.....8E-15

SUPPORT - INSTALLATION, LUMBAR....23-104

SUPPORT - INSTALLATION, SUN VISOR . . . 23-81

SUPPORT - REMOVAL, LUMBAR.......23-104

SUPPORT - REMOVAL, SUN VISOR......23-81

SUPPORT CYLINDER - INSTALLATION....23-42

SUPPORT CYLINDER - REMOVAL........23-42

SUPPORT PLATE - DRUM BRAKE -

INSTALLATION........................5-56

SUPPORT PLATE - DRUM BRAKE -

REMOVAL...........................5-56

SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO NOISE...........8A-11

SUPPRESSION COMPONENTS -

OPERATION, RADIO NOISE.............8A-12

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

.......9-11,9-85

SUSPENSION - DESCRIPTION, FRONT

......2-2

SUSPENSION - DESCRIPTION, REAR

......2-26

SUSPENSION - OPERATION, FRONT

........2-2

SUSPENSION - OPERATION, REAR

........2-26

RSINDEX31

Description Group-Page Description Group-Page Description Group-Page

ProCarManuals.com